Introduction

In the construction industry, precision and efficiency are paramount to meet the ever-growing demands of modern architecture. One crucial aspect of construction involves creating high-quality drywall studs for partitions and framing. Traditional methods of manufacturing drywall studs can be labor-intensive and time-consuming. However, with the advent of advanced technology, a game-changer has emerged: the drywall stud roll forming machine.

What is a Drywall Stud Roll Forming Machine?

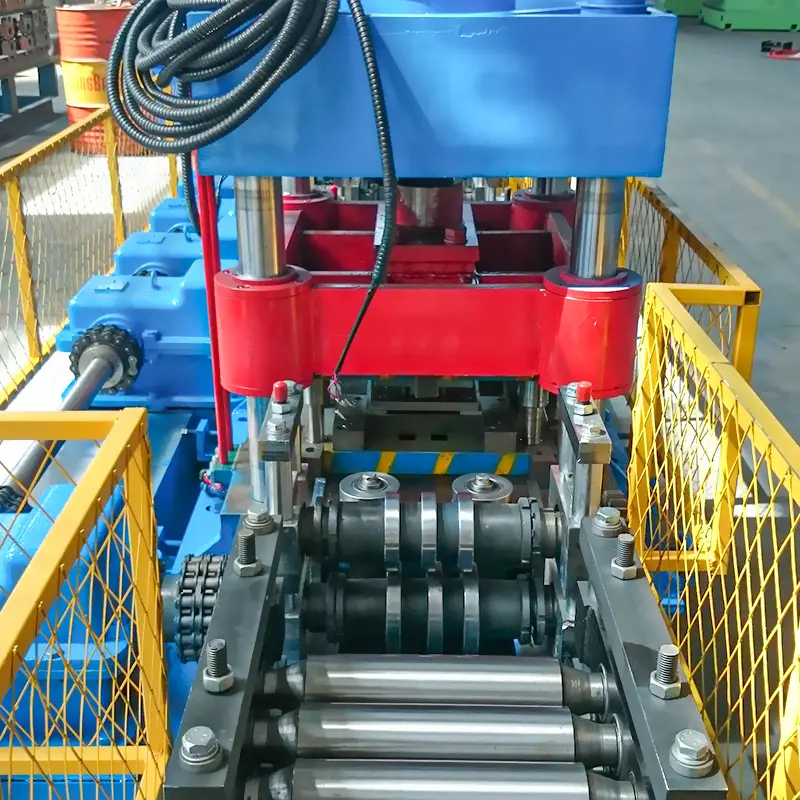

A drywall stud roll forming machine is a specialized equipment used to fabricate metal studs used in drywall construction. It operates on the roll forming principle, where a continuous strip of metal passes through multiple stations to gradually form the desired profile of the stud. The result is a precisely shaped and consistent metal stud, ready for use in various construction applications.

How Does a Drywall Stud Roll Forming Machine Work?

The working principle of a drywall stud roll forming machine is ingenious yet straightforward. The process begins with a coil of metal sheet, usually steel, fed into the machine. The sheet passes through a series of roller dies, each designed to shape a specific part of the stud profile. Gradually, the metal strip takes the shape of the stud as it moves through the stations. The final product is then cut to the required length and collected for packaging or further processing.

Advantages of Using a Drywall Stud Roll Forming Machine

The adoption of a drywall stud roll forming machine offers several advantages over traditional manufacturing methods:

- Enhanced Efficiency: The machine’s automated process significantly increases production speed, reducing the time required to manufacture each stud.

- Consistent Quality: With precise control over the forming process, each stud is uniform in shape and dimensions, ensuring superior quality.

- Cost Savings: Higher production rates and reduced labor requirements lead to cost savings in the long run.

- Versatility: Drywall stud roll forming machines can create a variety of stud profiles, catering to different construction needs.

- Waste Reduction: The process generates minimal waste, optimizing material usage and reducing environmental impact.

Types of Drywall Stud Roll Forming Machines

Several types of drywall stud roll forming machines are available, each designed to suit specific production requirements:

Single Profile Drywall Stud Roll Forming Machine

A single profile roll forming machine is ideal for businesses focusing on a particular stud profile. It offers simplicity and efficiency for producing large quantities of a single stud type.

Multiple Profile Drywall Stud Roll Forming Machine

For manufacturers dealing with various stud profiles, a multiple profile roll forming machine is the way to go. It provides versatility without compromising on production speed.

Fully Automatic Drywall Stud Roll Forming Machine

Fully automatic machines require minimal human intervention, as they can perform loading, forming, cutting, and stacking automatically.

Semi-Automatic Drywall Stud Roll Forming Machine

Semi-automatic machines are more budget-friendly and involve manual loading and unloading of materials while the machine handles the forming process.

Factors to Consider When Choosing a Drywall Stud Roll Forming Machine

Selecting the right machine for your business is crucial. Consider the following factors before making a decision:

Production Capacity

Assess your production needs and choose a machine that can meet or exceed your output requirements.

Material Compatibility

Ensure that the machine can handle the types and thicknesses of metal sheets you plan to use.

Customization Options

Some machines offer customization features, allowing you to produce studs of different lengths and profiles.

Energy Efficiency

Opt for energy-efficient machines to reduce operational costs and environmental impact.

Maintenance and Support

Choose a machine with good after-sales support and maintenance services to ensure smooth operations and longevity.

How to Operate a Drywall Stud Roll Forming Machine?

Operating a drywall stud roll forming machine requires proper training and adherence to safety guidelines. Here’s a basic guide to its operation:

- Machine Setup: Ensure the machine is correctly installed and the rollers are aligned as per the desired stud profile.

- Material Loading: Load the metal coil into the machine, securing it properly for smooth feeding.

- Start the Machine: Power up the machine and begin the roll forming process by activating the rollers.

- Monitor the Process: Keep an eye on the forming process to detect any irregularities or malfunctions.

- Cutting and Stacking: Once the stud reaches the required length, the machine will automatically cut it and stack the finished studs.

Safety Measures and Best Practices

Operating a drywall stud roll forming machine involves potential risks. Implement these safety measures to ensure a safe working environment:

Training and Certification

Only trained and certified operators should handle the machine to prevent accidents and ensure proper operation.

Safety Gear and Equipment

Operators must wear appropriate safety gear, including helmets, gloves, and safety glasses.

Machine Maintenance and Inspection

Regularly inspect the machine for wear and tear, and perform maintenance as required to avoid unexpected breakdowns.

Emergency Protocols

Establish clear emergency procedures and ensure all operators are aware of them to handle critical situations.

Maintenance and Troubleshooting Tips

To ensure the machine’s smooth operation, follow these maintenance and troubleshooting tips:

Regular Maintenance Checks

Perform routine checks on the machine’s parts, lubricate where necessary, and replace worn components promptly.

Common Issues and Solutions

Stay familiar with common issues that may arise during the operation of a drywall stud roll forming machine and their possible solutions:

- Uneven Forming: If the studs are coming out with uneven shapes, check for misalignment in the rollers. Adjust and realign them as needed to ensure a consistent profile.

- Material Jamming: If the metal strip gets stuck in the machine, stop the operation immediately, and clear the jam carefully. Regularly inspect the feeding system to prevent jams.

- Inconsistent Lengths: If the studs are not being cut to the desired length accurately, check the cutting mechanism and adjust the cutting blade or sensor as required.

- Machine Vibrations: Excessive vibrations during operation can lead to quality issues. Inspect and balance the rollers and ensure the machine’s foundation is stable.

- Strange Noises: Unusual noises could indicate a mechanical issue. Investigate the source of the noise and address it promptly to prevent further damage.

Upgrading Your Drywall Stud Roll Forming Machine

As technology advances, it’s essential to keep your equipment up-to-date. Consider these upgrade options for your drywall stud roll forming machine:

Software Updates

Manufacturers may release software updates to improve machine performance, add new features, or enhance automation. Regularly check for updates and install them to optimize your machine’s capabilities.

Hardware Upgrades

Some upgrades may involve replacing or adding components to your machine, such as advanced sensors or improved forming rollers. Consult the manufacturer or a specialist to assess upgrade possibilities.

Buying a Drywall Stud Roll Forming Machine

Purchasing a drywall stud roll forming machine requires careful consideration. Follow these guidelines to make an informed decision:

New vs. Used Machines

While new machines offer the latest technology and warranties, used machines can be cost-effective for startups or businesses with budget constraints. Ensure to inspect the condition and performance of a used machine before purchase.

Selecting a Reputable Manufacturer

Research and choose a reputable manufacturer with a proven track record of producing reliable and high-quality roll forming machines. Read reviews and customer testimonials to gauge customer satisfaction.

Price Comparison and Negotiation

Obtain quotes from multiple suppliers and negotiate the price to get the best deal. Consider factors such as machine specifications, after-sales support, and warranty coverage.

Case Studies: Real-Life Applications

Real-life case studies can demonstrate the impact of using a drywall stud roll forming machine. Here are a few examples:

- Construction of Commercial Buildings: A construction company significantly reduced construction time and costs by using a drywall stud roll forming machine to produce high-quality studs for multiple projects.

- Residential Renovation: A contractor improved productivity and precision in a residential renovation project by employing a multiple profile roll forming machine to create various stud sizes on-site.

- Infrastructure Projects: Large-scale infrastructure projects, such as schools and hospitals, benefited from the efficiency and consistency of drywall studs produced by fully automatic roll forming machines.

Future Trends in Drywall Stud Roll Forming Machines

As technology continues to advance, drywall stud roll forming machines will likely see further improvements:

- Advanced Automation: Machines may become more intelligent, with AI-driven automation, self-diagnostic capabilities, and remote monitoring.

- Energy Efficiency: Manufacturers may focus on developing more energy-efficient machines to reduce operational costs and environmental impact.

- Material Innovation: New materials and coatings may be introduced, offering improved strength, corrosion resistance, and fire resistance.

Environmental Impact and Sustainability

Drywall stud roll forming machines contribute to sustainability in the construction industry:

- Waste Reduction: By minimizing material waste during the roll forming process, these machines promote eco-friendly manufacturing.

- Recyclable Materials: Many drywall studs are made from recyclable materials, further reducing the environmental impact of construction projects.

Conclusion

The drywall stud roll forming machine has revolutionized the construction industry by streamlining the process of manufacturing metal studs. With their efficiency, precision, and versatility, these machines have become a valuable asset for modern construction projects. By choosing the right machine, ensuring proper training and safety measures, and staying updated with advancements, businesses can optimize their productivity and contribute to sustainable construction practices.

FAQs

Q: Can a drywall stud roll forming machine be used for other types of profiles?

A: Yes, certain machines can be customized to create various metal profiles for different construction applications.

Q: What maintenance schedule is recommended for the machine?

A: Regular maintenance checks should be conducted, with intervals determined by the machine’s usage and manufacturer’s recommendations.

Q: Are drywall stud roll forming machines suitable for small-scale businesses?

A: Yes, there are machines available that cater to small-scale production needs and can be cost-effective for such businesses.

Q: How much training is required to operate the machine safely?

A: Proper training and certification are essential, and the duration may vary depending on the complexity of the machine.

Q: Can I upgrade an existing machine with the latest technology?

A: Depending on the machine’s design and compatibility, certain upgrades may be possible. Consult with the manufacturer or an expert to explore upgrade options.

Additional Frequently Asked Questions (FAQ)

1) What tolerances can a modern Drywall Stud Roll Forming Machine maintain at speed?

With encoder-based length control and servo flying cutoff, expect length ±0.5–1.0 mm and hole-to-edge ±0.3–0.6 mm at 40–80 m/min, assuming quality coil and proper guiding.

2) Which materials and thicknesses are typical for drywall studs and tracks?

Most lines run galvanized steel coils to ASTM A653 or EN 10346 in 0.4–1.2 mm thickness (commonly 0.5–0.8 mm for interior partitions) with G40–G60/Z140–Z275 coatings.

3) How do auto changeover features impact short-run production?

Recipe-driven width/height adjustments and servo roll-gap setting can cut changeover from 20–30 minutes to 3–8 minutes, boosting OEE for high-mix stud/track SKUs.

4) What are key acceptance tests before shipment (FAT) for a stud roll former?

- Demonstrate speed at stated gauge and profile

- Verify cut length tolerance on 50+ consecutive parts

- Show punching alignment for service holes/knockouts

- Validate safety circuits (E-stops, interlocks) and CE/OSHA conformity

- Confirm data connectivity (OPC UA/MQTT) and documentation

5) How can I reduce oil stains on pre-painted coils when roll forming studs?

Use food-grade, low-residue lubricants with micro-spray systems, maintain roll cleanliness, and add air knives or wipers; verify paint compatibility with supplier TDS.

2025 Industry Trends for Drywall Stud Roll Forming Machines

- Shorter changeovers: Auto size-changeable stud/track systems with stored recipes become standard for contractors serving multi-SKU builds.

- Higher speeds with better QA: Inline vision for knockout/slot verification and straightness/camber monitoring reduces rework and callbacks.

- Energy efficiency: Regenerative drives and smart hydraulics cut energy intensity by 10–20% vs. 2023 baselines.

- Connectivity and traceability: OPC UA-ready PLCs enable OEE dashboards, coil traceability, and predictive maintenance via vibration/thermal sensors.

- Lightweight yet robust: Wider adoption of higher-yield steels (e.g., 350–550 MPa) allows thinner gauges while maintaining performance, reducing material use 8–12%.

- Safety by design: SIL-rated safety PLCs, interlocked guarding, and remote diagnostics increasingly specified by multinational builders.

2024–2025 Benchmarks and Buying Indicators

| KPI | 2024 Typical | 2025 Best-in-Class | Why it matters | Sources |

|---|---|---|---|---|

| Line speed (0.5–0.8 mm) | 40–60 m/min | 70–100 m/min | Throughput for large projects | OEM catalogs (e.g., Bradbury, Samco), The Fabricator |

| Changeover time (stud ↔ track/size) | 20–30 min | 3–8 min | OEE on high-mix runs | OEM datasheets; integrator case notes |

| Length tolerance (±) | 1.0–1.5 mm | 0.5–1.0 mm | Fit-up, less scrap | Inline metrology vendors |

| Hole/knockout positional (±) | 0.8–1.2 mm | 0.3–0.6 mm | Faster MEP pass-through | Case studies; AISI practice |

| Energy use (kWh/ton) | 100–140 | 85–110 | OpEx, CO2e | U.S. DOE AMO guidance |

| Installed price (USD) | $45k–$95k | $60k–$130k | Budgeting | 2025 industry quotes |

Authoritative references:

- ASTM A653 (galvanized) and A1003 (CFS studs): https://www.astm.org

- EN 10346 (continuously coated steels): https://standards.cen.eu

- AISI S220/S240 (nonstructural/structural studs): https://www.buildusingsteel.org

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo

- OPC Foundation (OPC UA): https://opcfoundation.org

- The Fabricator (roll forming insights): https://www.thefabricator.com

Latest Research Cases

Case Study 1: Auto Changeover Stud/Track Line Boosts OEE (2025)

Background: Regional drywall fabricator supplying mixed SKUs to multiple GC projects suffered frequent changeovers and setup scrap.

Solution: Implemented auto size-changeable Drywall Stud Roll Forming Machine with servo roll-gap, recipe library, barcode job loading, and inline vision for knockout alignment.

Results: Changeover cut from 26 to 5 minutes; OEE +16%; setup scrap −52%; labor hours per 10,000 m −11%; payback in 13 months.

Case Study 2: Energy-Optimized Drive Upgrade on Legacy Line (2024)

Background: Midwestern plant faced rising energy costs and inconsistent cut length on thin-gauge pre-painted coils.

Solution: Retrofitted regenerative VFDs, added laser length encoder and micro-spray lube system; introduced SPC on cut length and hole position.

Results: Energy intensity −14% (kWh/ton); cut length Cpk from 0.9 to 1.5; paint defects related to oil staining −60%; monthly downtime −18% via predictive alerts.

Expert Opinions

- Jennifer Kinder, Director of Product Management, Samco Machinery

Viewpoint: “For drywall stud and track, normalize vendor quotes by gauge, speed, and tolerance targets; otherwise you’re not comparing like for like.”

Company: https://www.samco-machinery.com - Phil Paxton, President, The Bradbury Group

Viewpoint: “Servo-based gap setting plus flying cutoff is the fastest ROI upgrade on high-mix stud/track lines.”

Company: https://www.bradburygroup.com - Dr. Benjamin Schafer, Professor of Civil Engineering, Johns Hopkins University

Viewpoint: “Tighter, repeatable cold-formed geometries improve connection reliability and reduce onsite rework across partition systems.”

Profile: https://engineering.jhu.edu

Practical Tools/Resources

- Standards and design

- AISI S220 (nonstructural) and S240 (structural studs): https://www.buildusingsteel.org

- ASTM A653/A1003 material standards: https://www.astm.org

- Euro norms EN 10346 for coated steels: https://standards.cen.eu

- Quality and operations

- NIST SPC resources and process capability guides: https://www.nist.gov/manufacturing

- DOE AMO motor/drive efficiency tools: https://www.energy.gov/eere/amo

- Connectivity and data

- OPC UA for machinery interoperability: https://opcfoundation.org

- Industry media/OEM discovery

- The Fabricator (best practices in roll forming): https://www.thefabricator.com

- Precision Metalforming Association directory: https://www.pma.org

- Representative OEMs: The Bradbury Group, Samco Machinery, Dallan, Formtek

Last updated: 2025-10-22

Changelog: Added 5 focused FAQs; introduced 2025 trends with benchmark table and authoritative sources; included two recent case studies; compiled expert viewpoints; provided practical tools/resources tailored to Drywall Stud Roll Forming Machine buyers and operators

Next review date & triggers: 2026-04-22 or earlier if AISI/ASTM standards update, OEM catalogs change speed/price ranges ±10%, or new case studies shift best-in-class KPIs by >10%