This auto size changeable C/U purlin roll forming machine is the perfect solution for businesses looking to produce high-quality C and U-shaped purlins quickly and efficiently. With a material thickness range of 1.5-3mm, and the ability to form purlins up to 4.0-6.0mm thick based on customer requirements, this machine is highly versatile and suitable for various applications.

We designed this machine to be highly customizable, with the ability to automatically adjust the sheet width and height via PLC, or manually adjust the handle wheel for different sizes. This feature saves time and is much more convenient than adjusting spacers.

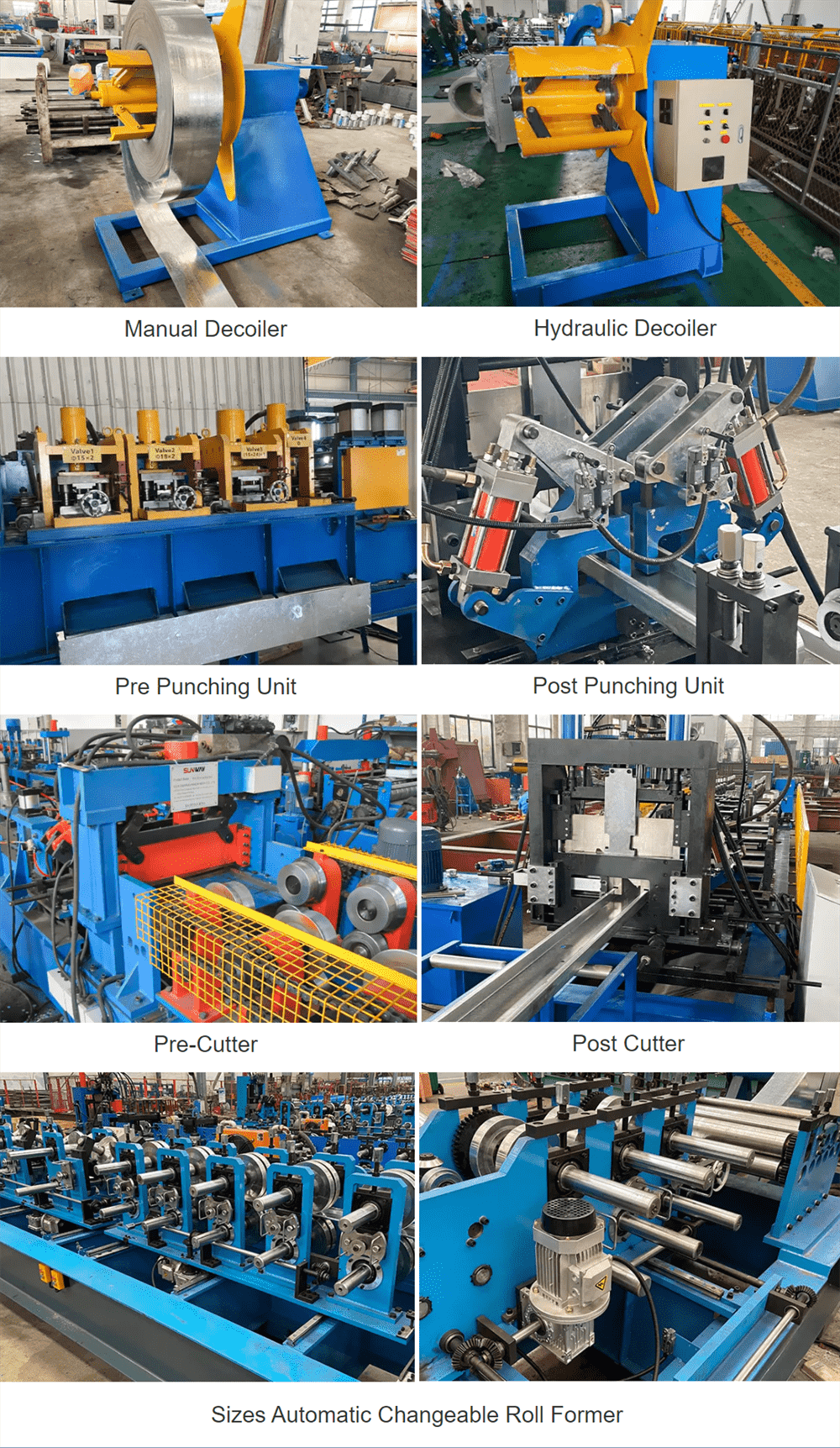

Regarding the punching unit, we can design pre-punching or post-punching options based on customer requirements. Customers can choose between pre-cut or post-cut, which is a universal cutting method.

The driving system uses a chain and mostly comes with gimbal/gearbox for transmission, providing strong driving power and stable performance when forming purlins from thicker materials.

Purlin roll forming machines are highly popular and widely used in metal building systems, huge roofing solutions, and construction and renovation projects. Our Purlin roll forming machine can produce C, U, and Z-shaped purlins with machineable size ranges of width: 100-300mm, height: 50-100mm, and thickness: 1.5-3mm. Additionally, we offer customized solutions based on customers’ specific drawing, tolerance, and budget requirements. Whether you need to produce a few sizes or multiple, we have solutions to meet your needs.

At SUNWAY Machinery, we provide professional one-to-one service and adaptable solutions to ensure customers receive the highest quality profiles. Whether you are a novice or experienced operator, our purlin roll forming machine is easy to operate and maintain, ensuring maximum productivity and profitability.

Click here to learn more about the purlin roll forming machine

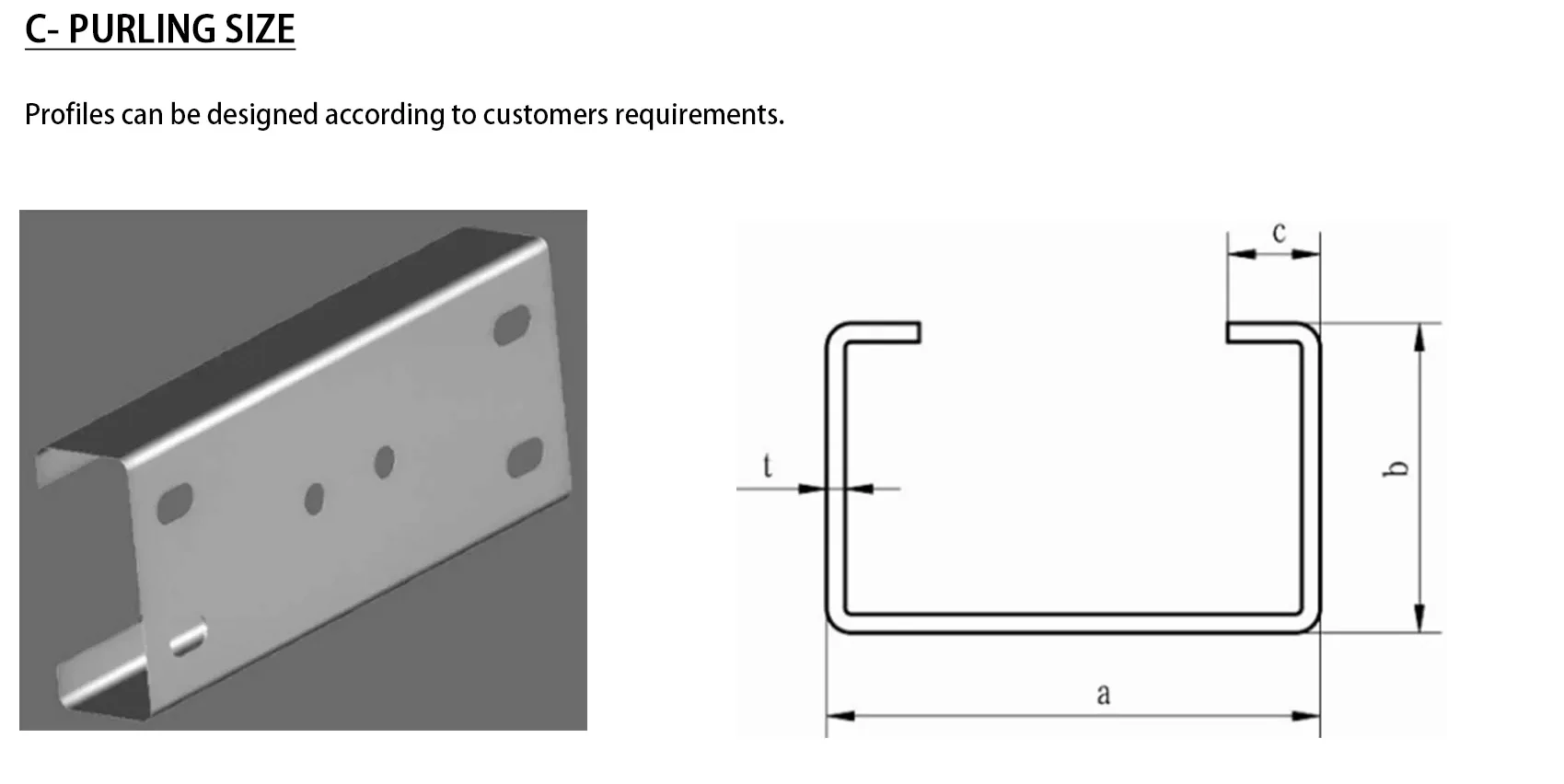

Auto Size Changeable C/U Purlin Roll Forming Machine Profile Drawings

Our Auto Size Changeable C/U Purlin Roll Forming Machine is a production equipment used to manufacture C/U-shaped steel purlins. The equipment is composed of multiple workstations that can perform different tasks. We use high-quality steel coils as the primary material, which can handle different thicknesses of steel coils. During the production process, the equipment converts the steel coil into precise C/U-shaped steel purlins through a series of steps, including uncoiling, forming, cutting, bending, and coiling. Additionally, the equipment can automatically switch to produce different sizes of steel purlins, thus improving production efficiency. In terms of design, our equipment features a simplified appearance and highly automated production process, reducing manual intervention and increasing production efficiency. We adopt advanced technology and materials, featuring high precision, efficiency, and longevity. We provide professional after-sales service to ensure that your equipment always maintains good operating status, making your production smoother.

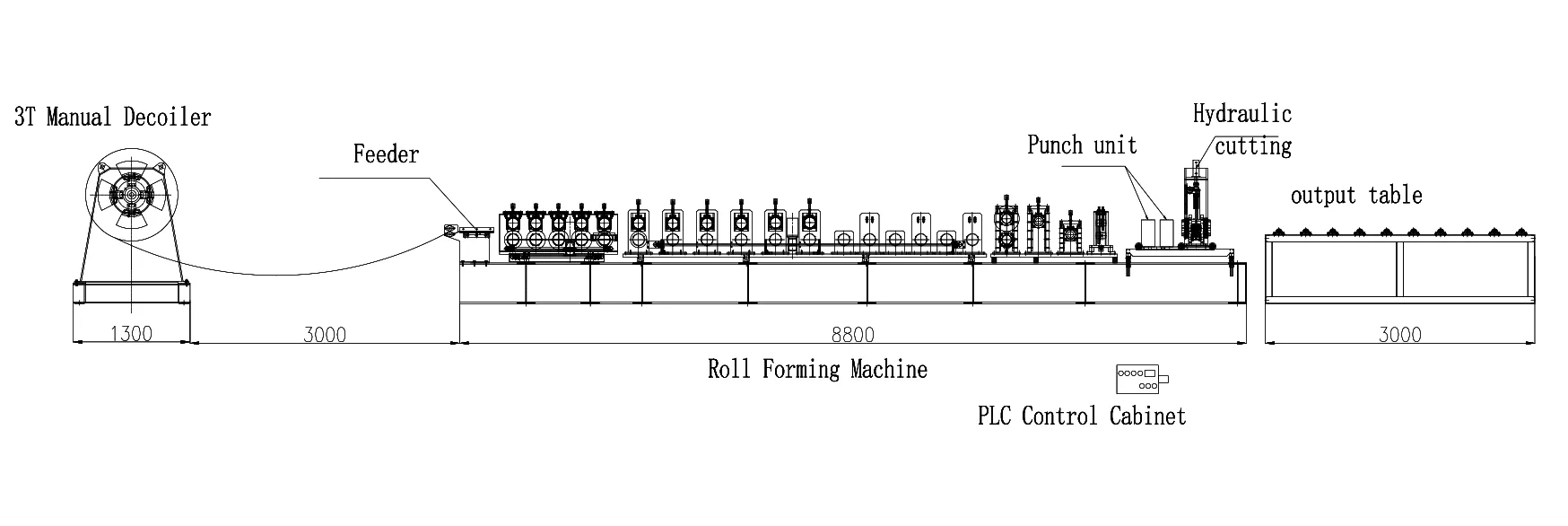

Auto Size Changeable C/U Purlin Roll Forming Machine Production Line

Our Auto Size Changeable C/U Purlin Roll Forming Machine Production Line is a highly automated production line used for manufacturing C/U-shaped steel purlins. The production line is composed of multiple workstations, each with a different function to perform different tasks during the manufacturing process. We use high-quality steel coils as the primary material, which can handle different thicknesses of steel coils depending on the machine’s design and configuration. Additionally, the production line can automatically switch to produce different sizes of steel purlins, thereby improving production efficiency. During the production process, multiple steps are involved, including uncoiling, pressing, forming, cutting, and coiling. Through precise control of the production process, the resulting steel purlins have precise dimensions and shapes, and high production efficiency. We provide professional after-sales service to ensure that your equipment always maintains a good operating state, making your production smoother.

Auto Size Changeable C/U Purlin Roll Forming Machine Product Details

Our Auto Size Changeable C/U Purlin Roll Forming Machine is an automated production line that utilizes advanced technology and materials to manufacture C/U-shaped steel purlins. The production features a PLC control system, servo motor, hydraulic cutting, and automatic spraying technology, ensuring high efficiency, accuracy, and longevity of the production. Additionally, the production can automatically adjust to produce different sizes of steel purlins, thereby increasing production efficiency. The production process involves multiple steps, including uncoiling, forming, cutting, bending, and coiling. Our production can manufacture various specifications of C/U-shaped steel purlins, with high precision, efficiency, and longevity. Furthermore, our equipment is easy to operate, reducing manual intervention and increasing production efficiency. We provide professional after-sales service to ensure that your equipment always maintains good operating status, making your production smoother.

Auto Size Changeable C/U Purlin Roll Forming Machine Product Parameters

| Auto Size Changeable C/U Purlin Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3 even up to 1.5 as per customer

|

| B) Carbon steel Coil | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G350 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Pre-punch / Post Punch (Optional) |

| Forming Station | 14-16 Stations | |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Forged Iron Station (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Requirement |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Pre-cutting | * Post-universal Cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Auto Size Changeable C/U Purlin Roll Forming Machine Application

Our Auto Size Changeable C/U Purlin Roll Forming Machine is a production equipment for construction, used to manufacture various types of C/U-shaped steel purlins. The equipment is widely used in different types of buildings, such as industrial plants, commercial buildings, residential buildings, etc. Here are some common questions and answers to help you better understand our equipment:

- What types of buildings can Auto Size Changeable C/U Purlin Roll Forming Machine be used for?

Our equipment is suitable for various buildings, including industrial plants, commercial buildings, residential buildings, etc. Different types of buildings require different specifications of steel purlins, and our equipment can meet the various needs of customers. - What are the advantages of using Auto Size Changeable C/U Purlin Roll Forming Machine?

Our equipment adopts advanced technology and materials, featuring high precision, efficiency, and longevity. Additionally, the equipment can automatically adjust to produce different sizes of steel purlins, thus improving production efficiency. Using our equipment can save time and costs and increase production efficiency. - Can Auto Size Changeable C/U Purlin Roll Forming Machine produce customized C/U-shaped steel purlins according to specific project requirements?

Yes, our equipment can produce customized C/U-shaped steel purlins according to the specific requirements of the customer’s project, ensuring that the produced steel purlins are accurate in size and meet the customer’s requirements. - What are the installation requirements for Auto Size Changeable C/U Purlin Roll Forming Machine?

Our equipment is easy to install and requires installation in a dry and ventilated indoor environment. Our equipment is also suitable for various types of production workshops. - Is Auto Size Changeable C/U Purlin Roll Forming Machine easy to operate?

Our equipment adopts advanced automation technology, is easy to operate, reduces manual intervention, and improves production efficiency. Additionally, we provide detailed user manuals and operation training to ensure customers can correctly operate the equipment. - Does Auto Size Changeable C/U Purlin Roll Forming Machine require frequent maintenance?

Our equipment adopts high-quality materials and advanced technology, has high stability, and does not require frequent maintenance. We also provide regular inspection and maintenance services to ensure the equipment is always in good working condition. - Is Auto Size Changeable C/U Purlin Roll Forming Machine suitable for batch production or small projects?

Our equipment is suitable for batch production and small projects and can be adjusted according to customer needs to ensure the equipment always meets production requirements. - What is the delivery time for Auto Size Changeable C/U Purlin Roll Forming Machine?

Our equipment is usually available in stock and can be delivered immediately. If the customer requires customized equipment, we will arrange production as soon as the order is confirmed and deliver it in the shortest possible time. - What type of warranty and after-sales service does Auto Size Changeable C/U Purlin Roll Forming Machine provide?

We provide one-year free maintenance and warranty service, as well as comprehensive after-sales service, including equipment installation and commissioning, equipment operation and maintenance training, etc., to ensure that the equipment is always in good working condition. - How does Auto Size Changeable C/U Purlin Roll Forming Machine compare in price and performance to similar equipment on the market?

Our equipment adopts advanced technology and materials, with superior performance and reasonable prices. We also provide customized services, offering personalized solutions according to customer needs. Compared with similar equipment on the market, our equipment has a higher cost-performance ratio and can meet various customer requirements.

what is purlin roll forming machine?

A purlin roll forming machine is a type of industrial machinery used in the manufacturing of purlins. Purlins are structural elements typically used in roof and wall systems of buildings to provide support and stability. They are horizontal beams or girders that span between the primary structural frames of a building and support the roof or wall panels.

The roll forming machine is designed to produce purlins from coils of metal, usually steel or aluminum. It consists of a series of rollers and dies that progressively shape the metal into the desired profile. The machine can be customized to produce different types of purlin profiles, such as C-purlins or Z-purlins, which have distinctive shapes and dimensions.

The process starts with feeding the metal coil into the machine. As the coil passes through the rollers, it is gradually formed into the purlin shape. The rollers apply pressure and bend the metal along its length, creating the required profile. Additional features, such as holes or notches, can also be added during the forming process.

Purlin roll forming machines are typically automated and controlled by computer systems, ensuring precise and efficient production. They can operate at high speeds and handle large volumes of metal coils, making them suitable for mass production in industries such as construction and steel fabrication.

type of purlin roll forming machine

- C-Purlin Roll Forming Machine: This machine is used to manufacture C-shaped purlins. C-purlins have a distinctive shape resembling the letter “C” and are widely used in roof and wall systems.

- Z-Purlin Roll Forming Machine: Z-purlin roll forming machines are designed to produce Z-shaped purlins. Z-purlins have a shape resembling the letter “Z” and are commonly used for secondary structural framing in buildings.

- Sigma Purlin Roll Forming Machine: Sigma purlins have a double-U shape, with a horizontal top and bottom flange connected by a vertical web. Sigma purlin roll forming machines are specialized for manufacturing this specific profile.

- Hat Purlin Roll Forming Machine: Hat purlins, also known as U-channels, have a U-shaped cross-section and are used in various applications, including framing, support structures, and bracing. Hat purlin roll forming machines are designed to produce this profile.

- Multi-profile Purlin Roll Forming Machine: Some roll forming machines are versatile and can produce multiple types of purlin profiles. These machines often feature quick-change systems that allow for easy adjustment between different profiles.

what about c purlin roll forming machine price?

The price of a C-purlin roll forming machine can vary depending on various factors such as the machine’s specifications, quality, manufacturer, and additional features. Additionally, market conditions and geographical location can also influence the price. Therefore, it is challenging to provide an exact price without specific details.

Generally, C-purlin roll forming machines can range in price from several thousand dollars to tens of thousands of dollars. Entry-level machines with basic features and lower production capacities tend to be more affordable, while high-end machines with advanced automation, higher production speeds, and additional capabilities can be more expensive.