Din rail roll forming machine is used to produce din rail which is the long metal strips that form the core part of a global industry standard component rail-mounting system in equipment cabinet racks. Din rails are designed for securely attaching electrical and industrial control products – such as circuit breakers, terminal blocks, power supplies, actuators, solenoids and so on – inside a typical equipment rack housing cabinet or frame.

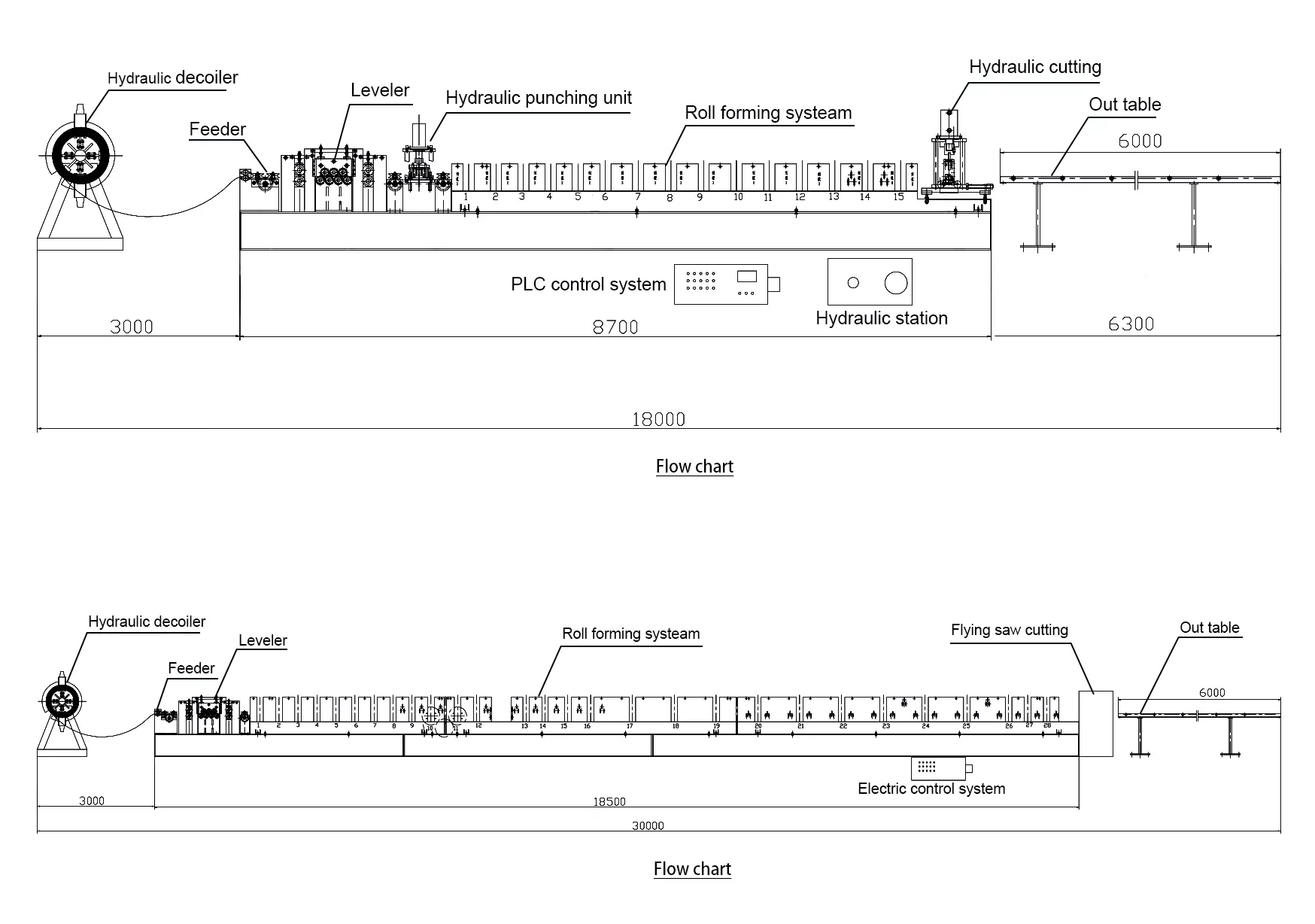

Din Rail Roll Forming Machine Drawings

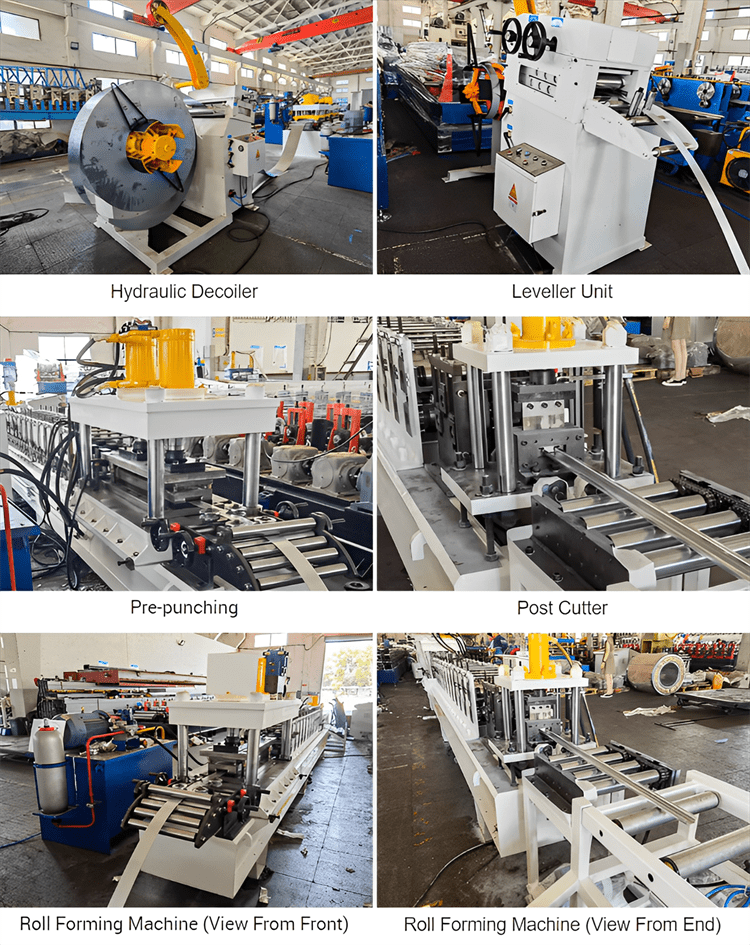

Din Rail Roll Forming Machine Production Line

Din Rail Roll Forming Machine Details

Product Parameters

| Din Rail Roll Forming Machine | ||

|

Machinable Material

|

A) Zinc-plated steel |

Thickness(MM): 1-1.5 or as per customer

|

| B) Aluminum | ||

| C) Stainless Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Punching Press (Optional) |

| Forming Station | 10 Stands | * According To Your Profile Drawings |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Cast Iron (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Profile Drawings |

| Rollers’ Material | Steel #45 | * GCr 15 (Optional) |

| Cutting System | Post-cutting | * Pre-cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

What is guide rail roll forming machine?

A guide rail roll forming machine is a specialized type of machinery used in the manufacturing process of guide rails. Guide rails are structural components typically used in various industries, such as construction, transportation, and material handling, to provide support and guidance to moving objects or systems.

The roll forming process involves shaping a continuous metal strip or coil into a desired profile or shape through a series of roll forming stations. These stations consist of sets of rollers and dies that gradually bend, shape, and form the metal strip. The guide rail roll forming machine is specifically designed to produce guide rails with consistent dimensions and precise profiles.

The machine operates by feeding the metal strip into the roll forming stations, where it undergoes a series of incremental shaping operations. Each roll forming station has adjustable rollers and dies that progressively form the metal strip into the desired guide rail shape. The process is typically automated, ensuring high production efficiency and accuracy.

Guide rail roll forming machines are versatile and can be customized to produce guide rails of different shapes, sizes, and material types, such as steel, aluminum, or stainless steel. These machines are widely used in the manufacturing industry to meet the demand for guide rails in various applications, including elevator systems, conveyor systems, sliding doors, and industrial machinery.

function din rail roll forming machine?

The key functions of a DIN rail roll forming machine include:

- Material Feeding: The machine feeds the metal strip or coil into the roll forming stations, ensuring a continuous supply of material for the forming process.

- Roll Forming Stations: The machine consists of multiple roll forming stations, each equipped with adjustable rollers and dies. These stations gradually shape the metal strip by bending, folding, and forming it into the specific profile of a DIN rail.

- Precision and Consistency: The machine ensures high precision and consistency in the dimensions and profiles of the DIN rails produced. The rollers and dies can be adjusted to meet the required specifications and tolerances.

- Automation: DIN rail roll forming machines are typically automated, minimizing manual intervention and ensuring efficient production. Automated controls regulate the feeding, forming, and cutting processes, resulting in consistent and accurate DIN rail production.

- Customization: The machine can be customized to produce DIN rails of different sizes, profiles, and materials. It offers flexibility to meet the specific requirements of various electrical and electronic installations.

What is slide rail roll forming machine?

A slide rail roll forming machine is a specialized machinery used to shape metal strips or coils into slide rails. It operates through a roll forming process, gradually bending and forming the metal strip into the desired profile. The machine is adjustable and can produce slide rails of different sizes and shapes. It ensures precision and consistency in the dimensions of the slide rails. The process is automated, improving efficiency and reducing labor. Slide rail roll forming machines are commonly used in furniture and cabinet manufacturing for smooth and controlled sliding mechanisms.

what is oem slide rail roll forming machine?

Some key characteristics of an OEM slide rail roll forming machine include:

- Customization: The OEM machine is designed and built to meet the specific needs of the customer. It can be customized in terms of size, configuration, forming capabilities, and automation features.

- Branding: The OEM machine can be branded with the customer’s logo or name, creating a customized and exclusive product for the customer.

- Specialized Features: The OEM machine may have unique features or modifications to cater to specific production requirements or to enhance efficiency, productivity, or quality.

- Technical Support: OEM manufacturers typically provide technical support, training, and maintenance services to ensure proper operation and performance of the machine.

- Long-Term Partnership: OEM machines are often supplied as part of a long-term partnership between the OEM and the customer. The OEM may offer ongoing support, spare parts, and future upgrades or enhancements as needed.