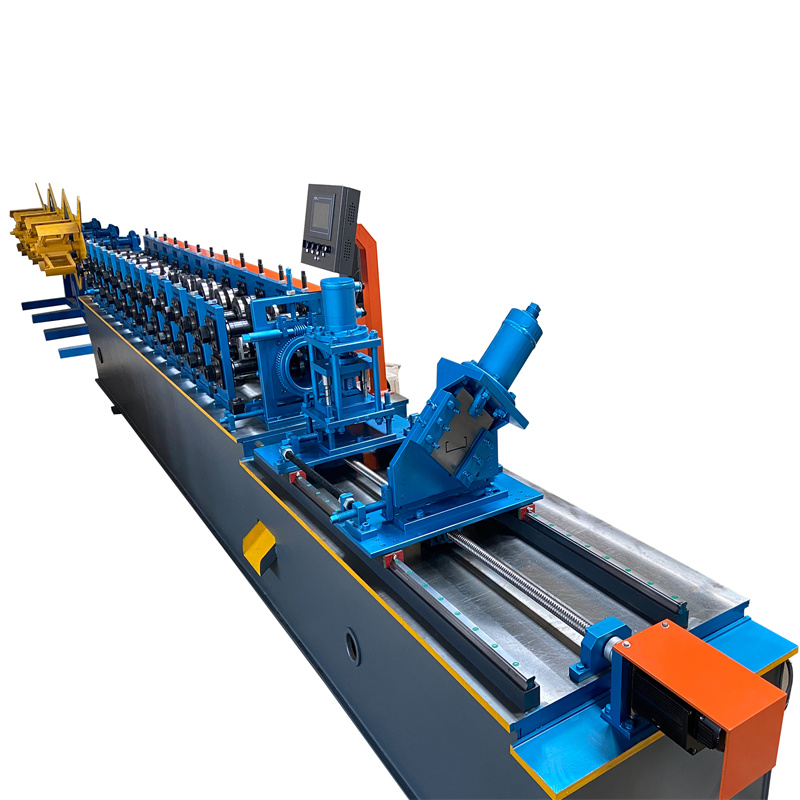

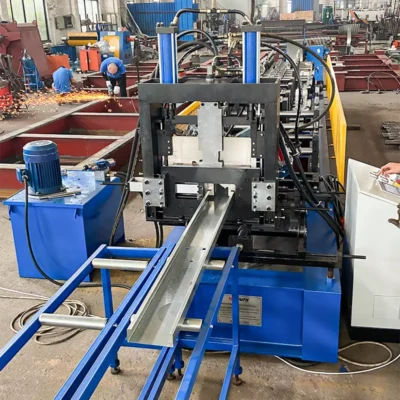

آلة تشكيل لفة الصلب Keel / Truss / C / U / U / أوميغا / Stud Steel Rolling ذات أبعاد صغيرة، سهلة النقل. يمكن أن تصل سرعة النقل إلى 60 م / دقيقة، وبالتالي فإن العمل سيكون أكثر استقرارًا. يمكننا أيضًا توريد الآلات المخصصة.

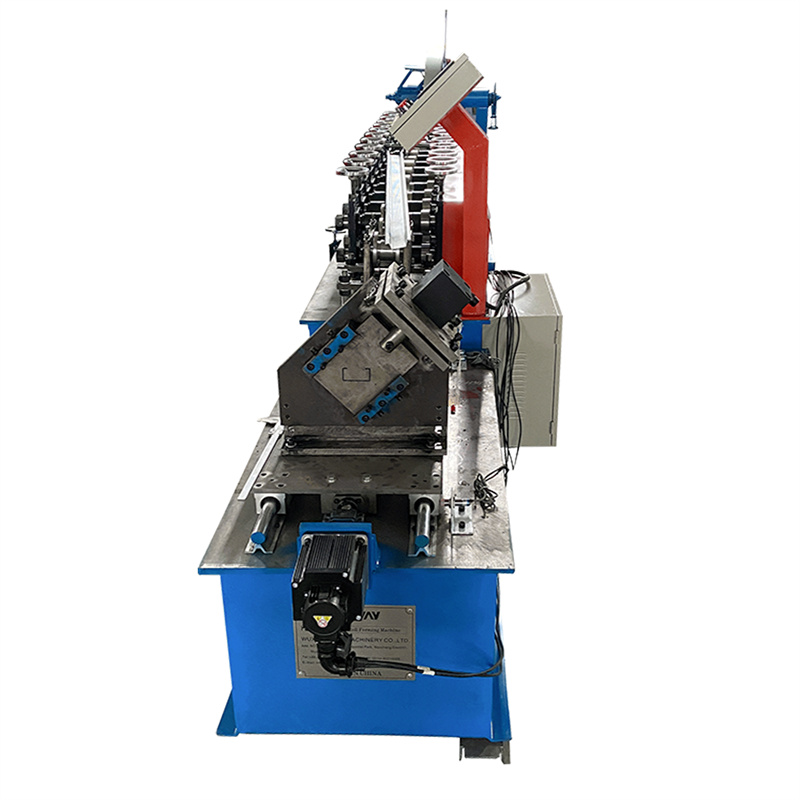

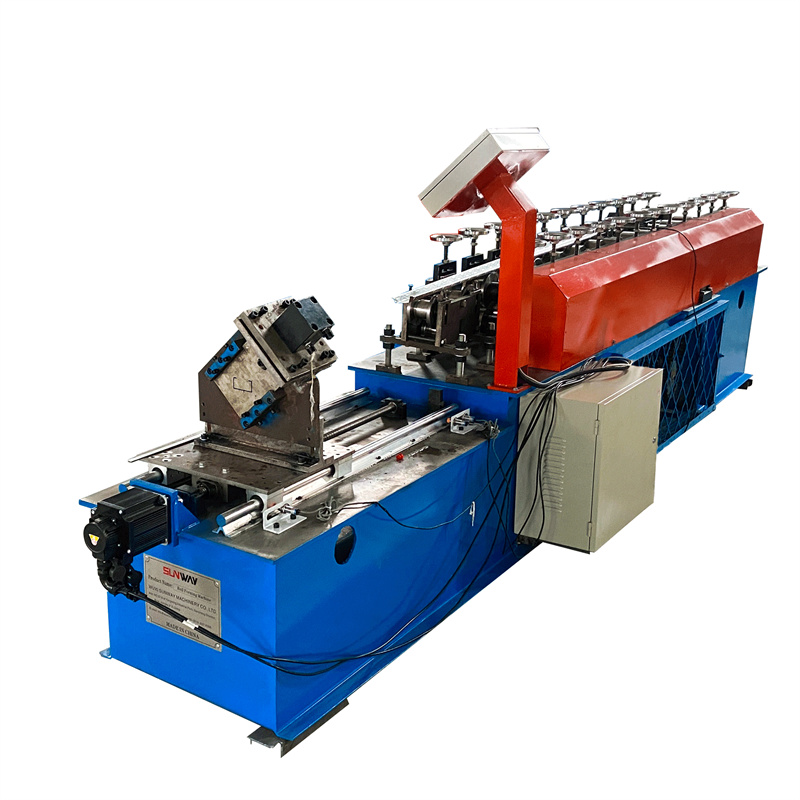

تفاصيل ماكينة تشكيل القنوات الفولاذية على شكل قناة C

سرعة عالية

يمكن أن تصل سرعة ماكينة تشكيل لفة مسمار C/U/Omega ذات السرعة العالية إلى 60 م/دقيقة. عادةً ما تكون سرعة ماكينة تشكيل المسامير C/U/U/Omega حوالي 45 م/دقيقة

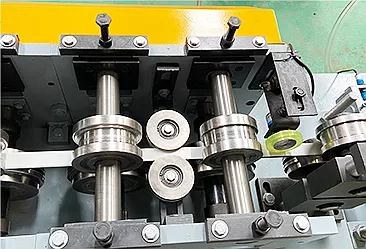

ماكينة التشكيل بالدلفنة ذات السرعة العالية CU/U/Omega تعتمد مثبت أسطواني من الصلب المصبوب

آلة تشكيل مسمار CU / أوميغا عالية السرعة CU / أوميغا تعتمد نظام PLC. يمكن للعميل ضبط كمية الإنتاج وسرعة الإنتاج على خزانة التحكم.

مهندس كبير وذوي خبرة يتحكم في العملية برمتها لتخصيصك.

معلمات ماكينة تشكيل القناة C الفولاذية على شكل قناة C

| المواد الخام | الصفيحة المجلفنة أو PPGI، PPGL |

| سُمك الورقة (مم) | مخصص |

| العملية | أوتوماتيكي بالكامل |

| ناقل الحركة | حسب السلسلة/المعدات |

| مادة الأسطوانة | Cr12 |

| قطر العمود | 50 مم أو حسب الملف الشخصي |

| محطة الرول | 10-16 محطة |

| القاطع | القطع المؤازر الهيدروليكي بسرعة عالية |

ما هي ماكينة تشكيل لفة القناة c؟

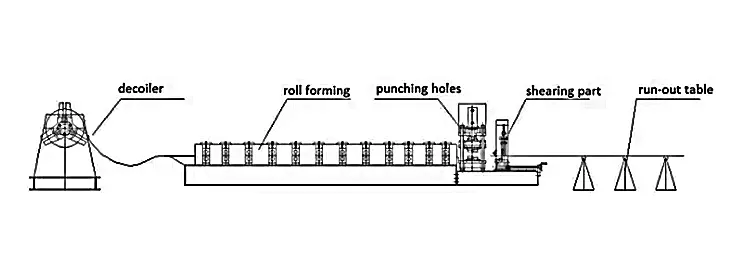

ماكينة التشكيل بالدلفنة للقنوات C هي قطعة متخصصة من المعدات المستخدمة في الصناعة التحويلية لإنتاج قنوات فولاذية على شكل حرف C من خلال عملية تسمى التشكيل بالدلفنة. التشكيل بالدلفنة هو عملية ثني مستمر حيث يتم تمرير شريط طويل من المعدن من خلال سلسلة من القوالب الدوارة لتشكيله تدريجيًا إلى الشكل الجانبي المطلوب.

يشيع استخدام المظهر الجانبي للقناة C في الإنشاءات والتطبيقات الإنشائية، حيث توفر القوة والثبات مع تقليل الوزن. وهي تشبه الحرف "C" عند النظر إليها في مقطع عرضي، مع ظهر مسطح وشفتين متعامدتين تمتدان إلى الخارج.

تتكون ماكينة التشكيل بالدلفنة للقنوات C من سلسلة من محطات التشكيل، كل منها مزودة بأزواج من البكرات التي تقوم بتشكيل الشريط المعدني تدريجيًا. هذه البكرات مصممة لإنتاج الأبعاد والخصائص المحددة للشكل الجانبي للقناة C، مثل عرض الحافة وحجم الشفة والأبعاد الكلية. قد تشتمل الماكينة أيضًا على محطات إضافية لقطع القنوات المشكلة بالطول المطلوب.

عادةً ما تكون ماكينات تشكيل القنوات C مؤتمتة ويمكنها التعامل مع الإنتاج بكميات كبيرة. وهي توفر تحكمًا دقيقًا في عملية التشكيل، مما يسمح للمصنعين بإنتاج قنوات C بأبعاد دقيقة وتشطيبات عالية الجودة باستمرار.

ما هي ماكينة تشكيل قنوات الفراء؟

ماكينة تشكيل قنوات الفراء هي نوع آخر من المعدات المتخصصة المستخدمة في الصناعة التحويلية. وهي مصممة لإنتاج قنوات الفراء من خلال عملية التشكيل بالدلفنة. تُستخدم قنوات الفراء بشكل شائع في البناء لتطبيقات مختلفة مثل إنشاء الأسقف المعلقة والجدران الفاصلة وربط الحوائط الجافة.

عادةً ما تكون قنوات التحزيز مصنوعة من الفولاذ المجلفن أو معادن أخرى ولها مقطع عرضي على شكل قبعة. وتتميز بقاعدة مسطحة ذات ساقين أو حواف متوازية تمتد لأعلى. تحتوي الأرجل على أنماط منقوشة أو مثقوبة لتوفير القوة وتسهيل التثبيت بمواد البناء الأخرى.

تتكون ماكينة تشكيل قنوات الفرن من سلسلة من محطات التشكيل، على غرار ماكينة تشكيل القنوات على شكل حرف C. هذه المحطات مجهزة بقوالب أسطوانية تقوم بتشكيل الشريط المعدني تدريجياً في شكل قناة التشكيل المطلوبة. قد تشتمل الماكينة أيضًا على محطات إضافية لتثقيب الثقوب أو نقش الأنماط على أرجل القناة.

أثناء عملية التشكيل بالدلفنة، يتم تغذية الشريط المعدني في الماكينة، وتقوم البكرات بثنيها وتشكيلها تدريجياً في شكل قناة فراء. يمكن قطع القنوات المشكلة إلى الطول المطلوب باستخدام محطة قطع مدمجة في الماكينة أو كعملية منفصلة بعد العملية.

صُممت ماكينات تشكيل قنوات الفرندة للإنتاج بكميات كبيرة، مما يوفر تحكمًا دقيقًا في أبعاد وخصائص القنوات. وهي تمكّن المصنعين من إنتاج قنوات الفرن بجودة متناسقة، مما يجعلها مثالية لمشاريع البناء التي تتطلب مكونات دقيقة وموحدة.

ما هي ماكينة تشكيل القنوات ذات القبعات؟

ماكينة تشكيل قنوات القبعات هي قطعة متخصصة من المعدات المستخدمة في الصناعة التحويلية لإنتاج قنوات القبعات من خلال عملية التشكيل بالدلفنة. تُستخدم القنوات ذات القبعات، والمعروفة أيضًا باسم قنوات الفراء أو القنوات المرنة، بشكل شائع في البناء لتطبيقات مثل ربط الحوائط الجافة وإنشاء الأسقف المعلقة وتوفير الدعم الهيكلي.

تتميز قنوات القبعة بشكل "القبعة" أو "U" المميز عند النظر إليها في المقطع العرضي. وهي تتألف من قاعدة مسطحة مع شفتين متوازيتين تمتدان لأعلى، لتشكل شكلًا جانبيًا على شكل حرف U. يوفر تصميم قنوات القبعة خصائص القوة والصلابة وتخميد الصوت.

تعمل ماكينة تشكيل قناة القبعة بالدلفنة بشكل مشابه لماكينات التشكيل بالدلفنة الأخرى. وهي تتألف من سلسلة من محطات التشكيل المجهزة بقوالب أسطوانية تقوم بتشكيل شريط معدني تدريجيًا في شكل قناة القبعة المطلوبة. تقوم البكرات بثني الشريط المعدني وتشكيله تدريجيًا، مما يتحكم بدقة في أبعاد وميزات قناة القبعة.

اعتمادًا على التطبيق المحدد، قد تشتمل ماكينة تشكيل قنوات القبعات على محطات إضافية لتثقيب الثقوب أو نقش الأنماط أو إضافة ميزات أخرى إلى القناة. تسمح هذه الاختلافات بالتخصيص لتلبية متطلبات المشروع المحددة.

من خلال استخدام ماكينة تشكيل قنوات القبعات، يمكن للمصنعين إنتاج قنوات القبعات بكميات كبيرة بجودة ثابتة وأبعاد دقيقة. تتيح أتمتة الماكينة ودقتها كفاءة الإنتاج، مما يجعلها أداة قيمة في صناعة البناء والتشييد.

آلة تشكيل المسامير المعدنية ولفائف الجنزير للبيع يمكن أن تغير الطريقة التي تفعل بها الصفائح المعدنية

5 أسباب لماذا يجب أن تستثمر في آلة تشكيل دعامة معدنية للبيع اليوم