Introduction

In the fast-paced world of construction, efficiency, precision, and speed are crucial elements for success. The advent of roll forming technology has significantly impacted the building industry, making it possible to produce high-quality wall panels with ease. In this article, we will explore the world of wall panel roll forming machines, their advantages, working mechanisms, and the various types of wall panels they can produce.

What is a Wall Panel Roll Forming Machine?

A wall panel roll forming machine is an advanced piece of equipment used in the manufacturing process of wall panels for residential, commercial, and industrial buildings. It employs a continuous bending process to shape metal coils into specific profiles and lengths. These machines play a vital role in modern construction by providing a cost-effective and efficient way to produce durable wall panels.

Advantages of Wall Panel Roll Forming Machine

Increased Efficiency and Productivity

The roll forming process allows for continuous production, reducing downtime and increasing productivity. With minimal manual intervention, the machine can produce a large number of wall panels in a short period.

Customization Options

Wall panel roll forming machines offer flexibility in design, allowing manufacturers to create customized profiles according to their clients’ requirements. This adaptability provides architects and builders with a wide array of design choices.

Cost Savings

Compared to traditional manufacturing methods, roll forming significantly reduces labor costs and material waste. The automated process ensures precise dimensions, minimizing the need for excess materials.

Durability and Strength

The wall panels produced by roll forming machines exhibit superior strength and durability due to the consistent forming process. They can withstand harsh weather conditions and offer long-lasting performance.

Reduced Material Waste

Roll forming machines optimize material usage, resulting in minimal waste. This not only benefits the environment but also contributes to cost savings for manufacturers.

How Does a Wall Panel Roll Forming Machine Work?

The roll forming process involves several stages that transform raw materials into finished wall panels.

Material Feeding

The process begins with feeding metal coils, typically steel or aluminum, into the machine. The material is guided through rollers and leveling equipment to ensure a smooth and even surface.

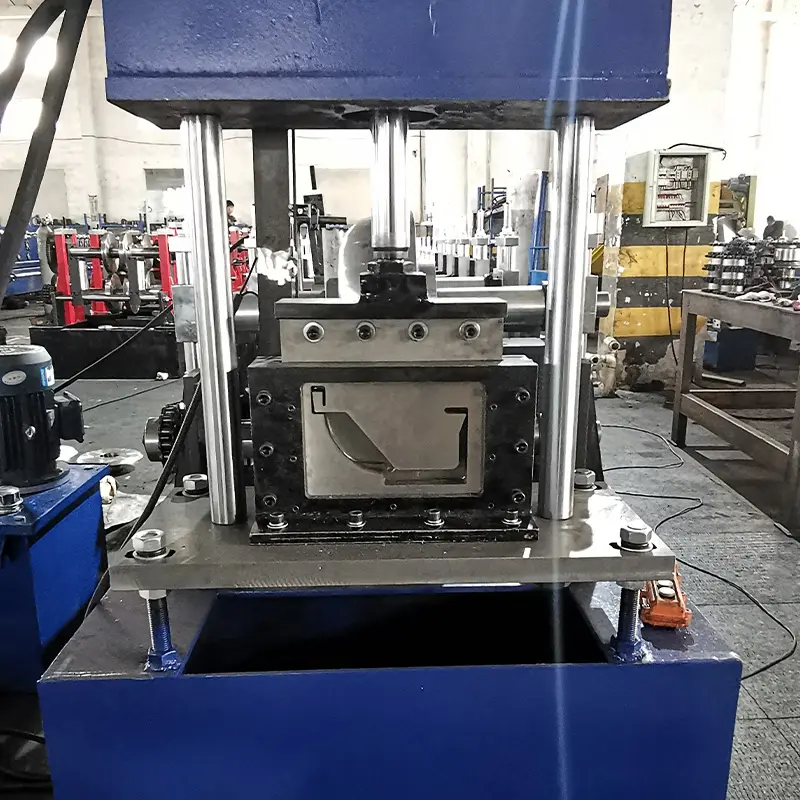

Roll Forming Process

The heart of the machine lies in the roll forming stations. Here, a series of rollers gradually shape the material into the desired wall panel profile. Each station corresponds to a specific part of the panel profile.

Cutting and Shearing

Once the panel reaches the required length, the roll forming machine cuts it using a flying shear or a stationary shear. This ensures precise and accurate panel lengths.

Stacking and Packaging

The finished wall panels are then stacked and packaged, ready for transportation and installation.

Types of Wall Panels Produced by Roll Forming Machines

Wall panel roll forming machines can produce a wide variety of panels to suit different building needs.

Corrugated Wall Panels

Corrugated wall panels are commonly used in agricultural and industrial buildings. The characteristic ridges add strength and stiffness to the panels, making them ideal for heavy-duty applications.

Insulated Wall Panels

Insulated wall panels feature a core material sandwiched between two metal layers. These panels offer excellent thermal insulation and are commonly used in energy-efficient buildings.

Standing Seam Wall Panels

Standing seam wall panels have raised seams that interlock to provide a clean and modern aesthetic. They are widely used in commercial and residential projects.

Ribbed Wall Panels

Ribbed wall panels are known for their strength and versatility. They are commonly used in roofing and siding applications.

Considerations for Choosing a Wall Panel Roll Forming Machine

Investing in a wall panel roll forming machine requires careful consideration to ensure the right fit for your manufacturing needs.

Material Compatibility

Choose a machine that is compatible with the type of material you plan to use for your wall panels. Different machines may be designed for specific materials like steel, aluminum, or other alloys.

Machine Size and Capacity

Evaluate your production requirements and select a machine with the appropriate size and capacity to meet your output demands.

Automation and Technology

Modern roll forming machines come with advanced automation features and integrated technology. Consider machines with user-friendly interfaces and data collection capabilities for process optimization.

Maintenance and Support

Look for machines from reputable manufacturers that offer reliable customer support and maintenance services to keep your production running smoothly.

Setting Up a Wall Panel Manufacturing Business

Starting a wall panel manufacturing business involves several crucial steps.

Market Research and Target Audience

Conduct thorough market research to identify potential customers and understand their needs. Define your target audience and tailor your product offerings accordingly.

Selecting the Right Machine

Choose a wall panel roll forming machine that aligns with your business goals and production requirements.

Factory Setup and Space Requirements

Set up a well-organized factory space with adequate room for the roll forming machine, material storage, and other equipment.

Staffing and Training

Hire skilled operators and provide them with comprehensive training on machine operation and safety protocols.

Quality Control and Testing

Implement rigorous quality control measures to ensure that your wall panels meet industry standards and customer expectations.

Troubleshooting Common Issues with Roll Forming Machines

Understanding and addressing common problems will help maintain the efficiency of your wall panel roll forming machine.

Uneven Roll Forming

Check for misaligned rollers and make adjustments to ensure a uniform forming process.

Material Jamming

Regularly inspect and clean the material feeding system to prevent jams and disruptions in the production process.

Inconsistent Panel Dimensions

Calibrate the machine regularly to maintain consistent panel dimensions throughout the production run.

Excessive Wear and Tear

Regular maintenance, including lubrication and parts replacement, will prolong the lifespan of your machine.

Maintenance Tips for Wall Panel Roll Forming Machine

Proper maintenance is essential to keep your machine in optimal condition.

Regular Cleaning and Lubrication

Clean the machine regularly to remove debris and apply lubrication to reduce friction and wear.

Inspection and Parts Replacement

Perform routine inspections and replace any worn-out or damaged parts promptly.

Calibration and Alignment

Ensure the machine is calibrated and aligned correctly to maintain precise panel dimensions.

Future Trends in Wall Panel Roll Forming Technology

As technology continues to advance, the roll forming industry is poised for exciting developments.

Industry 4.0 Integration

Integrating smart technology and data analytics will lead to more efficient production processes and predictive maintenance.

Sustainability and Green Manufacturing

Eco-friendly materials and energy-efficient production methods will become increasingly important in the roll forming industry.

Advanced Materials and Coatings

The adoption of innovative materials and coatings will enhance the performance and longevity of wall panels.

Conclusion

Wall panel roll forming machines have revolutionized the construction industry by offering a cost-effective, efficient, and sustainable solution for producing high-quality wall panels. From customization options to increased productivity, these machines are a game-changer for manufacturers and builders alike. Embracing this technology will lead to better construction practices and a more sustainable future.

FAQs

Q1: Can I use a wall panel roll forming machine for other profiles?

Yes, while wall panel roll forming machines are specifically designed for wall panels, they can be adapted to produce other profiles with minor adjustments.

Q2: How long does it take to set up a wall panel manufacturing business?

The time to set up a business varies based on factors like location, machinery delivery, and training. It typically takes a few months to get everything up and running.

Q3: Can I start a wall panel manufacturing business on a small scale?

Yes, starting small and gradually expanding your operations is a common approach in the manufacturing industry. As demand grows, you can scale up your production.

Q4: Are roll-formed wall panels as durable as traditional panels?

Roll-formed wall panels are highly durable and can withstand various environmental conditions. With proper maintenance, they can have a long lifespan comparable to traditional panels.

Q5: Can I use different materials in one roll forming machine?

It depends on the machine’s design and capabilities. Some machines can handle multiple materials, while others are designed for specific materials only. Always check the machine’s specifications before use.

Frequently Asked Questions (FAQ)

1) What metals and coatings work best for wall panel roll forming machines?

- Galvanized steel (ASTM A653 G90/Z275), Galvalume/Al-Zn (AZ50–AZ55), pre-painted coils (PE, SMP, PVDF), and aluminum 3003/3105 H14 are common. For coastal or industrial sites, Zn-Al-Mg (e.g., ZM250–310) improves corrosion resistance.

2) How do insulated wall panels (sandwich) integrate with roll forming lines?

- The face sheets are roll-formed inline; foam (PIR/PUR) or mineral wool is added via a continuous laminating section. Critical controls are sheet tension, adhesive application, and synchronized curing to avoid panel camber and delamination.

3) What determines the maximum line speed for wall panel production?

- Material thickness/grade, profile complexity (deep ribs/standing seam), punching patterns, cutoff type (servo flying shear vs. stop-cut), and decoiler/stacker throughput. Typical 2025 ranges: 20–60 m/min for single-skin panels; 6–18 m/min for insulated panels.

4) How can I reduce oil-canning on architectural wall panels?

- Improve entry leveling (6–9 roll leveler), use tension leveling coils, optimize flower design for balanced strain, specify thicker gauge or higher temper, and consider micro-ribbing/bead stiffeners to dissipate waviness.

5) What certifications or standards should wall panel lines and products reference?

- Machinery safety: ISO 12100, ISO 13849-1, IEC 60204-1; product/material: ASTM A653/EN 10346, ASTM E1592 (wind uplift), EN 508-1 for metal sheets, fire performance for insulated panels: EN 13501-1, FM 4880/4881/4471, NFPA 285 (assemblies).

2025 Industry Trends for Wall Panel Roll Forming Machines

- Smart lines with closed-loop vision: Inline laser/vision measures rib height, seam fit-up, and hole positions, auto-correcting stand positions and punch X/Y to cut first-article scrap to ~1–2%.

- Growth of insulated metal panels (IMPs): Demand driven by net-zero codes, cold-chain, and data centers; more lines add continuous lamination and edge-trimming modules.

- Faster changeovers: Servo-positioned stands and recipe-driven tooling reduce profile change time to 5–12 minutes, boosting OEE.

- Energy and sustainability: Regen drives and smart-idle reduce kWh/ton; shift toward Zn-Al-Mg coatings and higher recycled content coils.

- BIM and traceability: Datamatrix/QR panel marking tied to coil heat, coating, and panel geometry for clash-free installation and warranty tracking.

- Safety by design: Category 3/PL d safety, interlocked guards, light curtains at stackers, and predictive maintenance on bearings/gearboxes.

2025 Benchmarks and KPIs (Wall Panel Lines)

| KPI | 2023 Typical | 2025 Best-in-Class | Notes/Enablers | Sources |

|---|---|---|---|---|

| Line speed (single-skin, 0.5–0.7 mm) | 25–40 m/min | 45–60 m/min | Low-inertia stands, servo flying shear | FMA; The Fabricator |

| Line speed (IMP continuous) | 8–12 m/min | 12–18 m/min | Advanced foaming/curing control | EIMA; IMP Alliance |

| Changeover time (profile recipe) | 25–60 min | 5–12 min | Servo stand positioning, HMI recipes | OEM datasheets |

| First-article scrap | 3–6% | 1–2% | Inline vision and digital pass design | data M; UBECO |

| Energy intensity (kWh/ton) | 95–130 | 75–100 | VFDs, regen, smart idle | U.S. DOE AMO |

| Share of Zn-Al-Mg coils in façade work | ~20–30% | 35–50% | Corrosion performance | Eurofer; industry reports |

Authoritative references:

- ASTM A653/A792 materials: https://www.astm.org

- AISI/CFSEI design resources: https://www.buildusingsteel.org

- Eurocode EN 1993 and EN 508-1: https://standards.iteh.ai

- FMA Roll Forming: https://www.fmamfg.org

- The Fabricator (roll forming insights): https://www.thefabricator.com

- U.S. DOE AMO (energy benchmarks): https://www.energy.gov/eere/amo/advanced-manufacturing

- Insulated Metal Panel Alliance (IMPA): https://www.impalliance.org

Latest Research Cases

Case Study 1: Vision-Guided Wall Panel Line Cuts Oil-Canning Claims (2025)

- Background: An architectural façade fabricator had high warranty claims due to oil-canning on flat/ribbed wall panels for premium retail projects.

- Solution: Added 7-roll precision leveler, inline laser rib-height measurement, and camera-based flatness scoring; updated pass design and introduced micro-bead stiffening option.

- Results: Visible waviness complaints reduced by 58% YoY; first-article scrap 5.2% → 1.9%; achieved rib-height CpK 1.45; installation rework time down 22%.

Case Study 2: IMP Line Retrofit for Net-Zero Warehouse Program (2024)

- Background: Logistics developer required higher R-values and faster throughput for refrigerated and ambient warehouses.

- Solution: Retrofitted continuous laminator with tighter temperature/ratio control for PIR foam, upgraded servo flying shear and automatic edge trim/stacker; implemented QR traceability to BIM.

- Results: Throughput +32% (to 15 m/min); panel R-value +18% with stable density; NCRs down 40%; average installation time per bay -12% due to traceable panel mapping.

Expert Opinions

- Dr. Sarah McAllister, Director of Building Envelopes, Oak Ridge National Laboratory

- Viewpoint: “For high-performance wall systems, coupling roll-formed skins with PIR or mineral wool cores and verified thermal breaks is essential to meet 2025 code targets without sacrificing speed.”

- Source: https://www.ornl.gov

- Marco León, Head of Product, data M COPRA RF

- Viewpoint: “Digital flower design with automatic stand positioning is now table stakes; the differentiator is closed-loop vision feeding back to punch and cutoff in real time for architectural tolerances.”

- Source: https://www.datam.de/en/copra

- Emily Chan, Senior Engineer, Insulated Metal Panel Alliance (IMPA)

- Viewpoint: “Fire performance documentation and assembly testing (e.g., FM/NFPA/EN classifications) are becoming a procurement gate; aligning machine capability with certified panel constructions is critical.”

- Source: https://www.impalliance.org

Practical Tools/Resources

- Pass design software: COPRA RF (data M) https://www.datam.de/en/copra; UBECO PROFIL https://www.ubeco.com

- Inline QC hardware: Keyence vision systems https://www.keyence.com; Micro-Epsilon laser displacement https://www.micro-epsilon.com

- Standards and guidance: AISI/CFSEI https://www.buildusingsteel.org; ASTM standards https://www.astm.org; Eurocode references https://standards.iteh.ai

- Energy and maintenance: U.S. DOE Better Plants resources https://betterbuildingssolutioncenter.energy.gov/better-plants; Fiix CMMS https://www.fiixsoftware.com; UpKeep CMMS https://www.onupkeep.com

- Industry associations: Metal Construction Association https://www.metalconstruction.org; Insulated Metal Panel Alliance https://www.impalliance.org

- BIM/traceability: GS1 Datamatrix guidelines https://www.gs1.org/standards/datamatrix

Last updated: 2025-10-27

Changelog: Added 5 targeted FAQs; introduced 2025 trends with KPI table and references; created two recent case studies; included expert opinions; compiled practical tools and resources relevant to wall panel roll forming machines

Next review date & triggers: 2026-04-30 or earlier if first-article scrap > 2.5%, oil-canning claims rise > 10% QoQ, IMP throughput < 12 m/min, or changeover > 15 minutes on architectural profiles