Introduction

Welcome to our comprehensive guide on Z Purlin Roll Forming Machines. In this article, we will explore the features, benefits, working principles, key components, factors to consider, maintenance, safety precautions, application areas, and market trends related to Z Purlin Roll Forming Machines. Whether you are a construction professional or an enthusiast interested in metal fabrication, this article will provide you with valuable insights into the world of Z Purlin Roll Forming Machines.

What is a Z Purlin Roll Forming Machine?

A Z Purlin Roll Forming Machine is a specialized piece of equipment used in metal fabrication to produce Z-shaped steel purlins. Purlins are structural elements used in the construction industry to provide support and stability to roofs and walls. The Z Purlin Roll Forming Machine takes flat metal coils or sheets as input and transforms them into Z-shaped purlins with consistent dimensions and high precision.

Benefits of Using a Z Purlin Roll Forming Machine

Using a Z Purlin Roll Forming Machine offers several advantages over traditional methods of purlin production. These benefits include:

- Increased Efficiency: Z Purlin Roll Forming Machines automate the process of purlin production, resulting in higher efficiency and faster output compared to manual methods.

- Cost Savings: By eliminating the need for manual labor and reducing material waste, Z Purlin Roll Forming Machines can help save costs in the long run.

- Customization Options: Z Purlin Roll Forming Machines can be adjusted to produce purlins of various sizes, thicknesses, and profiles, providing flexibility for different construction requirements.

- Consistent Quality: The use of a Z Purlin Roll Forming Machine ensures consistent quality in the produced purlins. The machine’s precise forming process guarantees uniform dimensions and smooth finishes, meeting industry standards and customer expectations.

- Time-Saving: With automated processes and high production speeds, Z Purlin Roll Forming Machines significantly reduce the time required for purlin manufacturing, enabling faster project completion.

- Accuracy and Precision: The roll forming process of the machine ensures accurate bending and shaping of the metal, resulting in purlins with precise dimensions and tight tolerances.

- Durability and Strength: Z Purlin Roll Forming Machines produce purlins with excellent structural integrity and load-bearing capacity. The formed purlins exhibit high strength and durability, making them suitable for various construction applications.

Types of Z Purlin Roll Forming Machines

There are different types of Z Purlin Roll Forming Machines available, each designed to cater to specific production requirements. The following are the commonly used types:

Single-Sided Z Purlin Roll Forming Machine

A single-sided Z Purlin Roll Forming Machine forms purlins on one side of the machine. This type of machine is suitable for applications where only one flange of the purlin requires roll forming.

Double-Sided Z Purlin Roll Forming Machine

A double-sided Z Purlin Roll Forming Machine can simultaneously form both flanges of the purlin. This type of machine offers higher productivity and efficiency compared to the single-sided version.

Adjustable Z Purlin Roll Forming Machine

An adjustable Z Purlin Roll Forming Machine allows for easy adjustment of the machine parameters, such as the width and height of the purlin, to accommodate different design requirements. This type of machine offers versatility and customization options.

Working Principle of a Z Purlin Roll Forming Machine

The working principle of a Z Purlin Roll Forming Machine involves a series of sequential operations. Here is a step-by-step explanation of the process:

- Decoiling: The machine starts by unwinding the metal coil or sheet from a decoiler, which holds and feeds the material into the roll forming system.

- Roll Forming: The material passes through a series of rollers, gradually bending and shaping it into the desired Z-shaped profile. Each set of rollers corresponds to a specific section of the purlin.

- Punching: In some cases, the machine may include a punching system to create holes or slots in the purlins for fasteners or other purposes. The punching operation is synchronized with the roll forming process.

- Cutting: Once the desired length of the purlin is achieved, the machine performs a cutting operation to separate the formed purlin from the remaining material. Different cutting methods, such as hydraulic shearing or flying saw cutting, may be employed.

- Control System: Throughout the process, a control system regulates and monitors the machine’s operation, ensuring precise synchronization and control of various parameters.

Key Components of a Z Purlin Roll Forming Machine

A Z Purlin Roll Forming Machine consists of several essential components that contribute to its functionality and performance. Understanding these components is crucial for effectively operating and maintaining the machine. The key components include:

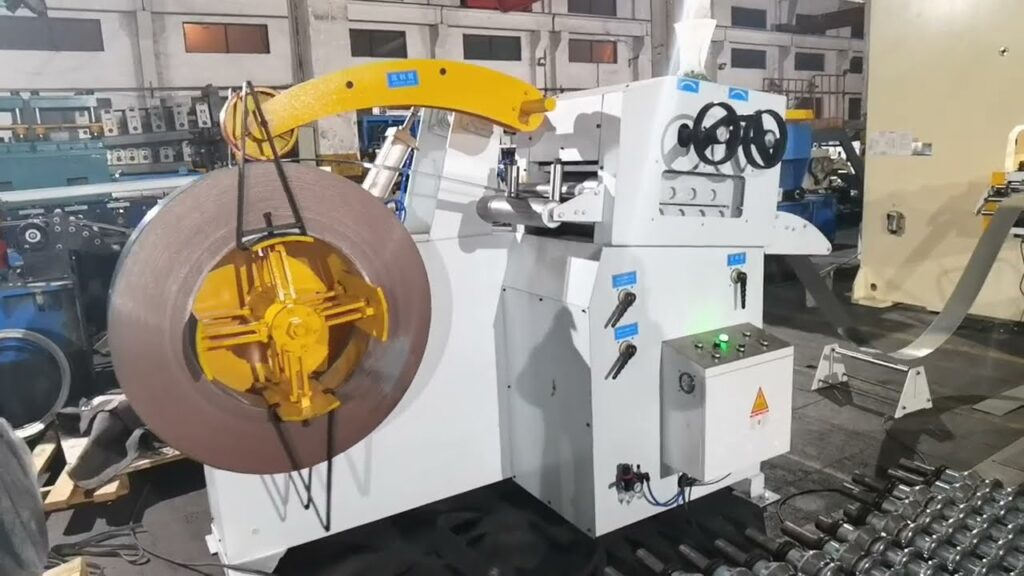

Decoiler

The decoiler holds the metal coil or sheet and feeds it into the roll forming system. It ensures a continuous supply of material during the production process.

Roll Forming System

The roll forming system consists of a series of rollers arranged in a specific configuration. These rollers gradually shape the flat metal into the desired Z-shaped profile, determining the dimensions and overall quality of the formed purlins. The roll forming system may include multiple stations, each responsible for bending and forming a specific section of the purlin.

Punching System

Some Z Purlin Roll Forming Machines are equipped with a punching system. This system allows for the creation of holes, slots, or other custom features in the purlins. The punching operation is synchronized with the roll forming process to ensure accurate positioning of the punched features.

Cutting System

Once the desired length of the purlin is achieved, a cutting system is employed to separate the formed purlin from the remaining material. The cutting system can utilize different methods such as hydraulic shearing or flying saw cutting. The choice of cutting method depends on factors such as production speed and precision requirements.

Control System

A control system is an integral part of the Z Purlin Roll Forming Machine. It provides centralized control and monitoring of various machine functions, including speed regulation, length measurement, synchronization of operations, and error detection. The control system ensures the smooth and efficient operation of the machine while maintaining accuracy and consistency in the produced purlins.

Factors to Consider when Choosing a Z Purlin Roll Forming Machine

When selecting a Z Purlin Roll Forming Machine for your specific requirements, several factors should be taken into consideration. These factors include:

Material Thickness and Width

The machine’s capabilities in handling the desired material thickness and width should align with your project requirements. Ensure that the machine can effectively process the metal coils or sheets you intend to use for purlin production.

Production Speed

Consider the required production speed to meet project deadlines and demand. Higher production speeds can significantly impact productivity, but it’s essential to balance speed with quality and precision.

Flexibility and Customization

If your project requires different sizes or profiles of purlins, choose a machine that offers flexibility and customization options. An adjustable Z Purlin Roll Forming Machine allows for easy adjustments, accommodating varying design requirements.

Quality and Durability

Invest in a machine constructed from high-quality materials and components to ensure its durability and longevity. A robust and reliable machine will deliver consistent results and withstand the rigors of long-term use.

After-Sales Support

Consider the availability of after-sales support, including technical assistance, spare parts availability, and maintenance services. A reputable manufacturer or supplier who provides excellent after-sales support can ensure smooth machine operation and minimize downtime.

Maintenance and Troubleshooting of a Z Purlin Roll Forming Machine

To keep a Z Purlin Roll Forming Machine in optimal condition and ensure its longevity, regular maintenance is essential. Additionally, understanding common troubleshooting techniques can help address any issues promptly. Here are some maintenance and troubleshooting guidelines:

Regular Cleaning and Lubrication

Keep the machine clean and free from debris that may affect its performance. Regularly lubricate the moving parts to reduce friction and prevent premature wear.

Inspection and Adjustment of Components

Periodically inspect the machine’s components, such as rollers, bearings, gears, and belts. Tighten loose connections, replace worn-out parts, and ensure proper alignment to maintain accurate roll forming and prevent malfunctions.

Troubleshooting Common Issues

Familiarize yourself with common issues that may arise during machine operation, such as material feeding problems, misalignment, or irregular purlin shapes. Follow troubleshooting procedures provided by the machine’s manufacturer and address issues promptly to minimize production interruptions.

Safety Precautions for Operating a Z Purlin Roll Forming Machine

Operating a Z Purlin Roll Forming Machine involves potential risks, and it is crucial to prioritize safety. Here are some important safety precautions to follow:

Proper Training and Supervision

Ensure that operators and personnel involved in operating the machine receive adequate training on its safe operation, including proper handling of materials, emergency procedures, and safety protocols. Supervision should be provided to maintain compliance with safety guidelines.

Use of Personal Protective Equipment (PPE)

Operators and workers should wear appropriate personal protective equipment, such as safety goggles, gloves, hearing protection, and safety shoes, to protect themselves from potential hazards during machine operation.

Machine Guarding

Implement proper machine guarding to prevent access to hazardous areas, such as the roll forming system, cutting area, and punching mechanisms. Install safety guards, barriers, and interlocking systems to minimize the risk of accidents and injuries.

Emergency Stop Systems

Ensure that the machine is equipped with easily accessible emergency stop buttons or switches. Train operators on how to use them effectively in case of any emergencies or immediate halting of the machine’s operation.

Application Areas of Z Purlin Roll Forming Machines

Z Purlin Roll Forming Machines find wide applications in the construction industry and other sectors where structural support is required. Some common application areas include:

- Roofing Systems: Z purlins are extensively used in roofing systems to provide support for roof panels, insulation, and other components.

- Wall Systems: Z purlins are employed in wall framing to enhance structural stability and support cladding materials.

- Industrial Sheds and Warehouses: Z purlins are widely used in the construction of industrial sheds and warehouses, providing cost-effective and efficient structural solutions.

- Prefab Buildings: Z purlin roll forming machines are essential for producing purlins used in prefabricated buildings, ensuring rapid and accurate construction.

- Agricultural Structures: Z purlins are utilized in agricultural structures such as barns, storage facilities, and livestock shelters.

Market Trends and Outlook for Z Purlin Roll Forming Machines

The market for Z Purlin Roll Forming Machines is witnessing steady growth, driven by the increasing demand for efficient and cost-effective metal fabrication solutions in the construction industry. Some notable market trends include:

- Technological Advancements: Manufacturers are constantly improving the design and functionality of Z Purlin Roll Forming Machines, incorporating advanced automation, computerized controls, and precision engineering to enhance productivity and accuracy.

- Customization and Flexibility: The market is seeing a growing demand for Z Purlin Roll Forming Machines that offer greater customization options, enabling the production of purlins with varying sizes, profiles, and hole patterns to meet specific project requirements.

- Focus on Energy Efficiency: Energy efficiency has become a key consideration in machine design. Manufacturers are developing energy-efficient Z Purlin Roll Forming Machines that optimize power consumption while maintaining high productivity levels.

- Rise of Prefabrication: The increased adoption of prefabricated construction methods has led to a surge in the demand for Z Purlin Roll Forming Machines. These machines play a crucial role in producing standardized purlins for efficient and rapid assembly of prefabricated structures.

- Emerging Construction Markets: Developing economies with growing construction industries, such as Asia-Pacific and the Middle East, present significant growth opportunities for the Z Purlin Roll Forming Machine market.

Conclusion

Z Purlin Roll Forming Machines have revolutionized the process of manufacturing Z-shaped steel purlins in the construction industry. These machines offer numerous benefits, including increased efficiency, cost savings, customization options, and consistent quality. Understanding the working principle, key components, and factors to consider when choosing a Z Purlin Roll Forming Machine is crucial for making informed decisions. Proper maintenance, adherence to safety precautions, and awareness of market trends further enhance the machine’s performance and productivity.

In conclusion, Z Purlin Roll Forming Machines have become indispensable tools for the production of high-quality purlins used in various construction applications. Their efficiency, precision, and versatility make them essential for modern metal fabrication processes. By investing in the right machine, adhering to safety guidelines, and staying updated with market trends, businesses can leverage the benefits of Z Purlin Roll Forming Machines to meet the growing demands of the construction industry.

FAQs

Q1: What materials can be used with a Z Purlin Roll Forming Machine?

A1: Z Purlin Roll Forming Machines can handle a variety of materials, including galvanized steel, cold-rolled steel, stainless steel, and aluminum.

Q2: Can a Z Purlin Roll Forming Machine produce purlins of different sizes?

A2: Yes, many Z Purlin Roll Forming Machines offer adjustability to produce purlins of different widths, heights, and thicknesses, allowing for customization according to project requirements.

Q3: Are Z purlins stronger than other types of purlins?

A3: Z purlins offer excellent strength and load-bearing capacity. However, the suitability of a particular purlin type depends on the specific application and structural requirements.

Q4: How often should a Z Purlin Roll Forming Machine be maintained?

A4: Regular maintenance is crucial to ensure the optimal performance of a Z Purlin Roll Forming Machine. It is recommended to follow the manufacturer’s guidelines and perform routine maintenance tasks, including cleaning, lubrication, and component inspection.

Q5: Can a Z Purlin Roll Forming Machine be used for other profiles besides Z-shaped purlins?

A5: Some Z Purlin Roll Forming Machines can be equipped with interchangeable tooling to produce different profiles, such as C purlins or U channels. This versatility enhances the machine’s functionality and widens its range of applications.

Frequently Asked Questions (FAQ)

1) What production tolerances are realistic for Z purlins at speed?

- With encoder feedback and a servo flying shear, expect cut-length tolerance of ±0.7–1.0 mm at 60–100 m/min; hole position tolerance ±0.5–0.8 mm using servo-electric punching; straightness ≤1.5 mm per 1,000 mm for typical Z purlin profiles.

2) How do I choose between hydraulic and servo-electric punching on a Z Purlin Roll Forming Machine?

- Servo-electric punching offers tighter positional accuracy, lower noise, and reduced maintenance. Hydraulic is robust for thicker gauges (>2.5–3.0 mm) or heavy patterns but increases energy use and upkeep.

3) What coil specs are optimal for stable Z purlin forming?

- Common ranges: galvanized steel (GI/GL) 1.2–3.0 mm thickness, 150–600 mm strip width, yield strength 235–550 MPa. Ensure consistent coil crown/flatness and specify edge wave and camber limits in RFQs.

4) How can I reduce changeover time on adjustable Z purlin lines?

- Use auto width/height adjustment, quick-change cassettes, barcode/recipe presets, and modular punching dies. Target ≤12–15 minutes for width/height changes and ≤30 minutes for full cassette swaps.

5) Which standards and safety directives apply to Z purlin roll forming equipment?

- Typical references: ISO 12100 (risk assessment), IEC 60204-1 (electrical safety), EN 12622/ISO 23125 analogs for guarding principles, and CE/Machinery Regulation compliance in the EU; NFPA 79 in North America. Verify local compliance and audited safety circuits (PL d/e).

2025 Industry Trends for Z Purlin Roll Forming Machines

- Quick-change and auto-sizing: Auto web/flange adjustment and cassette tooling are cutting changeovers below 10–12 minutes on high-mix Z/C lines.

- Higher-strength steels: Growing use of 450–550 MPa yield steels in industrial roofs requires optimized pass design and hardened rolls.

- Digital thread: ERP/BIM-integrated job tickets and QR-coded recipes reduce setup errors and enable lot-level traceability.

- Inline metrology: Vision and laser systems monitor hole offset, burr height, and cut length in real time, trimming scrap.

- Energy efficiency: IE4/IE5 motors, regenerative drives, and power monitoring reduce kWh/ton while supporting ESG reporting.

- Safety by design: Category 3/4 safety circuits and interlocked guards are becoming standard for CE/Machinery Regulation 2027 readiness.

2025 Benchmark Table (Z Purlin Lines)

| KPI | 2023 Typical | 2025 Best-in-Class | Impact Area | Source/Notes |

|---|---|---|---|---|

| Changeover (width/height) | 25–35 min | 8–12 min | OEE, agility | OEM demo lines; integrator reports |

| Line speed (mm 1.5–2.5) | 40–70 m/min | 80–120 m/min | Throughput | Vendor specs, user plants |

| Cut-length tolerance @ 80 m/min | ±1.5 mm | ±0.7–1.0 mm | Fit-up quality | EN 1090 practices; OEM data |

| Hole position tolerance | ±1.2–1.5 mm | ±0.5–0.8 mm | Assembly speed | Inline vision vendors |

| Scrap rate (GI 1.5–2.0 mm) | 2.0–3.0% | 0.8–1.5% | Material cost | Case implementations |

| Energy intensity (kWh/ton) | 160–200 | 120–150 | OpEx/ESG | ABB/Siemens efficiency notes |

| Inline QA adoption | ~25–35% | 50–65% | Rework avoidance | Market surveys 2024–2025 |

Authoritative references and further reading:

- ISO 12100: https://www.iso.org

- IEC 60204-1: https://webstore.iec.ch

- EU Machinery Regulation overview: https://ec.europa.eu

- EN 1090 overview (steel structures): https://standards.cen.eu

- ABB Drives energy optimization: https://new.abb.com/drives

- Siemens motion/automation efficiency: https://new.siemens.com

- Keyence inline inspection systems: https://www.keyence.com

- Micro-Epsilon laser displacement sensors: https://www.micro-epsilon.com

Latest Research Cases

Case Study 1: Quick-Change Z/C Combo Line for High-Mix Fabrication (2025)

Background: A roofing systems OEM produced short runs of Z and C purlins (1.6–2.5 mm GI) with frequent size changes, losing capacity to changeovers and rework.

Solution: Installed an adjustable Z Purlin Roll Forming Machine with auto web/flange adjustment, cassette tooling for Z↔C swap, servo-electric punching, and inline laser cut-length verification tied to HMI recipes.

Results: Changeover time fell from 28 to 10 minutes; scrap reduced from 2.4% to 1.2%; cut-length CpK improved to >1.67 at 90 m/min; payback achieved in 13 months.

Case Study 2: Forming High-Strength 550 MPa Z Purlins Without Cracking (2024)

Background: Transition to S550GD steel caused flange edge micro-cracks and twist in 2.0 mm Z sections.

Solution: Re-optimized pass progression, increased roll hardness/coating, added anti-buckle guides, and upgraded to a servo flying shear with improved strip support.

Results: Eliminated flange cracking; reduced twist to <1.0 mm/1,000 mm; line speed restored from 55 to 85 m/min with no increase in scrap.

Expert Opinions

- Elena Kovacs, Head of Manufacturing Engineering, Structural Steel Components

“On Z Purlin Roll Forming Machines, auto-sizing beats raw speed for real productivity. Sub-12-minute changeovers unlock daily output more than another 10 m/min.” - Omar Haddad, Senior Controls Engineer, Industrial Automation Integrator

“Servo-electric punching and encoder-synchronized flying shears are now baseline. If you can’t hold ±1 mm cut-length at speed, field fit-up costs will erase any capex savings.” - Prof. Daniel R. Chen, PhD, Advanced Forming Processes, University Research Lab

“Designing for 450–550 MPa steels requires revised pass design and roll metallurgy. With inline metrology feedback, you can push strength grades without paying in scrap.”

Practical Tools/Resources

- Roll design and simulation:

- COPRA RF (Dataplast): https://www.datam.de

- UBECO PROFIL: https://www.ubeco.com

- Altair Inspire/Form: https://www.altair.com

- Standards and safety:

- ISO 12100 (risk assessment): https://www.iso.org

- IEC 60204-1 (electrical): https://webstore.iec.ch

- EU Machinery Regulation overview: https://ec.europa.eu

- Inline QA and measurement:

- Keyence vision/laser systems: https://www.keyence.com

- Micro-Epsilon displacement/laser sensors: https://www.micro-epsilon.com

- Maintenance and OEE tracking:

- UpKeep CMMS: https://www.onupkeep.com

- Fiix CMMS: https://www.fiixsoftware.com

Implementation tip for RFQs/FAT: Specify cut-length ±1.0 mm at target speed, hole position ±0.8 mm, burr height ≤0.05 mm, changeover ≤12 minutes, energy intensity reporting (kWh/ton), and noise ≤80 dBA at 1 m.

Last updated: 2025-10-23

Changelog: Added 5 fresh FAQs, 2025 trend analysis with benchmark table and sources, two recent case studies, three expert viewpoints, and a curated tools/resources list with RFQ/FAT specs.

Next review date & triggers: 2026-05-22 or earlier if new Machinery Regulation guidance, major OEM releases (auto-sizing/cassette tooling), or updated benchmarks for accuracy, scrap, and energy are published.