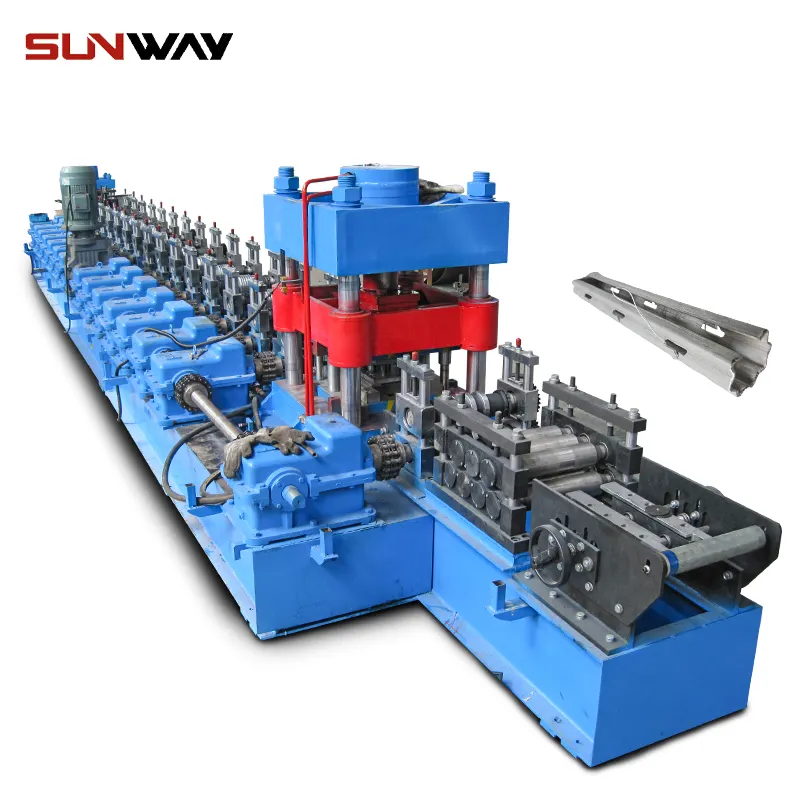

Vineyard post roll forming machine is used for vineyard and orchard to produce the stakes and posts. Normally, grape post is 1.5-2mm thickness. So we adopted gearbox driving system to make sure our machine working stably and with long working life.

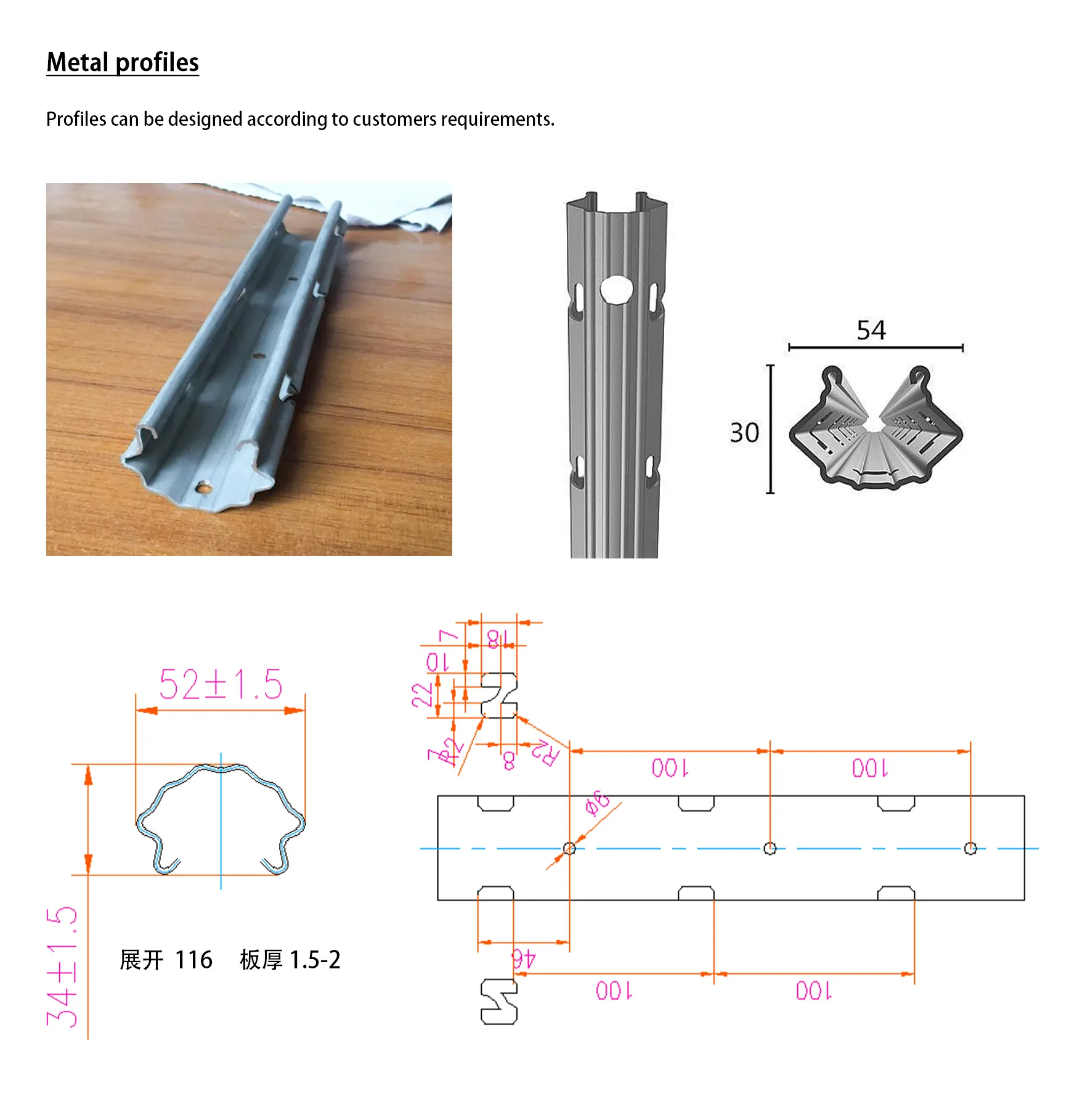

Vineyard Posts are used for piles in vineyards and gardens. Compared with cement piles, metal grape piles are easy to install and have low labor costs. The Z-shaped holes in the product are used to adjust the height of the wire as the grapes grow. The use of thick zinc layer anti-corrosion galvanized steel, because it is the world’s most cost-effective commercial popular.

Our intelligent Vineyard post roll forming machine could make the different posts according to your profile. Uncoiling, servo feeding, punching, roll forming, cutting etc process can be automatically realized on one line.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Profile Drawings

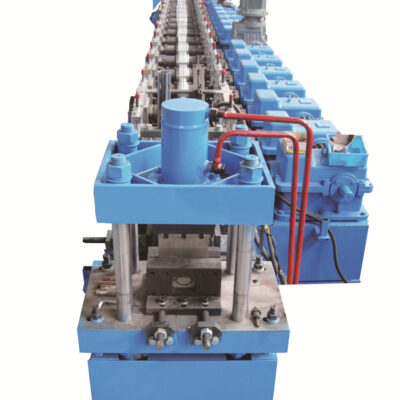

Production Line

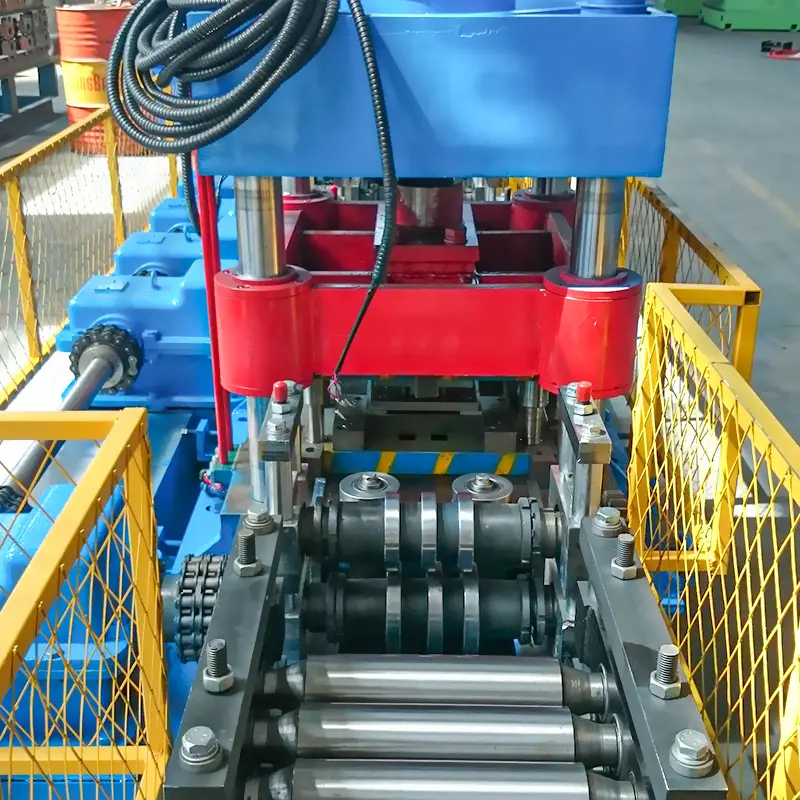

Product Details

Product Parameters

| Vineyard Post Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 1.5-2.0 as per customer

|

| B) Mild Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Punching Press (Optional) |

| Forming Station | About 16-18 Stands | * According To Your Profile Drawings |

| Driving System | Gearbox Drive | |

| Machine Structure | Cast Iron Stands | |

| Forming Speed | 5-10 (M/MIN) | * Or According To Your Profile Drawings |

| Rollers’ Material | GCr 15 | * Cr12 (Optional) |

| Cutting System | Hydraulic Cutting | * Saw Cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

what is rack roll forming machine?

A rack roll forming machine is a type of manufacturing equipment used to produce racks or shelves with consistent and precise shapes from coiled metal sheets or strips. Roll forming is a continuous bending process where the metal is passed through a series of rollers, gradually forming it into the desired profile.

In the case of a rack roll forming machine, the rollers are specifically designed to create the shape of the rack. The machine typically consists of a decoiler to hold and feed the metal strip, a set of rollers that progressively shape the metal, and a cutting mechanism to separate the formed racks into desired lengths.

The advantage of using a rack roll forming machine is its ability to produce racks with high dimensional accuracy and uniformity at a high production rate. The process is efficient, reducing material waste and eliminating the need for additional forming operations. Additionally, roll forming allows for the creation of complex profiles and customization options for different rack designs.

Rack roll forming machines are commonly used in industries such as warehousing, logistics, retail, and manufacturing, where storage and organization systems are essential. They enable the production of sturdy and reliable racks that can be used for various purposes, including storing goods, displaying products, or organizing inventory.

application of pallet rack roll forming machine

- Warehousing and Logistics: Pallet racks are extensively used in warehouses and distribution centers to store and organize goods efficiently. The roll forming machine enables the production of high-quality racks with consistent dimensions and structural integrity, ensuring safe and effective storage solutions.

- Retail and Supermarkets: Pallet racks are utilized in retail environments such as supermarkets, big-box stores, and convenience stores. They provide a means to store and display a wide range of products, including groceries, household items, electronics, and more. The roll forming machine allows for the production of racks that are customized to meet the specific requirements of retail environments.

- Manufacturing and Industrial Facilities: Pallet racks are commonly used in manufacturing plants and industrial facilities to store raw materials, components, work-in-progress items, and finished products. The roll forming machine can produce racks with varying load capacities and configurations to accommodate different types of items and optimize space utilization.

- E-commerce and Fulfillment Centers: With the growth of e-commerce, the demand for pallet racks in fulfillment centers has increased significantly. Pallet racks provide efficient storage solutions for managing large volumes of inventory, enabling quick and organized order fulfillment. The roll forming machine plays a crucial role in meeting the production demands of these centers.

- Automotive and Heavy Equipment Storage: Pallet racks are employed in automotive and heavy equipment industries for storing components, parts, and assemblies. The roll forming machine allows for the production of racks that can withstand heavy loads and provide easy access to items, enhancing operational efficiency in these sectors.

how to choose rack shelf roll forming machine

- Production Requirements: Determine your production needs in terms of the quantity and types of rack shelves you plan to produce. Consider factors such as production capacity, speed, and flexibility of the machine to meet your desired output.

- Rack Shelf Specifications: Assess the specific requirements of the rack shelves you intend to manufacture, including dimensions, material thickness, profile design, and load-bearing capacity. Ensure that the roll forming machine can accommodate the desired specifications and produce racks that meet industry standards and customer expectations.

- Material Compatibility: Consider the types of materials you will be using for rack shelf production, such as steel, aluminum, or other metals. Ensure that the roll forming machine is capable of handling the chosen materials and that it has the necessary features, such as adjustable roller sets and cutting mechanisms, to work with different material thicknesses.

- Machine Configuration: Evaluate the machine’s configuration and features to determine if they align with your specific needs. Consider factors such as the number of forming stations, the presence of additional features like hole punching or welding capabilities, and the ease of adjusting the machine for different rack shelf profiles.

- Quality and Durability: Assess the build quality and reliability of the roll forming machine. Look for a reputable manufacturer with a track record of producing high-quality machines. Consider factors such as the materials used in construction, the precision of the machine’s components, and the availability of technical support and spare parts.

- Cost and Return on Investment: Compare the cost of the roll forming machine with your budget and evaluate the potential return on investment. Consider factors such as the machine’s efficiency, production capacity, maintenance requirements, and potential energy savings to assess its long-term cost-effectiveness.

- Manufacturer Support and Service: Choose a manufacturer that offers comprehensive customer support, including training, installation, and after-sales service. A reliable manufacturer will provide technical assistance, troubleshooting, and spare parts to ensure smooth operation and minimize downtime.

- Safety and Compliance: Ensure that the roll forming machine meets safety standards and regulations to protect workers and comply with industry requirements. Look for features such as safety guards, emergency stop buttons, and compliance with relevant safety standards.