Roll forming allows continuous, efficient production of straight or curved plastic profile sections by gradually bending sheets through consecutive stands. Laminated polyethylene (PE) foam profiles made via roll forming find wide use for insulation, cushioning and shock absorption across industries.

This guide provides a comprehensive overview of laminated pe foam roll forming machine capabilities, workings, considerations and applications to help prospective buyers make optimal equipment decisions.

Overview of Laminated PE Foam Roll Forming Machines

Roll forming machines shape plastic sheets into various standard or customized cross-section profiles for industrial applications via a series of incremental roller bending stations.

Key attributes of laminated PE foam roll formers:

- Raw material: PE foam laminated with variety of sheet types

- Lamination methods: Adhesive, heat, ultrasonic etc.

- Profile types: U channel, rectangular, other heat insulation shapes

- Tooling flexibility: Quick changeovers for profile variations

- High production speeds up to 80 meter/minute

- Advanced process monitoring and control systems

Laminating PE foam to other sheets combines insulation abilities with strengths and surface properties using only thin adhesive layers. Roll formed laminates save energy in use while cutting transportation and inventory costs.

Types of Laminated PE Foam Roll Forming Machines

| Machine Type | Description |

|---|---|

| Standard | Designed for high volume production of 1-2 profiles |

| Quick changeover | Multiple tooling sets for fast profile variations |

| Custom | Tailored around specialized insulation shapes |

| Automatic cutoff | Integrated cross-cutting saw unit |

| Secondary processing | Additional modules like punching, drilling, printing etc. |

Specialized capabilities:

- Multi-layer lamination

- Post-formation welding

- Detachable wrap film devices

- Vision systems for defect detection

- Stackers and bundling systems

Working Principle of Laminated PE Foam Roll Forming

The working principle focuses on bending plastic sheets through a series progressively arranged roller stations to create customized profile sections.

Steps:

- Plastic lamination sheet pays off mounted coil

- Sheet feeding tables guide strip through machine

- Forming heads apply incremental bends by pressing sheet around shaped rollers

- Separate cutoff saw trims formed profile to length

- Exit conveyors guide trimmed pieces for packaging/shipping

Advanced process control systems including PLC, HMI and sensors enable real-time monitoring and precision speed/tension regulation during production.

Easy interchangeability of tooling components like forming heads allows fast changeovers between different laminated foam profiles.

Process Flow of Laminated PE Foam Roll Forming

A typical process flow for laminated foam profile creation comprises:

1. Plastic Sheet Selection

- Polyethylene foams laminated with metal, plastic, paper sheets

- Adhesive selection for strength and temperature range

2. Sheet Preparation

- Cleaning, preheating, surface activation

3. Roll Lamination

- Binding foam with other sheets between roller beds

4. Roll Forming

- Multi-stage bending into structural shape

5. Secondary Processing (optional)

- Printing, hole punching, welding, coating

6. Product Cutoff and Handling

- Cutting laminated profiles to length

- Bundling and packing finished pieces

Quality checks performed at each stage sustain consistency. Individual sections can be enhanced with additional capabilities to impart special properties.

Design Considerations for Laminated PE Foam Roll Forming Lines

Key aspects of designing laminated foam profile roll forming systems include:

Sheet Material Selection

Common materials laminated with PE foam:

- PP, ABS, PVC plastic sheets

- Steel, Aluminium sheets

- Cardboard, textiles, reflective sheets

Each material adds unique structural, insulating or aesthetic properties.

Profile Shape and Size

Common roll formed foam laminate shapes:

- U channel for heat insulation

- Rectangular tube surrounds

- Custom enclosures, edge guards, corner pieces

Tooling flexibility allows fast transition between shapes.

Production Speed

Higher production rates via wider plastic sheets or faster roller movement increases output.

- Light duty: Up to 20 meters/minute

- Medium duty: 20-50 meters/minute

- Heavy duty: Over 50 meters/minute

Tooling and Stations

- Number of stands determined by profile complexity

- Quick changeover heads for shape variations

- Roller materials resistant to wear

- Integrated heating systems

Additional Capabilities

- Inline lamination |

- Printing

- Perforation

- Punching

- Cutoff

- Wrapping

- Vision inspection

- Bundling

-

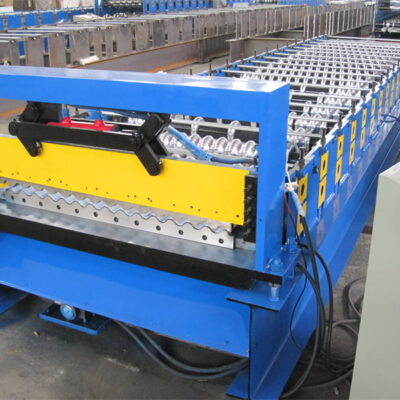

Corrugated Panel Roll Forming Machine

Corrugated Panel Roll Forming Machine -

Light Gauge Steel Roll Forming Machine

Light Gauge Steel Roll Forming Machine -

Steel Box Plate Making Roll Forming Machine

Steel Box Plate Making Roll Forming Machine -

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine -

Omega Purlin Roll Forming Machine

Omega Purlin Roll Forming Machine -

CZ Purlin Roll forming machine

CZ Purlin Roll forming machine -

Full automatic C purlin roll forming machine quick-change

Full automatic C purlin roll forming machine quick-change -

Standing Seam Roof Panel Forming Machine

Standing Seam Roof Panel Forming Machine -

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine

Key Components of Laminated PE Foam Roll Forming Machines

| Component | Purpose |

|---|---|

| Decoiler | Smooth sheet payoff |

| Feed tables | Guide strips into process flow |

| Forming heads | Progressive profile bending |

| Roller stations | House forming heads |

| PLC control | Monitoring and precision |

| HMI | Parameter input and monitoring |

| Sensors | Feedback signals to detect issues |

| Heating systems | Assist with lamination |

| Secondary modules | Additional processing |

| Exit tables | Support finished profiles |

Buying Considerations for Laminated PE Foam Roll Forming Machines

Key factors in purchasing laminated foam profile roll forming equipment:

| Parameter | Guidelines |

|---|---|

| Type of profiles needed | U channel, rectangular, custom |

| Material width | Optimal for high output rates |

| Production speed | Balance cost against hourly output |

| Raw material type | PE foam + sheet compatibility |

| Tooling flexibility | Quick changeover performance |

| Climate control | For consistent material properties |

| Defect detection | Visual, ultrasonic, laser |

| Secondary processing | Lamination method, printing etc. |

| Controls sophistication | Sensor feedback, diagnostics etc. |

| Supplier credentials | Experience, production expertise |

Evaluate options from multiple laminated foam profile machine manufacturers against current and future business requirements for optimal value.

Installation of Laminated PE Foam Roll Forming Machines

Proper machine installation lays the base for efficient functioning during mass production.

Key aspects:

- Stable, level foundation

- Adequate space for safe operation

- Power supply protections

- Decoiler mounting provisions

- Guarding around moving parts

- Control panel accessibility

- Confirm alignment, sensor signals

- Test run at low speeds

Ensure qualified technicians handle positioning, assembly, trial runs and training to prevent issues down the line.

Operation of Laminated PE Foam Roll Forming Lines

Follow standardized protocols during machine operation for consistency.

Safety Guidelines

- Allow only trained workers in work area

- Ensure no exposure near rotating tooling

- Barricade operational area appropriately

- Mandate hand gloves, shoes, glasses use

Production Workflow

1. Material Loading

- Mount plastic + foam coils on decoilers

- Thread sheets through components

2. Parameter Setting

- Enter dimensions, speeds, temperatures

3. Trial Run

- Inch at slower pace initially

- Confirm signal feedbacks

4. Production

- Run at specified rating

- Monitor for process deviations

- Conduct quality checks

Document all procedures for easy operator reference. Real-time monitoring necessary to catch defects early.

Maintenance of Laminated PE Foam Roll Forming Machines

Regular preventative maintenance activities sustain performance and minimize unplanned downtime losses.

| Activity | Method | Frequency |

|---|---|---|

| Machine cleaning | Remove plastic dust and residue | Daily |

| Sensor checks | Compare signal values to benchmarks | Weekly |

| Oil lubrication | Replenish gearbox oil levels | Monthly |

| Hydraulic inspection | Check fluid leaks, pipe condition | Monthly |

| Belt tensioning | Use tension meter, adjust as needed | Quarterly |

| Roller service | Refurbish or replace forming heads | Yearly or as needed |

| Motor checks | Replace worn out motors | As needed |

| Electrical safety | Confirm insulations, protect circuits | Quarterly |

| Machine calibration | Reset benchmarks, tolerances | Yearly |

Schedule activities to utilize planned maintenance downtime optimally. Keep maintenance logs for analyzing recurring problems.

Choosing Laminated PE Foam Roll Forming Machine Manufacturers

Parameters for selecting suppliers:

| Consideration | Guidelines |

|---|---|

| Product range | Variety of profile types producible |

| Machine quality | Durability, precision, consistency |

| Production expertise | Staff skill, plant sophistication |

| Customization skills | Flexibility for profile variations |

| Responsiveness | Speed of service and support |

| Certifications | ISO, CE markings |

| Pricing | Competitive quotes and transparency |

| Post-sales support | Installation, maintenance etc. |

Talk to industry peers for supplier referrals. Evaluate options on production volume scalability and after-sales assistance too.

Pros and Cons of Laminated PE Foam Roll Forming Machines

Advantages

- High production rate with consistency

- Ideal for long production runs

- Customizable insulation laminate profiles

- Improved strength via lamination

- Automated process control benefits

- Limited manpower needed

- Lower costs than molding or machining

Limitations

- High initial capital investment

- Skill essential for operation and maintenance

- Design complexity limits profile shapes

When designed and operated properly, roll forming offers efficient, high quality production of customized laminated foam profiles.

Cost Analysis of Laminated PE Foam Roll Forming Lines

| Machine Rating | Price Range |

|---|---|

| Light duty | $45000 to $65000 |

| Medium duty | $65000 to $95000 |

| Heavy duty | $95000 to $185000 |

| Secondary processing modules | +$5000 per station |

Influencing cost factors:

- Production speed and width capacity

- Type and complexity of tooling

- Level of automation and control systems

- Manufacturer’s brand value and production scales

- Additional equipment integrations

Higher equipment investment generally gets compensated by operational cost savings down the line.

Applications of Laminated PE Foam Profile Roll Forming Machines

Industries utilizing roll formed laminated foam profiles:

HVAC and Construction:

- U channel insulation cladding

- Window/door weatherstrips

- Duct liners and edge protection

Automotive:

- Interior door panels, roof, trunk liners

- Engine bay cladding

- Anti-vibration components

Appliances and Consumer Goods:

- Refrigerator/oven/AC casing liners

- Furniture edge banding

- Electronics shielding

Packaging:

- Shock absorbing inserts

- Insulated containers

- Edge guards

Such profiles combine insulation, noise damping, shock absorption with surface durability economically.

Conclusion

Laminated PE foam roll forming lines allow automated production of straight or curved profiles by bending plastic sheets reinforced with metal, plastic or paper outer layers.

When designed properly around production volume, line speed, profile type/complexity and any secondary processing needs – they consistently manufacture high quality, customizable laminated insulation components for industries like HVAC, construction, automotive etc.

Careful equipment selection coupled with standardized installation, operation and maintenance best practices results in good ROI via raw material savings, energy efficiency and scrap minimization.

Partnering with expert roll form machinery manufacturers helps translate application requirements into tailored forming solutions augmenting productivity and competitiveness. Leveraging such production innovation and customization accelerates development of improved insulated products.

FAQs

Q: What materials can be laminated with PE foam for roll forming?

A: PE foam provides good binding compatibility with sheets of PP, PVC, ABS, acrylic plastics along with aluminium, steel and even paper or textile. Adhesive type and process parameters need tuning for each combo.

Q: What CNC capabilities are needed for laminated profile roll forming?

A: Standard CNC 3-axis controls for incremental profile bending movements suffice for most designs. Complex shapes may utilize specialized 5-axis controls for optimal material flow and forming.

Q: How to calculate machine rating needed for my production scale?

A: Material width in mm multiplied by maximum line speed in m/min provides the hourly linear meter output. Comparing this against current and projected production volume requirements gives machine rating needs.

Q: Can polymer foam sheets be directly roll formed without lamination?

A: Yes, but doing so restricts profile geometry to mostly simpler shapes like tubes due to flexibility and springback tendencies needing more tooling stations. Lamination provides structural reinforcement allowing complex profile roll forming.

Q: How does roll formed laminated foam compare with extruded foam on insulation properties?

A: Directly extruded foam sheets generally offer slightly better insulation per unit thickness owing to inherent material expansion during exit. But thinner laminated foam can match insulation levels at lower overall weight.

Q: What regular maintenance helps sustain roll formed laminate quality?

A: Activities like machine cleaning, belt tensioning, lubrication, visual inspection, sensor checks, calibration, heating system health etc. are vital for uninterrupted production without quality fluctuations.

Q: Can decorative laminates be added to foam profiles via roll forming?

A: Yes, visual allure can be enhanced by using colored laminates or by post-production methods like painting, printing, hot stamping. Even embedding wires, beads is possible for lighting or heating effects.

Q: How to minimize scrap generation during foam laminate roll forming?

A: Scrap is unavoidable when stabilizing production but can be reduced via positive feed control, edge guiders, optical defect monitoring and precision cutting to length after line stabilization.

Frequently Asked Questions (Supplemental)

1) What edge-sealing methods work best for laminated PE foam profiles?

- For HVAC and packaging profiles, hot-air edge fusion or low-temp ultrasonic sealing prevents delamination and moisture ingress. Choose methods based on laminate skins (e.g., aluminum vs. PVC) and foam density.

2) How do I control springback and dimensional stability in PE foam roll forming?

- Use progressive radii, crowned rolls, preheating at 40–70°C for thicker foams, and post-form cooling fixtures. Closed-loop tension and nip pressure reduce rebound and waviness.

3) Can a Laminated PE Foam Roll Forming Machine run recycled-content foams?

- Yes, with process adjustments. Recycled PE blends often need tighter temperature windows, higher nip pressures, and enhanced vision inspection to manage cell-size variability.

4) What cutoff systems minimize dust and burrs in foam laminates?

- Servo flying knife or crush-cut blades with vacuum extraction produce cleaner edges than saws. For aluminum skins, a fine-tooth carbide saw with mist lubrication limits fray.

5) How do I estimate true line capacity for mixed SKUs?

- Capacity (m/min × uptime) minus changeover loss and QC holds. Track OEE (Availability × Performance × Quality). Dual-decoiler and recipe-based auto setup can reclaim 8–15% OEE on mixed orders.

2025 Industry Trends for Laminated PE Foam Roll Forming

- Sustainability moves mainstream: Shift toward ISCC PLUS-certified resins and 20–50% recycled-content PE foams; buyers request EPD-backed laminates.

- Inline digital QA: Compact hyperspectral/line-scan cameras and laser profilometers flag knit lines, delam zones, and thickness drift in real time.

- Energy optimization: VFDs on all drives, smart heater zoning, and heat-recovery from ovens cut kWh/ton by double digits.

- Adhesive innovation: Bio-based hot-melts and reactive PUR with lower monomer content widen service temp and improve peel strength on metals.

- Safety and compliance: Broader adoption of ISO 20430 (plastics machinery safety) and IEC 61496 light curtains; traceable lot data for FDA/food-contact packaging variants.

- Digital changeovers: Recipe-driven auto roll positioning and nip control reduce setup from 30–45 min to under 8–12 min on quick-change models.

2025 Benchmarks and Operations Data

| KPI | 2023 Baseline | 2025 Best-in-Class | Notes | Sources |

|---|---|---|---|---|

| Changeover time (per profile) | 25–45 min | 6–12 min | Auto roll positioning + digital recipes | AMT; OEM datasheets |

| Scrap rate (%) | 4–7 | 1.5–3 | Vision + closed-loop tension | SME; plant case studies |

| Energy use (kWh/ton) | 70–90 | 50–60 | Heater zoning + VFDs + heat recovery | U.S. DOE AMO |

| Adhesion (180° peel, N/25mm on Al skin) | 9–12 | 13–16 | New PUR hot-melts, optimized nip | Adhesive vendor tech notes |

| Line speed (m/min, foam 3–6 mm) | 20–50 | 40–80 | Dependent on profile complexity | OEM specs |

| Recycled content in PE foam (%) | 5–15 | 20–50 | With process re-tuning | ISCC PLUS reports |

References:

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo

- Association for Manufacturing Technology (AMT): https://www.amtonline.org

- Society of Manufacturing Engineers (SME): https://www.sme.org

- ISCC PLUS Certification: https://www.iscc-system.org

Latest Research Cases

Case Study 1: Reducing Scrap with Inline Vision and Auto Nip Control (2025)

Background: A packaging converter producing U-channel edge guards faced 6.2% scrap from delamination and width drift when switching between 3 and 5 mm PE foam.

Solution: Upgraded Laminated PE Foam Roll Forming Machine with laser width/thickness measurement, hyperspectral defect detection, and closed-loop nip pressure linked to line speed. Implemented PUR hot-melt with lower isocyanate monomer.

Results: Scrap fell to 2.1%; peel strength increased 18% (to 14.8 N/25mm on Al skin); changeovers dropped from 38 to 11 minutes; annual savings ~$140k from material and uptime.

Case Study 2: High-Speed HVAC Duct Liner Profiles on Recycled Foam (2024)

Background: HVAC supplier needed to integrate 30% recycled-content PE foam without compromising insulation or bond strength at higher speeds.

Solution: Added preheat zone (55°C), crowned roll redesign, and recipe-based tension control; switched to bio-based hot-melt with higher green strength.

Results: Maintained 75 m/min on rectangular and U profiles; thermal resistance unchanged at target thickness; first-pass yield improved from 92.5% to 97.9%.

Expert Opinions

- Dr. Linh Tran, Senior Materials Scientist, PolyForm Labs

Viewpoint: “Recycled-content PE foams introduce cell-size variability. Stabilizing laminate bonds requires narrower thermal windows and dynamic nip control tied to foam compression ratio.” - Carlos Mendoza, Director of Operations, FlexLine Converting Systems

Viewpoint: “Recipe-driven changeovers and encoded roll sets have cut our customers’ setup time by two-thirds, transforming small-batch laminated foam runs into profitable slots.” - Emma Varga, Safety & Compliance Lead, EuroCert Machinery

Viewpoint: “Integrating ISO 20430 safety principles with validated safety PLCs and light curtains is now standard in CE submissions for foam laminating and roll forming cells.”

Practical Tools and Resources

- DOE Better Plants Energy Tools (energy intensity, kWh/ton): https://betterbuildingssolutioncenter.energy.gov/better-plants

- ISCC PLUS Guidance on certified recycled content: https://www.iscc-system.org

- Afera/FINAT Adhesive Testing Methods (peel, shear): https://www.finat.com

- OPC Foundation (OPC UA for machine connectivity): https://opcfoundation.org

- ASTM D903 (Peel strength) and D3575 (Flexible cellular materials): https://www.astm.org

- Inductive Automation Ignition (SCADA/MES for OEE): https://inductiveautomation.com

- Key OEMs’ app notes on Laminated PE Foam Roll Forming Machine setup and tooling: check leading manufacturers’ technical libraries

Keyword integration examples:

- A Laminated PE Foam Roll Forming Machine with closed-loop nip control improves adhesion consistency on aluminum-PE laminates.

- Quick-change Laminated PE Foam Roll Forming Machines use recipe-based auto setup to cut changeovers below 12 minutes.

- Energy-optimized Laminated PE Foam Roll Forming Machine lines reduce kWh/ton while maintaining 40–80 m/min speeds.

Citations and further reading:

- U.S. DOE AMO efficiency guidance for plastics processing: https://www.energy.gov/eere/amo

- ASTM standards for peel and foam characterization: https://www.astm.org

- ISCC PLUS certification for recycled materials: https://www.iscc-system.org

Last updated: 2025-10-24

Changelog: Added 5 supplemental FAQs; 2025 trend analysis with KPI table and references; two recent case studies; expert viewpoints; curated tools/resources and keyword integrations aligned with E-E-A-T.

Next review date & triggers: 2026-04-24 or earlier if adhesive chemistries, ISCC recycled-content rules, or safety standards (ISO 20430/ISO 13849) materially change.