Classrooms are the foundation of education, and the furniture within them plays a critical role in creating an environment conducive to learning. From durable desks and ergonomic chairs to multifunctional storage units, the demand for high-quality school furniture is ever-growing. Central to meeting this demand are Machines de formage de rouleaux de mobilier scolaire, which enable manufacturers to produce robust, precise, and cost-effective furniture components at scale.

Dans cet article, nous explorerons what school furniture roll forming machines are, their applications in furniture manufacturing, pricing structures, key features, automation capabilities, and why Wuxi Sunway Machinery is a leading name in this niche. Whether you’re a furniture producer, an educational institution, or a supplier looking to optimize production, this guide will provide valuable insights.

What Are School Furniture Roll Forming Machines?

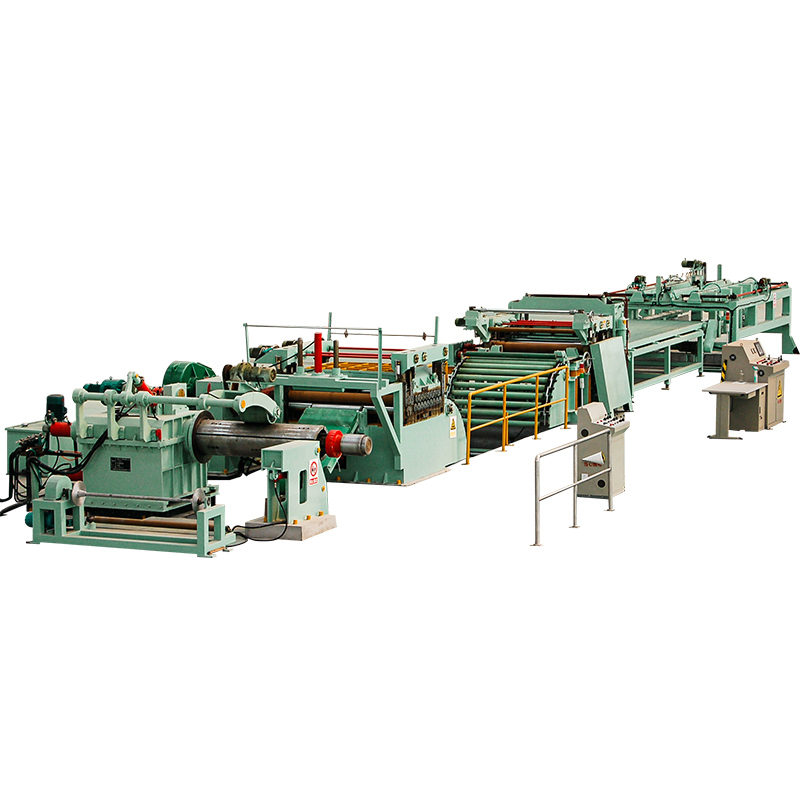

Machines de formage de rouleaux de mobilier scolaire are highly specialized manufacturing systems designed to produce metal profiles and components used in the assembly of classroom furniture. Using cold roll-forming technology, these machines transform metal coils into precise shapes that form the structural framework of desks, chairs, storage units, and other educational furniture.

Given the rigorous use of school furniture, the materials and manufacturing processes must prioritize durability, ergonomics, and cost efficiency. Roll-forming machines ensure consistent production quality, high-volume output, and the flexibility to create customized designs that cater to modern classroom needs.

Caractéristiques principales

- Haute précision: Ensures components meet exact dimensions for seamless assembly and structural integrity.

- Polyvalence des matériaux: Processes a range of metals, including galvanized steel, aluminum, and stainless steel.

- Durabilité: Produces furniture profiles that can withstand years of heavy use in school environments.

- Options de personnalisation: Supports diverse designs to meet the unique requirements of different educational settings.

- Rapport coût-efficacité: Reduces material waste and labor costs, making sturdy furniture more affordable.

Applications of School Furniture Roll Forming Machines

School furniture roll-forming machines are instrumental in producing various types of furniture commonly found in classrooms and educational institutions. Here’s a closer look at their applications:

1. Cadres de bureau

- Cas d'utilisation : Manufacturing the metal frames for student desks, which serve as the foundation for wooden or composite tabletops.

- Pourquoi c'est essentiel : Provides stability and longevity, even under continuous use.

2. Chair Frames

- Cas d'utilisation : Producing ergonomic chair frames that ensure proper posture for students and teachers.

- Pourquoi c'est bénéfique : Combines comfort with durability to support long hours of use.

3. Storage Units

- Cas d'utilisation : Crafting profiles for lockers, shelves, and cabinets used for storing books, supplies, and personal items.

- Pourquoi c'est nécessaire : Ensures a balance of strength and lightweight construction for easy handling and installation.

4. Adjustable Furniture Components

- Cas d'utilisation : Manufacturing height-adjustable frames for desks and chairs, catering to diverse age groups.

- Pourquoi il est unique : Adapts to the ergonomic needs of students from primary school to university.

5. Laboratory Furniture

- Cas d'utilisation : Producing frames for lab benches, stools, and storage units in science classrooms.

- Pourquoi c'est essentiel : Requires corrosion-resistant materials to withstand exposure to chemicals and moisture.

6. Multifunctional Tables

- Cas d'utilisation : Crafting folding or modular tables used in classrooms, libraries, and seminar rooms.

- Pourquoi c'est pertinent : Supports collaborative learning and flexible classroom layouts.

Key Features of Wuxi Sunway School Furniture Roll Forming Machines

Wuxi Sunway Machinery has long been a trusted provider of roll-forming solutions, offering machines tailored to the unique needs of school furniture manufacturers. Below are the standout features of their school furniture roll-forming machines:

1. Material Processing Versatility

- Ce qu'il traite :

- Acier galvanisé

- Acier inoxydable

- Aluminium

- CR (Cold Rolled) Steel

- Pourquoi c'est bénéfique : Allows manufacturers to produce furniture components that meet specific durability and aesthetic requirements.

2. Modular Tooling Design

- Ce qu'il permet : Quick changes between profiles for desks, chairs, lockers, and other furniture components.

- Pourquoi il est polyvalent : Supports multi-profile production without requiring multiple machines.

3. Découpe et poinçonnage intégrés

- Ce qui est inclus : Systèmes intégrés pour la découpe, le poinçonnage et l'encochage de précision pendant le processus de profilage.

- Pourquoi c'est efficace : Réduit le temps de production et garantit que les composants sont prêts pour un assemblage immédiat.

4. Ergonomic Profile Production

- Ce qu'il soutient : Shapes profiles that align with ergonomic principles, ensuring comfort for students and teachers.

- Pourquoi il est unique : Helps manufacturers meet modern educational furniture standards.

5. Efficacité énergétique

- Ce qu'il offre : Machines equipped with energy-efficient motors and optimized workflows.

- Pourquoi c'est durable : Reduces operational costs and aligns with eco-friendly manufacturing practices.

6. Production à grande vitesse

- Ce qu'il accomplit : Produces up to 60 meters of profiles per minute, depending on the complexity of the design.

- Pourquoi c'est essentiel : Keeps up with the high-volume demands of school furniture contracts.

Pricing of School Furniture Roll Forming Machines

Le coût d'un School Furniture Roll Forming Machine varie en fonction de ses caractéristiques, de sa capacité de production et de ses options de personnalisation. Vous trouverez ci-dessous un guide général des prix pour 2025 :

| Type de machine | Capacités | Fourchette de prix (USD) |

|---|---|---|

| Machines standard | Basic desk and chair profiles | 120 000 – 120 000 – 120 000 – 300 000 |

| Machines avancées | Systèmes de découpe et de poinçonnage intégrés à grande vitesse | 300,000–300,000–300,000–600,000 |

| Machines personnalisables | Modular tooling and ergonomic profile production | 600,000–600,000–600,000–1,200,000 |

For tailored pricing and financing options, reach out to Wuxi Sunway Machinery.

Advantages of Using School Furniture Roll Forming Machines

School furniture manufacturers face intense competition, requiring them to optimize production processes while maintaining quality. Machines de formage de rouleaux de mobilier scolaire provide the following advantages:

1. Durability

- Pourquoi c'est crucial : Produces components that can endure decades of heavy use by students and teachers.

2. Précision et cohérence

- Pourquoi c'est bénéfique : Ensures all components meet exact specifications, simplifying assembly and reducing waste.

3. La personnalisation

- Pourquoi c'est essentiel : Supports the production of furniture tailored to different classroom layouts and age groups.

4. Efficacité des coûts

- Pourquoi c'est pratique : Reduces material waste and labor costs, making durable furniture more affordable for schools.

5. L'évolutivité

- Pourquoi c'est pertinent : Meets high-volume production demands for large-scale educational projects.

6. Le développement durable

- Pourquoi c'est important : Minimizes waste and supports the use of recyclable materials, aligning with global sustainability goals.

Automation in School Furniture Roll Forming Machines

Automation has revolutionized the manufacturing of school furniture, enabling greater efficiency, precision, and cost savings. Here’s how automation enhances Machines de formage de rouleaux de mobilier scolaire:

1. Contrôle de qualité piloté par l'IA

- Ce qui est inclus : Real-time defect detection using artificial intelligence and sensor technology.

- Pourquoi il est précieux : Ensures flawless furniture components, minimizing waste and rework.

2. Maintenance prédictive

- Ce qu'il trace : Les capteurs IoT surveillent l'usure des composants des machines et prévoient les besoins de maintenance.

- Pourquoi c'est révolutionnaire : Prevents unexpected downtime, ensuring uninterrupted production.

3. Adaptive Material Handling

- What It Adjusts: Automatically calibrates settings to accommodate different material types and thicknesses.

- Pourquoi c'est bénéfique : Improves production accuracy and eliminates manual recalibrations.

4. Production multi-profils

- Ce qu'il soutient : Seamlessly switches between profiles for desks, chairs, and lockers within a single production run.

- Pourquoi il est polyvalent : Accommodates diverse manufacturing needs without additional setup time.

5. Surveillance et contrôle à distance

- Ce qu'il offre : Cloud-based systems for monitoring and controlling machine operations from anywhere.

- Pourquoi c'est pratique : Enhances productivity and troubleshooting capabilities.

FAQs About School Furniture Roll Forming Machines

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | Galvanized steel, stainless steel, aluminum, and cold-rolled steel. |

| Quelle est la vitesse de production ? | Jusqu'à 60 mètres par minuteen fonction du matériau et de la complexité du profil. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Yes, modular tooling supports bespoke profiles for diverse furniture applications. |

| Ces machines sont-elles respectueuses de l'environnement ? | Oui, ils sont équipés de moteurs à haut rendement énergétique et réduisent au minimum les déchets matériels. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 120,000to120,000 to 120,000to1,200,000en fonction des caractéristiques et de la personnalisation. |

| Ces machines s'intègrent-elles aux systèmes IdO ? | Oui, les fonctions compatibles avec l'IdO permettent une surveillance en temps réel et une maintenance prédictive. |

Real-World Success Stories: School Furniture Roll Forming Machines in Action

From small-scale manufacturers to global furniture suppliers, Machines de formage de rouleaux de mobilier scolaire have helped countless companies improve their production processes. Below are some inspiring success stories of how Wuxi Sunway Machinery’s roll-forming machines have transformed school furniture manufacturing.

1. Nationwide School Desk Production in Africa

Client : A government contractor in Kenya tasked with producing desks for schools across the country.

Défi : The client needed to manufacture durable yet affordable school desks to meet growing demand in rural and urban areas.

Solution : Wuxi Sunway provided a roll-forming machine optimized for galvanized steel, which is both cost-effective and corrosion-resistant.

Résultat :

- Increased production capacity by 50%, helping the client deliver desks ahead of schedule.

- Réduction des déchets de matériaux de 20%, diminuant ainsi les coûts de production globaux.

- Produced desks that could withstand challenging environmental conditions, including high humidity and frequent use.

2. Ergonomic Classroom Seating in Europe

Client : A premium furniture manufacturer in Germany specializing in ergonomic school chairs.

Défi : The client required precision-engineered frames that adhered to strict European Union standards for ergonomics and safety.

Solution : Wuxi Sunway supplied a machine with high-precision rollers and integrated cutting systems, capable of producing ergonomic profiles with tight tolerances.

Résultat :

- Delivered chairs that offered superior comfort and posture support, enhancing student focus and productivity.

- Reduced assembly time by 30%, enabling faster delivery to schools.

- Helped the client secure long-term contracts with educational institutions across Europe.

3. Modular Furniture Production for Smart Classrooms in Asia

Client : A furniture supplier in South Korea specializing in modular tables and chairs for technology-enhanced classrooms.

Défi : The supplier needed a machine that could quickly switch between different profiles to produce flexible furniture designs.

Solution : Wuxi Sunway designed a roll-forming machine with modular tooling for multi-profile production.

Résultat :

- Produced components for modular tables and chairs that could be easily reconfigured for different classroom layouts.

- Expanded the client’s product portfolio, allowing them to tap into the growing market for smart classrooms.

- Reduced setup time between production runs, improving overall efficiency.

4. Sustainable Furniture for Green Schools in North America

Client : An eco-conscious manufacturer in Canada producing furniture for environmentally certified “green schools.”

Défi : The client needed a machine capable of processing recyclable materials like aluminum and ensuring zero waste.

Solution : Wuxi Sunway delivered a machine with energy-efficient motors and features for minimizing scrap material.

Résultat :

- Produced lightweight yet durable furniture aligned with sustainability goals.

- Reduced energy consumption by 25%, lowering operational costs.

- Strengthened the client’s reputation as a leader in green manufacturing.

Troubleshooting Common Issues with School Furniture Roll Forming Machines

Même les plus avancés Machines de formage de rouleaux de mobilier scolaire can encounter operational challenges. Understanding how to troubleshoot these issues can help manufacturers maintain smooth and efficient production.

1. Uneven Material Feeding

- Symptômes : The material does not feed smoothly, causing misaligned or inconsistent profiles.

- Causes possibles :

- Rouleaux d'alimentation mal alignés.

- Variations de l'épaisseur ou de la qualité du matériau.

- Solution :

- Recalibrate the feeder rollers to ensure alignment.

- Inspect and replace raw materials with consistent thickness and quality.

2. Inaccurate Profile Dimensions

- Symptômes : Finished components do not meet the required specifications, leading to poor assembly.

- Causes possibles :

- Worn-out rollers or incorrect roller alignment.

- Insufficient forming pressure or unstable machine settings.

- Solution :

- Regularly inspect and replace worn rollers.

- Adjust forming pressure and recalibrate machine settings.

3. Usure rapide de l'outil

- Symptômes : Cutting and punching tools degrade quickly, reducing production efficiency.

- Causes possibles :

- Processing abrasive materials without proper lubrication.

- Using low-grade tooling components.

- Solution :

- Implement a lubrication regimen to reduce friction.

- Upgrade to high-grade tooling materials designed for heavy-duty applications.

4. Overheating of Motors

- Symptômes : The machine slows down or shuts off unexpectedly during extended operation.

- Causes possibles :

- Overloaded motors or blocked cooling vents.

- Solution :

- Utiliser la machine dans les limites de la capacité recommandée.

- Clean and maintain cooling vents to ensure proper airflow.

5. Dysfonctionnements des logiciels

- Symptômes : Le système de commande de la machine ne répond plus ou exécute mal les commandes.

- Causes possibles :

- Logiciel ou microprogramme obsolète.

- Défauts électriques dans le panneau de contrôle.

- Solution :

- Mettre à jour le logiciel de la machine avec la dernière version.

- Inspect and repair electrical connections to restore functionality.

Global Industry Trends for School Furniture Manufacturing in 2025

The global education sector is evolving rapidly, bringing new challenges and opportunities for furniture manufacturers. Here are the major trends shaping the future of school furniture production:

1. Increased Demand for Ergonomic Designs

- Tendance : Schools are prioritizing furniture that promotes good posture and reduces strain on students during long study hours.

- Impact : Roll-forming machines must support the production of complex ergonomic profiles with high precision.

2. Growth in Sustainable Manufacturing

- Tendance : Educational institutions are adopting eco-friendly practices, including the use of recyclable and sustainable furniture.

- Impact : Machines optimized for processing aluminum and other recyclable materials are in high demand.

3. Rise of Smart Classrooms

- Tendance : The integration of technology in classrooms is driving demand for modular and multifunctional furniture.

- Impact : Machines capable of producing flexible designs for adjustable desks and collaborative tables are critical.

4. Expansion sur les marchés émergents

- Tendance : Developing regions in Asia, Africa, and South America are investing in modernizing their educational infrastructure.

- Impact : Affordable roll-forming machines that offer high-volume production are essential for these markets.

5. Customization for Diverse Learning Environments

- Tendance : Schools are adopting furniture designed for specific learning spaces, such as STEM labs and art studios.

- Impact : Machines with modular tooling and multi-profile production capabilities are becoming more valuable.

Why Wuxi Sunway Machinery Leads the School Furniture Manufacturing Industry

Wuxi Sunway Machinery has earned a global reputation for delivering reliable, innovative, and customizable roll-forming solutions. Here’s why they remain a trusted partner for school furniture manufacturers:

- Une expertise reconnue : Decades of experience in designing roll-forming machines for diverse industries.

- Une portée mondiale : Des clients d'Asie, d'Europe, des Amériques et d'ailleurs lui font confiance.

- Excellence en matière de personnalisation : Tailored solutions for unique school furniture designs.

- Axé sur l'innovation : Pioneers in integrating IoT, AI, and modular tooling into their machines.

- Engagement en matière de développement durable : Conçoit des machines conformes aux pratiques de fabrication respectueuses de l'environnement.

- Soutien global : Fournit des services exceptionnels de consultation, d'installation, de formation et d'après-vente.

FAQs About School Furniture Roll Forming Machines

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | Galvanized steel, stainless steel, aluminum, and cold-rolled steel. |

| Quelle est la vitesse de production ? | Jusqu'à 60 mètres par minuteen fonction du matériau et de la complexité du profil. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Yes, modular tooling supports bespoke profiles for diverse furniture applications. |

| Ces machines sont-elles respectueuses de l'environnement ? | Oui, ils sont équipés de moteurs à haut rendement énergétique et réduisent au minimum les déchets matériels. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 120,000to120,000 to 120,000to1,200,000en fonction des caractéristiques et de la personnalisation. |

| Ces machines s'intègrent-elles aux systèmes IdO ? | Oui, les fonctions compatibles avec l'IdO permettent une surveillance en temps réel et une maintenance prédictive. |

Conclusion: Equipping Classrooms for the Future

As schools around the world strive to create more comfortable, sustainable, and technologically advanced learning environments, the demand for high-quality furniture will only grow. Machines de formage de rouleaux de mobilier scolaire play a critical role in meeting these demands, offering manufacturers the precision, efficiency, and scalability needed to produce exceptional products.

Ready to take your school furniture production to the next level? Partner with Wuxi Sunway Machinery and explore their cutting-edge roll-forming solutions. Together, let’s shape the future of education—one component at a time.