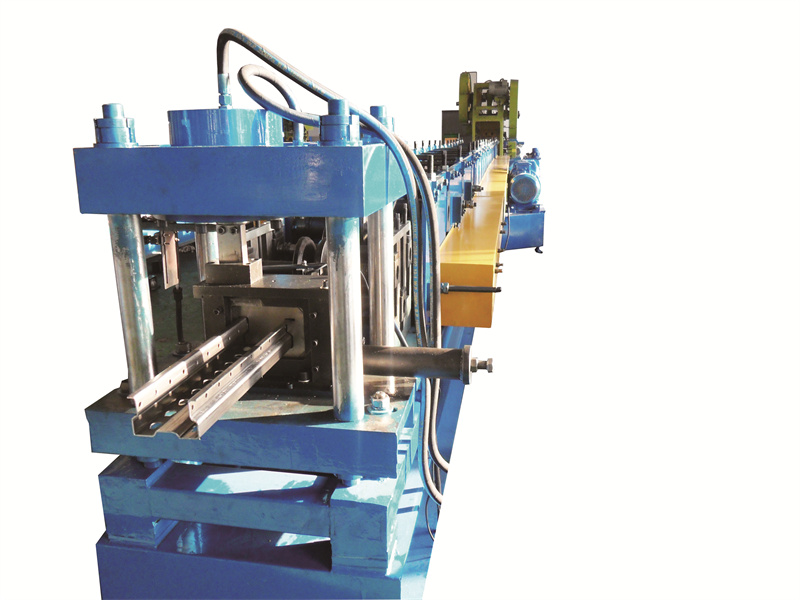

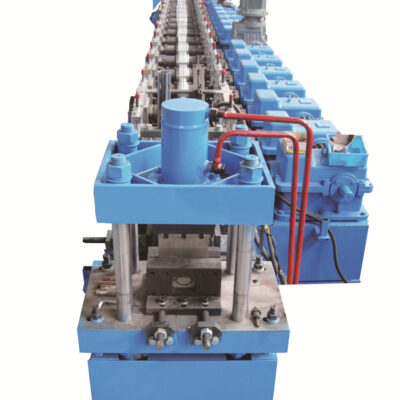

The cold roll forming machine is a precision machine that is used to produce a variety of different products, including wire and cable insulation, automotive parts, medical devices and electronic components. In this article, we will take a look at what this machine is and how it can help your business.

What is a cold roll forming machine?

A cold roll forming machine is a specialized piece of equipment that can help businesses produce high-quality cold rolls and other sheet products. The machine uses a continuous pressure system to deform the metal sheet into desired shapes, usually around tubes or coils. This process is often used in the automotive and electronics industries, where sheet products are often required for packaging or parts.

Cold roll forming machines come in a variety of sizes and can be customized to meet the specific needs of your business. By using one, you can easily create custom products without having to invest in expensive machinery or experienced personnel. Additionally, cold roll forming machines are relatively easy to operate, making them an ideal choice for small businesses that want to expand their product line without investing too much money upfront.

How does a roll forming machine work?

A roll forming machine is a manufacturing process used to create long, thin sheets of metal by rolling the metal around a cylindrical die. This process creates long, thin sheets that are often used in the automotive, electrical equipment and other industrial markets. The die can be made from different materials, including steel, aluminum or brass, and the cold roll forming machine can be configured to produce various thicknesses of metal sheet.

Benefits of using a cold roll forming machine

A cold roll forming machine is a machine that is used to form cold metal sheets into various shapes and sizes. This machine can be used for a variety of purposes, such as making jewelry and phone cases, but its most common use is in the manufacturing of automotive parts.

The benefits of using a cold roll forming machine include the following:

Low production costs- Compared to other methods of manufacturing, a cold roll forming machine is relatively low in production costs. This is because the machines are very fast and efficient, meaning that they can produce large quantities of products relatively quickly.

High product quality- Cold roll forming machines are known for their high levels of precision and detail, meaning that the finished products will be of high quality. This is due to the fact that the machines use extremely thin sheets of metal to create products, which means that there is little room for error.

Fast turnaround times- Because cold roll forming machines are so fast, it usually takes less time to produce products using this method than it does with other methods. This means that businesses can quickly move from concept to product without having to wait long periods of time.

-

Vineyard Post Roll Forming Machine

Vineyard Post Roll Forming Machine -

Auto Size Changeable Sigma Purlin Roll Forming Machine

Auto Size Changeable Sigma Purlin Roll Forming Machine -

Auto Size Changeable Z Purlin Roll Forming Machine

Auto Size Changeable Z Purlin Roll Forming Machine -

Full automatic quick-change C Z purlin roll forming machine

Full automatic quick-change C Z purlin roll forming machine -

Vineyards Post Roll Forming Machine

Vineyards Post Roll Forming Machine -

Omega Purlin Roll Forming Machine

Omega Purlin Roll Forming Machine -

L Angle roll forming machine

L Angle roll forming machine -

Light Gauge Keel Stud Track C Channel Steel Roll Forming Machine Drywall Metal C Stud Machinery

Light Gauge Keel Stud Track C Channel Steel Roll Forming Machine Drywall Metal C Stud Machinery

The different types of cold roll forming machines

Cold roll forming machines are designed to shape metal sheets into a variety of different shapes, including rounds, squares, and tubes. They work by moving the metal around a mandrel, which gradually deforms the metal into the desired shape.

There are two main types of cold roll forming machines: die-casting and press-forming. Die-casting machines use pressure to force the metal into round or other shapes. Press-forming machines use a hydraulic press to force the metal into square or other shapes.

Die-casting machines are typically used for small quantities of metals. Press-forming machines are more versatile and can be used for larger quantities of metals.

How will cold roll forming machine help my business?

A cold roll forming machine is an important tool for businesses that produce metal products. It helps to reduce the time and labor required to form metal sheets into desired shapes. The machine also produces consistent quality products, which can be a key differentiator in the market.

The benefits of using a cold rollforming machine include:

- Faster production times

- Reduced labor costs

- Improved product quality

Conclusion

A cold roll forming machine can help your business in a variety of ways. By using this equipment, you can create custom products faster and at a lower cost than if you were to make them by hand. Additionally, cold roll forming machines are versatile and can be used for a variety of applications, such as packaging andoboasts. If you’re interested in finding out more about how a cold roll forming machine could benefit your business, contact us today!

FAQ

What is cold roll forming?

Cold forming – often known as cold roll forming – is a forging technique used to shape metal materials at near room temperature. Forming metal at cooler temperatures retains or enhances the tensile strength of the material while still allowing high levels of intricate manipulation.