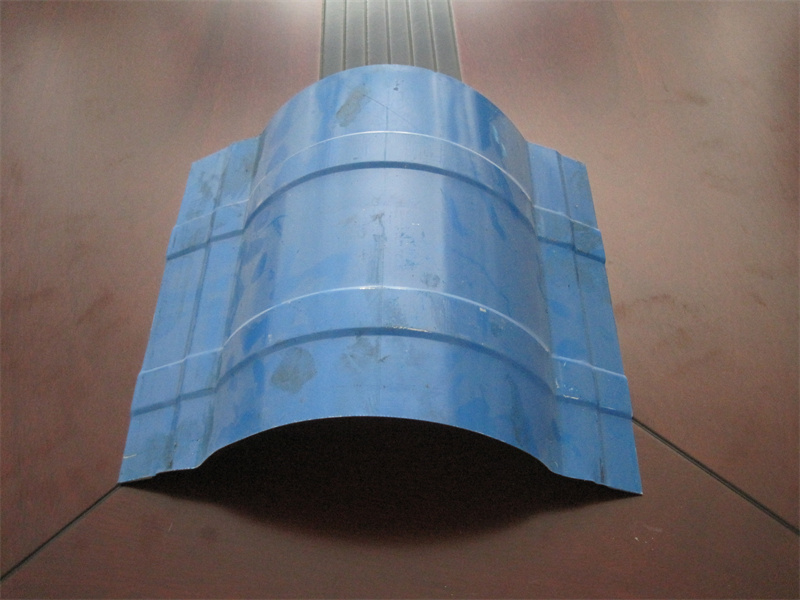

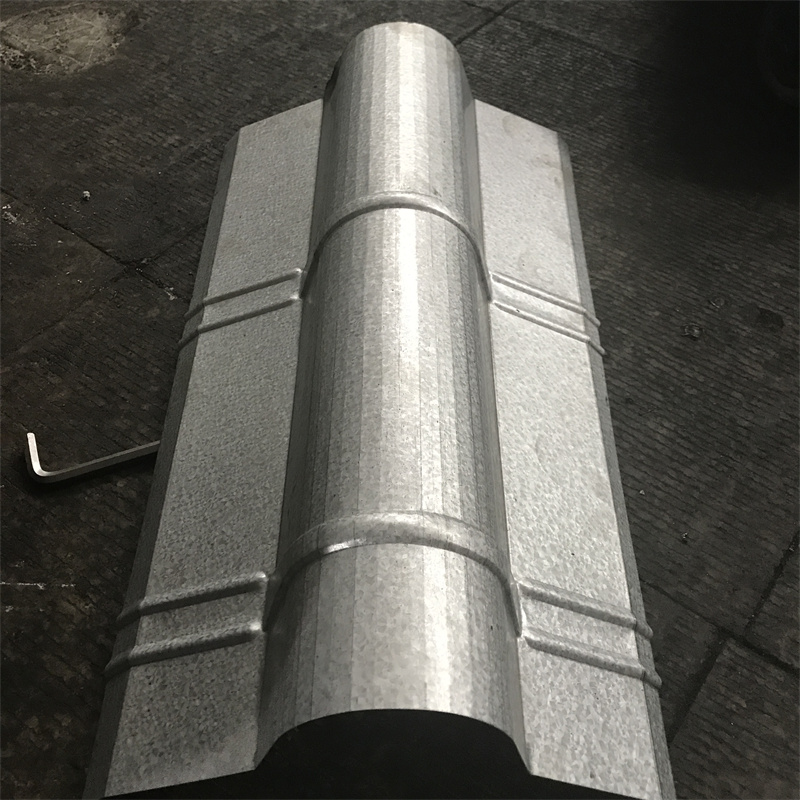

Panel Profile

Ridge Cap roll forming machine Technical Parameter

- Metaldecoiler:manual expanding,passive uncoil, inner Dia. 508mm

- weight capacity of decoiler:3T

- machine stand: welded “工” shape steel

- type of forming machine:wallboard type with chain transmission

- diameter of shaft: ¢75㎜

- chain:16A

- motor power of forming machine:5 KW

- motor of hydraulic station:3KW

- forming speed:10-15 m/min

- roll station:13stations

- material of roller: high-grade 45# steel

- surface of roller coated with chrome 0.05mm thickness

- type of cutting:hydraulic cutting

- material of cutting blade:Cr12mould steel

- heat treatment of cutting blade:HRC58°-60°

- thickness of steel coil:3-0.8mm

- tolerance of length:10±2mm

- transducer: Japan YASKAWA

- computer adopts Panasonic PLC

- computer operating board adopts Touch screen

- Voltage: 380V 3 phase 50HZ or at buyer’s requirement

Ridge Cap roll forming machine Technical Process

Manual decoiler→ feed with guide→ roll forming→ cutting with fixed length→ output with table

Flow chart

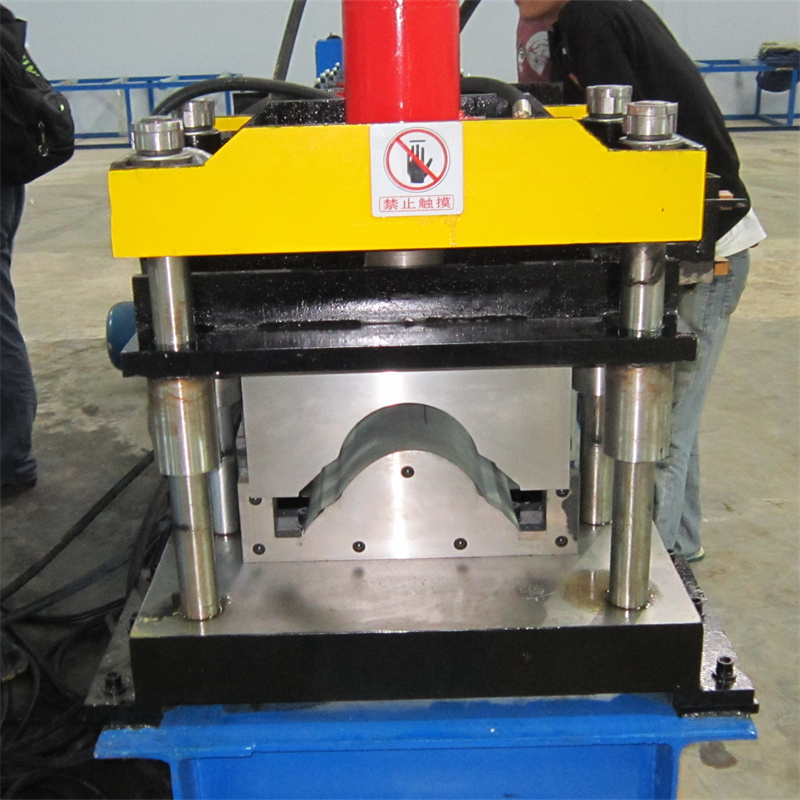

Equipment

Manual decoiler、main forming machine、hydraulic cutting device、hydraulic station、PLC computer control、output table

The time of producing: 30-35days after deposit

what is ridge cap tile roll forming machine?

A ridge cap tile roll forming machine is a specialized piece of equipment used in the construction industry for manufacturing ridge cap tiles. Ridge cap tiles are commonly used in roofing systems to cover the ridge or peak of a roof where two sloping sides meet.

The roll forming machine is designed to produce ridge cap tiles in a continuous process. It typically consists of a series of rollers and tooling that shape the metal or other material into the desired profile. The machine takes flat sheets or coils of material and passes them through a series of roll stations, where the material is gradually formed into the ridge cap tile shape.

The roll forming process involves bending the material along a series of progressively shaped rolls, which gradually transform the flat material into the final ridge cap tile profile. The machine can also incorporate additional operations, such as cutting, punching, and embossing, to create specific features or designs on the ridge cap tiles.

The ridge cap tile roll forming machine is highly efficient and allows for the rapid and precise production of ridge cap tiles in large quantities. It is often used by roofing material manufacturers or contractors to produce ridge cap tiles for various construction projects.

application of roof ridge cap roll forming machine

The roof ridge cap roll forming machine is primarily used for the manufacturing of ridge cap tiles, which serve an essential function in roofing systems. The ridge cap tiles are installed along the ridges or peaks of a roof to provide a protective covering and to enhance the aesthetic appeal of the structure. Here are some applications of the roof ridge cap roll forming machine:

- Residential roofing: The machine is widely used in the production of ridge cap tiles for residential buildings, including houses, apartments, and condominiums. It enables the manufacturing of ridge caps that match the style and design of the roofing system, providing a finished look to the roof.

- Commercial and industrial roofing: The roll forming machine is also utilized in the production of ridge cap tiles for commercial and industrial buildings, such as offices, factories, warehouses, and shopping malls. These structures often require customized ridge cap tiles to meet specific design requirements.

- Roofing material manufacturing: Roofing material manufacturers use the ridge cap roll forming machine to produce ridge cap tiles as part of their product line. They can offer a wide range of ridge cap profiles, materials, and finishes to cater to the diverse needs of the market.

- Roofing contractors: Roofing contractors employ the machine to fabricate ridge cap tiles for their installation projects. It allows them to produce ridge caps on-site or procure them from manufacturers, ensuring a precise fit and consistent quality for the roofing system.

- Roofing renovations and repairs: During roof renovations or repairs, the ridge cap roll forming machine can be utilized to manufacture replacement ridge cap tiles that match the existing ones. This helps maintain the overall visual harmony of the roof while ensuring proper protection against weather elements.

Overall, the roof ridge cap roll forming machine finds application in both the manufacturing and installation stages of roofing projects, enabling efficient production, customization, and maintenance of ridge cap tiles for various types of buildings.

Reviews

There are no reviews yet.