Introduction

In the world of manufacturing and construction, efficiency and precision are crucial factors. When it comes to producing metal studs for various applications, a stud roll forming machine emerges as an essential tool. This article explores the concept of stud roll forming machines, their benefits, key features, types, applications, operational considerations, safety measures, troubleshooting tips, and future trends in the industry.

What is a Stud Roll Forming Machine?

A stud roll forming machine is a specialized equipment used in the metalworking industry to produce metal studs or tracks with consistent shapes and dimensions. It utilizes a continuous bending process to convert metal coils into finished studs or tracks, which are commonly used in construction projects for framing walls, ceilings, and other structural components. The machine can handle various materials such as steel, aluminum, and galvanized steel, depending on the specific requirements.

Advantages of Using a Stud Roll Forming Machine

Using a stud roll forming machine offers several advantages over traditional manufacturing methods. Here are some key benefits:

- High Efficiency: Stud roll forming machines operate at high speeds, allowing for rapid production and increased output compared to manual or semi-automated methods.

- Precision and Consistency: These machines ensure precise dimensions and uniform quality for each produced stud, resulting in improved assembly and structural integrity.

- Cost-effectiveness: By automating the manufacturing process, stud roll forming machines reduce labor costs and minimize material waste, leading to overall cost savings.

- Versatility: Stud roll forming machines can produce a wide range of stud profiles, enabling flexibility to meet specific project requirements.

Key Features of a Stud Roll Forming Machine

A typical stud roll forming machine incorporates several key features to optimize the roll forming process and ensure efficient production. These features include:

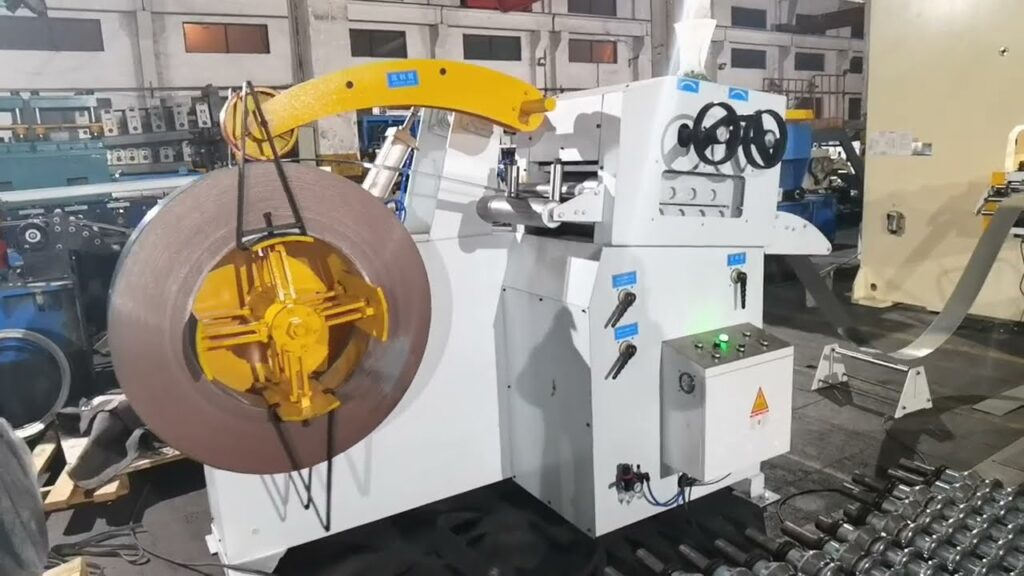

- Uncoiler: This component holds the metal coil and feeds it into the machine for continuous forming.

- Roll Forming Stations: The machine consists of a series of roll forming stations where the metal undergoes sequential bending and shaping.

- Cut-off Mechanism: After forming the desired length of the stud, the machine employs a cut-off mechanism to separate it from the continuous coil.

- Control System: Modern stud roll forming machines incorporate advanced control systems to monitor and adjust various parameters, such as speed, length, and cut-off precision.

- Safety Features: To ensure operator safety, these machines often include safety guards, emergency stop buttons, and interlock systems.

Types of Stud Roll Forming Machines

Stud roll forming machines come in different types, each designed to cater to specific production needs. The common types include:

Single-Sided Stud Roll Forming Machine

The single-sided stud roll forming machine produces studs or tracks with a single profile on one side. It is suitable for applications where one side of the stud will be visible or require specific features.

Double-Sided Stud Roll Forming Machine

The double-sided stud roll forming machine forms studs or tracks with profiles on both sides. This type is ideal for applications where both sides of the stud will be visible or need specific functionalities.

Track Roll Forming Machine

The track roll forming machine specializes in producing tracks used in ceiling systems or other applications where linear support structures are required. These tracks have a unique shape to accommodate suspended ceilings, lighting systems, or partition walls.

Applications of Stud Roll Forming Machines

Stud roll forming machines find widespread applications in the construction and manufacturing industries. Some common uses include:

- Framing systems for residential and commercial buildings

- Partition walls and suspended ceilings

- Roofing and cladding systems

- Drywall and gypsum board assemblies

- Prefabricated structures and modular buildings

Factors to Consider When Choosing a Stud Roll Forming Machine

Selecting the right stud roll forming machine is crucial to meet production requirements effectively. Consider the following factors before making a purchase:

Material Compatibility

Ensure the machine is compatible with the specific metal material you intend to use, such as steel, aluminum, or galvanized steel.

Production Speed

Evaluate the machine’s production speed to ensure it aligns with your desired output and project timelines.

Customization Options

Check if the machine allows for easy adjustment and customization of stud profiles, as different projects may require unique dimensions or features.

Machine Durability

Invest in a machine made from high-quality materials and components to ensure durability and long-term performance.

Maintenance and Support

Consider the availability of technical support, spare parts, and maintenance services to keep your machine running smoothly.

How to Operate a Stud Roll Forming Machine

Operating a stud roll forming machine involves several steps to ensure safe and efficient production:

- Setup: Prepare the machine by loading the appropriate metal coil and adjusting the roll forming stations according to the desired stud profile.

- Feeding: Start the machine and ensure the metal coil feeds smoothly into the forming stations, maintaining proper tension.

- Forming: The metal coil passes through each roll forming station, where it undergoes sequential bending and shaping according to the predefined profile.

- Cut-off: Once the desired stud length is achieved, activate the cut-off mechanism to separate the stud from the continuous coil.

- Collecting and Stacking: Collect the finished studs or tracks, and stack them securely for further processing or transportation.

Safety Measures for Using a Stud Roll Forming Machine

When operating a stud roll forming machine, it is essential to prioritize safety. Follow these safety measures:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection.

- Familiarize yourself with the machine’s safety features and emergency stop buttons.

- Regularly inspect the machine for any damaged or worn-out parts and replace them promptly.

- Ensure proper training and supervision for machine operators to minimize the risk of accidents.

Troubleshooting Common Issues with Stud Roll Forming Machines

Stud roll forming machines may encounter occasional issues during operation. Here are some common problems and their possible solutions:

- Material Jamming: Clear any debris or metal pieces that may cause the material to get stuck in the machine.

- Inconsistent Dimensions: Check and adjust the roll forming stations to ensure proper alignment and bending angles.

- Cut-off Errors: Verify the cut-off mechanism settings and adjust the blade position or replace any dull blades.

- Irregular Speed: Inspect the motor and drive systems for any malfunctions or misalignments that may affect the machine’s speed.

If the troubleshooting steps do not resolve the issues, it is recommended to consult the machine’s manual or contact the manufacturer for further assistance.

Future Trends in Stud Roll Forming Machine Technology

The field of stud roll forming machines continues to evolve, with advancements in technology shaping the future of this industry. Here are some emerging trends to watch for:

- Automation and Robotics: Increasing automation and integration of robotics into stud roll forming machines will enhance production efficiency and reduce the need for manual intervention.

- Smart Manufacturing: Integration of sensors and data analytics will enable real-time monitoring of machine performance, predictive maintenance, and optimization of production processes.

- Energy Efficiency: Manufacturers are focusing on developing energy-efficient stud roll forming machines by employing advanced motor and drive systems, reducing overall energy consumption.

- Enhanced Customization: Future machines will offer even greater flexibility in producing customized stud profiles to meet specific project requirements.

- Improved Safety Features: Ongoing research and development will lead to the implementation of advanced safety features, ensuring the highest levels of operator safety during machine operation.

Conclusion

Stud roll forming machines have revolutionized the production of metal studs and tracks, offering high efficiency, precision, and versatility. By automating the manufacturing process, these machines enable cost-effective production while maintaining consistent quality. When selecting a stud roll forming machine, factors such as material compatibility, production speed, customization options, machine durability, and maintenance support should be considered. Operating the machine safely and following troubleshooting techniques for common issues ensures smooth production. As the industry continues to advance, the future holds exciting possibilities with automation, smart manufacturing, and improved customization in stud roll forming machine technology.

FAQs

Q1. Are stud roll forming machines only used in the construction industry?

No, stud roll forming machines are also used in various manufacturing industries where metal studs or tracks are required, such as automotive, aerospace, and appliance manufacturing.

Q2. Can stud roll forming machines produce different sizes of studs?

Yes, stud roll forming machines can be adjusted to produce studs of various lengths and widths, allowing for customization based on project requirements.

Q3. Are stud roll forming machines difficult to operate?

While operating a stud roll forming machine requires proper training and knowledge, modern machines often come with user-friendly interfaces and control systems, making them relatively easy to operate.

Q4. How long does it take to set up a stud roll forming machine for a new profile?

The setup time for a new profile can vary depending on the complexity of the profile and the operator’s experience. Generally, it can take anywhere from a few minutes to an hour to set up the machine for a new profile.

Q5. Can stud roll forming machines work with different types of metal materials?

Yes, stud roll forming machines can work with various metal materials, including steel, aluminum, and galvanized steel. However, it is essential to ensure the machine is compatible with the specific material you intend to use.