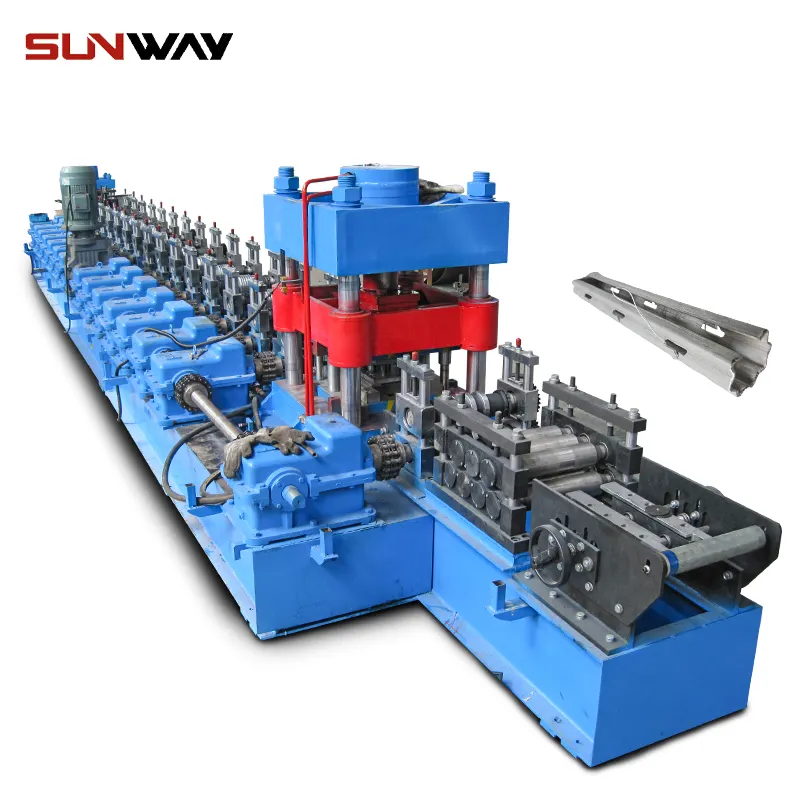

تُستخدم ماكينة تشكيل عمود العنب في مزارع الكروم في مزارع الكروم والبساتين لإنتاج الأوتاد والأعمدة. عادة، يبلغ سمك عمود العنب 1.5-2 مم. لذا فقد اعتمدنا نظام قيادة علبة التروس للتأكد من أن آلتنا تعمل بثبات وبعمر تشغيلي طويل.

تُستخدم أعمدة الكروم لأكوام العنب في مزارع الكروم والحدائق. بالمقارنة مع الأكوام الأسمنتية، فإن أكوام العنب المعدنية سهلة التركيب وتكاليف العمالة منخفضة. تُستخدم الثقوب على شكل حرف Z في المنتج لضبط ارتفاع السلك مع نمو العنب. استخدام الفولاذ المجلفن بطبقة سميكة من الزنك المضاد للتآكل، لأنه الأكثر شعبية من حيث التكلفة التجارية في العالم.

يمكن لآلة تشكيل أعمدة الكرم الذكية الخاصة بنا أن تصنع أعمدة مختلفة وفقًا لملفك الشخصي. يمكن تحقيق عملية الفك، والتغذية المؤازرة، والتثقيب، والتثقيب، والتشكيل بالدلفنة، والقطع وما إلى ذلك تلقائيًا على خط واحد.

نحن نقدم حلولًا مختلفة وفقًا لرسم العملاء والتسامح والميزانية ، ونقدم خدمة احترافية فردية ، وقابلة للتكيف مع جميع متطلباتك. بغض النظر عن الخط الذي تختاره ، ستضمن لك جودة ماكينات صنواي حصولك على ملفات تعريف وظيفية بشكل مثالي.

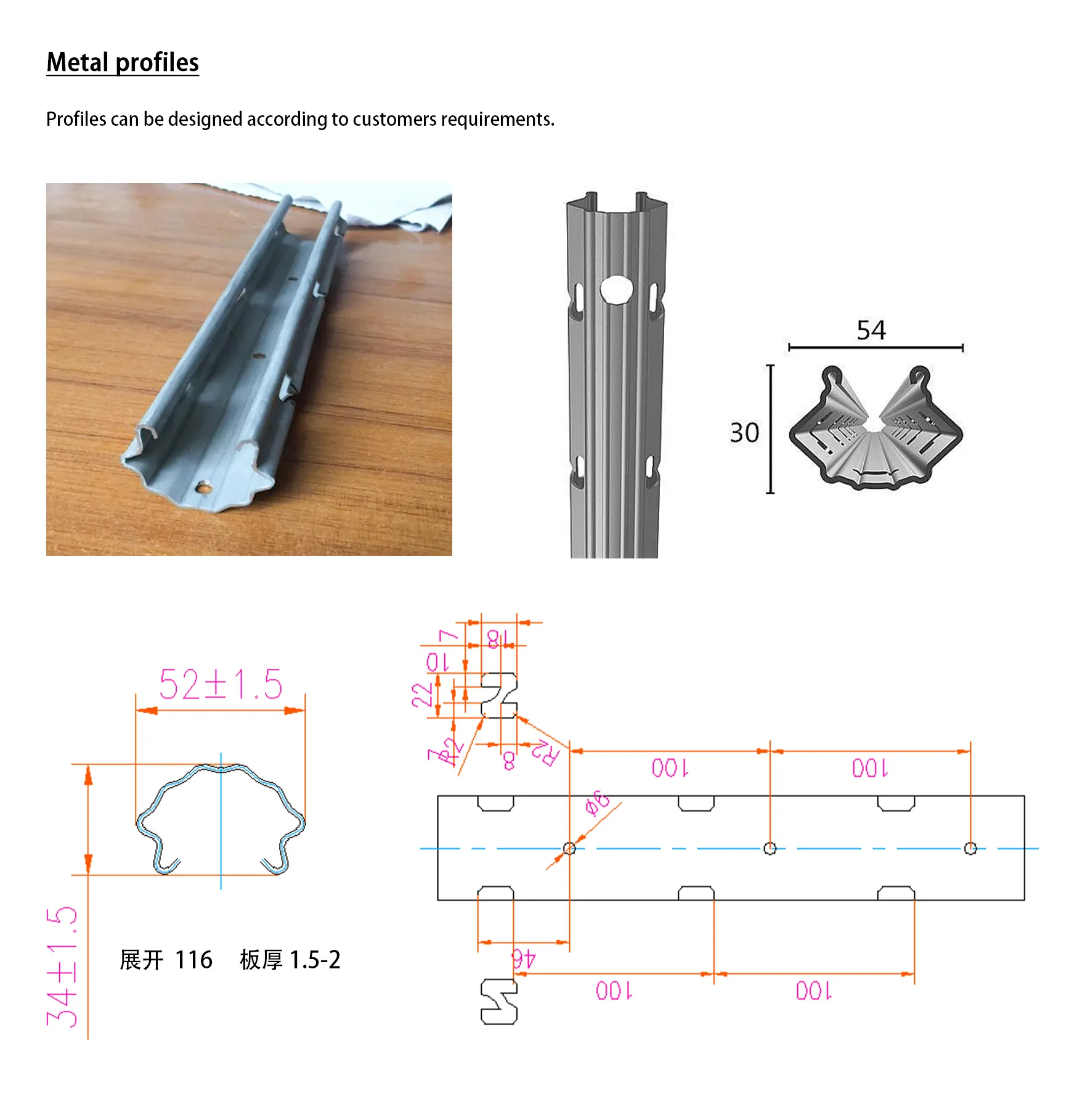

رسومات الملف الشخصي

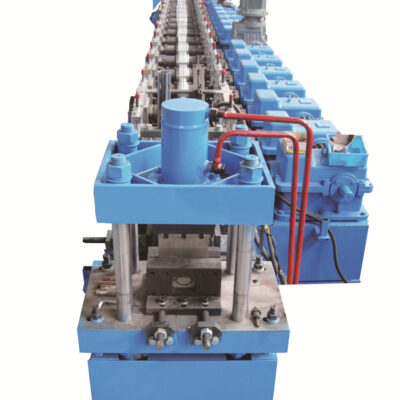

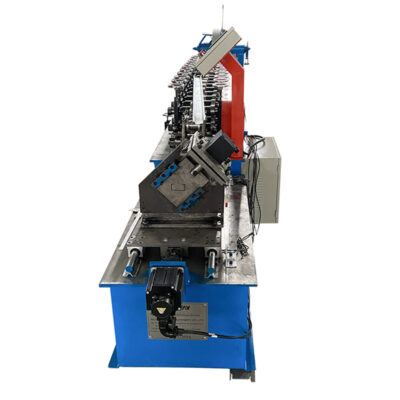

خط الإنتاج

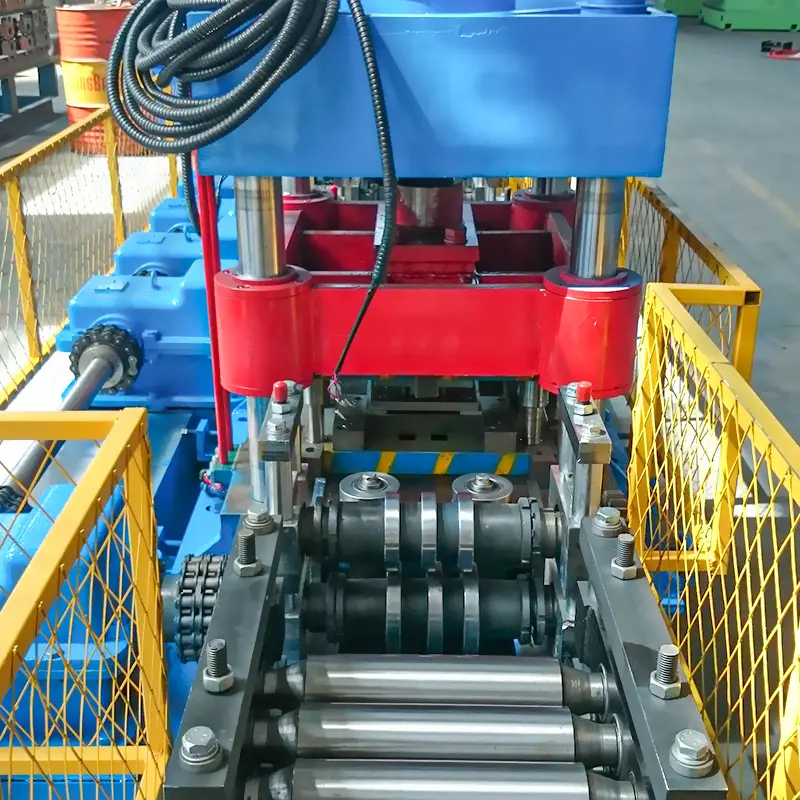

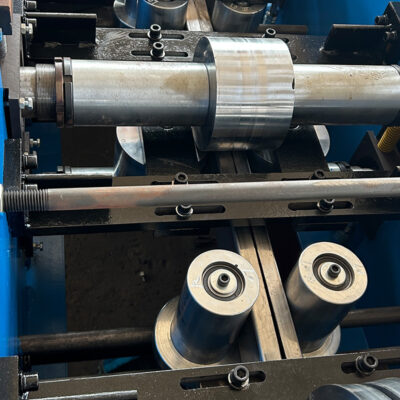

تفاصيل المنتج

معلمات المنتج

| آلة التشكيل بالدلفنة لكروم العنب | ||

|

المواد ألى

|

أ) الصلب المجلفن |

السُمك (مم): 1.5-2.0 حسب العميل

|

| ب) الفولاذ الطري | ||

| قوة الغلة | 250-550 ميجا باسكال | |

| الإجهاد الشد | G250 ميجا باسكال-G550 ميجا باسكال | |

| آلة التفكيك | آلة التفكيك اليدوي | * آلة فك اللفافة الهيدروليكية (اختياري) |

| نظام اللكم | محطة التثقيب الهيدروليكية | * الصحافة اللكم (اختياري) |

| محطة التشكيل | حوالي 16-18 ستاند | * وفقًا لرسومات ملف التعريف الخاص بك |

| نظام القيادة | محرك علبة التروس | |

| هيكل الآلة | حوامل من الحديد الزهر | |

| سرعة التشكيل | 5-10 (م/دقيقة) | * أو وفقًا لرسومات ملف التعريف الخاص بك |

| مواد البكرات | GCr 15 | * Cr12 (اختياري) |

| نظام القطع | القطع الهيدروليكي | * قطع المنشار (اختياري) |

| مغير التردد العلامة التجارية | ياسكاوا | * سيمنز (اختياري) |

| العلامة التجارية PLC | باناسونيك | * سيمنز (اختياري) |

| مزود الطاقة | 380V 50Hz 3ph | * أو حسب متطلباتك |

| لون الجهاز | الأزرق الصناعي | * أو حسب متطلباتك |

| لون الجهاز | الأزرق الصناعي | * أو حسب متطلباتك |

طلب

ما هي ماكينة تشكيل الحامل؟

ماكينة تشكيل الرفوف بالدلفنة هي نوع من معدات التصنيع المستخدمة لإنتاج رفوف أو أرفف بأشكال متناسقة ودقيقة من صفائح أو شرائح معدنية ملفوفة. التشكيل بالدلفنة هو عملية ثني مستمر حيث يتم تمرير المعدن من خلال سلسلة من البكرات لتشكيله تدريجياً إلى الشكل المطلوب.

في حالة ماكينة تشكيل الحامل، تكون البكرات مصممة خصيصًا لإنشاء شكل الحامل. وتتكون الماكينة عادةً من آلة فك اللفائف لحمل الشريط المعدني وتغذيته، ومجموعة من البكرات التي تشكل المعدن تدريجيًا، وآلية قطع لفصل الرفوف المشكلة إلى الأطوال المطلوبة.

وتتمثل ميزة استخدام ماكينة تشكيل الرفوف في قدرتها على إنتاج رفوف ذات دقة أبعاد عالية وتوحيدها بمعدل إنتاج مرتفع. وتتسم العملية بالكفاءة، مما يقلل من هدر المواد ويزيل الحاجة إلى عمليات تشكيل إضافية. بالإضافة إلى ذلك، تتيح عملية التشكيل بالدلفنة إنشاء تشكيلات معقدة وخيارات تخصيص لتصاميم الرفوف المختلفة.

تُستخدم ماكينات تشكيل الرفوف بشكل شائع في صناعات مثل التخزين، والخدمات اللوجستية، وتجارة التجزئة، والتصنيع، حيث تكون أنظمة التخزين والتنظيم ضرورية. فهي تتيح إنتاج رفوف قوية وموثوقة يمكن استخدامها لأغراض مختلفة، بما في ذلك تخزين البضائع أو عرض المنتجات أو تنظيم المخزون.

تطبيق آلة تشكيل لفة رفوف البليت

- التخزين والخدمات اللوجستية: تستخدم رفوف البليت على نطاق واسع في المستودعات ومراكز التوزيع لتخزين البضائع وتنظيمها بكفاءة. تتيح ماكينة التشكيل بالدلفنة إنتاج رفوف عالية الجودة بأبعاد متناسقة وسلامة هيكلية، مما يضمن حلول تخزين آمنة وفعالة.

- متاجر التجزئة والسوبر ماركت: تُستخدم رفوف البليت في بيئات البيع بالتجزئة مثل محلات السوبر ماركت والمتاجر الكبيرة والمتاجر الصغيرة. وهي توفر وسيلة لتخزين وعرض مجموعة كبيرة من المنتجات، بما في ذلك البقالة والأدوات المنزلية والإلكترونيات وغيرها. تتيح ماكينة التشكيل بالدلفنة إنتاج رفوف مخصصة لتلبية المتطلبات المحددة لبيئات البيع بالتجزئة.

- مرافق التصنيع والمنشآت الصناعية: تُستخدم رفوف البليت عادةً في منشآت التصنيع والمنشآت الصناعية لتخزين المواد الخام والمكونات والمواد قيد التنفيذ والمنتجات النهائية. يمكن لماكينة التشكيل بالدلفنة إنتاج رفوف ذات سعات تحميل وتكوينات مختلفة لاستيعاب أنواع مختلفة من العناصر وتحسين استخدام المساحة.

- التجارة الإلكترونية ومراكز الوفاء: مع نمو التجارة الإلكترونية، زاد الطلب على رفوف المنصات النقالة في مراكز الوفاء بشكل كبير. وتوفر رفوف المنصات حلول تخزين فعالة لإدارة كميات كبيرة من المخزون، مما يتيح تنفيذ الطلبات بسرعة وتنظيم. تلعب ماكينة التشكيل بالدلفنة دورًا حاسمًا في تلبية متطلبات الإنتاج في هذه المراكز.

- تخزين السيارات والمعدات الثقيلة: تستخدم رفوف البليت في صناعات السيارات والمعدات الثقيلة لتخزين المكونات والقطع والتركيبات. تسمح ماكينة التشكيل بالدلفنة بإنتاج رفوف يمكنها تحمل الأحمال الثقيلة وتوفر سهولة الوصول إلى العناصر، مما يعزز الكفاءة التشغيلية في هذه القطاعات.

كيفية اختيار ماكينة تشكيل رفوف الرفوف

- متطلبات الإنتاج: حدد احتياجاتك الإنتاجية من حيث كمية وأنواع أرفف الرفوف التي تخطط لإنتاجها. ضع في اعتبارك عوامل مثل القدرة الإنتاجية والسرعة ومرونة الماكينة لتلبية الإنتاج المطلوب.

- مواصفات رفوف الرفوف: قم بتقييم المتطلبات المحددة لأرفف الرفوف التي تنوي تصنيعها، بما في ذلك الأبعاد، وسُمك المواد، وتصميم المظهر الجانبي، وقدرة التحميل. تأكد من أن ماكينة التشكيل بالدلفنة يمكنها استيعاب المواصفات المطلوبة وإنتاج رفوف تلبي معايير الصناعة وتوقعات العملاء.

- توافق المواد: ضع في اعتبارك أنواع المواد التي ستستخدمها لإنتاج رفوف الرفوف، مثل الفولاذ أو الألومنيوم أو المعادن الأخرى. تأكد من أن ماكينة التشكيل بالدلفنة قادرة على التعامل مع المواد المختارة وأن لديها الميزات اللازمة، مثل مجموعات البكرات وآليات القطع القابلة للتعديل، للعمل مع سماكات المواد المختلفة.

- تهيئة الماكينة: قم بتقييم تكوين الماكينة وميزاتها لتحديد ما إذا كانت تتماشى مع احتياجاتك الخاصة. ضع في اعتبارك عوامل مثل عدد محطات التشكيل، ووجود ميزات إضافية مثل إمكانيات التثقيب أو اللحام، وسهولة ضبط الماكينة لمختلف أشكال أرفف الرفوف.

- الجودة والمتانة: قم بتقييم جودة بناء وموثوقية ماكينة التشكيل بالدلفنة. ابحث عن مُصنِّع حسن السمعة له سجل حافل في إنتاج ماكينات عالية الجودة. ضع في اعتبارك عوامل مثل المواد المستخدمة في البناء، ودقة مكونات الماكينة، وتوافر الدعم الفني وقطع الغيار.

- التكلفة والعائد على الاستثمار: قارن تكلفة ماكينة التشكيل بالدلفنة بميزانيتك وقم بتقييم العائد المحتمل على الاستثمار. ضع في اعتبارك عوامل مثل كفاءة الماكينة، والقدرة الإنتاجية، ومتطلبات الصيانة، ووفورات الطاقة المحتملة لتقييم فعالية التكلفة على المدى الطويل.

- دعم وخدمة الشركة المصنعة: اختر الشركة المصنعة التي تقدم دعمًا شاملاً للعملاء، بما في ذلك التدريب والتركيب وخدمة ما بعد البيع. ستوفر الشركة المصنعة الموثوق بها المساعدة الفنية واستكشاف الأخطاء وإصلاحها وقطع الغيار لضمان التشغيل السلس وتقليل وقت التوقف عن العمل.

- السلامة والامتثال: تأكد من أن ماكينة التشكيل بالدلفنة تفي بمعايير ولوائح السلامة لحماية العمال والامتثال لمتطلبات الصناعة. ابحث عن ميزات مثل واقيات السلامة، وأزرار إيقاف الطوارئ، والامتثال لمعايير السلامة ذات الصلة.