The Metal carriage panel roll forming machine is designed to produce truck side boards with different designs. normally thickness is from 1-3mm in ranges.

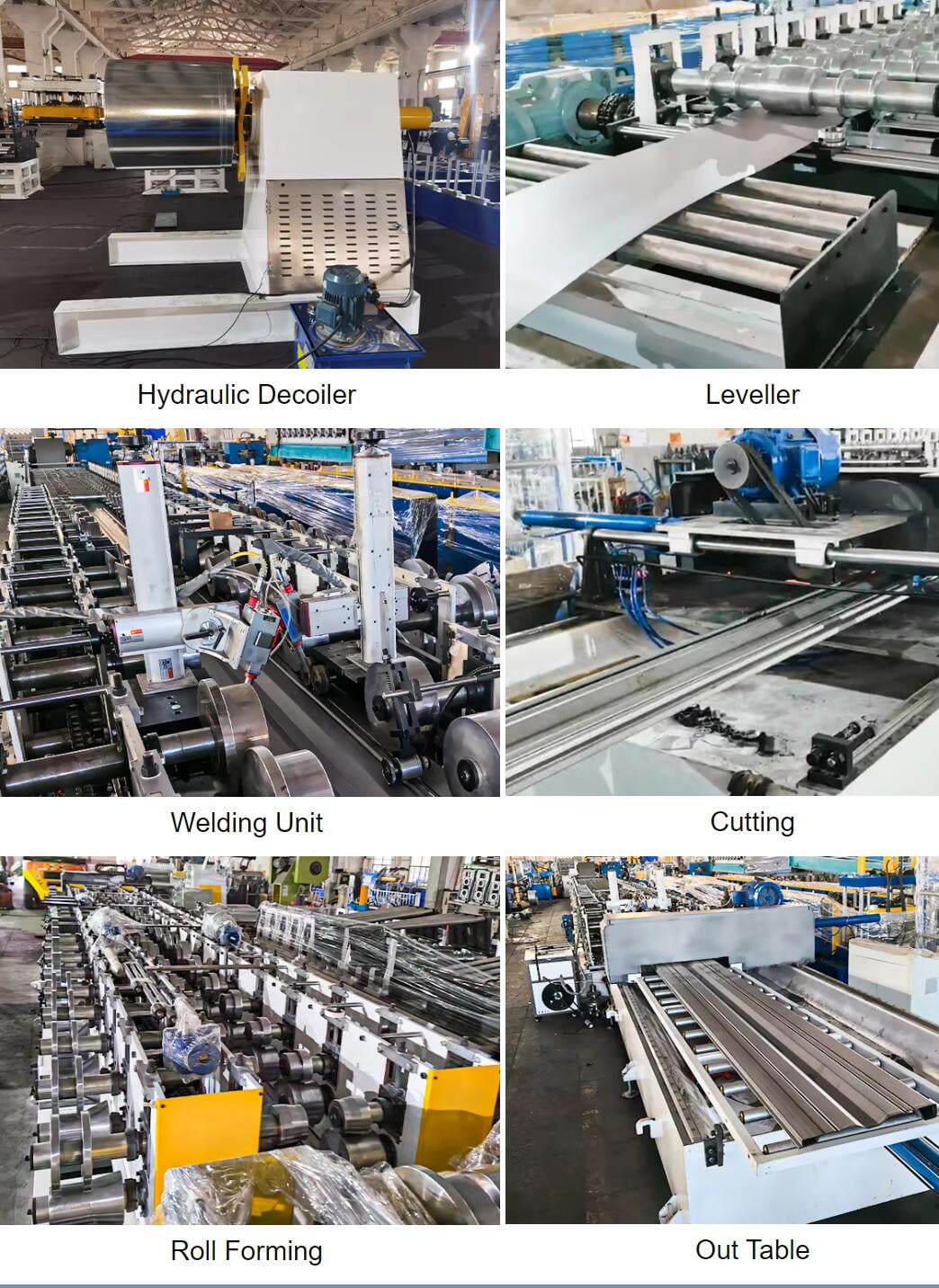

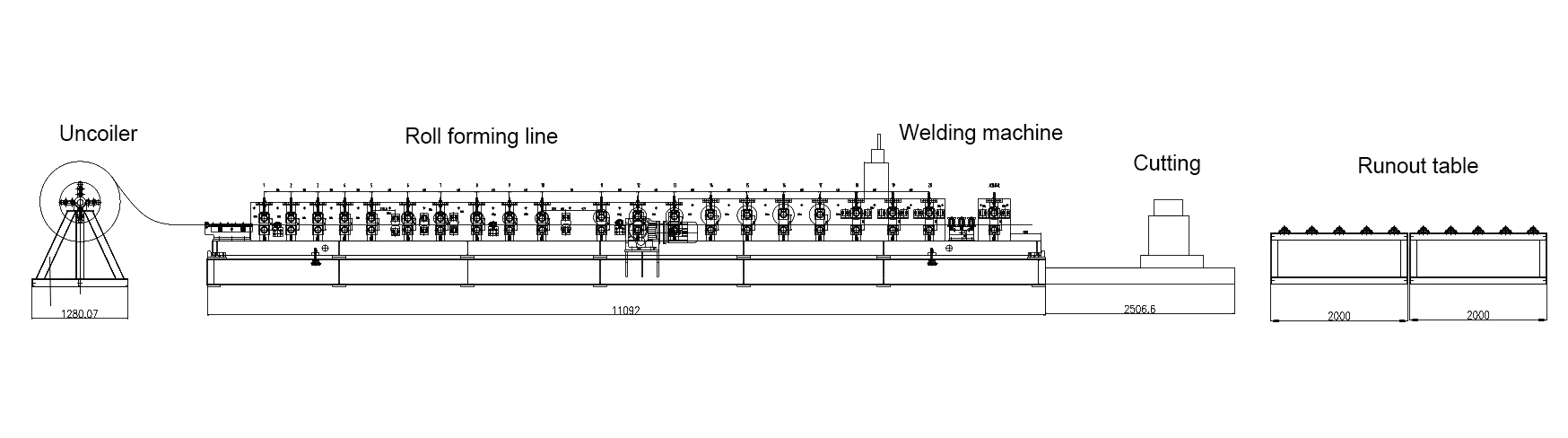

Truck carriage board roll forming machine is an automatic machine, used for making carriage top, bottom, and side plate of truck carriage plate. It includes decoiler, leveller, roll former, welder, cutter, controlling system, hydraulic system, etc.

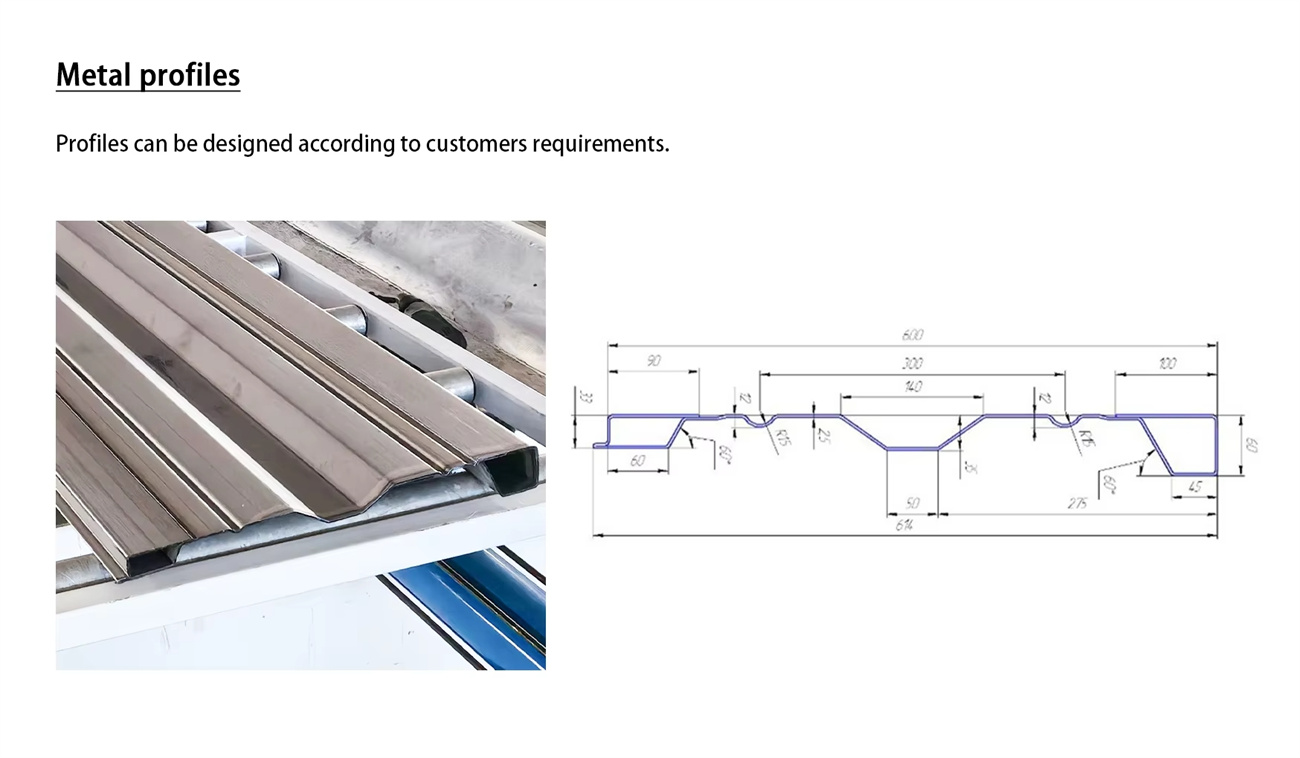

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

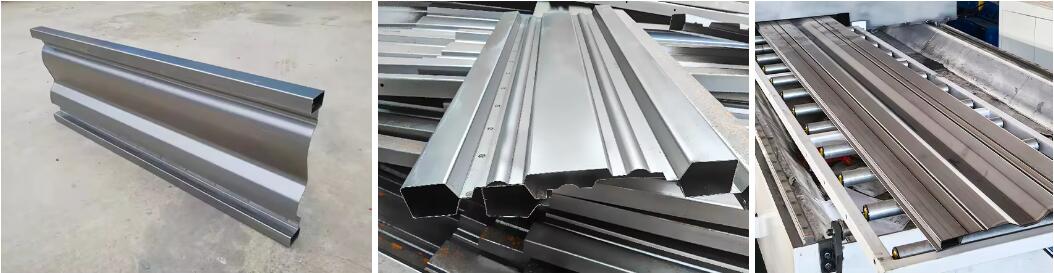

Profile Drawings

Production Line

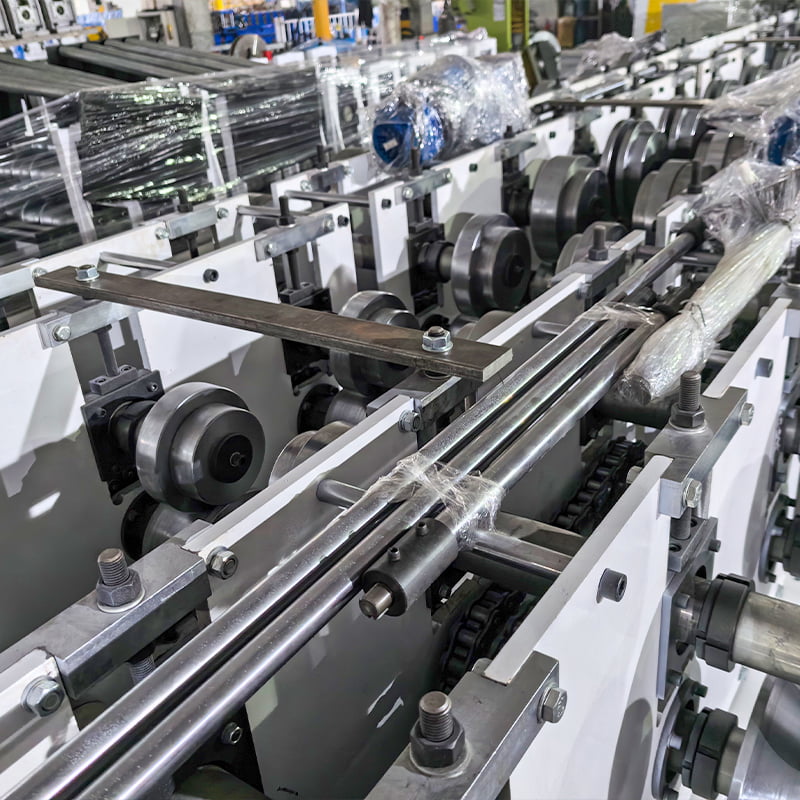

Product Details

Product Parameters

| Carriage Board Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 1.0-3.0 Or As Per Customer

|

| B) Cold Rolled Or Hot Rolled | ||

| C) Carbon Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Profiles | As Per Customer | |

| Decoiler | Hydraulilc Decoiler | |

| Forming Station | About 24 Stations Or According To Profile Drawings | |

| Driving System | Gearbox Drive | * Chain Drive (Optional) |

| Machine Structure | Forged Iron Station | |

| Forming Speed | 0-10 (M/MIN) | * Not including cutting |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Post-cutting | * Pre-cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

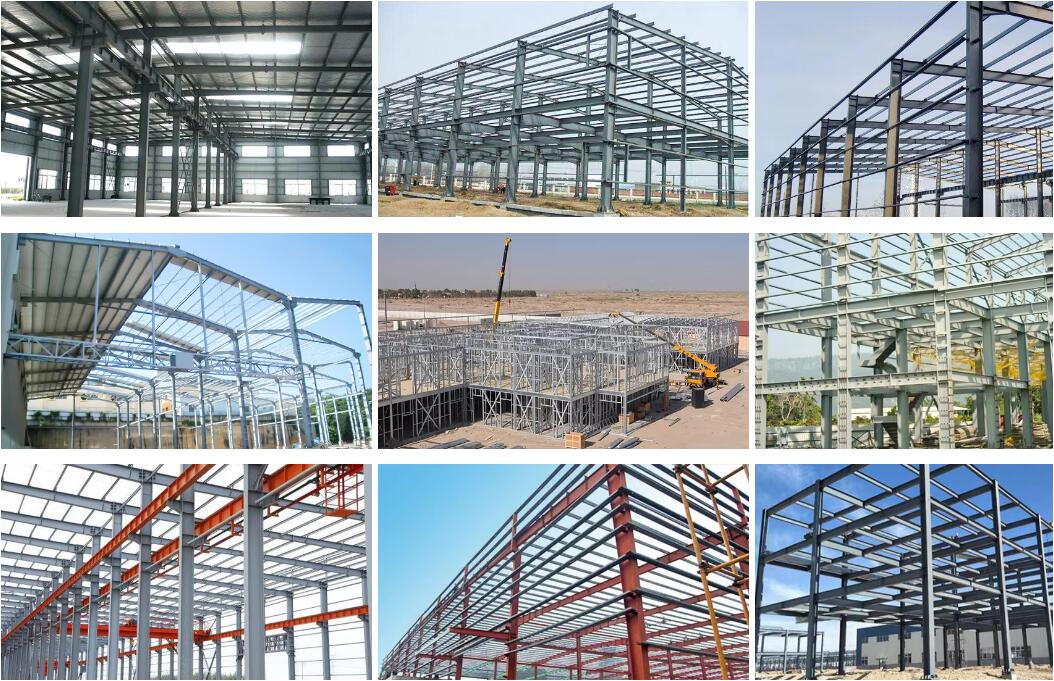

Application