Imagine a workshop bustling with activity. Sheets of metal are fed into whirring machines, emerging moments later as precisely formed channels and beams. This is the domain of the electric cabinet frame forming machine, the unsung hero behind the sturdy enclosures that house critical electrical components in countless industries.

In this comprehensive guide, we’ll delve into the world of electric cabinet frame forming machines, exploring their functions, types, applications, and the nitty-gritty details like suppliers and pricing. We’ll answer all your burning questions (pun intended for our electrician friends!) and equip you with the knowledge to make informed decisions for your enclosure production needs.

Function of Electric Cabinet Frame Forming Machine

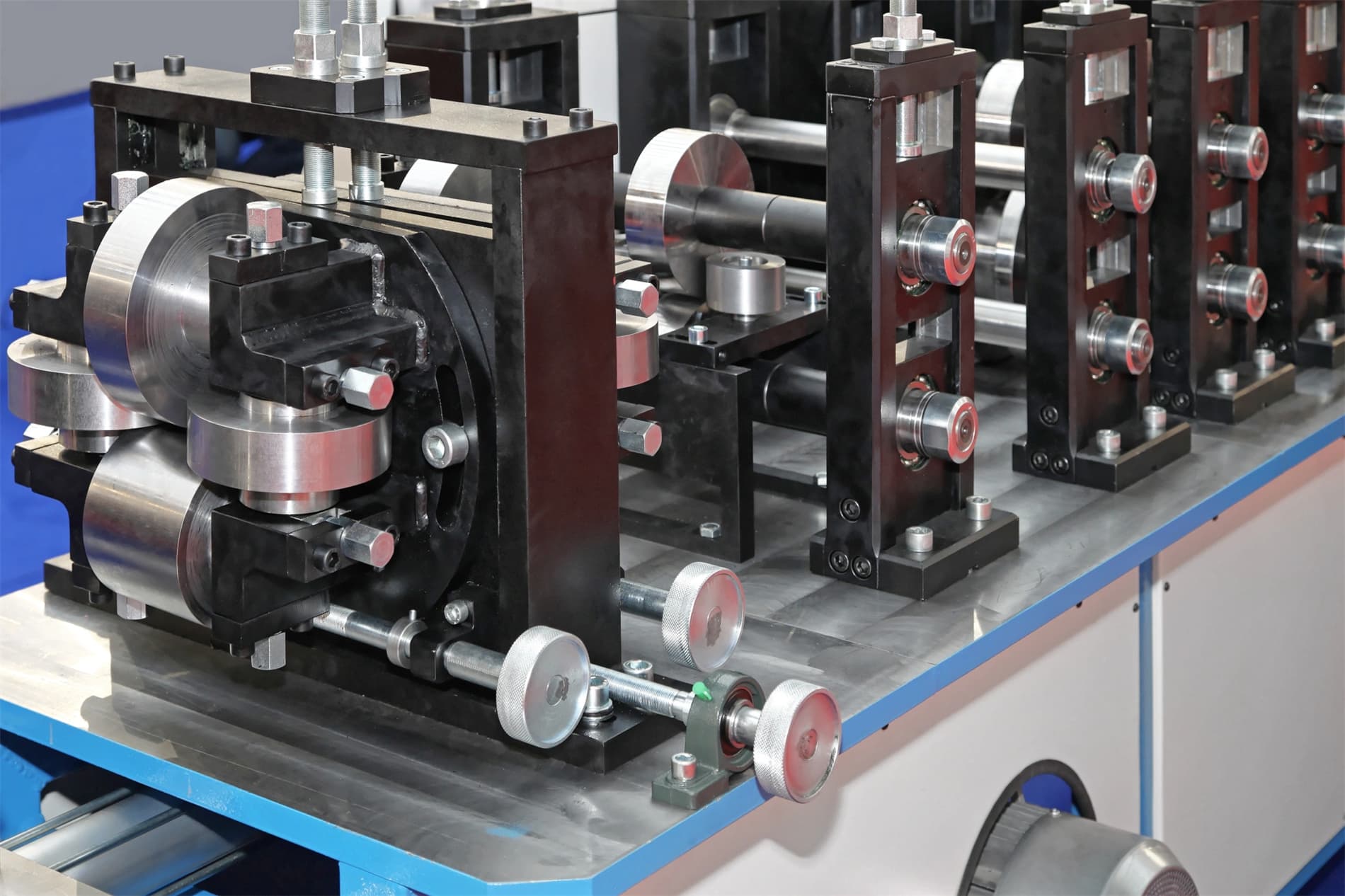

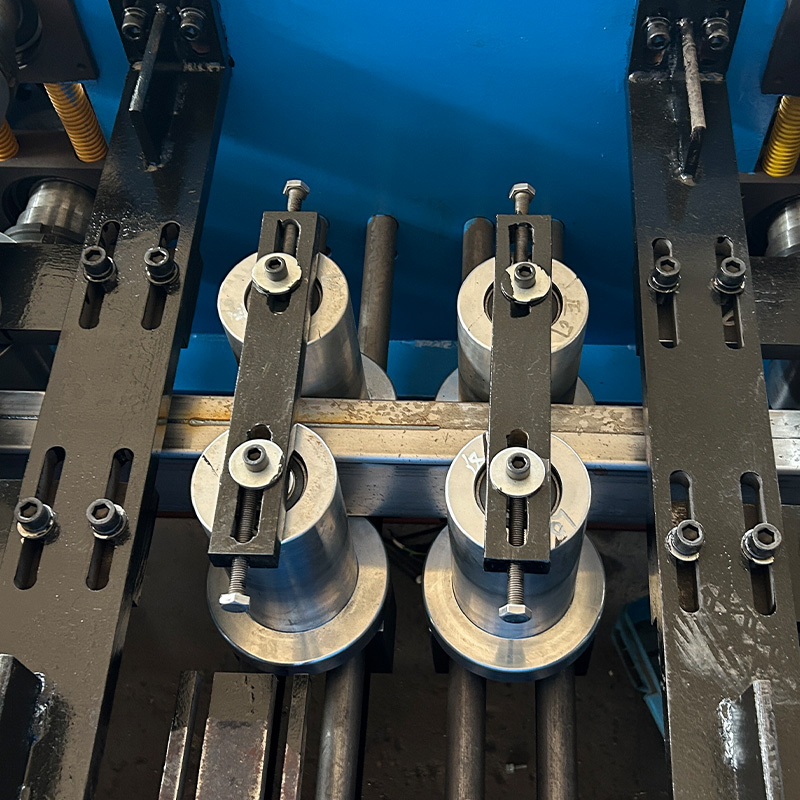

Electric cabinet frame forming machines are marvels of metal manipulation. Their primary function is to transform flat sheets of metal, typically steel or aluminum, into complex shapes that form the frames of electrical cabinets. These machines achieve this using a series of precisely machined rollers that bend and fold the metal sheet progressively, mimicking a three-dimensional origami master at lightning speed.

Think of it this way: Imagine a rolling pin that can morph into different shapes as it presses down on dough. That’s essentially what these rollers do, transforming flat metal into the intricate profiles needed for cabinet frames.

Types of Electric Cabinet Frame Forming Machines

The world of electric cabinet frame forming machines isn’t a one-size-fits-all affair. There are two main categories to consider:

- Roll Forming Machines: These workhorses are the most common type. They utilize a series of sequential rollers that progressively bend the sheet metal into the desired profile. Imagine a long assembly line where each station shapes the metal a little further until the final form is achieved.

- Punching and Bending Machines: These machines combine two processes: punching holes for mounting components and attachments, and bending the metal into shape. This two-in-one approach can streamline production, but may not offer the same level of customization as dedicated roll forming machines.

Choosing the right type depends on your specific needs. For high-volume production of standard cabinet sizes, roll forming machines are the way to go. If you require more flexibility in frame design with hole placements, a punching and bending machine might be a better fit.

Here’s a handy table to summarize the key differences:

| Feature | آلة تشكيل لفة | Punching and Bending Machine |

|---|---|---|

| Function | Bends metal sheet into desired profile | Punches holes and bends metal sheet into desired profile |

| Process | Sequential rollers progressively shape the metal | Punching unit creates holes, followed by bending stations |

| التخصيص | High for profile shapes, may require separate punching for holes | Moderate for profile shapes, hole placement is pre-determined |

| Production Speed | Generally faster for high-volume production | Slower due to additional punching step |

| التطبيقات | Mass production of standard cabinets | Production of cabinets with specific hole patterns |

Let’s delve a little deeper into some additional considerations:

- Material Compatibility: Ensure the machine is compatible with the type of metal you plan to use (steel, aluminum, etc.).

- Profile Complexity: Consider the level of detail and complexity required in your cabinet frames. Roll forming machines can handle a wider range of profiles.

- Production Volume: If you anticipate high-volume production, a roll forming machine’s speed and efficiency might be crucial.

Applications of Electric Cabinet Frame Forming Machines

Electric cabinet frame forming machines are the silent partners in a wide range of industries that rely on electrical enclosures. Here are some prominent examples:

- Industrial Automation: Control panels, motor control centers, and other electrical components housed in enclosures play a vital role in factory automation.

- Telecommunications: Telecom equipment and servers require robust enclosures for protection and proper functioning.

- Power Distribution: Electrical panels and switchgear that manage power flow within buildings necessitate sturdy enclosures.

- Machine Building: Industrial machinery often incorporates electrical components housed in custom-designed enclosures.

- Renewable Energy: Solar inverters, wind turbine control systems, and other renewable energy equipment rely on protective enclosures.

The applications extend far beyond this list, encompassing any industry that utilizes electrical components requiring safe and secure housing.

Advantages of Electric Cabinet Frame Forming Machines

Investing in an electric cabinet frame forming machine can bring several advantages to your operation:

- Increased Efficiency: Compared to manual bending or outsourcing frame production, these machines offer significant speed and consistency.

- Enhanced Accuracy: Precisely machined rollers ensure consistent and repeatable frame dimensions, minimizing errors and rework.

- Reduced Labor Costs: Automating frame production frees up manpower for other tasks, leading to potential cost savings.

- Improved Quality (continued): resulting in higher quality enclosures that better protect electrical components.

- Material Savings: Efficient use of metal minimizes waste compared to manual cutting and bending methods.

- Design Flexibility: Many roll forming machines can handle a variety of profile shapes, allowing for some customization in frame design.

- Increased Production Capacity: The ability to produce frames in-house can enable you to scale up production and meet higher demands.

Of course, no piece of equipment is perfect. Here’s a balanced view by considering some potential drawbacks:

-

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

آلة التشكيل بالدلفنة لكروم العنب

آلة التشكيل بالدلفنة لكروم العنب -

آلة تشكيل لفة Sigma Purlin قابلة للتغيير ذات الحجم الأوتوماتيكي

آلة تشكيل لفة Sigma Purlin قابلة للتغيير ذات الحجم الأوتوماتيكي -

آلة التشكيل بالدلفنة لإطار الخزانة الكهربائية

آلة التشكيل بالدلفنة لإطار الخزانة الكهربائية -

آلة التشكيل بالدلفنة للسكك الحديدية Din

آلة التشكيل بالدلفنة للسكك الحديدية Din -

اثنين من موجات الطريق السريع الدرابزين آلة

اثنين من موجات الطريق السريع الدرابزين آلة

Disadvantages of Electric Cabinet Frame Forming Machines

- Initial Investment: Electric cabinet frame forming machines can be a significant upfront investment, especially for high-end models.

- Floor Space Requirements: These machines have a footprint, so ensure you have adequate space for installation and operation.

- Maintenance Needs: Regular maintenance is crucial to ensure optimal performance and longevity. Factor in routine maintenance costs.

- Skill Requirement: While operation may not be overly complex, some level of training is necessary to operate the machine safely and efficiently.

- Limited Customization: While some machines offer profile flexibility, they may not be suitable for highly customized or intricate frame designs.

The decision to invest in an electric cabinet frame forming machine hinges on weighing the advantages against the potential drawbacks. Consider your production volume, budget, and specific needs to make an informed choice.

Suppliers and Pricing of Electric Cabinet Frame Forming Machines

The landscape of electric cabinet frame forming machine suppliers is vast, with manufacturers from around the globe. Here’s a glimpse into what you might encounter:

- Chinese Manufacturers: China is a major player, offering a wide range of machines at competitive prices. Be sure to research quality and reputation before committing.

- European Manufacturers: European manufacturers often focus on high-end machines known for precision, durability, and advanced features, but expect a premium price tag.

- North American Manufacturers: North American suppliers offer a good balance between quality, features, and price. Look for established brands with reliable after-sales support.

Here’s a table with a sampling of suppliers and estimated price ranges to give you a general idea (please note that prices can vary depending on features, capacity, and exchange rates):

| Supplier | Location | Price Range (USD) |

|---|---|---|

| Bosch Rexroth | Germany | $50,000 – $200,000+ |

| Amada Machinery America | Japan (US Subsidiary) | $30,000 – $150,000+ |

| Jiangsu Bosj Science and Technology Co., Ltd. | China | $10,000 – $50,000 |

| Yawei Machinery Group | China | $15,000 – $75,000 |

| Davi North America | Italy (US Subsidiary) | $40,000 – $100,000+ |

Remember, these are just a few examples. It’s crucial to conduct thorough research to find reputable suppliers that offer machines that align with your specific needs and budget.

Here are some additional tips for finding the right supplier:

- Read customer reviews and industry publications.

- Compare features and specifications of different models.

- Request quotes from multiple suppliers.

- Factor in after-sales support and availability of spare parts.

- Consider visiting a showroom or attending industry trade shows to see machines in action.

التعليمات

Now that we’ve covered the essential aspects of electric cabinet frame forming machines, let’s address some frequently asked questions:

Q: What is the typical lifespan of an electric cabinet frame forming machine?

A: With proper maintenance, a well-built electric cabinet frame forming machine can last for decades. Factors like usage frequency and maintenance practices will influence its longevity.

Q: Can these machines handle different metal thicknesses?

A: Yes, most machines have a range of compatible metal thicknesses. The specific range will depend on the machine model and its capabilities.

Q: Do I need a skilled operator to run an electric cabinet frame forming machine?

A: While the operation may not be overly complex, some training is necessary for safe and efficient use. The level of training required can vary depending on the specific machine.

Q: Are there any safety precautions to consider when using these machines?

A: Absolutely. Always follow the manufacturer’s safety guidelines, which typically include wearing proper safety gear and adhering to lockout/tagout procedures during maintenance.