L’industrie de la défense opère dans les conditions les plus exigeantes, nécessitant des équipements alliant résistance, durabilité et fiabilité. Des composants de véhicules blindés aux profils structuraux pour les bases militaires, la production de pièces haute performance est cruciale pour la sécurité nationale. Entrez dans Machines de formage de rouleaux pour équipements militaires, la technologie de pointe à l’origine de nombreux composants durables et précis utilisés dans les applications militaires. Ces machines respectent les normes strictes de la fabrication pour la défense, permettant la production de profils capables de résister à des environnements extrêmes et à des conditions rigoureuses.

Dans ce guide, nous explorerons applications, caractéristiques, prix, tendances du marchéet comment Wuxi Sunway Machinery les solutions de formage par rouleaux pour l’industrie de la défense. Que vous soyez contractant de défense, ingénieur militaire ou simplement curieux de la technologie qui alimente les infrastructures militaires modernes, cet article vous apporte toutes les réponses.

Qu’est-ce qu’une machine de formage par rouleaux pour équipements militaires ?

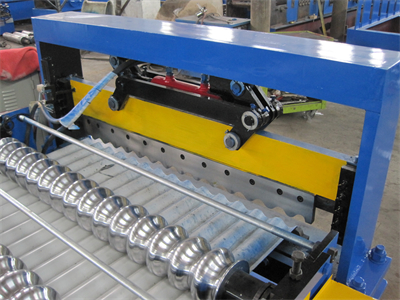

UN Machine de formage par rouleaux pour équipements militaires est un équipement spécialisé conçu pour produire des profils durables et haute performance utilisés dans la construction de véhicules militaires, d’infrastructures et d’équipements. Ces machines transforment des tôles ou bobines métalliques plates – généralement fabriquées en acier haute résistance, alliages balistiques ou matériaux résistants à la corrosion– en formes précises répondant aux exigences rigoureuses des opérations militaires.

Composants clés produits

- Panneaux de véhicules blindés: Profils utilisés dans les chars, véhicules blindés de transport de troupes (VBTT) et autres véhicules militaires.

- Supports d’armes: Composants pour monter des armes sur des plateformes terrestres, aériennes ou navales.

- Structures de tentes portables: Profils légers mais durables pour tentes militaires et abris de campagne.

- Profils pour infrastructures de base: Poutres, canaux et supports pour la construction de bases et avant-postes militaires.

- Systèmes de stockage de munitions: Profils pour racks et conteneurs utilisés dans le stockage sécurisé d’armes et de munitions.

- Profils personnalisés: Conceptions uniques pour applications militaires spécialisées, telles que systèmes radar, plateformes de drones et tours de communication.

Ces machines excellent dans l’automatisation de la production de composants militaires, garantissant précision, consistance et conformité aux normes de défense strictes.

Applications des machines de formage par rouleaux pour équipements militaires

La polyvalence des Machines de formage de rouleaux pour équipements militaires les rend indispensables pour une large gamme d’applications liées à la défense. Voici quelques cas d’usage principaux :

1. Fabrication de véhicules blindés

- Cas d'utilisation : Production de panneaux et profils structuraux pour chars, VBTT et véhicules résistants aux mines et aux embuscades (MRAP).

- Pourquoi c'est essentiel : Assure la survie du personnel et des équipements en zones de combat.

2. Composants de systèmes d’armes

- Cas d'utilisation : Fabrication de supports, équerres et châssis pour systèmes d’armes sur véhicules, aéronefs et navires.

- Pourquoi c'est important : Fournit l’intégrité structurelle nécessaire à un fonctionnement précis et fiable des armes.

3. Abris de campagne portables

- Cas d'utilisation : Confection de châssis légers pour tentes, abris et centres de commandement mobiles.

- Pourquoi il est précieux : Permet un déploiement et un assemblage rapides en environnements reculés ou hostiles.

4. Construction de bases militaires

- Cas d'utilisation : Production de poutres, colonnes et supports pour casernes, hangars et autres infrastructures de base.

- Pourquoi c'est pertinent : Améliore la durabilité et la sécurité des installations militaires.

5. Stockage d’armes et de munitions

- Cas d'utilisation : Création de profils sécurisés pour racks, casiers et conteneurs destinés au stockage d’armes et de munitions.

- Pourquoi c'est essentiel : Évite les dommages et garantit une manipulation et un transport sécurisés des matériaux sensibles.

6. Plateformes pour équipements spécialisés

- Cas d'utilisation : Fabrication de profils pour systèmes radar, plateformes de lancement de drones et tours de communication.

- Pourquoi c'est bénéfique : Soutient les technologies militaires avancées et améliore les capacités opérationnelles.

Principales caractéristiques des machines de formage par rouleaux pour équipements militaires Wuxi Sunway

Wuxi Sunway Machinery, leader mondial en technologie de formage par rouleaux, propose des machines adaptées aux exigences uniques du secteur de la défense. Voici les caractéristiques phares qui rendent leurs machines idéales pour la fabrication militaire :

1. Traitement des matériaux à haute résistance

- Matériaux pris en charge :

- Acier balistique

- Alliages d'aluminium

- Métaux résistants à la corrosion

- Titane

- Pourquoi c'est important : Assure la production de composants durables capables de résister à des conditions extrêmes.

2. Précision et cohérence

- Performance : Tolérances dimensionnelles jusqu’à ±0,05 mm, garantissant l’uniformité dans les applications critiques.

- Pourquoi c'est essentiel : Réduit les erreurs d’assemblage et assure la compatibilité avec d’autres équipements.

3. Outillage personnalisable pour conceptions spécialisées

- Ce qu'il apporte : Systèmes d’outillage modulaires pour créer des profils uniques adaptés aux spécifications militaires.

- Pourquoi c'est essentiel : Soutient la production de composants sur mesure pour applications de défense spécialisées.

4. Systèmes intégrés de découpe et de poinçonnage

- Ce qui est inclus : Systèmes pour découpe précise, poinçonnage et perforation pendant la production.

- Pourquoi il est précieux : Simplifie l'assemblage et réduit les opérations post-production.

5. Production à grande vitesse

- Performance : Capable de produire jusqu'à 20–100 mètres de profils par minuteen fonction du matériau et de la complexité.

- Pourquoi c'est bénéfique : Répond aux besoins de production en grand volume des projets de défense à grande échelle.

6. Intégration de l'IdO et de l'automatisation

- Ce qu'il permet : Surveillance en temps réel, ajustements automatisés et maintenance prédictive à l'aide de systèmes IoT.

- Pourquoi cela change la donne :

- Améliore l'efficacité de la production.

- Réduit les temps d'arrêt et les coûts de maintenance.

- Fournit des informations exploitables en vue d'une amélioration continue.

7. Traitements de surface avancés

- Le reportage : Machines conçues pour appliquer des revêtements anti-corrosion, anti-rouille et réfléchissants.

- Pourquoi c'est important : Prolonge la durée de vie des composants exposés à des environnements hostiles.

Flux de production d’une machine de formage par rouleaux pour équipements militaires

Le processus de fabrication des composants militaires est optimisé pour la durabilité, la précision et l’efficacité. Voici un aperçu du flux de travail typique :

1. Chargement du matériel

- Des tôles ou bobines de matériaux balistiques sont chargées sur un décolleurassurant ainsi un approvisionnement continu.

2. Redressement et mise à niveau

- Une unité de dressage assure que le matériau est plan et exempt de défauts avant le début du formage par rouleaux.

3. Formage de rouleaux

- Le matériau passe à travers une série de rouleaux qui le façonnent progressivement au profil désiré, en respectant des tolérances strictes.

4. Poinçonnage et découpe

- Des systèmes intégrés ajoutent des trous de précision pour fixations ou connecteurs et découpent les profils aux longueurs personnalisées.

5. Application du revêtement

- Des systèmes optionnels appliquent des revêtements protecteurs, tels que anti-corrosion ou balistiques, pendant ou après la production.

6. Contrôle de la qualité

- Les profils finis sont inspectés pour vérifier la précision dimensionnelle, la résistance et la conformité aux normes militaires.

7. Emballage et livraison

- Les composants terminés sont regroupés, étiquetés et préparés pour un transport sécurisé vers les contractants de défense ou installations militaires.

Tarification des machines de formage par rouleaux pour équipements militaires

Le coût d'un Machine de formage par rouleaux pour équipements militaires dépend de ses caractéristiques, de sa compatibilité avec les matériaux et des options de personnalisation. Voici un guide tarifaire général pour 2025 :

| Type de machine | Capacités | Fourchette de prix (USD) |

|---|---|---|

| Machines standard | Production de profils de base pour applications de défense | 500,000–500,000–500,000–1,200,000 |

| Machines avancées | Systèmes de découpe et de poinçonnage intégrés à grande vitesse | 1 200 000–1 200 000–1 200 000–2 800 000 |

| Machines entièrement personnalisables | IoT, outillage modulaire et manipulation avancée des matériaux | 2 800 000–2 800 000–2 800 000–5 000 000 |

Pour obtenir des informations détaillées sur les prix et les options de financement, veuillez contacter Wuxi Sunway Machinery.

Tendances du marché pour les machines de formage par rouleaux pour équipements militaires en 2025

L’industrie de la défense évolue rapidement, portée par les avancées technologiques et les facteurs géopolitiques. Voici les tendances qui façonnent le marché :

1. Matériaux avancés

- La tendance : Utilisation croissante de métaux balistiques et d’alliages légers dans les équipements militaires.

- Rôle de la machine :

- Permet le formage précis de matériaux avancés.

- Réduire les déchets de matériaux grâce à une ingénierie de précision.

2. Systèmes militaires autonomes

- La croissance : Demande croissante pour drones, UAV et véhicules autonomes dans les opérations de défense.

- Contribution de la machine :

- Produit des profils légers et durables pour plateformes autonomes.

- Soutient des conceptions innovantes pour technologies militaires avancées.

3. Solutions de déploiement rapide

- Le point de mire : Développement d’infrastructures militaires portables et modulaires pour déploiement rapide.

- Impact de la machine :

- Permet la production en masse de châssis d’abris portables et de structures de support.

- Soutient l’assemblage sur site avec des profils préfabriqués.

4. Croissance des budgets de défense

- La croissance : Augmentation des budgets de défense mondiaux stimulant la demande d’équipements militaires avancés.

- Impact de la machine :

- Soutient la production à grande échelle de composants militaires.

- Améliore l’efficacité de production pour respecter les délais serrés.

FAQ sur les machines de formage par rouleaux pour équipements militaires

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | Acier balistique, alliages d’aluminium, titane et métaux résistants à la corrosion. |

| Quelle est la vitesse de production de ces machines ? | Les machines peuvent produire jusqu'à 20–100 mètres de profils par minuteen fonction du matériau et de la complexité. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Oui, l’outillage modulaire permet la création de profils militaires sur mesure. |

| Ces machines sont-elles économes en énergie ? | Oui, elles intègrent des moteurs économes en énergie et des flux optimisés pour réduire les coûts. |

| Quelles sont les industries qui bénéficient de ces machines ? | Défense, sécurité intérieure et secteurs d’infrastructures lourdes. |

| Ces machines sont-elles conformes aux normes de sécurité ? | Oui, elles respectent les normes ISO, CE et spécifiques aux militaires. |

| Quelle est la durée de vie de ces machines ? | Avec un entretien adéquat, ces machines peuvent durer 20-30 ans ou plus. |

| La formation est-elle fournie à l'achat ? | Oui, Wuxi Sunway propose une formation complète et une assistance après-vente à tous ses clients. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 500 000 à 500 000 à 500 000 à 5 000 000selon les caractéristiques et les options de personnalisation. |

| Ces machines peuvent-elles soutenir une production durable ? | Oui, ils sont optimisés pour minimiser les déchets et favoriser les matériaux recyclables. |

Histoires de succès du monde réel : Machines de profilage pour équipements militaires en action

L'utilisation de Machines de formage de rouleaux pour équipements militaires joue un rôle déterminant dans la résolution de certains des défis les plus complexes auxquels font face les fabricants d’équipements de défense. Voici des exemples concrets illustrant comment ces machines ont transformé la production militaire.

1. Étude de cas : Panneaux pour véhicules blindés de transport de troupes (APC)

- Client : Un contractant de défense mondial spécialisé dans les véhicules terrestres tactiques.

- Défi : Besoin de panneaux en acier haute résistance pour APC capables de résister aux menaces balistiques et aux impacts explosifs.

- Solution : Wuxi Sunway Machinery a fourni une machine de profilage conçue pour usiner de l'acier balistique avec des systèmes intégrés de coupe et de poinçonnage pour trous de fixation.

- Résultats :

- Réduction du temps de production de 40 %, permettant une livraison plus rapide des véhicules.

- Amélioration de la durabilité des panneaux, conforme aux normes balistiques de l'OTAN.

- Réduction des déchets de matière de 15 %, optimisant les coûts d'entrée.

2. Étude de cas : Infrastructures de déploiement rapide

- Client : Un fournisseur d'abris militaires portables et d'hôpitaux de campagne.

- Défi : Besoin de cadres légers et modulaires pour abris déployables rapidement en zones de conflit ou lors d'opérations de secours en cas de catastrophe.

- Solution : Wuxi Sunway a livré une machine de profilage capable de produire des profilés en aluminium haute résistance avec outillage modulaire pour divers designs.

- Résultats :

- Permet la production d'abris assemblables en moins de 30 minutes.

- Réduction du poids de 25 % par rapport aux cadres en acier traditionnels, facilitant la logistique de transport.

- Augmentation de la durabilité des abris, garantissant une fiabilité dans des environnements hostiles.

3. Étude de cas : Étagères de stockage de munitions

- Client : Une entreprise de logistique gérant le stockage de munitions et d'armes pour bases militaires.

- Défi : Besoin de profilés résistants à la corrosion pour étagères de munitions supportant des températures et une humidité extrêmes.

- Solution : Wuxi Sunway a fourni une machine conçue pour usiner de l'acier galvanisé avec application de revêtements anticorrosion pendant la production.

- Résultats :

- Production d'étagères conformes aux exigences militaires de sécurité et de longévité.

- Réduction des coûts de maintenance de 30 % grâce à une meilleure résistance à la corrosion.

- Permet une production de masse efficace pour répondre aux besoins croissants de stockage.

4. Étude de cas : Cadres pour Véhicules Aériens Sans Pilote (VASP)

- Client : Un fabricant de drones fournissant à l'armée des VASP tactiques pour la reconnaissance et la logistique.

- Défi : Besoin de cadres ultralégers et durables pour améliorer les temps de vol et la capacité de charge des VASP.

- Solution : Wuxi Sunway a développé une machine de profilage capable d'usiner des matériaux composites avancés en profilés personnalisés pour VASP.

- Résultats :

- Augmentation de la durée de vol des VASP de 20 %, améliorant les capacités opérationnelles.

- Réduction des délais de production de 35 %, permettant une livraison plus rapide aux clients militaires.

- Soutien aux designs modulaires pour VASP, autorisant une personnalisation rapide sur le terrain.

Personnalisation : L'avantage clé des machines de profilage pour équipements militaires

Dans l'industrie de la défense, une taille unique ne convient pas à tous. Les applications militaires exigent souvent profils personnalisés pour répondre à des exigences opérationnelles uniques. Les machines de profilage de Wuxi Sunway Machinery offrent une flexibilité inégalée pour créer ces solutions sur mesure.

1. Outillage modulaire

- Ce qu'il offre : Systèmes d'outillage facilement interchangeables permettant aux fabricants de passer rapidement d'un design de profilé à un autre.

- Pourquoi il est précieux :

- Soutient des besoins de production diversifiés, des panneaux blindés aux cadres d'abris.

- Réduit les temps d'arrêt liés aux changements d'outillage.

- Permet la production en petites séries pour prototypes ou composants spécialisés.

2. Polyvalence des matériaux

- Matériaux pris en charge :

- Acier balistique

- Alliages d'aluminium

- Titane

- Matériaux composites (p. ex., fibre de carbone)

- Pourquoi c'est essentiel :

- Offre la flexibilité de produire des composants optimisés pour la résistance, le poids ou la résistance à la corrosion.

- Soutient l'innovation dans la conception d'équipements de défense.

3. Diversité des profilés

- Capacités : Les machines peuvent produire une large gamme de profilés, dont :

- Canaux en U

- Profilés en Z

- Poutres caissons

- Géométries personnalisées

- Pourquoi c'est important :

- Permet aux fabricants de répondre aux besoins spécifiques de diverses applications militaires.

- Soutient l'intégration avec d'autres composants pour un assemblage fluide.

4. Intégration avancée de revêtements

- Ce qui est inclus : Systèmes d'application de revêtements comme anticorrosion, réfléchissants ou camouflages pendant la production.

- Pourquoi c'est bénéfique :

- Améliore la durabilité et la fonctionnalité des composants.

- Réduit les étapes post-production, économisant temps et coûts.

Normes de conformité pour les machines de profilage d'équipements militaires

Les composants militaires doivent respecter des normes internationales strictes pour garantir sécurité, durabilité et performance. Wuxi Sunway Machinery conçoit ses machines pour produire des profilés conformes ou supérieurs à ces exigences :

| Standard | Région | Exigence |

|---|---|---|

| Spécifications MIL-STD | ÉTATS-UNIS | Définit les exigences de grade militaire pour matériaux et composants. |

| ISO 9001 | Mondial | Garantit une gestion cohérente de la qualité dans les processus de fabrication. |

| Normes STANAG de l'OTAN | Pays membres de l'OTAN | Spécifie les normes d'interopérabilité et de performance des équipements militaires. |

| Marquage CE | L'Europe | Certifie la conformité aux normes européennes de sécurité et de qualité. |

| Conformité RoHS | L'Europe | Limite les substances dangereuses dans les matériaux de fabrication. |

| Conformité ITAR | ÉTATS-UNIS | Assure le respect des réglementations internationales sur le trafic des armes pour l'exportation. |

En adhérant à ces normes, Wuxi Sunway Machinery veille à ce que ses machines de profilage fournissent des composants sûrs, durables et conformes mondialement.

FAQ sur les machines de formage par rouleaux pour équipements militaires

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | Acier balistique, alliages d'aluminium, titane et matériaux composites. |

| Quelle est la vitesse de production de ces machines ? | Les machines peuvent produire jusqu'à 20–100 mètres de profils par minuteen fonction du matériau et de la complexité. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Oui, l’outillage modulaire permet la création de profils militaires sur mesure. |

| Ces machines sont-elles économes en énergie ? | Oui, elles intègrent des moteurs économes en énergie et des flux de travail optimisés pour réduire les coûts d'exploitation. |

| Quelles sont les industries qui bénéficient de ces machines ? | Secteurs de la défense, de la sécurité intérieure et de la réponse aux urgences. |

| Ces machines sont-elles conformes aux normes de sécurité ? | Oui, elles respectent les normes MIL-STD, STANAG de l'OTAN et autres standards militaires internationaux. |

| Quelle est la durée de vie de ces machines ? | Avec un entretien adéquat, ces machines peuvent durer 20-30 ans ou plus. |

| La formation est-elle fournie à l'achat ? | Oui, Wuxi Sunway propose une formation complète et une assistance après-vente à tous ses clients. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 500 000 à 500 000 à 500 000 à 5 000 000selon les caractéristiques et les options de personnalisation. |

| Ces machines peuvent-elles soutenir une production durable ? | Oui, ils sont optimisés pour minimiser les déchets et favoriser les matériaux recyclables. |

Pourquoi choisir Wuxi Sunway Machinery pour les machines de profilage d'équipements militaires ?

Wuxi Sunway Machinery s'est imposé comme un partenaire de confiance dans la fabrication de défense, offrant des solutions innovantes de profilage adaptées au secteur militaire. Voici pourquoi les contractants de défense choisissent Sunway :

- Des décennies d'expertise : Antécédents prouvés dans la fourniture de machines de haute qualité pour applications militaires.

- Une portée mondiale : Approuvé par les fabricants de défense en Asie, en Europe, en Amérique du Nord et au-delà.

- Technologie de pointe : Des fonctionnalités comme l'intégration IoT, l'outillage modulaire et les systèmes de revêtement avancés distinguent leurs machines.

- Engagement en matière de développement durable : Machines conçues pour minimiser l'impact environnemental grâce à l'efficacité énergétique et la manipulation de matériaux recyclables.

- Soutien global : De la consultation à l'installation et au service continu, Wuxi Sunway assure à ses clients un fonctionnement sans heurts.

Conclusion : Renforcer les défenses avec les machines de profilage

Machines de formage de rouleaux pour équipements militaires révolutionnent l'industrie de la défense en permettant la production de composants haute performance, durables et fiables répondant aux exigences de la guerre moderne et de la sécurité. Ces machines jouent un rôle critique dans le renforcement des capacités de défense nationale et le soutien aux scénarios de déploiement rapide.

Prêt à élever votre production d'équipements militaires ? Partenariat avec Wuxi Sunway Machinery dès aujourd'hui et découvrez leurs solutions de profilage de pointe. Construisons l'avenir de la défense — un profilé à la fois.