If you’re looking for a metal roof panel roll forming machine that is worth your money, then you need to be sure to know what type of machine is best for your needs. These machines are all different in size, speed, and even the cost! Find out how to buy the perfect roll forming machine in this article.

What is a metal roof panel roll forming machine?

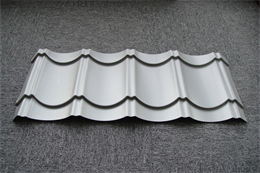

A metal roof panel roll forming machine is a production-line tool used to create custom metal roof panels. Metal roof panels are an important part of modern building construction, and their quality depends on the accuracy and precision of the metal roll forming process.

Metal roof panel roll forming machines use a variety of techniques to form metal sheets into desired shapes and sizes. The most common technique is called “die rolling,” which uses pressure and heat to press the metal into a desired shape. Other techniques used in metal roof panel roll forming machines include “bend rolling” and “cold rolling.”

How to Buy A Metal Roof Panel Roll Forming Machine?

If you are in the market for a metal roof panel roll forming machine, there are a few things you should keep in mind. First, make sure that the machine you choose can accommodate the size of your panels. Second, consider the type of metal roll forming you need. There are three main types of machines: hydraulic, pneumatic and manual. Hydraulic machines use pressurized fluid to form the metal into desired shapes. Pneumatic machines use air pressure to create the same effect. Manual roll forming machines require a person to manually push and pull the metal around until it is formed into the desired shape.

The final consideration when buying a metal roof panel roll forming machine is price. Most machines range in price from $5,000 to $10,000. Once you have determined what type of machine best suits your needs and has a price range that fits within your budget, it’s time to look for a dealer or online retailer that sells these machines.

-

Standing Seam Roof Panel Curving Machine

Standing Seam Roof Panel Curving Machine -

Barrel Corrugated Roll Forming Machine

Barrel Corrugated Roll Forming Machine -

Hydraulic Roof Sheet Curving Machine

Hydraulic Roof Sheet Curving Machine -

Stand Seaming Roof Panel Roll Forming Machine

Stand Seaming Roof Panel Roll Forming Machine -

Downspout Pipe Roll Forming Machine

Downspout Pipe Roll Forming Machine -

Gutter Roll Forming Machine

Gutter Roll Forming Machine -

Trapezoidal Panel Roll Forming Machine

Trapezoidal Panel Roll Forming Machine -

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine -

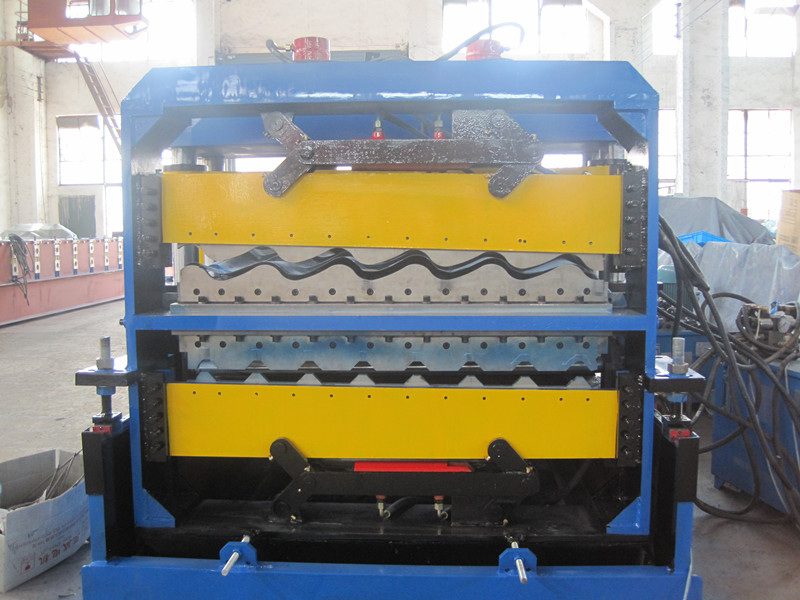

Double Layer Panel Roll Forming Machine

Double Layer Panel Roll Forming Machine

Benefits and Drawbacks of a Metal Roof Panel Roll Forming Machine

A metal roof panel roll forming machine is a great tool for manufacturing metal roof panels. It has a number of benefits, including the ability to quickly produce high-quality, precision-formed metal panels. However, there are also drawbacks to using a metal roof panel roll forming machine. Here are some of the key benefits and drawbacks of using this type of machine:

Benefits of a Metal Roof Panel Roll Forming Machine :

- A metal roof panel roll forming machine is an efficient way to produce high-quality, precision-formed metal panels.

- The machine can quickly produce large amounts of panels, which can be useful if you need to manufacture many panels quickly.

- The machine is easy to operate and requires minimal setup time.

- The machine produces consistent results, which makes it possible to ensure that each panel is accurate in shape and size.

- The machines are relatively affordable, making them an economical option compared to other methods of manufacturing metal roof panels.

Drawbacks of a Metal Roof Panel Roll Forming Machine :

- Some users report that the machines produce harsh sounds when in operation, but this is typically only an issue when the machines are new or if they are not properly maintained over time.

- There are some potential drawbacks associated with using a metal roof panel roll forming machine, including the possibility that the panels can be difficult to install due to their precise dimensions.

Common Problems Associated with using a Metal Roof Panel Roll Forming Machine

There are a few common problems associated with using a metal roof panel rolling forming machine. First, the dies must be properly aligned and calibrated for accurate results. Second, the die surfaces must be smooth so that the plastic sheeting doesn’t cling to them. Third, the machine must be properly maintained in order to prevent die wear and tear, which can lead to inaccurate formed panels. Finally, care must be taken when handling the finished products to avoid causing damage.

Conclusion

Metal roof panel roll forming machines are a great investment for businesses that need to produce large quantities of metal products. With this type of machine, you can quickly and easily form metal panels into any desired shape or size. Not only is a metal roof panel roll forming machine an important tool for businesses in the manufacturing industry, but it can also be used by individuals who need to create custom-made items. If you’re interested in investing in a metal roof panel roll forming machine, be sure to check out our selection and find the perfect model for your needs.

FAQ

What is rolled metal roofing?

Metal roofing – A roofing system made from metal panels or tiles characterized by its high wind/storm resistance, impermeability, and longevity. Metal coils/sheets – Metal roofing starts out as metal coils or sheets, which are then rolled out, cut, and rollformed into panels for installation.