Dans le monde de haute technologie d'aujourd'hui, les équipements de surveillance sont essentiels dans des secteurs allant des télécommunications à la gestion de l'énergie. La demande de boîtiers, de cadres et de panneaux conçus avec précision pour abriter ces équipements est en hausse, et il est nécessaire d'en tenir compte. Équipement de surveillance Machines de formage de rouleaux relèvent le défi. Ces machines rationalisent la production de composants métalliques de haute qualité, garantissant la durabilité, la précision et l'évolutivité qu'exigent les systèmes de surveillance modernes.

Dans cet article, nous allons explorer les les applications, les caractéristiques, les prix, les normes de sécurité et les innovations technologiques de ces machines, et pourquoi Wuxi Sunway Machinery est un nom de confiance dans la fourniture de solutions de profilage de premier ordre. Si vous êtes un fabricant d'équipements de surveillance ou d'infrastructures connexes, ce guide vous fournira des informations utiles sur les avantages d'investir dans une solution de profilage adaptée aux équipements de surveillance.

Qu'est-ce qu'un équipement de surveillance ?

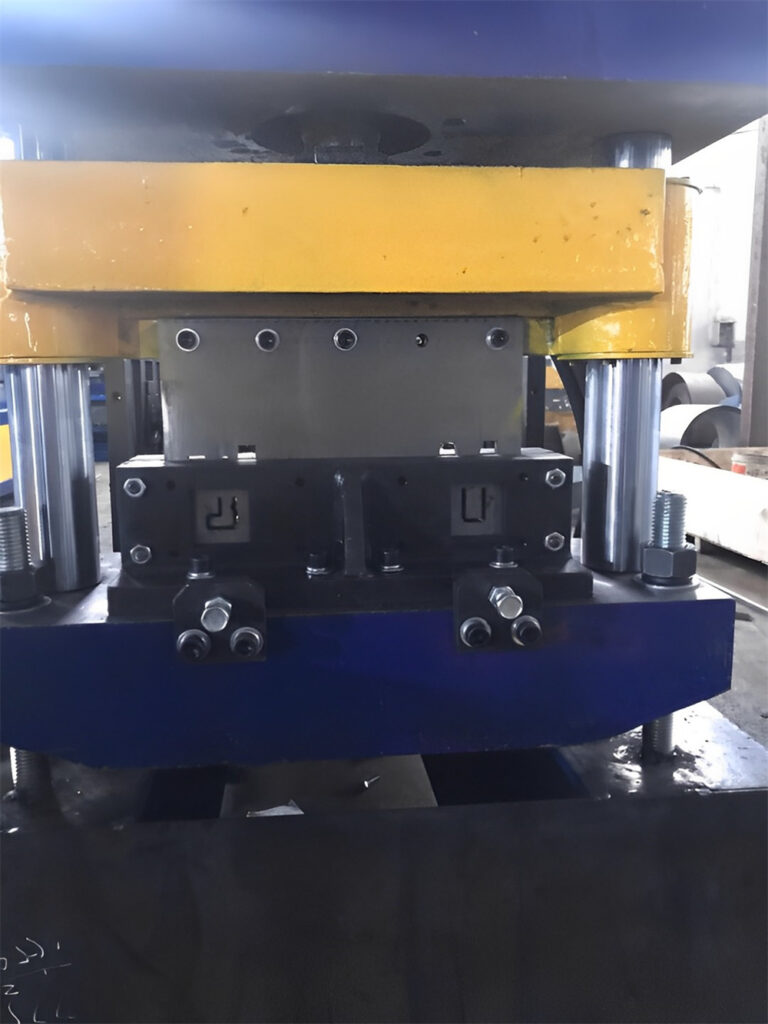

UN Équipement de surveillance Machine de formage de rouleaux est une machine spécialisée conçue pour produire des cadres, des boîtiers, des supports et des panneaux métalliques destinés à abriter des systèmes de surveillance. Ces systèmes comprennent des serveurs, des équipements de télécommunications, des compteurs d'énergie, des panneaux de contrôle, etc. Les machines fonctionnent en alimentant des feuilles ou des bobines de métal dans une série de rouleaux, façonnant progressivement le matériau dans le profil souhaité avec précision et cohérence.

Caractéristiques principales

- Ingénierie de précision: Veille à ce que les profils répondent aux spécifications exactes en matière de compatibilité avec l'équipement de contrôle.

- Outillage personnalisable: Permet la production de modèles uniques adaptés à des systèmes de surveillance spécifiques.

- Production à grande vitesse: Capable de livrer de grandes quantités sans compromettre la qualité.

- Compatibilité avec les matériaux intelligents: Traite des matériaux tels que l'aluminium, l'acier inoxydable et les métaux pré-revêtus.

- Pratiques respectueuses de l'environnement: Réduire les déchets et favoriser l'utilisation de matériaux recyclables.

Applications de l'équipement de surveillance des machines de formage de rouleaux

Ces machines sont essentielles à la fabrication de composants pour les systèmes de surveillance utilisés dans diverses industries. Voici les principales applications dans lesquelles elles se distinguent :

1. Infrastructure de télécommunications

- Cas d'utilisation : Production de boîtiers et de cadres pour les tours de télécommunications, les stations de base et les baies de serveurs.

- Pourquoi c'est essentiel : Garantit des composants durables et résistants aux intempéries, capables de supporter les défis environnementaux.

2. Systèmes de gestion de l'énergie

- Cas d'utilisation : Fabrication de panneaux et de cadres pour les compteurs d'énergie, les supports de panneaux solaires et les infrastructures de réseaux intelligents.

- Pourquoi c'est essentiel : Fournit des composants de précision qui assurent la précision et la fiabilité des systèmes de contrôle de l'énergie.

3. Automatisation industrielle

- Cas d'utilisation : Création d'armoires et de coffrets pour les automates programmables (PLC) et les systèmes SCADA (Supervisory Control and Data Acquisition).

- Pourquoi il est précieux : Protège les équipements sensibles dans les environnements industriels difficiles.

4. Systèmes de gestion des bâtiments (GTB)

- Cas d'utilisation : Production de panneaux de contrôle et de composants métalliques pour les systèmes HVAC (chauffage, ventilation et climatisation) et les systèmes de sécurité.

- Pourquoi c'est pertinent : Assure la compatibilité avec les technologies des bâtiments intelligents et les systèmes basés sur l'IdO.

5. Surveillance des énergies renouvelables

- Cas d'utilisation : Fabrication de supports, d'étriers et de cadres pour les éoliennes, les onduleurs solaires et les systèmes de stockage de batteries.

- Pourquoi c'est bénéfique : Permet de surveiller et de gérer efficacement les systèmes d'énergie renouvelable.

6. Systèmes de transport

- Cas d'utilisation : Fabrication de composants pour la surveillance du trafic, la signalisation ferroviaire et les systèmes de contrôle des aéroports.

- Pourquoi il est unique : Fournit des composants durables et résistants aux intempéries pour les solutions de surveillance en extérieur.

Principales caractéristiques des profileuses à rouleaux de Wuxi Sunway Monitoring Equipment

Lorsqu'il s'agit de solutions de formage par roulage pour les équipements de surveillance, Wuxi Sunway Machinery est un leader en matière d'innovation et de fiabilité. Voici ce qui distingue ses machines :

1. Systèmes d'outillage modulaires

- Ce qu'il offre : Outillage interchangeable pour produire une variété de profils sur une seule machine.

- Pourquoi c'est essentiel :

- Réduit les temps d'arrêt lors des changements d'outils.

- Permet des conceptions personnalisées pour des applications uniques d'équipement de surveillance.

2. Haute précision et exactitude

- Performance : Les tolérances sont aussi faibles que ±0,02 mm, ce qui garantit des dimensions exactes.

- Pourquoi c'est important :

- Garantit une intégration parfaite avec l'équipement de surveillance.

- Réduit les retouches et les déchets de matériaux.

3. Manutention avancée

- Matériaux pris en charge :

- Acier galvanisé

- Acier inoxydable

- Aluminium

- Métaux pré-revêtus

- Pourquoi c'est bénéfique :

- Assure la compatibilité avec les matériaux qui offrent une durabilité et une résistance à la corrosion.

- Soutient les conceptions légères pour les équipements de surveillance modernes.

4. Intégration de l'IdO

- Ce qu'il permet :

- Contrôle en temps réel des performances de la machine et des données de production.

- Alertes de maintenance prédictive pour éviter les temps d'arrêt.

- Pourquoi c'est révolutionnaire :

- Améliore l'efficacité de la production et réduit les coûts opérationnels.

- S'aligne sur les normes de l'industrie 4.0.

5. Fonctionnement à grande vitesse

- Performance : Produit jusqu'à 30-80 mètres de profils par minuteen fonction du matériau et de la complexité de la conception.

- Pourquoi c'est nécessaire :

- Répond aux exigences de volume élevé des projets de systèmes de surveillance à grande échelle.

6. Découpe et poinçonnage intégrés

- Le reportage : Des capacités de découpe et de poinçonnage de précision intégrées au processus de formage par laminage.

- Pourquoi cela change la donne :

- Élimine la nécessité d'un usinage post-production.

- Accélère la livraison de composants prêts à être assemblés.

7. Réduction du bruit et des vibrations

- Ce qui est inclus : Ingénierie avancée pour minimiser le bruit et les vibrations pendant le fonctionnement.

- Pourquoi il est précieux :

- Crée un environnement de travail plus sûr et plus confortable.

- Réduit l'usure des composants de la machine.

Innovations en matière d'équipement de surveillance Technologie de formage de rouleaux

L'industrie du profilage est en constante évolution, les nouvelles technologies améliorant l'efficacité, la précision et la durabilité. Voici quelques-unes des innovations les plus intéressantes en matière de Équipement de surveillance Machines de formage de rouleaux:

1. Contrôle de la qualité par l'IA

- Ce qu'il fait : Utilise l'intelligence artificielle pour analyser les données de production et détecter les défauts en temps réel.

- Pourquoi c'est révolutionnaire :

- Améliore la qualité des produits en identifiant les problèmes à un stade précoce.

- Réduit les déchets et les reprises.

2. Technologie des jumeaux numériques

- Ce qu'il simule : Modèles virtuels de la machine et du processus de production pour optimiser les réglages avant la production réelle.

- Pourquoi c'est utile :

- Réduit le temps d'installation et les ajustements par tâtonnement.

- Garantit une qualité constante dès le premier passage.

3. Capacité multi-profils

- Ce qu'il permet : Produit plusieurs profils simultanément, ce qui augmente la vitesse de production et la polyvalence.

- Pourquoi c'est bénéfique :

- Appuie la conception d'équipements de surveillance complexes.

- Réduit les délais de production pour les projets de grande envergure.

4. Applications de revêtements écologiques

- Ce qui est inclus : Systèmes d'application de revêtements protecteurs ou décoratifs pendant le processus de formage par laminage.

- Pourquoi c'est essentiel :

- Améliore la durabilité et l'esthétique des pièces métalliques.

- S'aligne sur les efforts déployés par l'industrie en faveur de la fabrication durable.

5. Systèmes de maintenance intelligents

- Ce qu'il apporte : Alertes de maintenance prédictive basées sur les données IoT et les algorithmes d'apprentissage automatique.

- Pourquoi c'est efficace :

- Prévient les temps d'arrêt non planifiés.

- Prolonge la durée de vie de la machine.

Prix des équipements de surveillance Machines de formage de rouleaux

Le coût d'un Équipement de surveillance Machine de formage de rouleaux dépend de ses caractéristiques, de sa capacité et de son niveau de personnalisation. Vous trouverez ci-dessous un guide général des prix pour 2025 :

| Type de machine | Capacités | Fourchette de prix (USD) |

|---|---|---|

| Machines standard | Profilage de base pour l'équipement de surveillance | 150,000–150,000–150,000–400,000 |

| Machines avancées | Systèmes de découpe et de poinçonnage intégrés à grande vitesse | 400,000–400,000–400,000–1,000,000 |

| Machines entièrement personnalisables | IoT, outillage modulaire et capacités multi-profils | 1,000,000–1,000,000–1,000,000–2,500,000 |

Pour obtenir des informations détaillées sur les prix et les options de financement, veuillez contacter Wuxi Sunway Machinery.

Pourquoi choisir Wuxi Sunway Machinery pour la surveillance des machines de formage de rouleaux ?

Wuxi Sunway Machinery est un leader mondial de la technologie de formage par roulage, offrant des solutions inégalées aux fabricants d'équipements de surveillance. Voici pourquoi des clients du monde entier lui font confiance :

- Une expertise reconnue : Des décennies d'expérience dans la conception et la fourniture de machines de profilage à hautes performances.

- Une portée mondiale : Des machines qui fonctionnent avec succès en Asie, en Europe, en Amérique et ailleurs.

- Axé sur l'innovation : Des fonctionnalités telles que l'intégration IoT, le contrôle qualité alimenté par l'IA et l'outillage modulaire distinguent leurs machines.

- Engagement en matière de développement durable : Des machines optimisées pour une efficacité énergétique et une production respectueuse de l'environnement.

- Soutien global : De la consultation initiale à l'installation et au service après-vente, Wuxi Sunway garantit une expérience sans faille.

FAQ sur le contrôle des équipements Machines de formage de rouleaux

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | Acier galvanisé, acier inoxydable, aluminium et métaux pré-revêtus. |

| Quelle est la vitesse de production de ces machines ? | Jusqu'à 30-80 mètres par minuteen fonction du matériau et de la complexité du profil. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Oui, l'outillage modulaire permet de réaliser des profils sur mesure pour des systèmes de surveillance uniques. |

| Ces machines sont-elles dotées de dispositifs de sécurité ? | Oui, ils sont équipés d'arrêts d'urgence, de protections et de systèmes de réduction du bruit. |

| Ces machines sont-elles respectueuses de l'environnement ? | Oui, ils sont équipés de moteurs à haut rendement énergétique et réduisent les déchets matériels. |

| Quelles sont les industries qui bénéficient de ces machines ? | Télécommunications, gestion de l'énergie, automatisation industrielle et systèmes de transport. |

| Quelle est la période de garantie habituelle ? | Les machines sont généralement livrées avec un Garantie de 1 à 2 ansavec des options étendues disponibles. |

| Ces machines peuvent-elles fonctionner avec des systèmes IdO ? | Absolument ! L'intégration de l'IdO permet une surveillance en temps réel et une maintenance prédictive. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 150 000 à 150 000 à 150 000 à 2 500 000selon les caractéristiques et les options de personnalisation. |

Études de cas réels : Surveillance de l'équipement Machines de formage de rouleaux en action

La polyvalence et l'efficacité des Équipement de surveillance Machines de formage de rouleaux ont transformé les processus de fabrication dans diverses industries. Voici quelques exemples de réussites concrètes qui démontrent leur impact :

1. Étude de cas : Fabricant d'équipements de télécommunications

- Client : Un leader mondial dans la production d'infrastructures pour les réseaux 5G.

- Défi : L'entreprise avait besoin d'une profileuse capable de produire des boîtiers légers mais durables pour les tours de télécommunications.

- Solution : Wuxi Sunway Machinery a fourni une machine de profilage sur mesure avec des capacités de découpe et de poinçonnage intégrées.

- Résultats :

- Réduction du temps de production de 40%, permettant une livraison plus rapide aux clients.

- Amélioration de la qualité des produits grâce à des tolérances précises, garantissant la compatibilité avec l'équipement 5G.

- Diminution des déchets matériels de 15%, conformément aux objectifs de durabilité de l'entreprise.

2. Étude de cas : Fournisseur de systèmes de gestion de l'énergie

- Client : Fabricant européen de compteurs intelligents et de panneaux de contrôle de l'énergie.

- Défi : L'entreprise avait besoin d'un outillage modulaire pour produire différents modèles de panneaux pour différentes applications.

- Solution : Wuxi Sunway a livré une profileuse avec des systèmes d'outillage interchangeables.

- Résultats :

- Augmentation de la flexibilité de la production, ce qui permet à l'entreprise de répondre aux besoins divers des clients.

- Réduction des temps d'arrêt lors des changements d'outils grâce à 50%.

- Elle a permis l'utilisation de matériaux recyclables, soutenant ainsi des pratiques de production respectueuses de l'environnement.

3. Étude de cas : Fournisseur d'automatisation industrielle

- Client : Fournisseur de boîtiers pour automates et systèmes SCADA en Amérique du Nord.

- Défi : L'entreprise avait besoin de boîtiers capables de résister à des conditions industrielles extrêmes, notamment à des températures élevées et à l'humidité.

- Solution : Wuxi Sunway a fourni une machine de profilage capable de traiter l'acier inoxydable et l'aluminium avec des finitions de surface avancées.

- Résultats :

- Les boîtiers produits sont résistants à la corrosion, ce qui prolonge la durée de vie des produits.

- Il a obtenu une qualité constante sur de grandes séries de production, en respectant les normes strictes de l'industrie.

- Réduction des coûts d'exploitation grâce à l'optimisation de l'utilisation des matériaux.

4. Étude de cas : Systèmes de surveillance des énergies renouvelables

- Client : Entreprise spécialisée dans les systèmes de surveillance des parcs solaires et des éoliennes.

- Défi : Le client avait besoin de cadres légers et résistants aux intempéries pour des applications extérieures.

- Solution : Wuxi Sunway a conçu une machine qui traite l'aluminium et les métaux pré-revêtus pour une meilleure durabilité.

- Résultats :

- Augmentation de l'efficacité de la production par 30%.

- Fourniture de cadres conformes aux normes internationales en matière d'équipements pour les énergies renouvelables.

- Renforcement de la position de l'entreprise en tant que fournisseur de premier plan dans le secteur des énergies renouvelables.

Tendances du marché mondial des équipements de surveillance des machines de formage de rouleaux en 2025

Alors que les industries du monde entier adoptent les technologies intelligentes et l'automatisation, la demande de composants d'équipements de surveillance évolue. Voici les principales tendances du marché qui stimulent la croissance des composants de l'équipement de surveillance. Équipement de surveillance Machines de formage de rouleaux:

1. L'essor de l'adoption de l'IdO

- Tendance : L'intégration d'appareils IoT dans des secteurs tels que les télécommunications, l'énergie et l'industrie manufacturière fait naître le besoin de boîtiers précis et fiables.

- Impact sur les machines :

- Les machines doivent produire des composants avec des tolérances serrées pour abriter des équipements électroniques sensibles.

- Les machines de profilage compatibles avec l'IdO deviennent essentielles pour le suivi de la production en temps réel.

2. L'accent mis sur le développement durable

- Tendance : Les gouvernements et les entreprises accordent la priorité aux pratiques de fabrication durables afin de réduire l'impact sur l'environnement.

- Impact sur les machines :

- Les machines doivent favoriser l'utilisation de matériaux recyclables tels que l'aluminium et l'acier prélaqué.

- Les moteurs et les flux de travail économes en énergie deviennent des caractéristiques standard.

3. Demande accrue de systèmes modulaires

- Tendance : Les systèmes modulaires et personnalisables sont de plus en plus populaires dans des secteurs tels que la gestion de l'énergie et l'automatisation industrielle.

- Impact sur les machines :

- Les machines de profilage doivent offrir un outillage modulaire pour produire divers profils sur une seule ligne de production.

- La flexibilité est un argument de vente essentiel pour les fabricants qui répondent aux besoins dynamiques du marché.

4. Expansion des réseaux 5G

- Tendance : Le déploiement mondial des réseaux 5G stimule la demande d'infrastructures de télécommunications.

- Impact sur les machines :

- Les machines doivent produire des composants légers et résistants à la corrosion pour les installations de télécommunications extérieures.

- Les capacités de production à grande vitesse sont essentielles pour respecter les délais serrés des projets.

5. Croissance des projets d'énergie renouvelable

- Tendance : Le secteur des énergies renouvelables se développe rapidement, nécessitant des systèmes de surveillance pour les fermes solaires, les éoliennes et les unités de stockage de batteries.

- Impact sur les machines :

- Les machines doivent produire des composants durables et résistants aux intempéries pour des applications extérieures.

- La précision et la qualité sont essentielles pour garantir la fiabilité des systèmes d'énergie renouvelable.

Normes de sécurité pour les équipements de surveillance Machines de formage de rouleaux

La sécurité est une priorité absolue dans l'industrie moderne. Équipement de surveillance Machines de formage de rouleaux sont conçus pour répondre à des normes de sécurité strictes. Voici les principales caractéristiques de sécurité et les mesures de conformité :

1. Marquage CE

- Région : L'Europe

- Exigence : Veiller à ce que les machines soient conformes aux normes européennes en matière de sécurité, de santé et de protection de l'environnement.

- Caractéristiques de la machine : Les machines Wuxi Sunway sont conformes à la réglementation CE, ce qui garantit la tranquillité d'esprit des fabricants européens.

2. Conformité à l'OSHA

- Région : ÉTATS-UNIS

- Exigence : Protège les travailleurs contre les risques sur le lieu de travail dans le cadre de l'administration de la sécurité et de la santé au travail (Occupational Safety and Health Administration).

- Caractéristiques de la machine : Comprend les systèmes d'arrêt d'urgence, les dispositifs de protection et les technologies de réduction du bruit.

3. Certification ISO 45001

- Région : Mondial

- Exigence : Systèmes de gestion de la santé et de la sécurité au travail.

- Caractéristiques de la machine : Wuxi Sunway conçoit ses machines de manière à minimiser les risques pour l'opérateur grâce à des commandes ergonomiques et à des processus automatisés.

4. Rideaux légers

- Ce qu'il fait : Détecte les objets ou le personnel dans les zones dangereuses et interrompt automatiquement les opérations de la machine.

- Pourquoi c'est essentiel : Prévient les accidents sans interrompre les flux de production.

5. Protections et verrouillages de sécurité

- Ce qui est inclus : Barrières de protection autour des pièces mobiles et systèmes de verrouillage qui empêchent la machine de fonctionner si toutes les protections ne sont pas en place.

- Pourquoi c'est efficace : Réduit le risque de blessures causées par des erreurs humaines ou des dysfonctionnements mécaniques.

Pratiques de durabilité dans la fabrication d'équipements de surveillance

Les industries donnent la priorité à la responsabilité environnementale, Équipement de surveillance Machines de formage de rouleaux s'adaptent pour soutenir les pratiques durables. Voici comment :

1. Efficacité énergétique

- Fonctionnalité : Les moteurs à économie d'énergie et les flux de travail optimisés réduisent la consommation d'électricité.

- Impact : La réduction de la consommation d'énergie minimise l'empreinte carbone des opérations de fabrication.

2. Réduction des déchets matériels

- Fonctionnalité : Les systèmes de découpe et de formage de précision minimisent les rebuts pendant la production.

- Impact : Réduit les besoins en matières premières et préserve les ressources naturelles.

3. Soutien aux matériaux recyclables

- Fonctionnalité : Les machines sont conçues pour traiter des matériaux tels que l'aluminium, qui peut être recyclé indéfiniment.

- Impact : Favorise les pratiques d'économie circulaire et réduit les déchets mis en décharge.

4. Composants à longue durée de vie

- Fonctionnalité : Les composants durables nécessitent des remplacements moins fréquents, ce qui réduit la consommation globale de matériaux.

- Impact : Prolonge le cycle de vie de l'équipement de surveillance, réduisant ainsi l'impact sur l'environnement.

FAQ sur le contrôle des équipements Machines de formage de rouleaux

| Question | Réponse |

|---|---|

| Ces machines peuvent-elles produire des profils personnalisés ? | Oui, les machines de Wuxi Sunway sont dotées d'un outillage modulaire pour des conceptions uniques. |

| Quels matériaux ces machines peuvent-elles traiter ? | Acier galvanisé, acier inoxydable, aluminium et métaux pré-revêtus. |

| Ces machines sont-elles respectueuses de l'environnement ? | Oui, ils sont équipés de moteurs à haut rendement énergétique et réduisent les déchets matériels. |

| Ces machines répondent-elles aux normes de sécurité internationales ? | Absolument ! Ils sont conformes aux certifications CE, OSHA et ISO 45001. |

| Ces machines sont-elles adaptées à une production en grande quantité ? | Oui, ils peuvent produire jusqu'à 80 mètres de profils par minute. |

| Quelle est la période de garantie de ces machines ? | Généralement 1 à 2 ansavec possibilité d'extension de garantie. |

| Ces machines peuvent-elles s'intégrer à des systèmes IdO ? | Oui, les fonctions compatibles avec l'IdO permettent une surveillance en temps réel et une maintenance prédictive. |

| Quelles sont les industries qui bénéficient de ces machines ? | Télécommunications, gestion de l'énergie, automatisation industrielle et énergies renouvelables. |

| Quelle est la gamme de prix de ces machines ? | Les prix varient de 150 000 à 150 000 à 150 000 à 2 500 000en fonction des caractéristiques et de la personnalisation. |

Conclusion : L'avenir de la fabrication d'équipements de surveillance

Équipement de surveillance Machines de formage de rouleaux façonnent l'avenir de la précision et de l'efficacité dans la fabrication. Dotées de caractéristiques de pointe, de pratiques durables et de normes de sécurité rigoureuses, ces machines sont essentielles pour répondre aux exigences d'un marché en évolution rapide.

Prêt à investir dans l'avenir de la production d'équipements de surveillance ? Associez-vous à l'équipe de Wuxi Sunway Machinery et découvrez leurs solutions de pointe. Ensemble, révolutionnons la fabrication, un profil à la fois.