2 profile in 1 roll forming machine Summary

- Material: Color steel, Galvanized coil

- Material Thickness: 0.4-1.5mm

- Forming Speed: 10-15m/min

2 profile in 1 roll forming machine Main Parts

- Manual Decoiler

- Feeding Guide

- Roll Forming System

- Hydraulic Cutting

- PLC Control System

- Run-out Table

Working Flowing

Decoiler— Guide–Roll Forming—- cutting–Run out table

2 profile in 1 roll forming machine Technical Data:

1). Manual Decoiler

- * Decoiler Type: Manual Decoiler

- * Weight Capacity Of Decoiler: 3 Ton

- * Inner Diameter. Φ460-520mm

- * Outer Diameter. Φ1400mm

Reference picture:

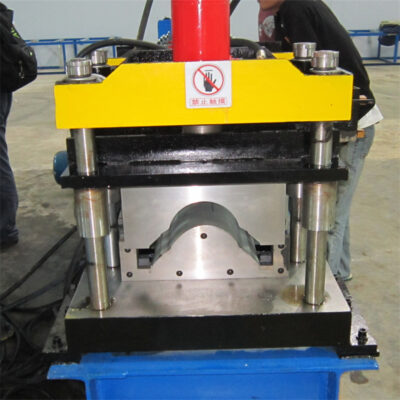

2). Roll Forming system

- Axis Diameter:60 mm

- Forming Roller stand: 10-12Groups

- Main Axis material: First grade 45# steel, heated and quenched

- Roller material: First grade 45# steel, with hard chrome 0.05mm, Quenched and heated process

- Drive Type: 1” Chain of transmission

- Chain material: 45#steel, HRC45-50

- Machine Frame stand: Welded structural steel

- Main motor Power: 5.5 KW

Reference picture:

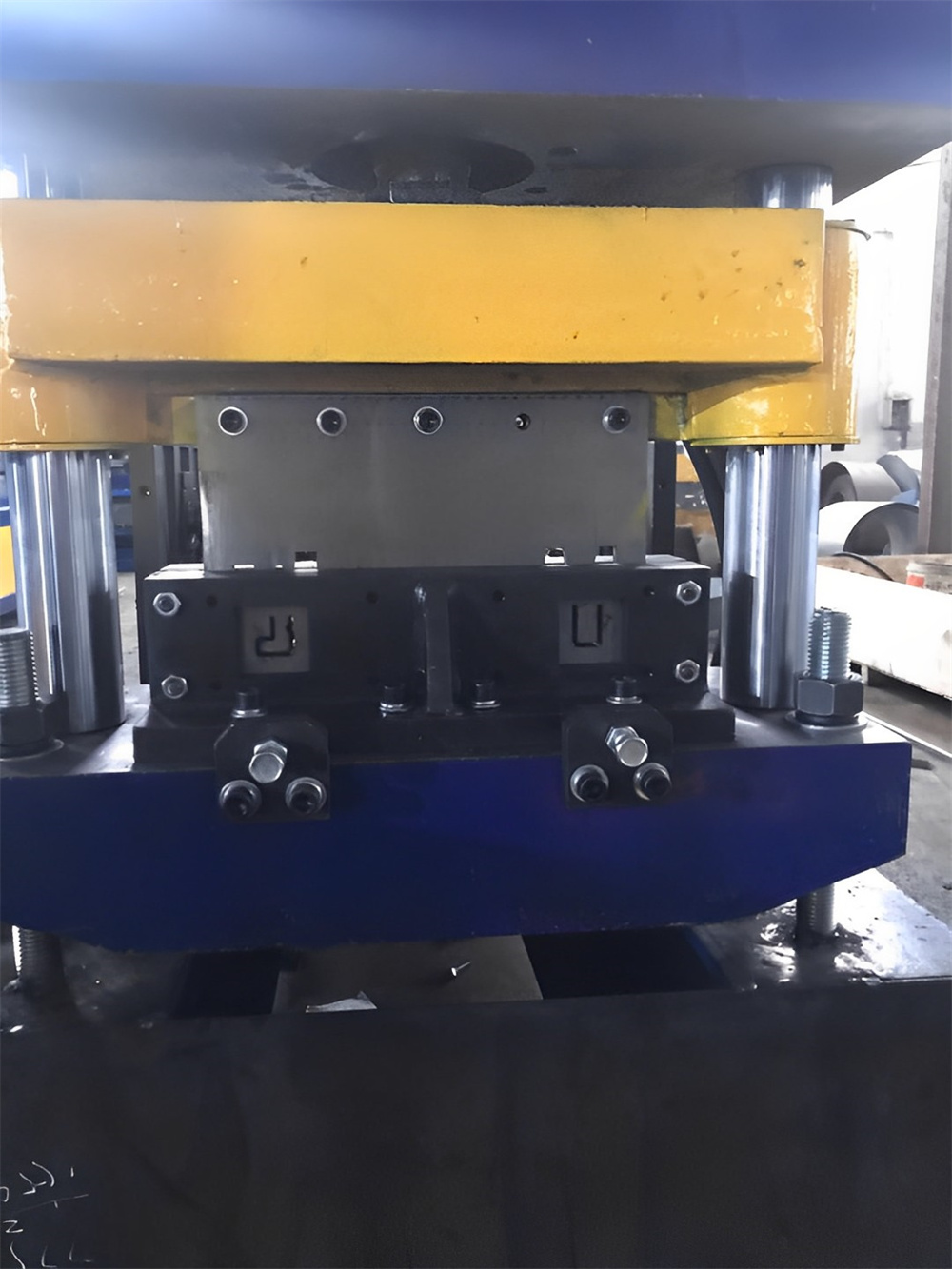

3) Cutting Device (include 2 size)

- Cutting type: Hydraulic cutting

- Hydraulic pump station power: 4 KW

- Hydraulic pressure: 12Mpa

- Hydraulic Blade and cutter material: Cr12, quenching process 58-62

- Cutting length tolerance: 10M+/- 2.0 mm

Reference picture:

4). Electrical System

- Voltage: 380V, 3 Phase 50Hz

- PLC Electrical control system: PANASONIC

- Length Controller: Encoder Frequency Control System

- Operation: Touch Screen

- Transducer: Japan YASKAWA

Reference picture:

5) Runout Table

- Non-power type

- Quantity:2

Reviews

There are no reviews yet.