Overview of Roll Forming Machines in the Netherlands

The Netherlands’ industrial, construction, and automotive sectors are growing steadily, increasing the demand for high-quality roll forming machines. These machines are vital for producing roofing sheets, structural steel components, solar mounting brackets, and industrial metal profiles.

If you’re searching for the best roll forming machine manufacturer in the Netherlands, this guide will help you explore top manufacturers, pricing trends, industry applications, and how to choose the right roll forming machine in 2025.

Top Roll Forming Machine Manufacturers in the Netherlands

The Netherlands has several local and international suppliers of roll forming machines. Below are the leading manufacturers serving the Dutch market in 2025.

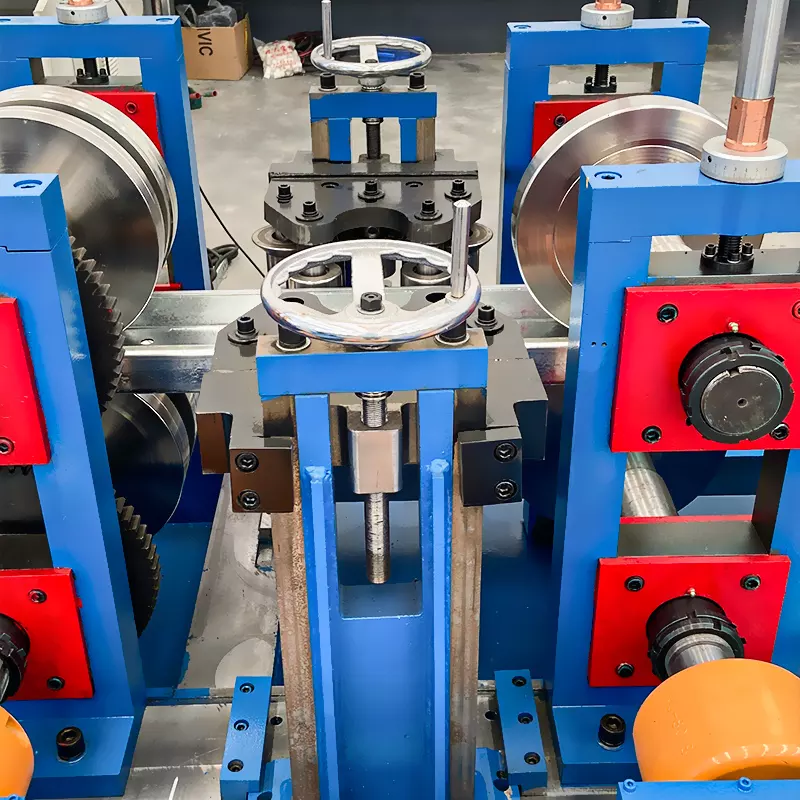

1. WUXI SUNWAY MACHINERY CO., LTD (Global Leader in Roll Forming Machines with a Strong Presence in the Netherlands)

WUXI SUNWAY MACHINERY CO., LTD is a highly trusted global manufacturer specializing in cold roll forming machines. Sunway serves industries in the Netherlands, Europe, and beyond, offering custom-built, high-precision roll forming machines at competitive prices.

Why Choose Sunway Machine?

✅ Custom-built machines tailored for the Dutch market

✅ More affordable than European brands and higher quality than local options

✅ Advanced automation & CNC precision technology

✅ Reliable technical support & after-sales service

✅ Durable materials designed for European climate conditions

Explore Sunway’s roll forming machines.

2. Dallan S.p.A. (Italy) (Leading European Roll Forming Machine Manufacturer Servicing the Netherlands)

- Specializes in high-precision roll forming solutions for industrial, construction, and metal fabrication sectors.

- Provides fully automated roll forming machines with advanced technology.

3. Boschert GmbH (Germany) (High-Quality Industrial Roll Forming Machines for the Dutch Market)

- Offers custom roll forming solutions for automotive, aerospace, and metal processing.

- Known for high-performance sheet metal processing equipment.

4. Fagor Arrasate (Spain) (European Manufacturer with Strong Presence in the Netherlands)

- Provides high-speed roll forming machines for automotive, construction, and renewable energy industries.

- Offers advanced manufacturing technology, including integrated automation systems.

5. Netherlands-Based Local Suppliers & Distributors

- Several local machine distributors provide custom roll forming solutions, servicing small and medium-sized businesses.

Comparison of Top Roll Forming Machine Manufacturers in the Netherlands

| Manufacturer | Strengths | Industries Served |

|---|---|---|

| WUXI SUNWAY MACHINERY | Customizable, high-quality, global support, cost-effective | Construction, Automotive, Industrial, Renewable Energy |

| Dallan S.p.A. | Premium European technology, automation | Industrial, Construction |

| Boschert GmbH | High-precision metal forming solutions | Automotive, Aerospace |

| Fagor Arrasate | High-speed roll forming machines | Automotive, Renewable Energy |

| Local Dutch Suppliers | Quick local service, custom solutions | Small to mid-sized businesses |

Need expert guidance? Contact Sunway Machine today!

Which Roll Forming Machine is Best for the Dutch Market?

The best roll forming machine depends on industry requirements, production volume, and material specifications. Below are the Netherlands’ most in-demand roll forming machines:

1. Roofing Sheet Roll Forming Machine

Best for: The Netherlands’ construction sector

- Produces corrugated sheets, rib-type metal roofing, and standing seam roofing.

- Ideal for residential, commercial, and industrial buildings.

2. C & Z Purlin Roll Forming Machine

Best for: Steel structure applications

- Produces C and Z-shaped steel purlins for metal buildings and pre-engineered structures.

- Adjustable settings for various sizes and thicknesses.

3. Cable Tray Roll Forming Machine

Best for: Electrical and industrial infrastructure

- Used to manufacture cable trays for factories, power plants, and industrial projects.

4. Automotive Roll Forming Machine

Best for: The Netherlands’ growing automotive sector

- Produces chassis reinforcements, bumper beams, and crash protection elements.

5. Solar Mounting Bracket Roll Forming Machine

Best for: The Netherlands’ renewable energy sector

- Specialized in manufacturing solar panel mounting structures.

Need a custom roll forming machine? Explore Sunway’s customizable solutions.

Roll Forming Machine Price in the Netherlands: What Affects the Cost?

The price of a roll forming machine in the Netherlands depends on:

1. Machine Type & Complexity

- Basic machines (e.g., roofing sheets) are more affordable than highly automated machines (e.g., automotive roll forming).

2. Automation Level

- Fully automatic machines cost more but offer higher efficiency and lower labor costs.

3. Material & Thickness

- Machines designed for thicker steel require higher power, increasing costs.

4. Manufacturer & Brand

- European brands tend to be more expensive, while imported machines from China offer better automation and cost-efficiency.

- Sunway Machine offers global quality at competitive pricing.

Typical Price Ranges for Roll Forming Machines in the Netherlands

| Machine Type | Price Range (EUR) |

|---|---|

| Roofing Sheet Roll Forming Machine | €10,000 – €40,000 |

| C & Z Purlin Roll Forming Machine | €15,000 – €60,000 |

| Cable Tray Roll Forming Machine | €20,000 – €75,000 |

| Automotive Roll Forming Machine | €25,000 – €100,000 |

| Solar Panel Mounting Bracket Machine | €30,000 – €120,000 |

Get a custom quote from Sunway Machine today!

Industries Using Roll Forming Machines in the Netherlands

The Netherlands has a thriving industrial sector, with construction, automotive, electrical, and renewable energy industries relying on roll forming machines for high-precision metal fabrication. Let’s explore how different industries in the Netherlands use roll forming technology.

1. Construction & Infrastructure Industry

The Dutch construction sector is one of the largest consumers of roll-formed products, including:

- Corrugated and rib-type metal roofing sheets

- Wall cladding & facade panels

- C & Z purlins for steel structures

- Aluminum & steel door/window frames

Due to the Netherlands’ rainy and windy climate, roll-formed steel sheets provide weather resistance, durability, and cost-effectiveness, making them ideal for residential, commercial, and industrial buildings.

2. Automotive Industry

The Netherlands is home to automotive manufacturing and assembly plants, with companies like VDL Nedcar producing cars for BMW and MINI. Roll forming machines are widely used to manufacture:

- Reinforced steel chassis

- Crash-resistant bumper beams

- Structural automotive components

With the Netherlands leading in electric vehicle (EV) adoption, roll forming technology ensures strong yet lightweight automotive parts, improving energy efficiency.

3. Industrial & Electrical Infrastructure

Roll forming machines are critical for the Netherlands’ industrial & electrical sectors, producing:

- Cable trays & conduits

- Electrical enclosures & switchgear cabinets

- HVAC ducting systems

These components are essential for factories, industrial automation, data centers, and power distribution systems across the country.

4. Renewable Energy (Solar & Wind)

The Netherlands is one of Europe’s leaders in renewable energy, increasing demand for:

- Solar panel mounting brackets

- Steel support structures for wind turbines

With the government’s commitment to sustainability, roll forming machines are essential for producing solar and wind energy infrastructure.

Looking for a roll forming machine for your industry? Explore Sunway’s product range.

Importing Roll Forming Machines to the Netherlands: Logistics & Regulations

If you’re considering importing a roll forming machine to the Netherlands, understanding customs regulations, tariffs, and logistics is essential.

1. Customs Duties & Tariffs

The Netherlands follows EU import regulations, meaning import duties depend on:

- Standard EU tariffs on industrial machinery (0% to 8%)

- Preferential tax rates for imports from China, Turkey, and the EU

Tip: Work with a licensed customs broker to ensure compliance and optimize costs.

2. Shipping & Logistics

Most roll forming machines are imported via sea freight or air freight through major Dutch ports:

- Port of Rotterdam – Europe’s largest shipping hub for industrial machinery

- Port of Amsterdam – Ideal for manufacturing and industrial imports

- Schiphol Airport – For urgent air shipments

Once in the Netherlands, machines are transported via road freight to their final destinations.

3. Compliance & Certification

Imported roll forming machines must meet:

- European CE Marking compliance

- ISO 9001 quality certification

- Electrical safety standards for industrial equipment

Need help importing a roll forming machine? Contact Sunway Machine’s export specialists.

Roll Forming Machine Market Trends in the Netherlands (2025)

The Dutch roll forming machine market is evolving, driven by automation, energy efficiency, and advanced materials. Key trends shaping the industry in 2025 include:

1. Smart Manufacturing & Automation

Dutch manufacturers are investing in fully automated roll forming machines, featuring:

- CNC precision control

- AI-powered defect detection

- IoT-enabled remote monitoring

2. Growth of Renewable Energy Projects

With the Netherlands focusing on solar and wind energy, demand is rising for solar mounting bracket roll forming machines.

3. Use of High-Strength, Corrosion-Resistant Materials

Manufacturers are shifting to stronger, weather-resistant steel alloys to improve efficiency in construction and automotive applications.

Roll Forming vs. Bending vs. Stamping: What’s Best for the Netherlands?

Dutch manufacturers often compare roll forming, bending, and stamping to determine the best metal fabrication method for their production needs. Here’s how they compare:

| Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Roll Forming | High-speed production, consistent quality, cost-effective for large volumes | High initial machine cost | Roofing sheets, automotive parts, steel framing |

| Bending | Simple process, low setup cost | Limited to small batches, slower production | Custom sheet metal parts |

| Stamping | High precision, great for mass production | High tooling costs | Automotive structural components |

Looking for the best roll forming machine? Explore Sunway’s solutions.

FAQ: Roll Forming Machines in the Netherlands

1. How much does a roll forming machine cost in the Netherlands?

The price depends on machine type and automation level. See the pricing table above for details.

2. How long does it take to import a roll forming machine to the Netherlands?

Shipping times vary:

| Shipping Route | Estimated Time |

|---|---|

| China to the Netherlands (Sea Freight) | 20-35 days |

| Europe to the Netherlands (Road Freight) | 5-10 days |

| Turkey to the Netherlands (Road Transport) | 7-15 days |

3. What industries use roll forming machines in the Netherlands?

- Construction (roofing sheets, purlins, wall panels)

- Automotive (chassis, reinforcements)

- Electrical & Industrial (cable trays, enclosures)

- Renewable Energy (solar panel brackets)

4. Can I customize a roll forming machine for my business?

Yes! Sunway Machine provides custom-built roll forming machines tailored to your specific needs.

5. Where can I buy a roll forming machine in the Netherlands?

You can purchase from:

- Local suppliers (higher costs, limited options)

- International manufacturers like Sunway Machine for high-quality, customized solutions at competitive prices.

Final Thoughts: Why Choose Sunway Machine for Your Roll Forming Needs?

WUXI SUNWAY MACHINERY CO., LTD is a trusted global manufacturer of roll forming machines, offering:

✅ High-precision machines for roofing, automotive, and industrial applications

✅ Custom solutions to fit your business needs

✅ Global support & after-sales service

✅ Competitive pricing for the Dutch market

Ready to invest in a high-quality roll forming machine? Contact Sunway Machine today!