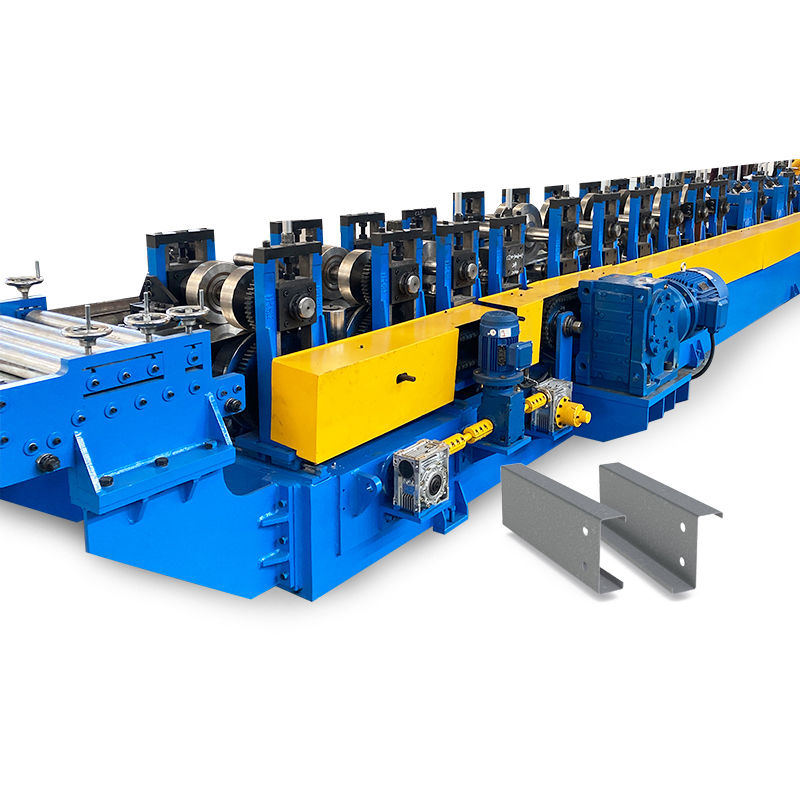

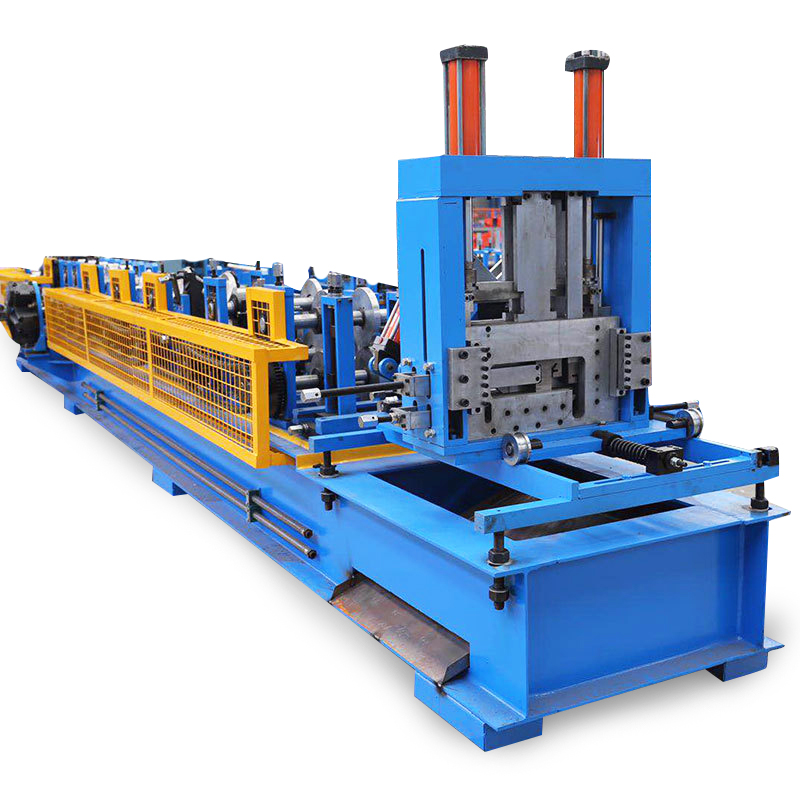

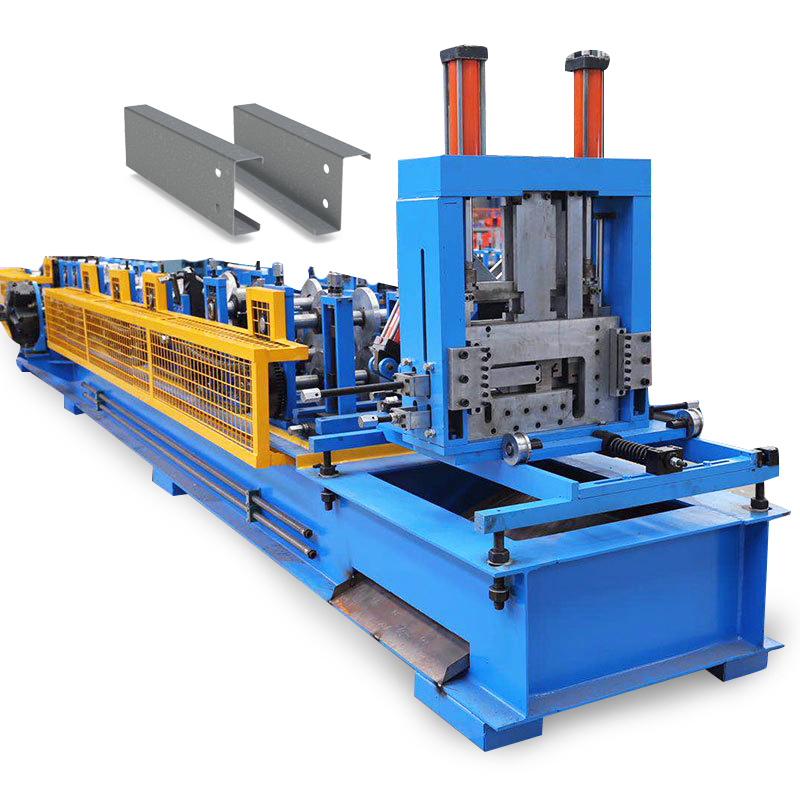

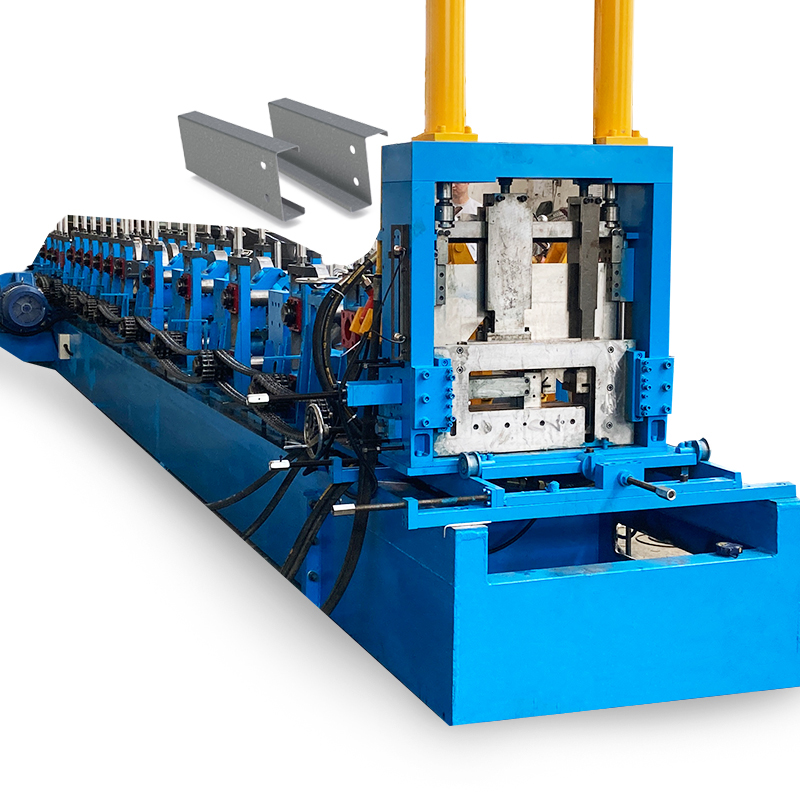

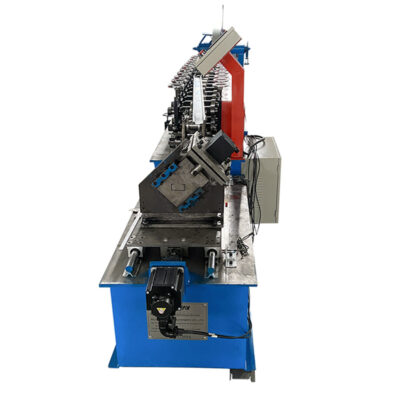

Fully automatic C&Z purlin quick Interchangeable Roll Forming Machine, adopts a special structure for both C and Z purlin making. The rollers for C & Z are changed very quickly without dismantle any parts. Cutter adopts universal hydraulic cutting device, no need to change cutter blade while producing different profiles with different sizes which save labor costs and improve production efficiency.

C Purlin Making Machine Details

Stand Base

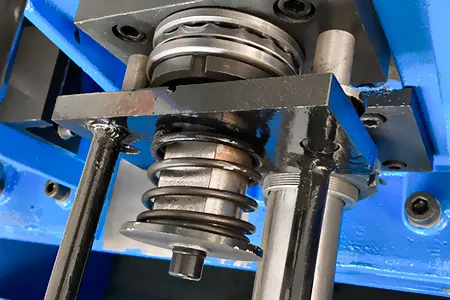

Roll stands adopt cast iron single station which is most heavy and strong.

Interchangeable

Produce different purlin sizes without changing rollers or spacers.

Only need to overturn the rollers 180 degree, Save cost and time.

Universal Cut

Universal post cutter. No need change cutter blades for different sizes.

Customization

Senior and experienced engineer control the whole process for your customize.

C Purlin Making Machine Parameters

| Product |

C&Z purlin Quick Interchangeable Roll Forming Machine

|

| Model |

C Channel Profile / Z Shape Profile (Customizable )

|

| Base Material |

Galvanized Steel Hot And Cold Rolled Steel

|

| Thickness |

1.5-3.0mm (Customizable)

|

| Effective Width |

According To Profile Size

|

| Roller Station |

About 16 Stations

|

| Roller Material |

Bearing Steel / Cr12Mov

|

| Roller Driven Type |

By Chain/ Gearbox

|

| Color |

According To Customer Requirements / Customizable

|

| Brand | SUNWAY |

| Control System |

Worldwide Famous Brand PLC (Panasonic, Siemens, Delta, etc.)

|

| Power | 15KW-18KW |

| Frame |

350 H Steel / 400 H Steel

|

| Cutting Drive | Hydraulic Drive |

| Cutting & Hydraulic Type |

Type:Post Universal Cutter

|

What is the function of the purlin making machine?

A purlin making machine is used in the construction industry to produce purlins, which are horizontal structural members that provide support and stability to the roof of a building. The machine is designed to efficiently and accurately fabricate purlins from various materials, such as steel or aluminum.

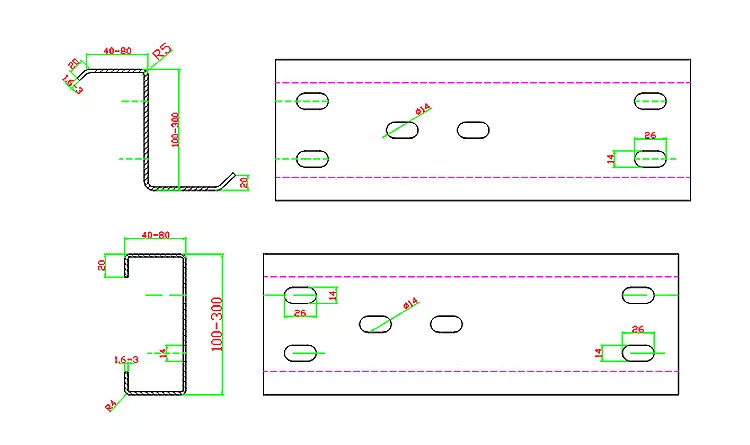

The main function of a purlin making machine is to roll-form the raw material into the desired shape and size of purlins. It typically consists of a series of rollers, forming stations, and cutting mechanisms. The machine takes flat or coil stock material and passes it through the rollers, which gradually shape it into a “C” or “Z” profile, depending on the specific design requirements.

Purlin making machines are programmable and can produce purlins of different lengths and dimensions, allowing for customization based on the building’s specifications. The machine can also incorporate features such as punching holes or slots into the purlins to accommodate fasteners, electrical wiring, or other components.

By automating the purlin production process, these machines can significantly increase productivity and reduce labor costs compared to manual fabrication methods. They ensure consistent quality and accuracy in the manufacturing process, resulting in purlins that are precise and fit seamlessly within the building structure.

Overall, the function of a purlin making machine is to streamline the production of purlins for construction projects, providing strong and reliable roof support components efficiently and effectively.

The Specific Application of Automatic C Purlin Roll Forming Machine in the Construction Industry

The automatic C purlin roll forming machine plays a crucial role in the construction industry, specifically in the production of C-shaped purlins. Here are some specific applications of this machine in construction:

- Roofing Systems: C purlins are commonly used in roofing systems to provide structural support for the roof panels. The roll forming machine produces C-shaped purlins with consistent dimensions, allowing for easy installation and ensuring the structural integrity of the roof.

- Wall Systems: C purlins are also used in wall systems to create a framework for attaching exterior or interior wall panels. The roll forming machine can produce purlins of various sizes and lengths, accommodating different wall heights and design requirements.

- Industrial Buildings: The automatic C purlin roll forming machine is extensively used in the construction of industrial buildings such as warehouses, factories, and logistics centers. These buildings often require large quantities of purlins to support the roof and walls, and the machine enables efficient and cost-effective production to meet the demand.

- Commercial Buildings: Many commercial buildings, including shopping malls, offices, and retail spaces, utilize C purlins in their construction. The roll forming machine ensures the consistent production of purlins with precise dimensions, enabling faster installation and contributing to the overall efficiency of the construction process.

- Agricultural Structures: C purlins are widely employed in agricultural buildings like barns, storage facilities, and livestock shelters. The roll forming machine allows for the production of purlins that can withstand heavy loads, providing a sturdy framework for these structures.

The automatic C purlin roll forming machine offers advantages such as high production speed, accuracy, and the ability to customize purlin sizes according to project requirements. By automating the production process, it improves efficiency, reduces labor costs, and ensures consistent quality, making it an essential tool in modern construction practices.

how to choose roll forming machine for c purlin?

When choosing a roll forming machine for C purlin production, there are several factors to consider to ensure you select the right machine for your specific needs. Here’s a step-by-step guide to help you choose the appropriate roll forming machine:

- Determine your production requirements: Consider the volume and frequency of C purlin production you anticipate. This will help you determine the speed and capacity requirements of the roll forming machine you need.

- Assess the material specifications: Identify the specific material properties, such as the thickness, width, and type of steel or metal coil you plan to use. This information is crucial in selecting a machine capable of handling the desired material specifications.

- Evaluate the profile specifications: Define the precise dimensions and design specifications of the C purlin you intend to manufacture. This includes the height, width, flange size, lip size, and any custom features required. Ensure the roll forming machine can produce the exact profile you need.

- Consider the flexibility of the machine: Determine if you will be producing C purlins exclusively or if you require the capability to manufacture other profiles as well. If you need versatility, choose a roll forming machine that offers quick and easy changeover between different profiles.

- Assess the machine’s durability and quality: Research and evaluate the reputation, reliability, and build quality of the roll forming machine manufacturer. Read customer reviews, examine the machine’s construction, and consider the warranty and after-sales service provided.

- Evaluate the automation level: Decide on the level of automation you require based on your production needs and available workforce. Automation features may include automatic material feeding, cutting, punching, and stacking. Higher automation levels can enhance productivity but may come at a higher cost.

- Consider the floor space and power requirements: Assess the available space in your facility and ensure the roll forming machine you select can fit comfortably. Additionally, check the power requirements of the machine to ensure your facility can accommodate its electrical needs.

- Budget and ROI analysis: Determine your budget for acquiring a roll forming machine and perform a return on investment (ROI) analysis to assess the potential financial benefits of the machine over time. Consider factors such as increased production capacity, reduced labor costs, and potential expansion of your product offerings.

- Consult with experts: If you’re unsure about any aspect of the roll forming machine selection process, it’s advisable to consult with industry experts or manufacturers who can provide guidance and recommend suitable machines based on your requirements.

By carefully considering these factors and conducting thorough research, you’ll be able to choose a roll forming machine for C purlin production that meets your specific needs and helps optimize your manufacturing process.

Reviews

There are no reviews yet.