Scaffolding walk board roll forming machine Features:

Metaldeck scaffolding is revolutionary metal decking access platform for tubular scaffolds since first introduces, has established a reputation for reliable and safe performance. The strong yet lightweight galvanized metal scaffold deck is now used extensively throughout the industry in place of conventional timber.

The METALDECK is placed by the scaffolding in order to bridge (span) its frames and create a horizontal level (work area platform). During placement on the side of the scaffolding frame, each METALDECK must be “secured” at the bottom with a specific security pin in order to ensure the safe placement and to avoid its involuntary elevation.

Metaldeck Scaffolding Roll Forming Machine is composed of de-coiler, guide rack, leveler, flatting, continuously punching machine, roll forming, correction, cutting-to-length (punching), collection table, electrical control system etc.

Applications

Metaldeck scaffolding is widely used in construction site.

Process Flow

Decoiling —- Leveling —- Punching —- Roll Forming —- Cutting —- Rou out Table

Machine Configurations

| 1. Hydraulic Uncoiler | 2. Side Guide |

| 3. Leveling Device |

4. Continuous Punching Unit

|

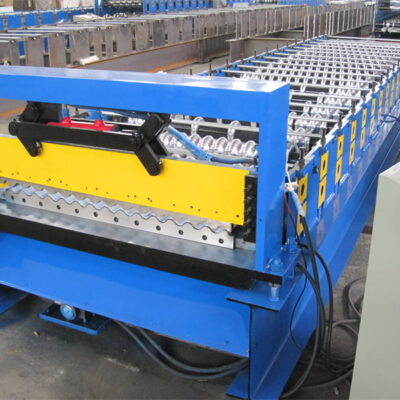

| 5. Rollforming Part |

6. Cutting Device

|

| 7. Run Out Table |

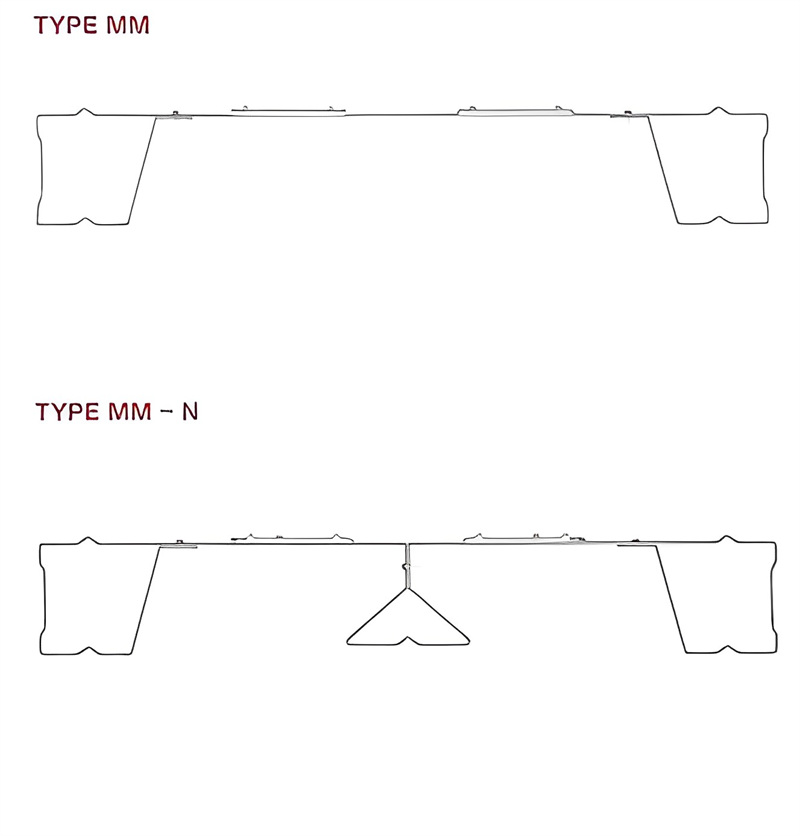

Profile Drawings for Reference

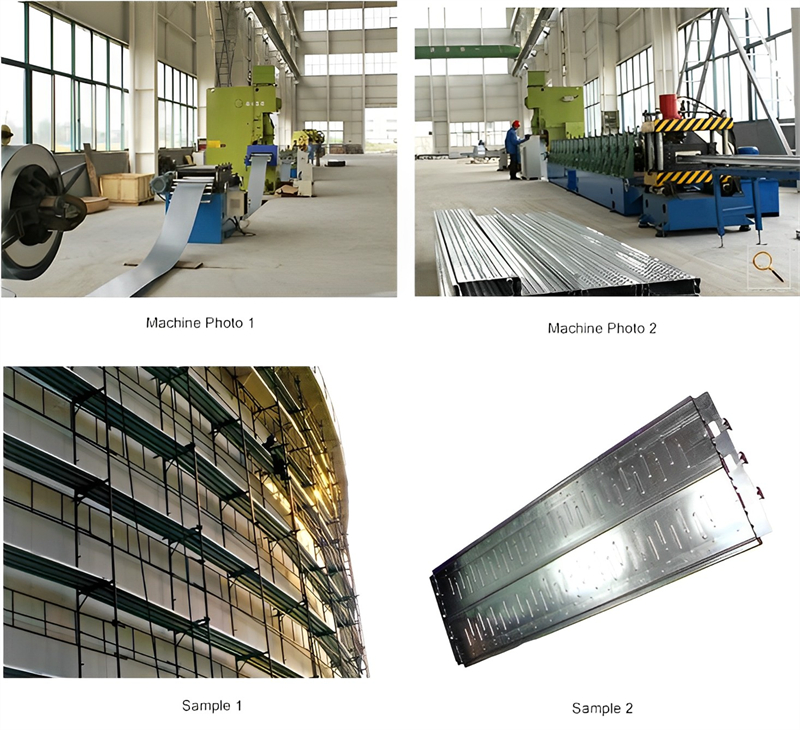

Photos for Reference

What is carriage board roll forming machine?

A carriage board roll forming machine is a type of industrial machinery used to manufacture carriage boards through a process known as roll forming.

Carriage boards are long, flat panels that are typically used in the construction industry for various purposes, such as siding for buildings, partitions, or decorative elements. They are usually made from materials like metal or plastic.

The roll forming machine is designed specifically for the production of carriage boards. It consists of a series of rollers and dies arranged in a sequential order. The raw material, such as a metal coil or plastic sheet, is fed into the machine, and as it passes through the rollers, it undergoes a series of bending, shaping, and cutting operations.

The rollers and dies in the machine are strategically designed to progressively shape the material into the desired profile. Each roller set is responsible for forming a specific part of the carriage board, such as the corrugations or other decorative patterns. The material is continuously fed through the machine, and as it moves along, it undergoes the necessary operations until it reaches the end of the line.

The carriage board roll forming machine is often automated and equipped with various control systems to ensure precision and consistency in the manufacturing process. It can produce carriage boards in large quantities and at high speeds, making it an efficient solution for mass production.

Overall, the carriage board roll forming machine is a specialized piece of equipment used in the construction industry to produce carriage boards with specific profiles and dimensions, offering a cost-effective and efficient manufacturing solution.

What are the main applications of sheet metal roll forming machines in?

Sheet metal roll forming machines have a wide range of applications in various industries. Some of the main applications include:

- Construction and Architecture: Roll forming machines are extensively used in the construction industry for manufacturing roofing sheets, wall panels, cladding systems, gutters, and other structural components. These machines can produce profiles with different shapes, sizes, and finishes, providing versatile solutions for architectural designs.

- Automotive Industry: Roll forming machines play a crucial role in the automotive sector for producing parts like door frames, window channels, roof rails, bumper beams, and other structural components. The machines can handle high-strength materials and produce complex profiles required for automotive body frames and chassis.

- HVAC (Heating, Ventilation, and Air Conditioning): Sheet metal roll forming machines are utilized in the HVAC industry to manufacture ductwork, ventilation pipes, air diffusers, and other components. The machines can produce precise profiles with consistent dimensions, ensuring efficient airflow and proper functioning of HVAC systems.

- Furniture Manufacturing: Roll forming machines find application in the furniture industry for producing various metal components used in furniture construction. These include profiles for bed frames, shelves, table legs, and other structural elements. The machines can create customized profiles to meet specific design requirements.

- Electrical Enclosures and Panels: Roll forming machines are used in the production of electrical enclosures, control panels, switchgear cabinets, and other electrical equipment housings. The machines can form sheet metal into profiles with accurate dimensions and provide slots, holes, and other features necessary for component mounting and wiring.

- Shelving and Racking Systems: Roll forming machines are employed in the manufacturing of shelving units, racking systems, and storage solutions. The machines can produce profiles for shelves, beams, uprights, and other components, allowing for efficient storage and organization of goods in warehouses, retail spaces, and industrial settings.

- Solar Energy Industry: Roll forming machines are used in the production of mounting structures and frames for solar panels. The machines can create profiles that are strong, durable, and capable of withstanding environmental conditions, providing support and stability for solar energy systems.

These are just a few examples of the many applications of sheet metal roll forming machines. Their versatility, efficiency, and ability to produce consistent and high-quality profiles make them valuable equipment in various industries.

function of metal deck roll forming machine

A metal deck roll forming machine is specifically designed for the production of metal deck sheets, which are used in the construction industry as a structural component for composite floor systems. The machine performs several functions to transform raw materials into finished metal deck sheets:

- Uncoiling: The metal deck roll forming machine typically features an uncoiler, which unwinds the metal coil and feeds it into the machine. This function ensures a continuous supply of raw material for the manufacturing process.

- Material Feeding: The machine then feeds the metal coil through a series of rollers and guides, ensuring proper alignment and positioning of the material as it progresses through the forming process.

- Roll Forming: The core function of the machine is roll forming, where the metal coil is progressively shaped into the desired profile of the metal deck sheet. The roll forming process involves multiple pairs of rollers and dies that gradually bend, shape, and press the material to achieve the required configuration. The rollers and dies are strategically designed to create specific features such as embossing, stiffening ribs, and interlocking mechanisms.

- Cutting: Once the metal deck sheet reaches the desired length, the machine incorporates a cutting mechanism to trim the sheet to the correct size. This can be done using a flying cutoff or a stationary shear depending on the design of the machine.

- Stacking or Discharging: After the metal deck sheet is cut, the machine may have a stacking system that neatly stacks the finished sheets for easy handling and transportation. Alternatively, the machine may discharge the sheets onto a conveyor or other means of collecting the finished product.

- Forming Variations: Metal deck roll forming machines often have the capability to produce different profiles and sizes of metal deck sheets. This can be achieved by adjusting the settings and configurations of the rollers, dies, and cutting mechanisms, allowing for versatility in manufacturing various types of metal deck sheets.

Overall, the metal deck roll forming machine combines various functions, including uncoiling, material feeding, roll forming, cutting, and stacking/discharging, to efficiently produce metal deck sheets used in composite floor systems in the construction industry. These machines provide precise and consistent manufacturing of metal deck sheets, ensuring high-quality and reliable structural components for buildings.

Reviews

There are no reviews yet.