Floor decking roll forming machine Applications

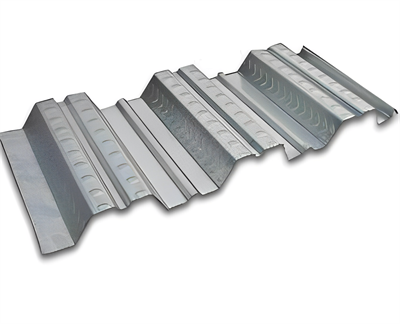

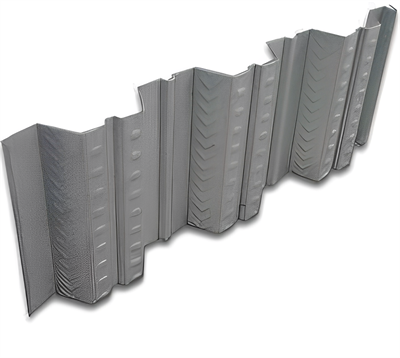

he finished products are widely used in floor flat, after make embossing of the sheet, it will increase the strength between the steel and concrete, thereby increasing the floor of the fastness.

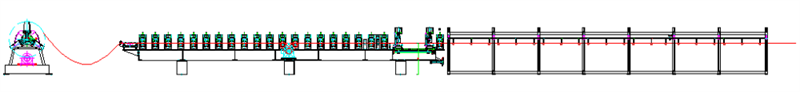

Process Flow

Uncoiler — Feeding — Roll Forming — Cutting — Output table

Machine Configurations

| 1. Uncoiler |

2. Guide feeder

|

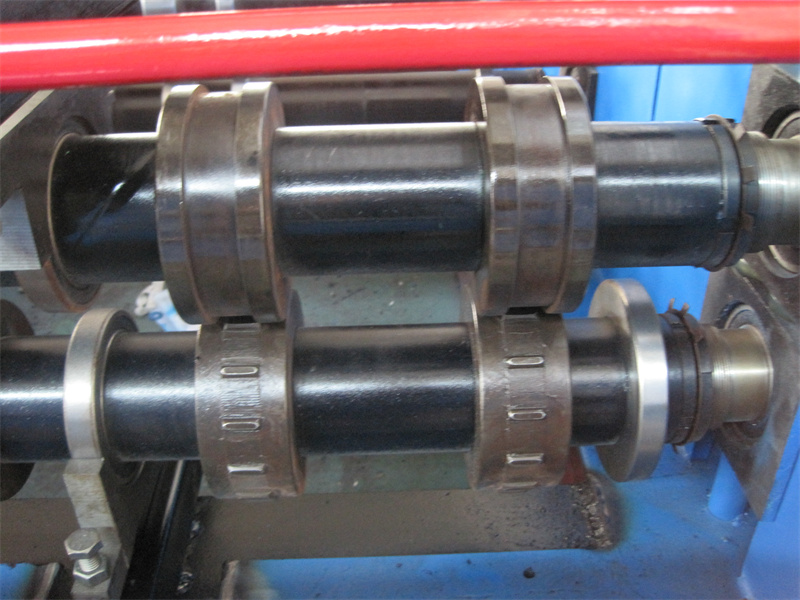

| 3. roll forming |

4. Hydraulic cutting unit

|

| 5. PLC Control System | 6. Hydraulic station |

| 7. Output conveyor |

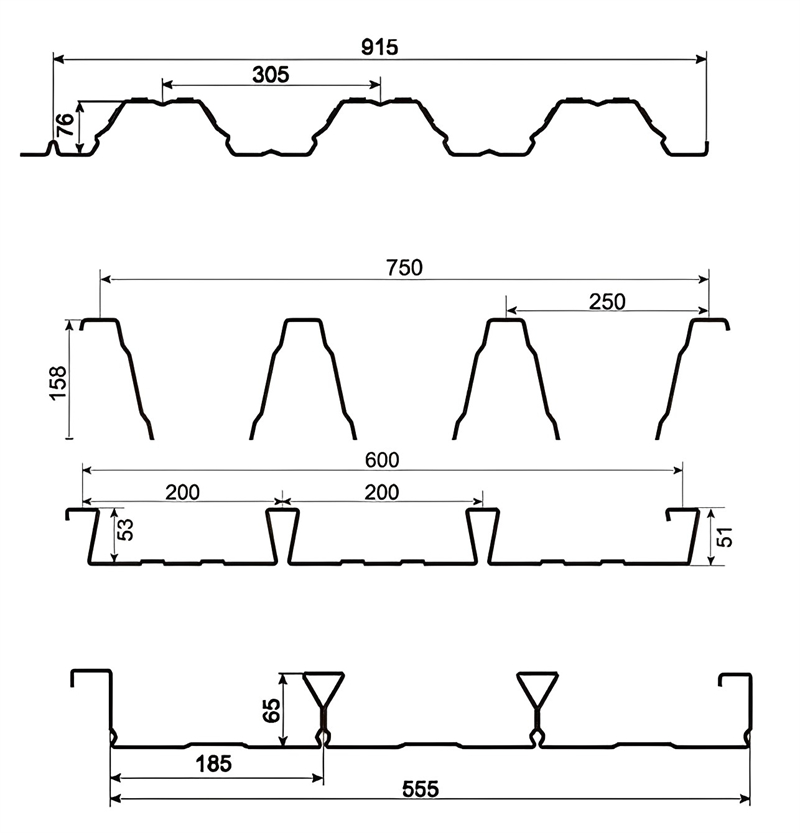

Profile Drawings for Reference

What is Floor decking roll forming machine?

A floor decking roll forming machine is a type of industrial machinery used in the construction industry to produce floor decking panels or sheets. It is designed to take metal coil stock, typically steel or aluminum, and shape it into a specific profile or pattern known as floor decking.

The machine operates by feeding the metal coil into a series of rollers and tooling stations, where it undergoes a continuous forming process. The rollers and tooling are configured to gradually shape the metal coil into the desired floor decking profile. This profile usually consists of a series of ribs, corrugations, or embossed patterns that enhance the structural strength and load-bearing capacity of the floor decking panels.

The floor decking roll forming machine is typically equipped with various components, including decoilers, feeding systems, leveling devices, roll formers, cutting mechanisms, and control systems. These components work together to ensure precise and efficient production of floor decking panels with consistent dimensions and quality.

The resulting floor decking panels produced by the machine are commonly used in the construction of commercial and industrial buildings as a structural component for floors. They provide a stable and durable surface for supporting loads, such as equipment, machinery, or storage materials. The panels can be installed quickly and easily, contributing to faster construction times and cost savings in the overall building process.

function of double deck roll forming machine

- Increased productivity: By forming two profiles simultaneously, the double deck roll forming machine can significantly increase the production output compared to a single deck machine. This feature allows for higher manufacturing efficiency and faster processing times.

- Space-saving: Instead of operating two separate roll forming machines, a double deck machine combines the functions into a single unit. This helps save valuable factory floor space, as it requires less installation area and reduces the need for additional equipment.

- Versatility: The machine offers versatility by allowing the production of two different profiles or patterns concurrently. It enables manufacturers to diversify their product offerings and meet varying customer demands without the need for multiple machines or tooling changes.

- Cost-effective: The double deck roll forming machine offers cost savings by reducing the equipment investment and maintenance costs associated with operating two separate machines. It also helps lower labor costs since fewer operators are required to oversee the production process.

- Precision and consistency: The machine is engineered to ensure precise and consistent forming of both profiles. With advanced control systems and tooling, it maintains tight tolerances, resulting in high-quality finished products.

- Time-saving setup: The double deck roll forming machine often incorporates quick-change systems, allowing for efficient and rapid switching between different profile setups. This feature minimizes downtime during production changeovers and improves overall operational efficiency.

application area of steel deck roll forming machine

- Commercial and Industrial Buildings: Steel decking panels produced by roll forming machines are commonly used as a structural component in the construction of commercial and industrial buildings. They serve as a base for concrete floors, providing a stable and durable surface for supporting loads such as equipment, machinery, storage materials, and people.

- High-Rise Buildings: Steel decking panels are frequently employed in the construction of high-rise buildings. They offer excellent load-bearing capacity, fire resistance, and structural stability, making them ideal for use in multi-story structures.

- Mezzanine Floors: Mezzanine floors are intermediate floors constructed within a building to create additional usable space. Steel decking panels are commonly used for mezzanine flooring due to their strength, durability, and ease of installation. These panels provide a solid and secure platform for storage, office spaces, or other functional areas.

- Roofing Systems: Steel decking panels can be used as a component of roofing systems in various types of buildings. They provide structural support for roofing materials, such as insulation and waterproofing membranes. Steel decking panels offer excellent load-bearing capacity, durability, and resistance to weather conditions.

- Infrastructure Projects: Steel decking panels produced by roll forming machines are utilized in infrastructure projects such as bridges, platforms, walkways, and railway stations. They provide a stable and secure surface for pedestrian and vehicular traffic.

- Temporary Structures: Steel decking panels are also employed in the construction of temporary structures such as exhibition halls, warehouses, and event venues. They offer a quick and efficient solution for creating functional spaces that can be easily disassembled and relocated as needed.

Reviews

There are no reviews yet.