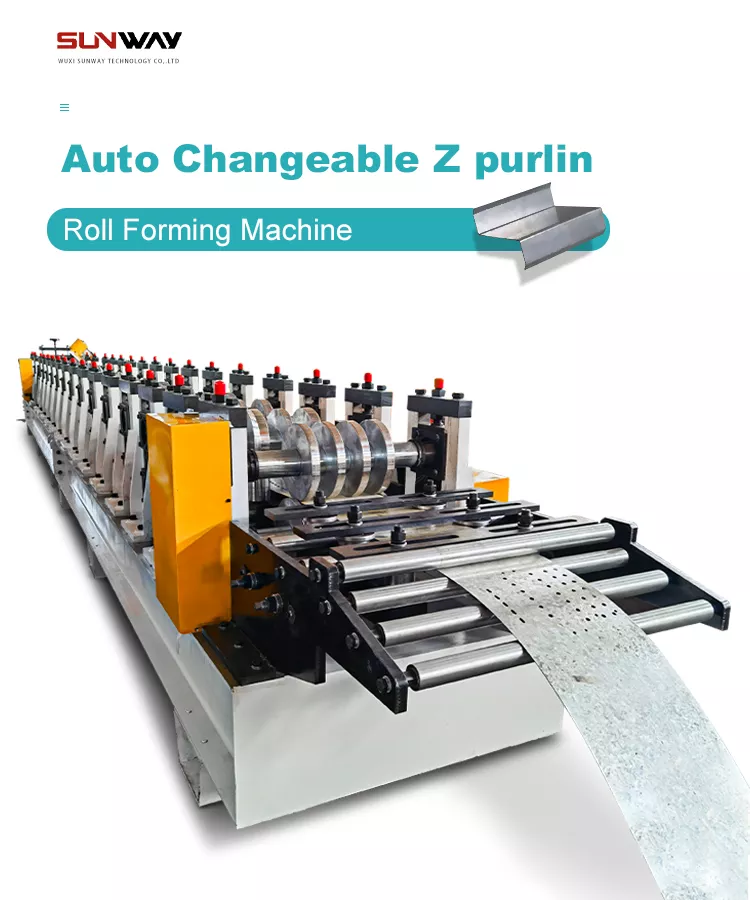

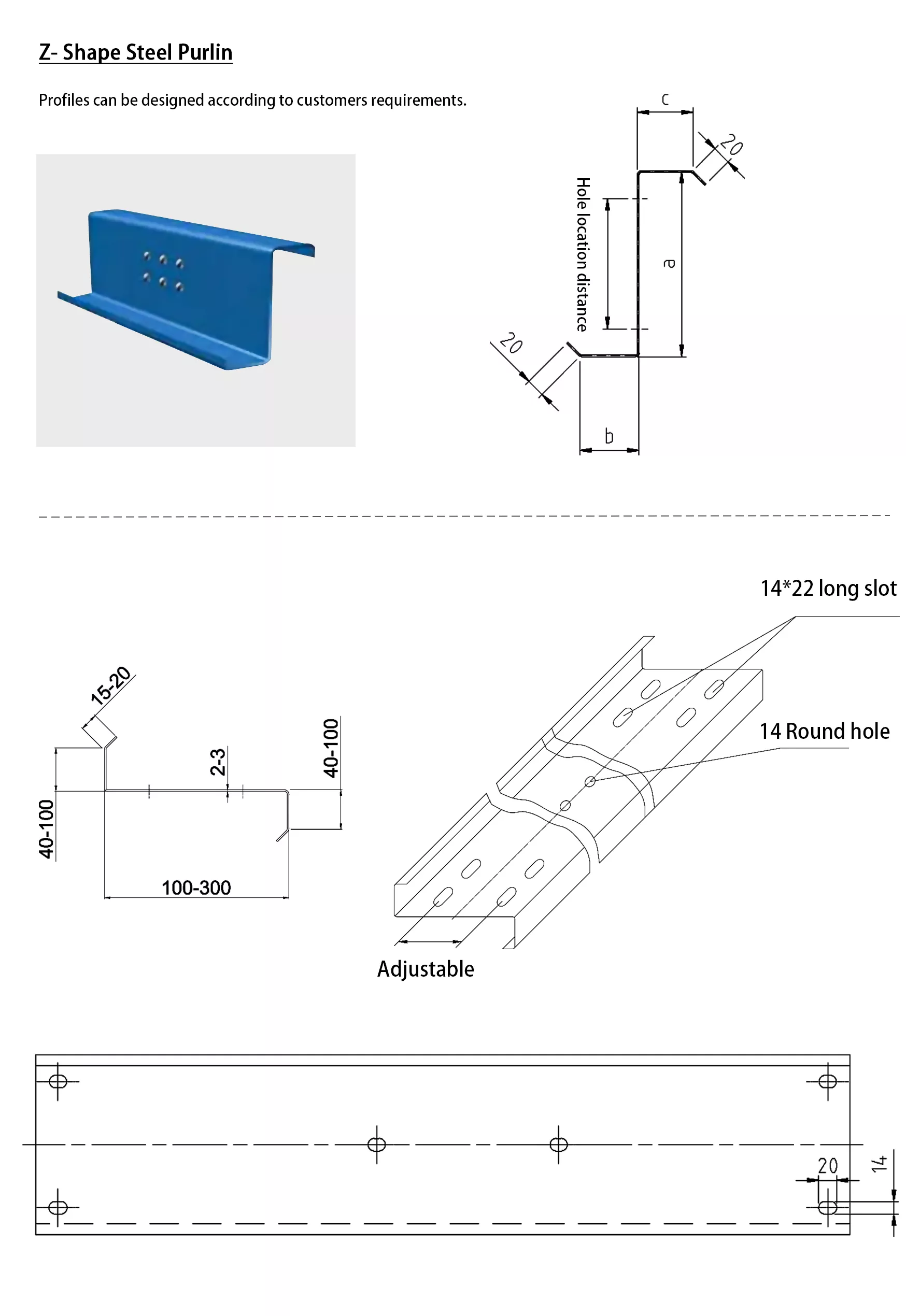

This Z Purlin Roll Forming Machine is used to produce Z shape purlins from 100-300mm of width, normally its material thickness is1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

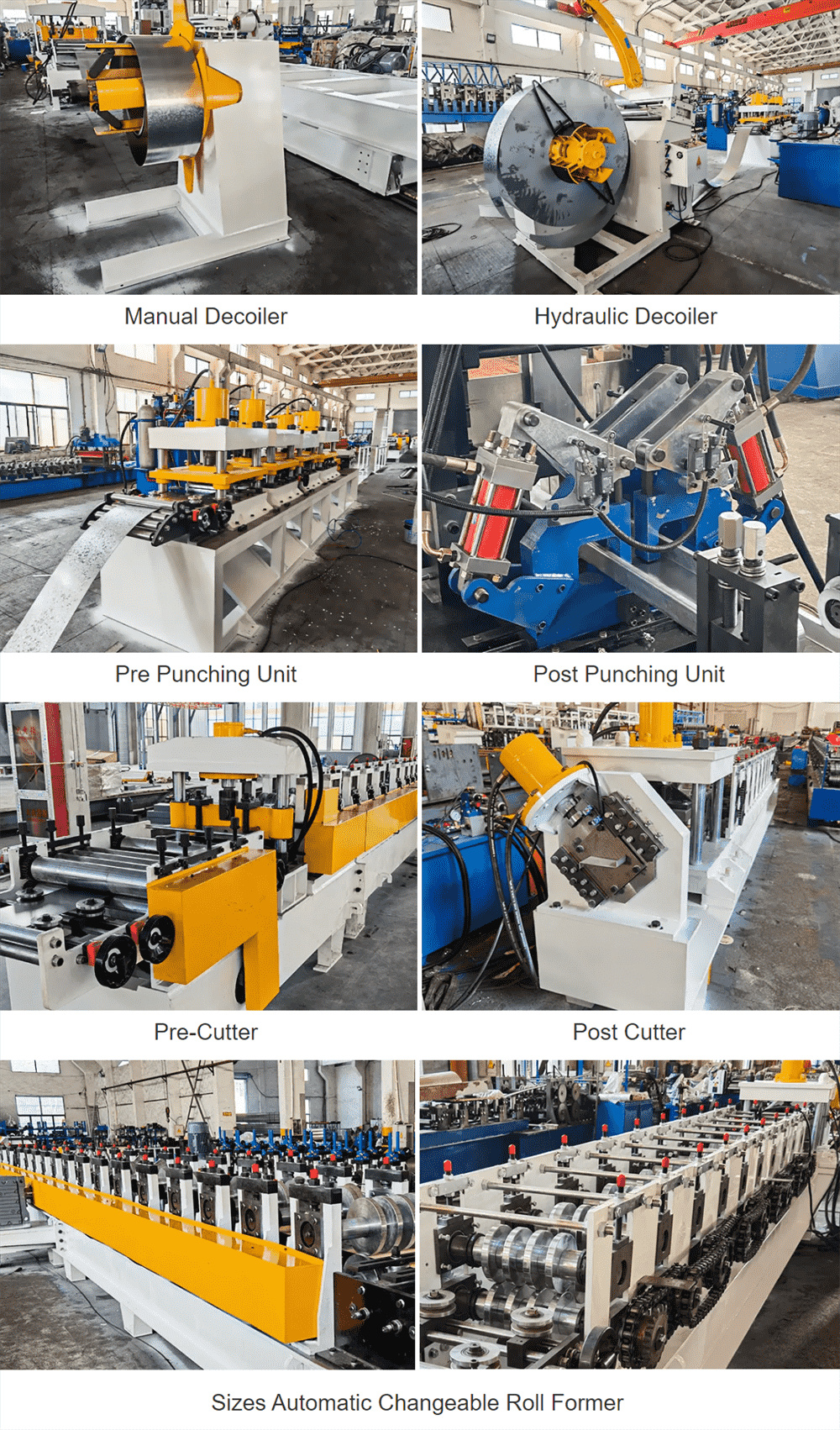

SUNWAY design this machine to work with any size of the purlin, automatically adjustable sizes by PLC or manually adjust handle wheel to change the sheet width to get different width and height. This is much more easily than adjust the spacers and can save more time. Regarding the punching unit, we can design pre punching, post punching according to your requirement. For cutting unit, you can choose the pre-cut or post-cut which is universal cutting. The driving system we adopt the chain and mostly with gimbal /gearbox for transmission if the raw material is thicker than 2.5mm,this is much more strong driving power and more stable when forming the purlins.

Purlin roll forming machine is the most popular and has an extensive use in Metal Building Systems, Huge RoofingSolutions,Construction and Renovation Projects etc. Our Purlin roll forming machine could produce C purlin, U purlin, Z purlin, machineable size range as follow: Width:100-300mm, Height: 50-100mm, Thickness:1.5-3mm. According to your section profile, size range,thickness range we could provide you different solutions of purlin roll forming machine to manufacturer a complete range of structual purlins (height and width change using automatic system by motors): If you only need to produce few sizes, we also suggest manually change sleeves, it’s more affordable.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Click here to learn more about the purlin roll forming machine

Profile Drawings

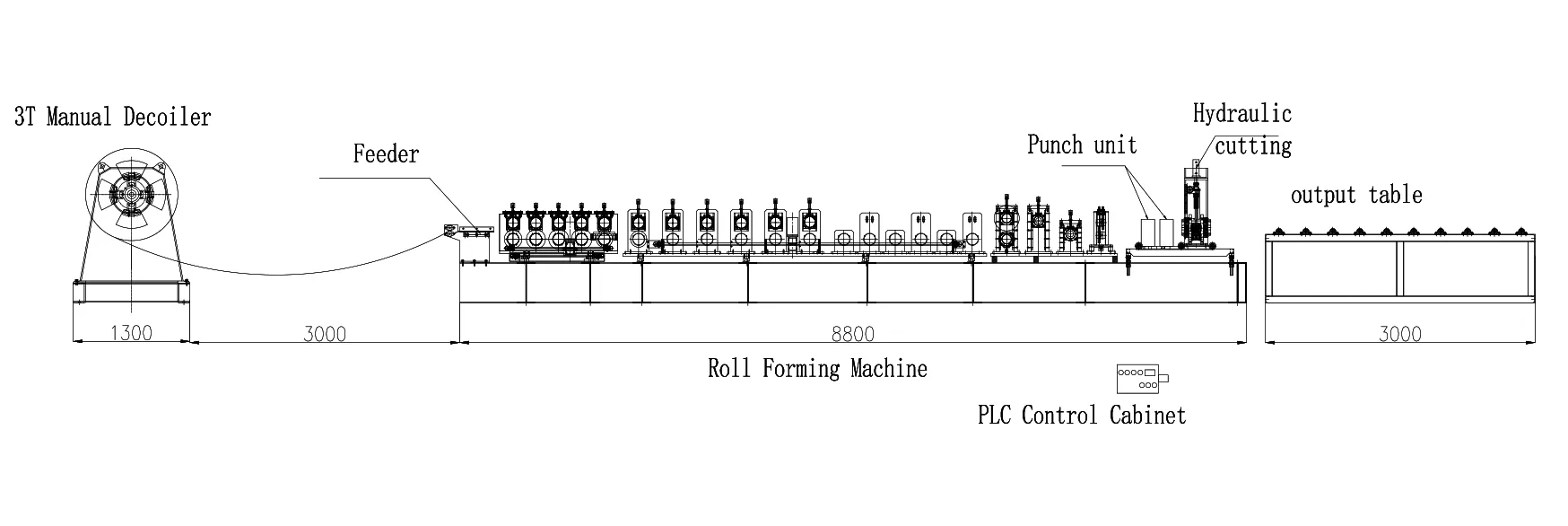

Z Purlin Roll Forming Machine Production Line

Product Details

Z Purlin Roll Forming Machine Product Parameters

| Auto Size Changeable Z Purlin Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3 or as per customer

|

| B) Carbon Steel Coil | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G350 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Pre-punch / Post Punch (Optional) |

| Forming Station | 16-18 Stations | |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Forged Iron Station (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Requirment |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Pre-cutting | * Post- universal Cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirment |

| Machine Color | Industrial Blue | * Or According To Your Requirment |

Application

What is z purlin roll forming machine?

A Z purlin roll forming machine is a specialized piece of equipment used in the manufacturing of Z-shaped purlins. Purlins are structural members commonly used in the construction industry to provide support for roof and wall panels. They are typically made from steel and come in various shapes, including C, Z, and U.

The roll forming machine is designed to shape flat metal coils or sheets into the desired Z-shaped purlin profile. It consists of a series of rollers and forming stations that progressively bend the metal to the required shape. The machine typically includes a decoiler to hold and feed the metal coil, a leveling system to ensure the material is flat, and various roll forming stations to shape the purlin.

During the roll forming process, the metal coil passes through the machine, and each roll station performs a specific bending or shaping operation. The rollers are carefully designed to gradually bend the metal, forming the Z shape and achieving consistent dimensions throughout the length of the purlin. Once the metal has been shaped, the purlins can be cut to the desired lengths and stacked for further use in construction projects.

Z purlin roll forming machines are efficient and precise, allowing for high-speed production of purlins with consistent quality. They are commonly used in steel fabrication plants or construction material manufacturing facilities. The resulting Z-shaped purlins are lightweight, strong, and easy to install, making them popular for a wide range of building applications.

top 5 c z purlin roll forming machine manufacturers

- WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

- Bradbury Group: The Bradbury Group is a renowned manufacturer of roll forming equipment, including C and Z purlin roll forming machines. They offer a range of solutions for various metal forming applications.

- Samco Machinery: Samco Machinery is a global leader in roll forming technology. They specialize in designing and manufacturing roll forming equipment, including machines for C and Z purlin production.

- Formtek Group: The Formtek Group is a well-established company that offers a comprehensive range of metal forming equipment. They provide roll forming machines for various applications, including C and Z purlin production.

- Zhongyuan Machinery Factory: Zhongyuan Machinery Factory is a Chinese manufacturer with a strong presence in the roll forming industry. They offer a wide range of roll forming machines, including those for C and Z purlin manufacturing.

application of changeable u purlin roll forming machine

A changeable U purlin roll forming machine is a specialized piece of equipment used to manufacture U-shaped purlins with the ability to change the dimensions or sizes of the purlins being produced. These machines are versatile and can be used in various applications within the construction and manufacturing industries. Here are some common applications of a changeable U purlin roll forming machine:

- Roofing and Cladding Systems: U-shaped purlins are commonly used in roofing and cladding systems to provide structural support for roof panels and wall panels. The changeable nature of the roll forming machine allows for flexibility in producing purlins of different sizes and profiles to suit specific project requirements.

- Industrial Sheds and Warehouses: U purlins are widely used in the construction of industrial sheds and warehouses for their strength and load-bearing capabilities. The roll forming machine enables the efficient production of U-shaped purlins of varying dimensions, which can be tailored to the specific design and load requirements of the structure.

- Steel Framing Systems: Changeable U purlin roll forming machines are also utilized in the manufacturing of steel framing systems. U purlins are an integral component of steel frames, providing support for walls, floors, and ceilings. The machine allows for the production of purlins with different sizes and thicknesses to meet the specific needs of the framing system.

- Agricultural Buildings: U purlins find extensive use in agricultural buildings such as barns, livestock shelters, and storage facilities. These structures require robust and durable purlins to withstand various environmental conditions. A changeable U purlin roll forming machine can produce purlins of different dimensions, accommodating the specific requirements of agricultural building projects.

- Residential Construction: In residential construction, U purlins are utilized for various applications such as roof trusses, floor joists, and load-bearing walls. The ability to change the dimensions of the purlins using the roll forming machine allows for greater flexibility in adapting to different architectural designs and structural requirements.