C Bracing Section Roll Forming Machine also named C beam roll forming machine is developed to produce C beam which is for supporting the uprights rack and shelving panels at the side of the whole warehouse pallet tacking system.

Our intelligent C Bracing Section Roll Forming Machine could make various sizes of C beam according to the rack system requirements and thickness, normally 1.5-1.8mm. Uncoiling, feeding, roll forming, punching, cutting, etc. process can be automatically realized on one line. Meantime, we have the roll forming machine to make step beam, upright rack, box beam and shelf panel. All these are components of Pallet racking system.

In warehouse pallet racking system, we are able to manufacture more machines like Step beam roll forming machine, Upright rack roll forming machine and box beam roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

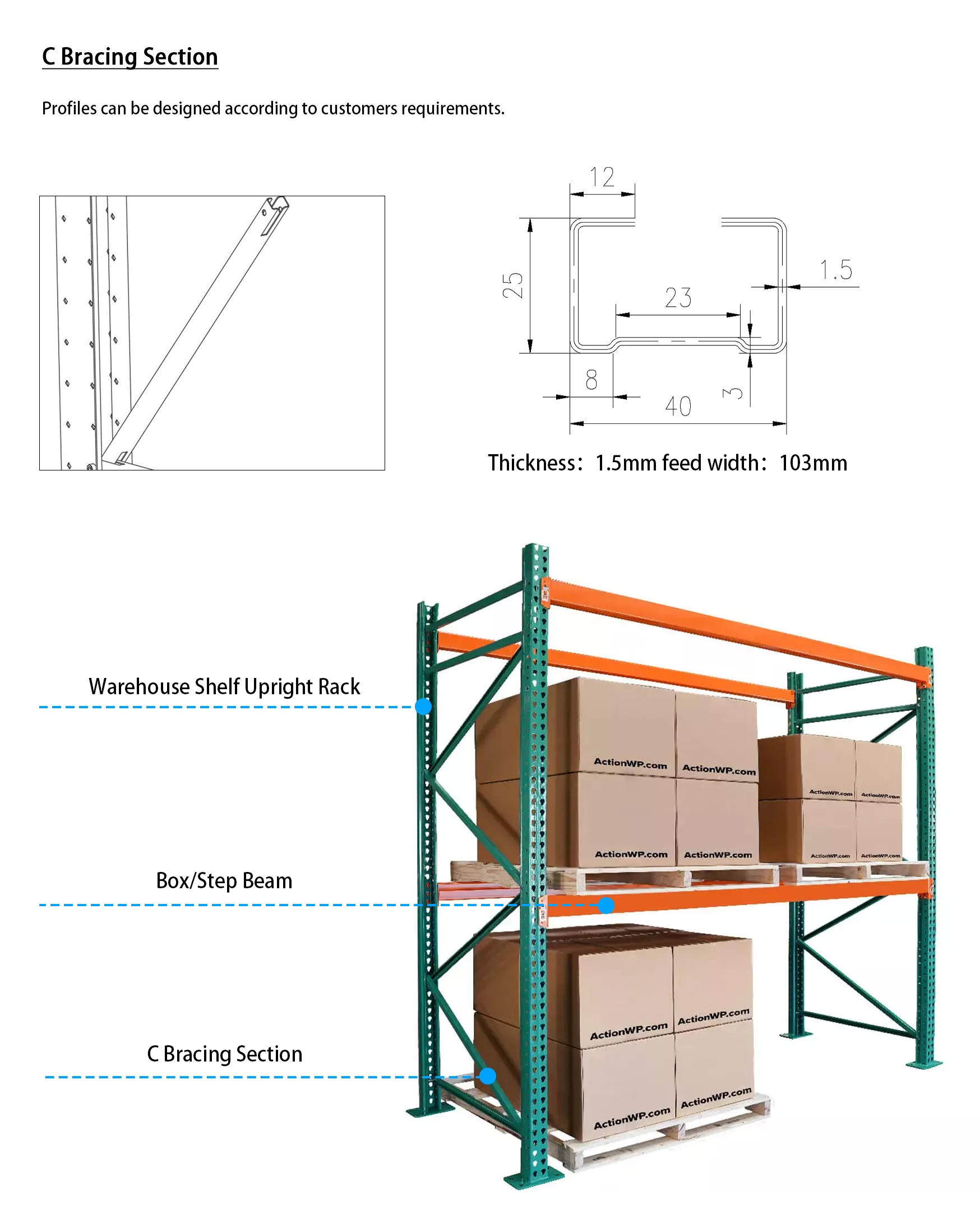

Profile Drawings

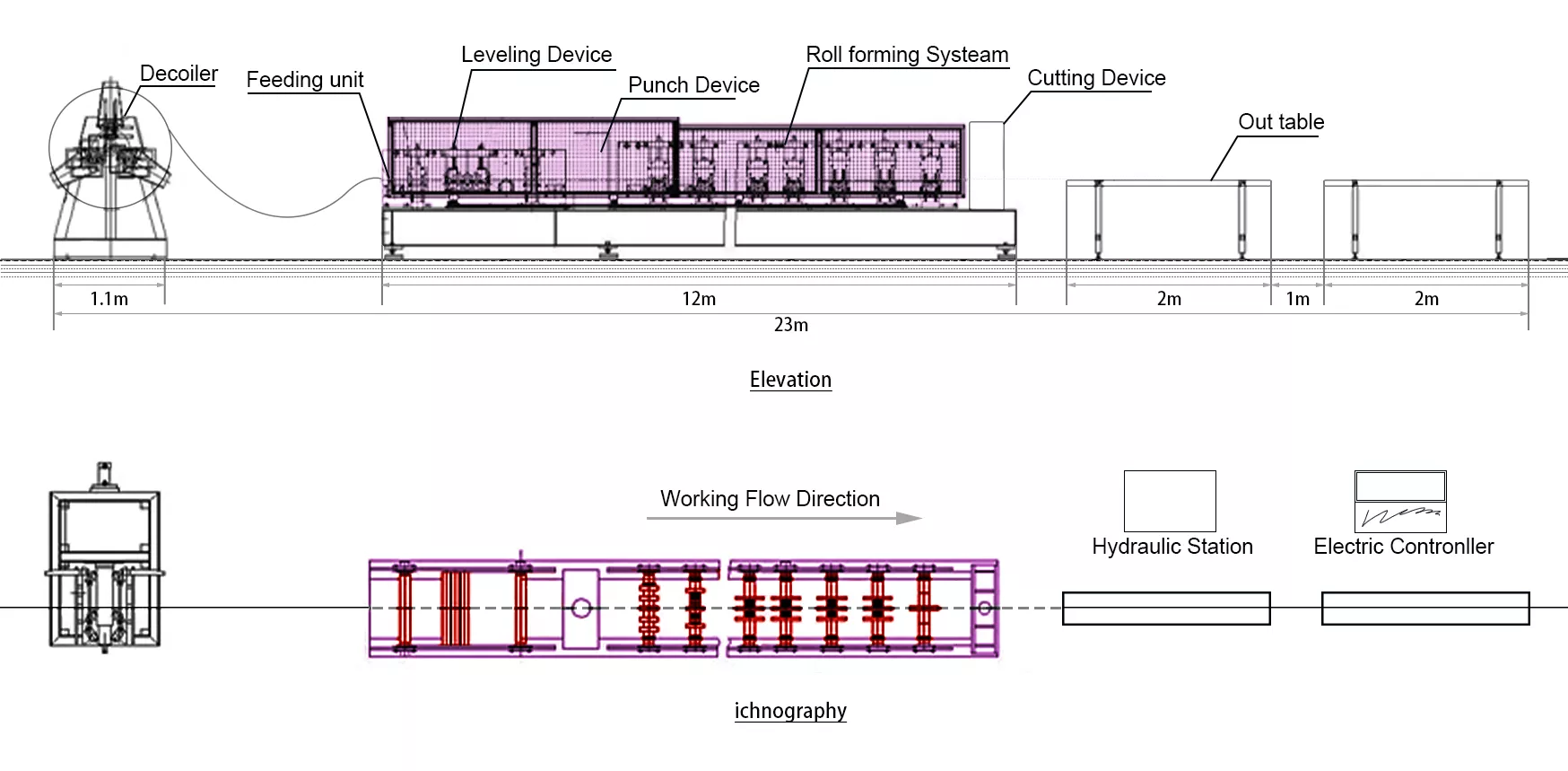

Production Line

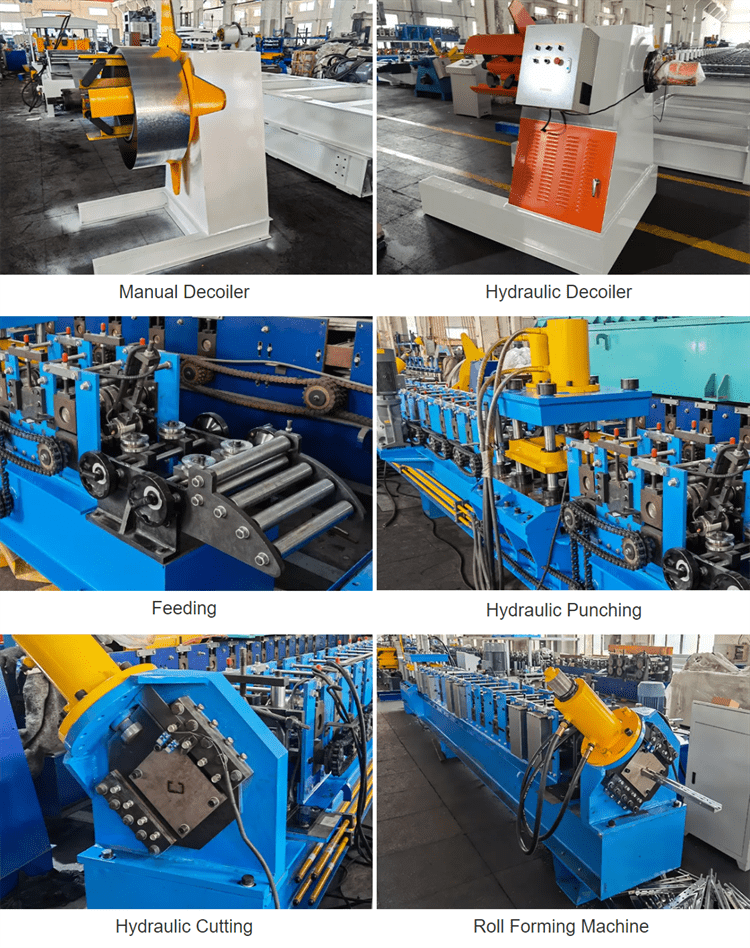

Product Details

Product Parameters

| C Bracing Section Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-1.8 as per customer

|

| B) PPGI, PPGL | ||

| C) Cold-rolled Steel | ||

| D) Carbon Steel | ||

| Yield Strength | 250 – 350 Mpa | |

| Tensil Stress | 350 Mpa-500 Mpa | |

| Nominal Forming Speed(M/Min) | 10-15 | * Or According To Your Requirement |

| Forming Station | About 14 | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Cast Iron Stands (Optional) |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Hydraulic Pre-cut | |

| Punching System | Hydraulic Punching | |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

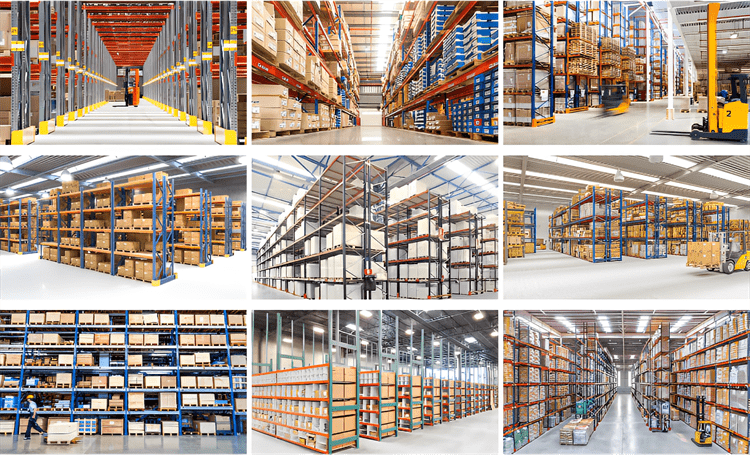

Application

what is rack roll forming machine?

A rack roll forming machine is a type of industrial machinery used in the manufacturing process of racks, shelves, or storage systems. It is designed to shape and form metal sheets or coils into specific profiles that are used to construct the structural components of racks.

The roll forming process involves passing a continuous strip of metal through a series of roller dies, which progressively shape the metal into the desired rack profile. The rollers apply a combination of bending, stretching, and forming actions to gradually transform the flat metal sheet into the final shape.

Rack roll forming machines typically consist of a feeding system, a series of roll forming stations, and a cutting system. The feeding system feeds the metal strip into the machine, while the roll forming stations house the roller dies that shape the metal. The cutting system is used to cut the formed profiles to the desired lengths.

These machines are highly customizable and can produce racks with different sizes, shapes, and configurations. They are often used in industries such as warehousing, logistics, retail, and manufacturing, where storage systems are required to organize and store goods efficiently.

By utilizing rack roll forming machines, manufacturers can achieve high production rates, consistent quality, and precise dimensional accuracy in their rack manufacturing processes.

what’s different between rack roll forming machine and rack shelf roll forming machine?

Rack roll forming machine and rack shelf roll forming machine are closely related but have slight differences in their applications.

A rack roll forming machine is a general term used to describe a roll forming machine that is specifically designed to produce various types of racks, including rack shelves. It can be used to manufacture different rack components such as uprights, beams, bracing, and other structural elements.

On the other hand, a rack shelf roll forming machine refers to a roll forming machine specifically designed to produce rack shelves, which are the horizontal platforms or surfaces used to store items on a rack. Rack shelves are typically flat and have specific dimensions and features to accommodate different types of products.

what is c section roll forming machine?

C-section roll forming machine, also known as a C-purlin roll forming machine, is a type of industrial machinery used in the manufacturing process of C-shaped steel sections called C-purlins. C-purlins are widely used in the construction industry as structural components in buildings, particularly in roof and wall systems.

The C-section roll forming machine is designed to shape and form metal coils, typically made of galvanized steel or other types of steel, into the desired C-shaped profile. The machine utilizes a series of roll forming stations that gradually bend, shape, and form the metal strip into the final C-purlin shape.

The process involves feeding the metal coil into the machine, where it passes through a series of rollers that progressively shape it. These rollers apply specific bending and forming actions to achieve the desired dimensions and profile of the C-purlin. The machine may also have additional stations for punching holes or adding other features to the C-purlin as required.

C-purlins produced by the C-section roll forming machine are commonly used as structural members in roofing and cladding systems, providing support and stability to the roof and wall panels. They are lightweight, durable, and easy to install, making them a popular choice in the construction of industrial buildings, warehouses, and commercial structures.

The C-section roll forming machine allows for high production rates, precise dimensional accuracy, and consistent quality, making it an efficient and cost-effective solution for manufacturing C-purlins used in various construction applications.