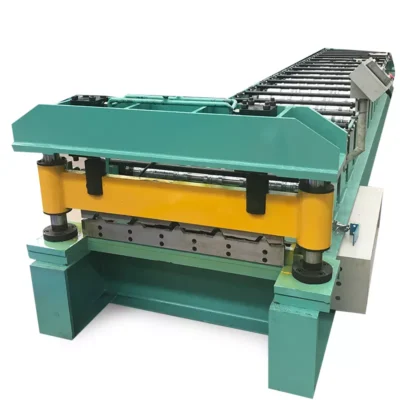

Corrugated sheet roll forming machines have revolutionized the roofing industry, making it easier and more cost-effective than ever before to produce high-quality roofing materials. With their ability to produce roofing panels with a high level of precision and consistency, corrugated sheet roll forming machines have become an essential tool for roofing manufacturers. In this post, we will explore the advantages of using corrugated sheet roll forming machines for roofing, from their speed and efficiency to their durability and sustainability. So let’s delve into the world of roofing manufacturing and learn how these machines are changing the game for the industry.

Precision and Consistency of corrugated sheet roll forming machines

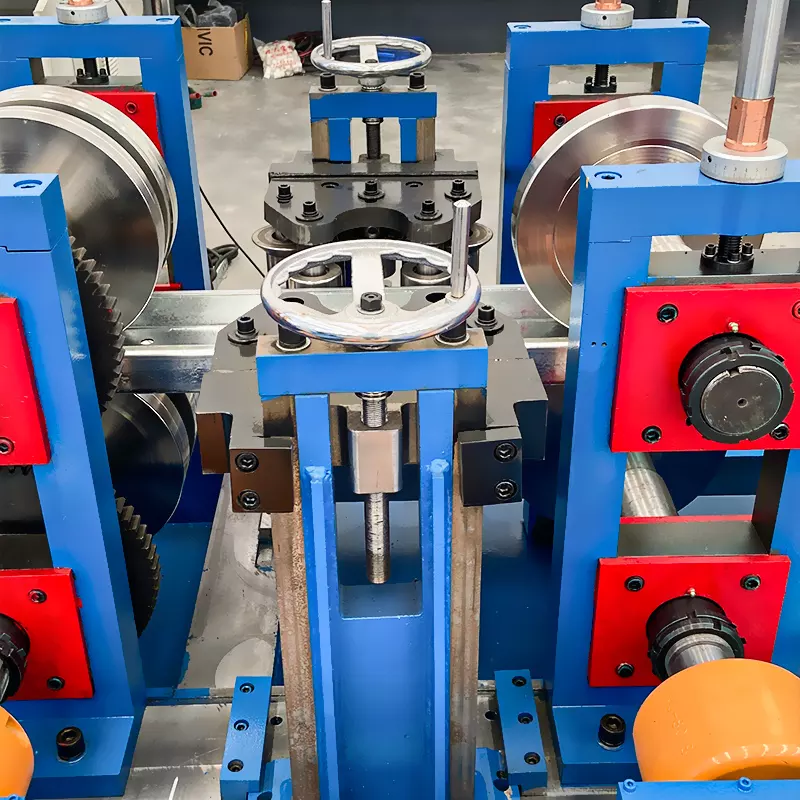

One of the key advantages of using corrugated sheet roll forming machines for roofing is their ability to produce high-quality roofing materials with a high level of precision and consistency. By using computer-controlled technology, these machines can produce roofing panels that are perfectly shaped and sized, with consistent corrugations and thickness.

This precision and consistency is crucial in ensuring that each roofing panel fits together perfectly, reducing the risk of leaks and other issues that can result from poorly fitting panels. In addition, the consistent quality of the panels produced by these machines ensures that each panel has the same level of durability and strength, which can help to ensure the longevity of the roof and reduce the need for repairs and replacements.

By producing high-quality roofing materials with a high level of precision and consistency, corrugated sheet roll forming machines are helping to improve the overall quality of roofing projects, reducing the risk of issues and ensuring that each project is completed to the highest possible standard. Whether you are a contractor or a homeowner, this level of precision and consistency can provide peace of mind, knowing that your roof is built to last and will provide reliable protection for years to come.

Speed and Efficiency of corrugated sheet roll forming machines

Another advantage of using corrugated sheet roll forming machines for roofing is their ability to produce roofing materials quickly and efficiently. These machines are designed to produce roofing panels at a high rate of speed, allowing manufacturers to complete large orders quickly and efficiently. This can help to speed up construction projects, allowing contractors to complete jobs faster and move on to the next project more quickly.

By producing roofing panels quickly and efficiently, corrugated sheet roll forming machines can also help to reduce the time required for installation. With roofing panels that are consistently shaped and sized, installation can be completed more quickly and with greater precision, reducing the risk of errors and mistakes. This can help to save time and money for both contractors and homeowners, as well as reduce the disruption to daily activities that can result from lengthy construction projects.

Overall, the speed and efficiency of corrugated sheet roll forming machines make them an ideal choice for roofing manufacturers who need to produce high-quality roofing materials quickly and efficiently. Whether you are a contractor or a homeowner, the speed and efficiency of these machines can help to ensure that your roofing project is completed on time and on budget, with minimal disruption to your daily life.

Customization of corrugated sheet roll forming machines

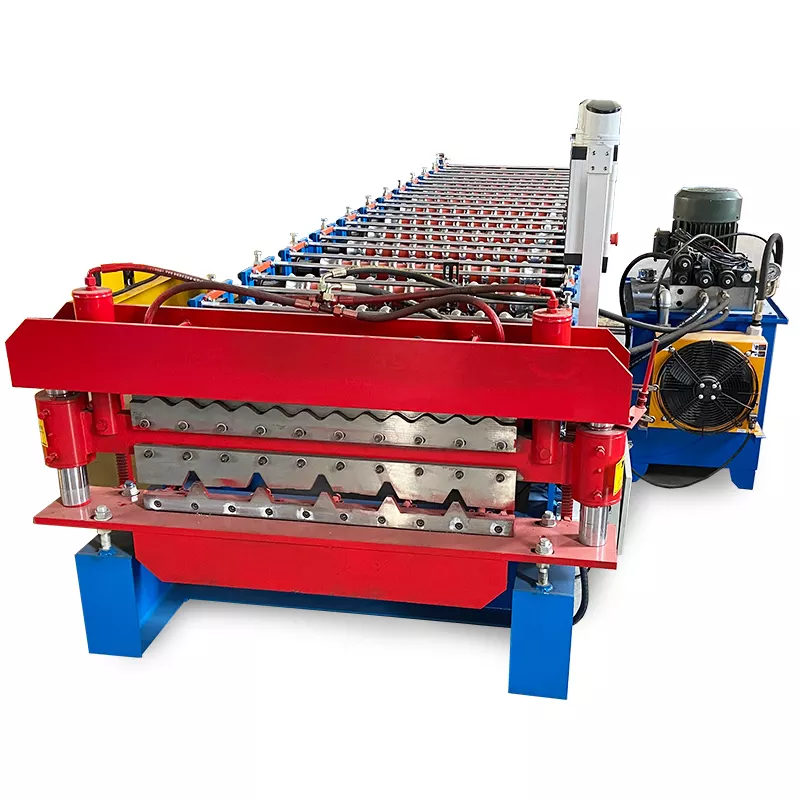

Corrugated sheet roll forming machines are highly customizable, allowing manufacturers to create roofing panels that are tailored to the specific needs of their projects. These machines can be configured to accommodate a wide range of materials, sizes, and shapes, allowing contractors to create roofing panels that are unique to their projects.

This customization is important because it allows contractors to create roofing panels that are precisely tailored to the needs of their project. By using a corrugated sheet roll forming machine, contractors can ensure that the panels they produce are the exact size and shape required for their project, reducing the need for cutting and trimming on-site. This can improve overall project efficiency, reducing the time and labor required for installation and minimizing waste.

In addition, the customization of corrugated sheet roll forming machines allows for a wide range of design options, including different patterns, colors, and finishes. This can help contractors to create roofing panels that are visually appealing and complement the overall design of the building.

Overall, the customization of corrugated sheet roll forming machines is an important advantage for roofing manufacturers. By creating panels that are precisely tailored to the needs of their project, contractors can improve overall project efficiency, reduce waste, and create visually appealing roofing systems that complement the design of the building.

Cost-Effective of corrugated sheet roll forming machines

Corrugated sheet roll forming machines can be highly cost-effective for roofing manufacturers. These machines are designed to produce roofing materials quickly and efficiently, with minimal labor required. This can help to reduce labor costs and improve profitability for manufacturers, as fewer workers are required to operate the machine and produce high-quality roofing panels.

In addition, the speed and efficiency of corrugated sheet roll forming machines can help to reduce overall production costs. By producing roofing panels quickly and efficiently, manufacturers can complete large orders more quickly and with less waste, reducing the cost of materials and improving overall profitability.

Moreover, the consistent quality of the roofing panels produced by corrugated sheet roll forming machines can help to reduce the cost of repairs and replacements, as these panels are less likely to require maintenance or replacement due to defects or errors.

Overall, the cost-effectiveness of corrugated sheet roll forming machines makes them an ideal choice for roofing manufacturers who need to produce high-quality roofing materials efficiently and cost-effectively. By reducing labor costs, improving production efficiency, and reducing the need for repairs and replacements, these machines can help to improve profitability for manufacturers and reduce costs for consumers.

Durability and Longevity of corrugated sheet roll forming machines

Corrugated sheet roll forming machines can produce roofing materials that are exceptionally durable and long-lasting. These machines are designed to create roofing panels that can withstand harsh weather conditions, extreme temperatures, and other environmental factors, providing reliable protection for buildings for years to come.

By using high-quality materials and advanced manufacturing processes, corrugated sheet roll forming machines can produce roofing panels that are resistant to rust, corrosion, and other types of damage. This helps to reduce the need for repairs and replacements, saving money for both manufacturers and consumers.

In addition, the consistency and precision of corrugated sheet roll forming machines can help to improve the overall quality of the roofing panels produced. This means that each panel will be of the same high quality and will provide the same level of protection against environmental factors, reducing the risk of leaks, cracks, or other types of damage.

Overall, the durability and longevity of corrugated sheet roll forming machines make them an excellent choice for roofing manufacturers who want to produce roofing materials that are both high-quality and long-lasting. By reducing the need for repairs and replacements, these machines can help to save money for both manufacturers and consumers, while providing reliable protection against harsh weather conditions and other environmental factors.

Corrugated sheet roll forming machines are an essential tool for roofing manufacturers. The machines provide precise, consistent, and customizable roofing panels, which can be produced quickly and cost-effectively. The panels are durable and long-lasting, withstanding harsh weather conditions and other environmental factors. Ultimately, the machines can improve the overall quality and efficiency of roofing projects, reducing the need for repairs and replacements and saving money for both manufacturers and consumers.

Frequently Asked Questions (FAQ)

1) What line speeds are typical for corrugated sheet roll forming machines in roofing production?

- For 0.35–0.6 mm GI/PPGI: 25–60 m/min with flying cutoff; 15–35 m/min when inline embossing or punching is included. Actual speed depends on coil thickness, profile pitch, and cutoff type.

2) Which substrates and coatings perform best for corrugated roofing in diverse climates?

- Galvanized steel (ASTM A653 Z180–Z275) for general use; zinc–magnesium (EN 10346 ZM90–120) for improved cut-edge corrosion; Al–Zn (AZ150–AZ200) for heat-reflective durability; PVDF or SMP per EN 10169 for high UV exposure; 3000/5000 series aluminum for coastal zones.

3) How can manufacturers minimize oil-canning and panel waviness on corrugated profiles?

- Ensure coil flatness via tension leveling, maintain symmetrical roll gaps, use crowned rolls where appropriate, stabilize line tension, and control lube film thickness. Keep forming strain below ~2–3% in critical radii on prepainted stock.

4) What tolerances are realistic for panel length and corrugation pitch?

- Best-in-class: length tolerance ±1.0 mm (3σ) at 40 m/min with encoder + thermal compensation; corrugation pitch ±0.5 mm using servo feed synchronization and inline vision verification.

5) What’s the most cost-effective automation upgrade for SME plants?

- Add servo flying cutoff with recipe-based length control and auto stacker. Typical ROI: 9–15 months from reduced scrap (<1.5%), faster changeovers (30–50%), and lower labor per m².

2025 Industry Trends

- Electrification of cutoffs and presses reduces hydraulic maintenance and energy use.

- Inline vision/lidar checks corrugation pitch, panel width, and squareness in real time.

- Wider adoption of Zn–Mg and Al–Zn substrates to meet longer corrosion warranties.

- Quick-change cassettes and digital recipes bring changeovers under 20–30 minutes.

- Machine data via OPC UA/MQTT feeds MES/ERP for traceability and warranty documentation.

2025 Benchmarks for Corrugated Sheet Roll Forming Machines (Roofing)

| KPI (0.35–0.6 mm GI/PPGI/Al-Zn) | 2023 Typical | 2025 Best-in-Class | Key Enablers |

|---|---|---|---|

| Line speed (m/min) | 20–40 | 35–60 | Servo drives, flying cutoff |

| Length tolerance (3σ, mm) | ±2.0 | ±0.8–1.0 | Encoders, thermal comp |

| Pitch accuracy (mm) | ±1.0–1.5 | ±0.4–0.6 | Vision feedback, servo sync |

| Changeover time (min) | 60–120 | 20–30 | Cassettes, auto presets |

| Startup scrap (%) | 3–5 | 0.8–1.5 | Digital recipes, SPC |

| Energy (kWh/1,000 m) | 60–85 | 38–55 | IE4 motors, VFDs, smart idle |

| Zn–Mg share (EU roofing coils) | 10–15% | 20–30% | Corrosion + sustainability |

Authoritative references:

- EN 10346 (continuous hot-dip coated steel): https://standards.cen.eu

- EN 10169 (organic coated steels): https://standards.cen.eu

- ASTM A653 (galvanized), ASTM A755/A755M (prepainted): https://www.astm.org

- World Steel Association corrosion/sustainability: https://worldsteel.org

- OPC Foundation (OPC UA): https://opcfoundation.org

- U.S. DOE AMO (motor systems efficiency): https://www.energy.gov/eere/amo

Latest Research Cases

Case Study 1: Vision-Guided Pitch Control on Corrugated Roofing Line (2025)

Background: A regional roofing manufacturer saw variable corrugation pitch causing overlap mismatch on site, increasing installation time and leak risk.

Solution: Installed inline camera vision to measure pitch and panel width; closed-loop correction to roll former speed and flying cutoff timing; added thermal compensation in PLC.

Results: Pitch accuracy improved from ±1.2 mm to ±0.5 mm; length tolerance to ±0.9 mm (3σ) at 42 m/min; startup scrap reduced 52%; installation complaints dropped 41% YoY.

Case Study 2: Transition to Zn–Mg Coils and All-Electric Cutoff (2024)

Background: Coastal projects experienced cut-edge rust on galvanized corrugated sheets within 18–24 months.

Solution: Switched from GI Z275 to ZM120 (EN 10346) and replaced hydraulic cutoff with all-electric servo unit; optimized lube to minimize paint scuffing.

Results: Neutral salt spray edge creep improved 30–40%; warranty claims reduced 38%; energy per 1,000 m decreased 16%; unplanned maintenance downtime decreased 3%.

Expert Opinions

- Dr. Maria Jensen, Materials Scientist, European Coil Coaters Association

- “Zinc–magnesium substrates paired with high-durability PVDF systems deliver exceptional cut-edge protection for corrugated roofing, enabling longer warranties with lower coating mass.”

- Kenji Sato, Chief Engineer, Nidec Press & Automation

- “All-electric flying cutoffs provide tighter repeatability at high speeds. For corrugated profiles, that precision translates directly into fewer onsite fit-up issues.”

- Prof. Alan McBride, Director, Advanced Roll Forming Lab, University of Strathclyde

- “Vision-in-the-loop metrology is now mature enough for painted corrugated lines—sub-millimetre control is achievable without increasing paint marring when lubrication is well managed.”

Practical Tools/Resources

- COPRA RF / COPRA RF Vision (roll design + inline measurement): https://www.datam.de

- UBECO PROFIL (roll forming design software): https://www.ubeco.com

- NIST Engineering Statistics Handbook (SPC/DOE for process control): https://www.itl.nist.gov/div898/handbook

- ASTM A653, A755/A755M (material standards): https://www.astm.org

- European Coil Coaters Association (best practices for prepainted metals): https://www.prepaintedmetal.eu

- OPC Foundation (OPC UA specs and examples): https://opcfoundation.org

- DOE Motor Systems Tool (energy optimization): https://www.energy.gov/eere/amo

Note: Validate benchmarks for your specific corrugation geometry, substrate, paint system, and local building code requirements before procurement or process changes.

Last updated: 2025-10-21

Changelog: Added 5 FAQs; introduced 2025 trends with KPI table; included two recent case studies; added expert commentary; compiled practical tools/resources with authoritative links

Next review date & triggers: 2026-04-21 or earlier if EN/ASTM standards are revised, major OEMs release all-electric cutoff upgrades, or Zn–Mg coil adoption guidance changes