wall panel roll forming machine factory

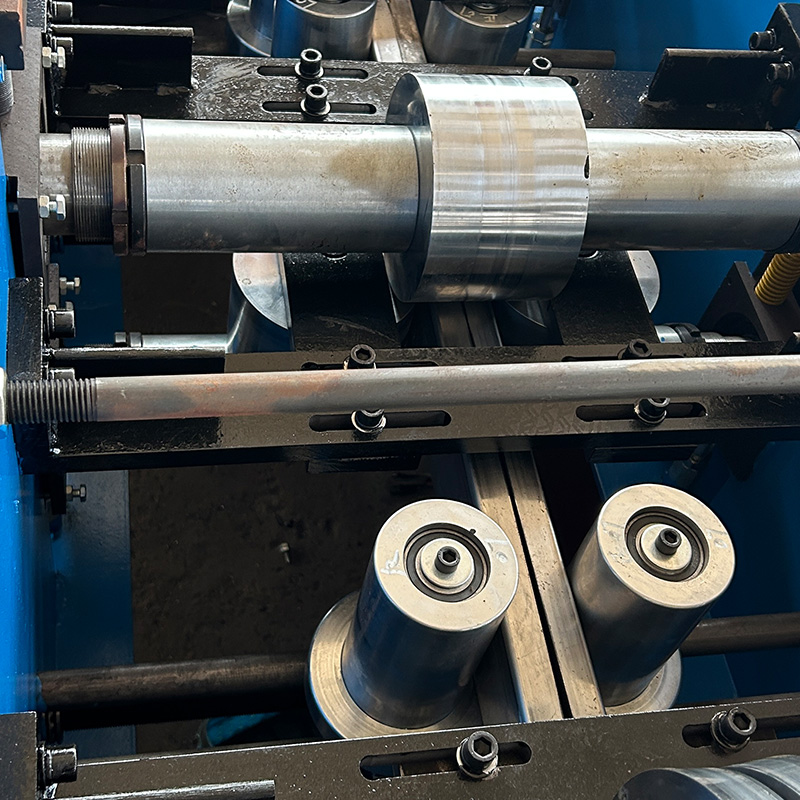

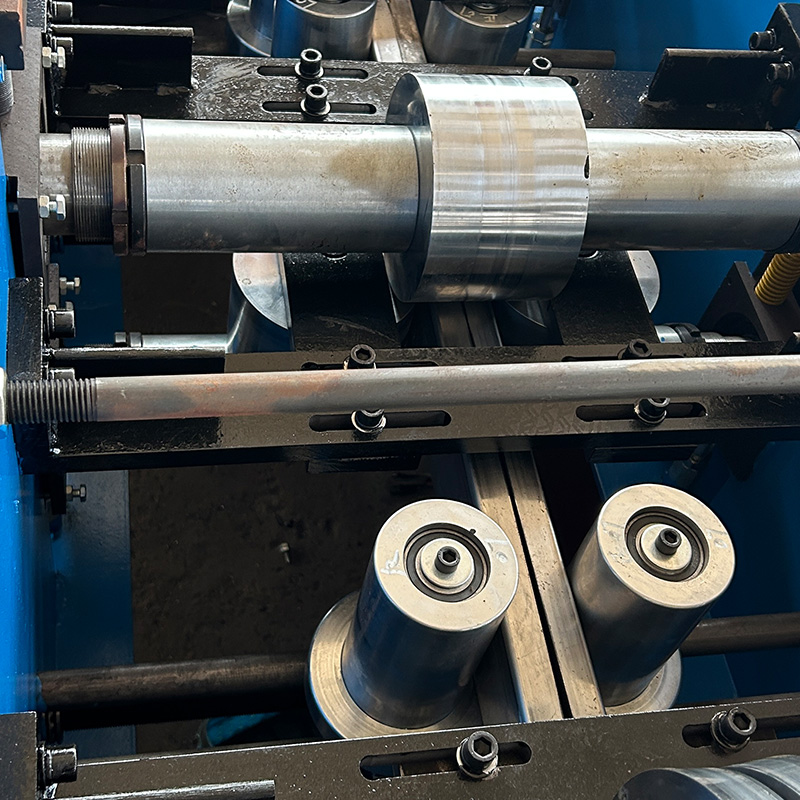

Wall panel roll forming is a process of progressively bending metal coils into customized panel profiles for walls and roofing. It is an efficient automated method to produce straight or

Wall panel roll forming is a process of progressively bending metal coils into customized panel profiles for walls and roofing. It is an efficient automated method to produce straight or

China roll forming machine is an efficient method of producing long sheet metal parts with constant cross-sections. Roll formed products have widespread applications across industries like construction, infrastructure, agriculture, automobile,

OEM u channel roll forming machines are used to form u channel metal profiles for construction, racks, frames, and various structural applications. This article provides a comprehensive guide on u

Overview of slide rail roll forming machine Roll forming is a continuous bending operation in which sheet or strip metal is gradually formed into a desired cross-sectional profile through a

Overview of oem shutter roll forming machine Roll forming is a continuous bending operation in which sheet or strip metal is gradually formed into a specified cross-sectional shape by passing

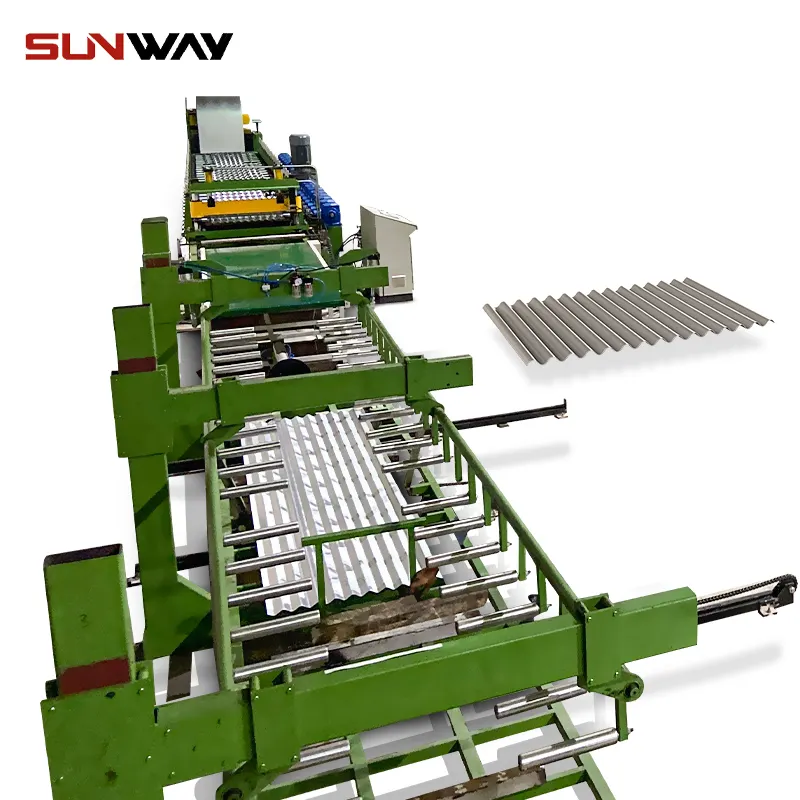

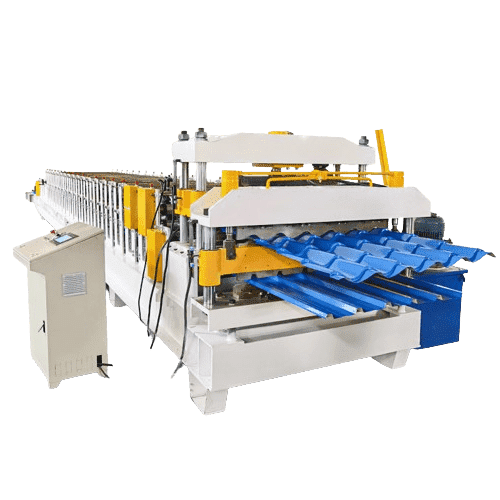

Tile roll forming machines are essential equipment for tile manufacturers. This guide provides a comprehensive overview of OEM (original equipment manufacturer) tile roll forming machines, including working principles, types, processes,

oem door shutter roll forming machine shape metal coils into customized profiles by progressively bending the material through a series of roller dies. OEM door shutter roll forming machines are

Containerized bemo sheet roll forming machines are prefabricated modular systems used to form metal sheets and coils into customized profiles. These machines offer advantages like easy transport, quick installation, and

Overview of snap lock standing seam roll forming machine Snap lock standing seam roll forming machines are equipment used to produce standing seam metal roofing panels. They form the distinctive

oem gutter roll forming machines are used to manufacture rain gutters for buildings in an automated process. This comprehensive guide covers everything you need to know about OEM gutter roll

half round gutter roll forming machine are used to produce continuous metal profiles with custom cross-sections by progressive bending of sheet or coil material as it passes through a series

Roll forming allows continuous, efficient and economical production of custom profiles from metal coils using roller dies. OEM light keel roll forming machines produce light keel sections rapidly to consistent

Roll forming allows continuous, efficient and economical shaping of metal coils into customized sections using roller dies. OEM door frame roll forming machines produce door frame profiles rapidly to consistent

Metal roofing offers durability, weather resistance and long lifespan for buildings. Roll forming technology allows cost-effective, high speed production of strong metal roofing sheet profiles via continuous bending of coils

Roll forming allows continuous, efficient production of straight or curved plastic profile sections by gradually bending sheets through consecutive stands. Laminated polyethylene (PE) foam profiles made via roll forming find

Introduction Choosing the right roll forming machine is a big decision, but what better way to understand its impact than

Introduction Choosing the right roll forming machine can be challenging—especially with so many options available in the market. Whether you’re

Introduction Automation is revolutionizing the roll forming industry, making production faster, more precise, and less dependent on manual labor. As

Introduction The roll forming industry is undergoing a technological revolution, driven by automation, AI, sustainability, and advanced materials. As we