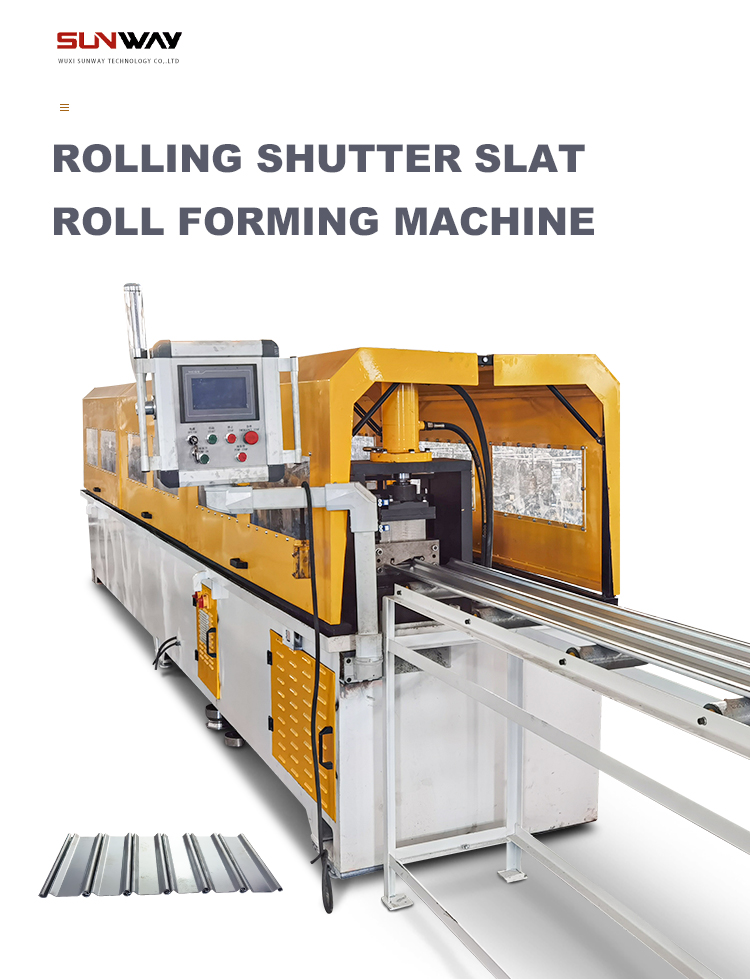

Rolling Shutter Slat roll forming machine is to make roller shutter slat which is common used for Garage Doors, Commercial Counter Shutter, Commercial fire door, industrial, office public, Kiosks, pavilions, windows etc. Machinable steel material can be galvanized steel, stainless steel (304 and 316), aluminum, Ral etc. The steel thickness range could be Gauge 16, Gauge 18, Gauge 20, Gauge 22, Gauge 24, which is widely used in America, or could be 0.6-1.5mm at international market.

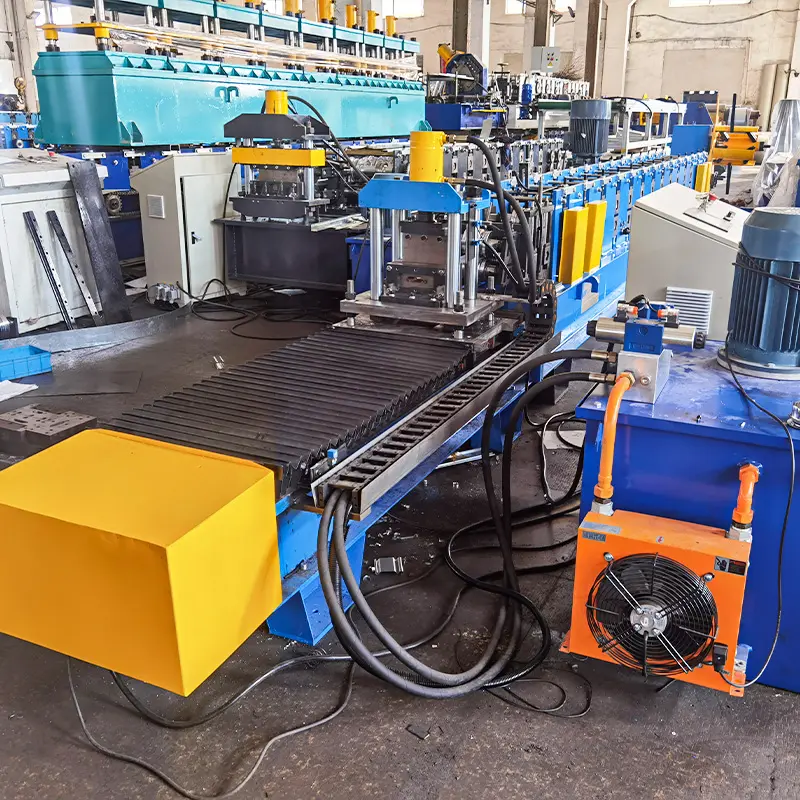

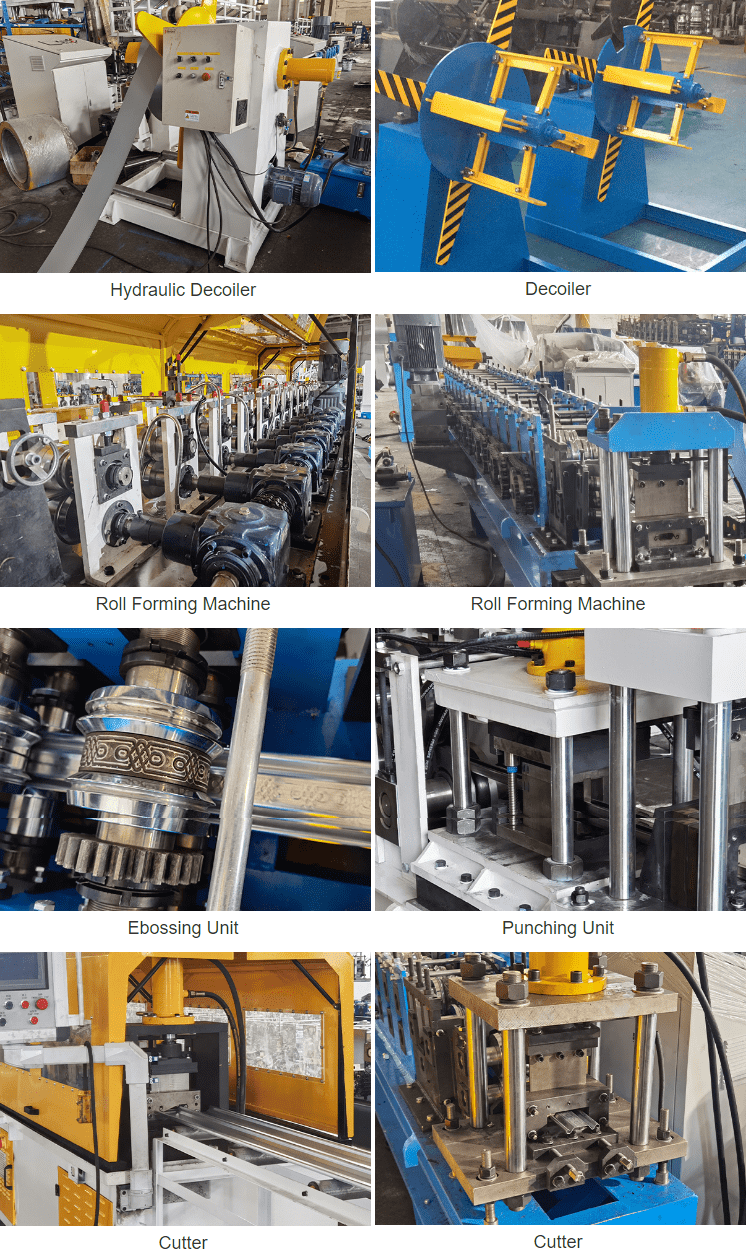

This Roller shutter door slat machine consists of decoiler, guiding and feeding, roll forming section, hydraulic cutter, collecting table, hydraulic system, control system.

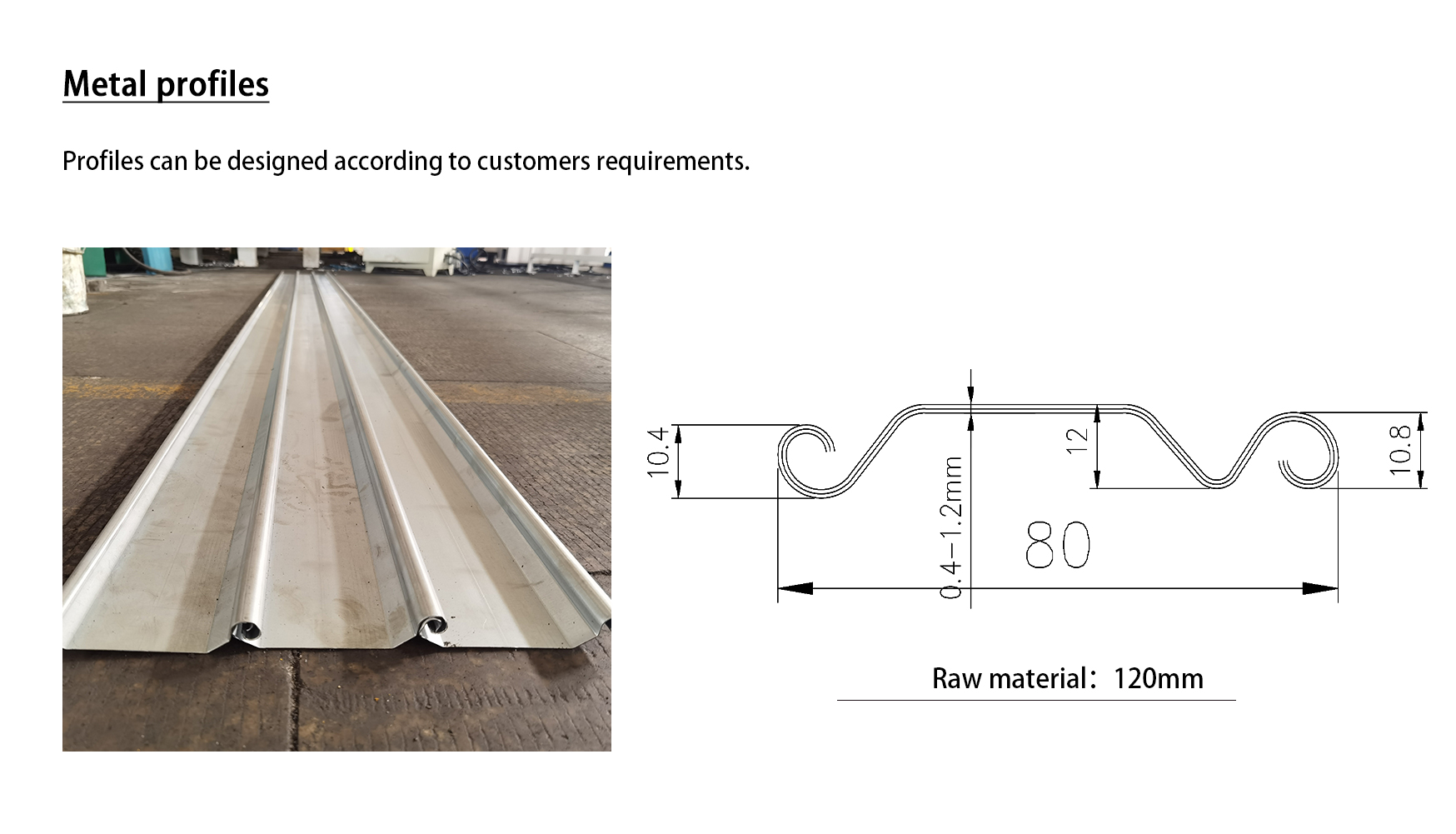

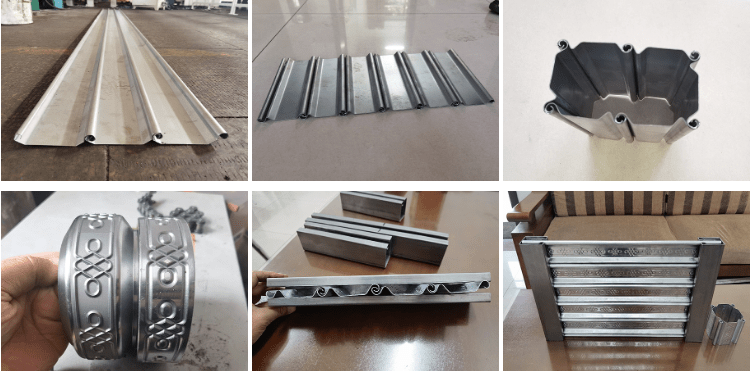

SUNWAY could design and make any kinds of roller shutter slat roll forming machine according to your profiles drawings and meet your high-precision requirements, making surface pretty and burr-free also high-precision punch holes, especially for micro- perforation slat, we could make 0.3mm tolerance for holes’ distance with servo feeder system. In roller shutter slat industry, roll forming machine could also produce other accessories like: ① Octagonal tube ② Rail for slat door ③ Guide channel ④ Bottom bar: I-bottom bar, T-bottom bar and L-bottom bar.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Profile Drawings

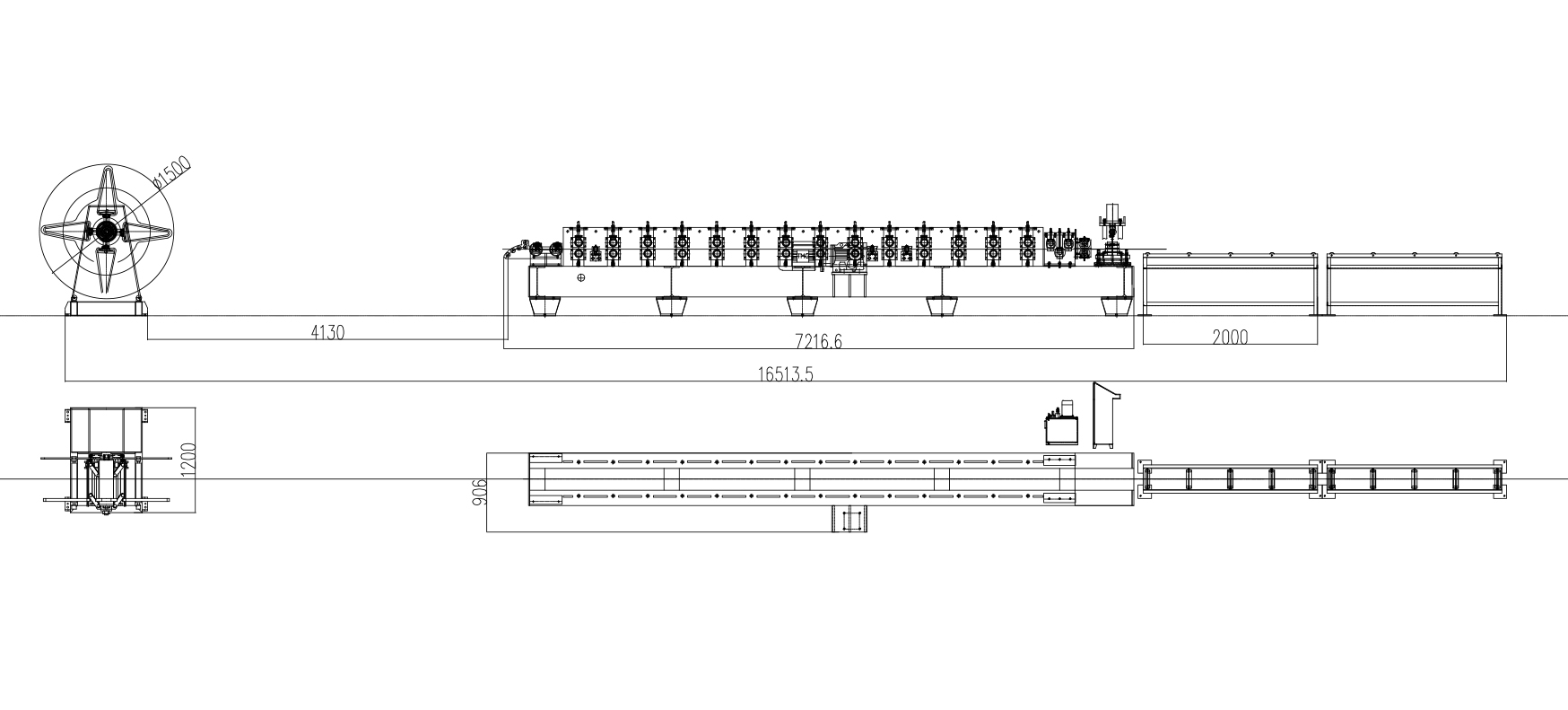

Production Line

Product Details

Product Parameters

| Rolling Shutter Slat Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 0.6-1.5 mm Or According To Customer

|

| B) PPGI | ||

| C) Carbon Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Slat Type | Slat, With Slotted Holes, With Embossing, With PU | |

| Decoiler | Hydraulic Decoiler | |

| Punching System | Hydraulic Punching Station | |

| Forming Station | About 10-16 Stations | * According To Your Profile Drawings |

| Driving System | Gearbox Drive | Chain Drive |

| Machine Structure | Forged Iron Station | Wall Plated Steel |

| Forming Speed | 0-20 (M/MIN) | Not Including Cutting And Punching |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Hydraulic Cutting | * Saw-cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application