The growing demand for renewable energy has placed wind turbines at the forefront of sustainable power generation. As wind turbine technology evolves, so does the need for precision, scalability, and efficiency in manufacturing components such as structural supports, tower sections, and blade reinforcements. Enter Machines de formage de rouleaux pour éoliennes—advanced systems designed to produce high-strength and durable components essential for wind turbine construction.

Dans cet article, nous explorerons what wind turbine roll forming machines are, their applications, pricing, automation features, environmental benefits, and why Wuxi Sunway Machinery stands out as a global leader in this field. Whether you’re a manufacturer scaling up production or a renewable energy developer exploring cost-effective solutions, this guide will provide valuable insights.

What Are Wind Turbine Roll Forming Machines?

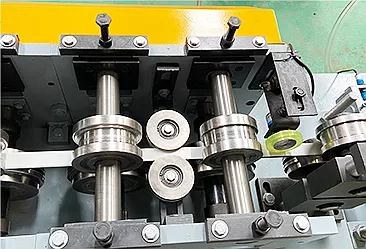

Machines de formage de rouleaux pour éoliennes are specialized systems that use roll-forming technology to manufacture metal components required in constructing wind turbines. These machines shape flat metal sheets or coils into precise profiles, ensuring high strength, durability, and compliance with stringent industry standards.

Given the massive scale of modern wind turbines, these roll-forming machines are designed to handle large materials while maintaining accuracy and efficiency. From producing tower sections to crafting reinforcements for blades, these machines are integral to the wind energy industry.

Caractéristiques principales

- Haute précision: Ensures exact dimensions, meeting the rigorous standards of wind turbine construction.

- Polyvalence des matériaux: Processes high-strength steel, galvanized steel, and aluminum.

- Profils personnalisés: Capable of producing unique shapes tailored to specific wind turbine designs.

- Durabilité: Outputs components that can withstand extreme environmental conditions.

- Évolutivité: Supports large-scale production to meet the growing demand for renewable energy projects.

Applications of Wind Turbine Roll Forming Machines

The components of a wind turbine must be engineered to meet stringent safety, performance, and durability standards. Roll-forming machines play a critical role in manufacturing these components with precision and efficiency.

1. Tower Sections

- Cas d'utilisation : Producing cylindrical or tapered sections of wind turbine towers.

- Pourquoi c'est essentiel : Provides the structural integrity required to support the turbine at high altitudes.

2. Blade Reinforcements

- Cas d'utilisation : Shaping metal reinforcements for turbine blades to enhance their strength and resistance to wind forces.

- Pourquoi c'est bénéfique : Ensures the blades can withstand extreme wind speeds and prolonged operational stress.

3. Framework and Base Structures

- Cas d'utilisation : Crafting the frameworks and base plates that anchor turbines to the ground or seabed.

- Pourquoi c'est nécessaire : Ensures stability and safety, even in harsh environmental conditions.

4. Nacelle Components

- Cas d'utilisation : Manufacturing the housing units that protect critical turbine components like generators and gearboxes.

- Pourquoi il est unique : Offers durability and precision, safeguarding sensitive equipment from the elements.

5. Support Beams and Braces

- Cas d'utilisation : Producing braces and beams that enhance the structural integrity of the turbine.

- Pourquoi c'est essentiel : Prevents structural deformations caused by continuous wind pressure and rotor movement.

6. Offshore Wind Turbine Components

- Cas d'utilisation : Crafting specialized components designed for turbines installed in marine environments.

- Pourquoi c'est pertinent : Provides corrosion resistance and structural durability in high-salinity conditions.

Advantages of Using Wind Turbine Roll Forming Machines

The renewable energy sector demands manufacturing solutions that can deliver precision, efficiency, and scalability. Here’s why Machines de formage de rouleaux pour éoliennes are indispensable for wind energy projects:

1. Ingénierie de précision

- Pourquoi c'est crucial : Meets the tight tolerances required for components that must operate efficiently in extreme conditions.

2. Production à grande vitesse

- Pourquoi c'est bénéfique : Enables manufacturers to meet the growing global demand for wind turbines without compromising quality.

3. La personnalisation

- Pourquoi c'est essentiel : Supports the production of unique profiles tailored to specific turbine designs and site requirements.

4. Le rapport coût-efficacité

- Pourquoi c'est pratique : Reduces material waste and labor costs, making renewable energy projects more financially viable.

5. Durabilité

- Pourquoi c'est pertinent : Produces components capable of withstanding prolonged exposure to wind, rain, and temperature fluctuations.

6. Fabrication respectueuse de l'environnement

- Pourquoi c'est important : Minimizes waste and supports the use of recyclable materials, aligning with the sustainability goals of wind energy.

Key Features of Wuxi Sunway Wind Turbine Roll Forming Machines

Wuxi Sunway Machinery is at the forefront of roll-forming technology, offering machines specifically tailored for the wind energy sector. Here’s what sets their machines apart:

1. Manutention avancée

- Matériaux pris en charge :

- Acier à haute résistance

- Acier galvanisé

- Aluminium

- Pourquoi c'est bénéfique : Ensures compatibility with materials that provide the strength and durability required for wind turbine components.

2. Systèmes d'outillage modulaires

- Ce qu'il offre : Outillage interchangeable pour la production de profils multiples sur une seule machine.

- Pourquoi il est polyvalent : Permet de répondre à divers besoins de fabrication sans nécessiter d'équipement supplémentaire.

3. Integrated Cutting, Punching, and Welding

- Ce qui est inclus : Built-in systems for precision cutting, punching, and welding during the roll-forming process.

- Pourquoi c'est efficace : Réduit le temps de production et garantit des composants prêts à être installés.

4. Intégration de l'IdO et de l'automatisation

- Ce qu'il permet : Surveillance en temps réel, ajustements automatisés et maintenance prédictive à l'aide de systèmes IoT.

- Pourquoi c'est révolutionnaire :

- Améliore l'efficacité de la production.

- Minimise les temps d'arrêt et les coûts d'exploitation.

5. High-Capacity Production

- Ce qu'il offre : Machines capable of producing large-scale components to meet the demands of utility-scale wind farms.

- Pourquoi c'est essentiel : Keeps up with the rapid growth of the renewable energy market.

6. Conception écologique

- Ce qui est inclus : Moteurs à haut rendement énergétique, optimisation des flux de travail et systèmes de réduction des déchets.

- Pourquoi c'est durable : Supports global efforts to reduce the carbon footprint of manufacturing.

Pricing of Wind Turbine Roll Forming Machines

Le coût d'un Wind Turbine Roll Forming Machine dépend de ses caractéristiques, de sa capacité de production et de ses options de personnalisation. Vous trouverez ci-dessous un guide général des prix pour 2025 :

| Type de machine | Capacités | Fourchette de prix (USD) |

|---|---|---|

| Machines standard | Basic profiles for towers and supports | 500,000–500,000–500,000–1,200,000 |

| Machines avancées | High-speed, integrated cutting and welding systems | 1,200,000–1,200,000–1,200,000–2,500,000 |

| Machines entièrement personnalisables | Outil modulaire compatible avec l'IdO, caractéristiques respectueuses de l'environnement | 2,500,000–2,500,000–2,500,000–5,000,000 |

Pour obtenir des informations détaillées sur les prix et les options de financement, veuillez contacter Wuxi Sunway Machinery.

Automation in Wind Turbine Roll Forming Machines

L'automatisation transforme le paysage industriel et Machines de formage de rouleaux pour éoliennes are no exception. Here’s a look at some advanced automation features:

1. Détection des défauts en temps réel

- Ce qui est inclus : AI-powered systems that identify surface defects, misalignments, or structural faults in real time.

- Pourquoi il est précieux : Ensures only flawless components are used, reducing waste and rework.

2. Maintenance prédictive

- Ce qu'il trace : IoT sensors monitor wear and tear on components and predict maintenance needs before failures occur.

- Pourquoi c'est révolutionnaire : Prévient les temps d'arrêt imprévus et prolonge la durée de vie de la machine.

3. Réglage adaptatif des rouleaux

- Ce qu'il fait : Ajuste automatiquement la position des rouleaux en fonction de l'épaisseur du matériau et de la conception des profils.

- Pourquoi c'est bénéfique : Eliminates manual calibration, improving efficiency and precision.

4. Cloud-Based Monitoring and Control

- Ce qui est inclus : Remote access to operational data, diagnostics, and controls via cloud-based systems.

- Pourquoi c'est pratique : Allows operators to oversee production from anywhere, ensuring maximum uptime.

5. Production multi-profils

- Ce qu'il permet : Seamlessly switches between various profiles within a single production run.

- Pourquoi c'est pratique : Permet de répondre à des besoins de fabrication diversifiés sans temps de configuration supplémentaire.

Environmental Benefits of Wind Turbine Roll Forming Machines

As the world shifts toward renewable energy, the manufacturing processes behind these technologies must also align with environmental goals. Here’s how Machines de formage de rouleaux pour éoliennes contribuer à la durabilité :

1. Réduction des déchets matériels

- Comment cela est réalisé : La précision de l'ingénierie permet de réduire au minimum les rebuts lors de la production.

- Impact : Conserves resources and reduces disposal costs.

2. Efficacité énergétique

- Comment cela fonctionne-t-il ? Machines are equipped with energy-efficient motors and optimized workflows.

- Impact : Réduit la consommation d'énergie et l'empreinte carbone de la fabrication.

3. Utilisation de matériaux recyclables

- Ce qu'il soutient : Processes materials like aluminum and steel, which are fully recyclable.

- Impact : Encourage les pratiques durables et promeut une économie circulaire.

4. Sorties durables

- Pourquoi c'est important : Les composants produits sont durables et réduisent le besoin de remplacements fréquents.

- Impact : Supports the longevity and reliability of wind turbines.

FAQs About Wind Turbine Roll Forming Machines

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | High-strength steel, galvanized steel, and aluminum. |

| Quelle est la vitesse de production ? | Jusqu'à 100 mètres par minuteen fonction du matériau et de la complexité du profil. |

| Ces machines sont-elles respectueuses de l'environnement ? | Oui, ils sont équipés de moteurs à haut rendement énergétique et réduisent au minimum les déchets matériels. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Absolutely! Modular tooling supports bespoke profiles for diverse wind turbine components. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 500,000to500,000 to 500,000to5,000,000Les prix sont calculés sur la base des caractéristiques et de la personnalisation. |

| Ces machines s'intègrent-elles aux systèmes IdO ? | Oui, les fonctions compatibles avec l'IdO permettent une surveillance en temps réel et une maintenance prédictive. |

Real-World Success Stories: Wind Turbine Roll Forming Machines in Action

The efficiency and reliability of Machines de formage de rouleaux pour éoliennes have enabled manufacturers worldwide to meet the increasing demand for wind energy infrastructure. Below are some key success stories that demonstrate how these machines have transformed the production landscape.

1. Offshore Wind Farm in Europe

Client : A prominent renewable energy developer specializing in offshore wind farms.

Défi : The client needed corrosion-resistant tower sections and base structures for turbines stationed in high-salinity marine environments.

Solution : Wuxi Sunway supplied a roll-forming machine capable of processing galvanized steel with anti-corrosion coatings applied during production.

Résultat :

- Produced tower sections with superior corrosion resistance, extending the turbines’ operational lifespan by 20 years.

- Increased production capacity by 35%, enabling the wind farm to be operational ahead of schedule.

- Reduced material waste by 15%, cutting overall project costs.

2. Onshore Wind Turbine Project in North America

Client : A manufacturer supplying components for onshore wind turbine installations in remote areas.

Défi : The client required lightweight yet durable support braces that could be easily transported and assembled on-site.

Solution : Wuxi Sunway provided a roll-forming machine optimized for high-strength steel with integrated cutting and welding features.

Résultat :

- Delivered components that reduced overall turbine weight, improving transportation efficiency.

- Enhanced the structural stability of turbines, ensuring safety in high-wind conditions.

- Achieved a 25% reduction in production time, meeting tight project deadlines.

3. Hybrid Wind-Solar Energy Project in Asia

Client : A renewable energy contractor developing a hybrid wind-solar power plant.

Défi : The project required custom-designed turbine components compatible with hybrid energy systems.

Solution : Wuxi Sunway supplied a roll-forming machine with modular tooling for producing bespoke profiles tailored to the hybrid system’s specifications.

Résultat :

- Enabled the creation of innovative, multi-functional components.

- Strengthened the contractor’s position as a leader in hybrid energy solutions.

- Achieved a 20% cost reduction compared to traditional manufacturing methods.

4. Small-Scale Wind Turbines for Rural Electrification in Africa

Client : A non-profit organization focused on providing renewable energy to rural communities.

Défi : The organization needed cost-effective and scalable solutions for manufacturing small-scale wind turbine components.

Solution : Wuxi Sunway delivered a compact roll-forming machine designed for lightweight materials such as aluminum.

Résultat :

- Produced affordable components suitable for small-scale applications.

- Empowered rural communities with access to sustainable energy.

- Reduced the carbon footprint of the manufacturing process, aligning with the non-profit’s mission.

Troubleshooting Common Issues in Wind Turbine Roll Forming Machines

Même les plus avancés Machines de formage de rouleaux pour éoliennes may encounter operational challenges. Here’s a guide to troubleshooting common issues and maintaining seamless production.

1. Inconsistent Component Profiles

- Symptômes : Produced components vary in dimensions or fail to meet design specifications.

- Causes possibles :

- Rouleaux mal alignés ou outillage usé.

- Uneven material feeding.

- Solution :

- Inspecter et recalibrer régulièrement les rouleaux pour garantir un alignement correct.

- Utiliser des matières premières de haute qualité et uniformes pour éviter les incohérences.

2. Material Jams During Feeding

- Symptômes : Le matériau s'arrête ou se bloque pendant le processus d'alimentation.

- Causes possibles :

- Tension ou alignement incorrect du chargeur.

- Débris ou objets étrangers dans la trajectoire d'alimentation.

- Solution :

- Adjust feeder settings to match material specifications.

- Nettoyez le chemin d'alimentation et vérifiez qu'il n'y a pas d'obstructions avant de commencer la production.

3. Usure rapide de l'outil

- Symptômes : Cutting and welding tools require frequent replacements, leading to downtime.

- Causes possibles :

- Matériaux de qualité inférieure provoquant une usure excessive.

- Lubrification insuffisante des pièces mobiles.

- Solution :

- Opt for high-grade materials designed for roll forming.

- Implement a maintenance schedule to lubricate and clean tools regularly.

4. Surchauffe de la machine

- Symptômes : La machine fonctionne de manière inefficace ou s'arrête de manière inattendue.

- Causes possibles :

- Moteurs surchargés ou fonctionnement prolongé à la capacité maximale.

- Les évents de refroidissement sont obstrués ou le débit d'air est insuffisant.

- Solution :

- Utiliser la machine dans les limites de la capacité recommandée.

- Veillez à une bonne ventilation et nettoyez régulièrement les systèmes de refroidissement.

5. Software or Control Panel Failures

- Symptômes : The machine’s control system becomes unresponsive or fails to execute commands.

- Causes possibles :

- Logiciel ou microprogramme obsolète.

- Connexions électriques défectueuses.

- Solution :

- Mettre à jour le logiciel de la machine avec la dernière version.

- Inspecter et réparer les connexions électriques afin de garantir leur bon fonctionnement.

Global Market Trends for Wind Turbine Roll Forming Machines in 2025

The demand for wind energy is surging globally, driven by advancements in technology, government incentives, and sustainability goals. Here are some key trends shaping the market for Machines de formage de rouleaux pour éoliennes:

1. Expansion of Offshore Wind Farms

- Tendance : Countries are investing heavily in offshore wind projects to harness stronger and more consistent wind resources.

- Impact : Machines capable of producing corrosion-resistant and large-scale components are in high demand.

2. Croissance sur les marchés émergents

- Tendance : Developing countries in Africa, Asia, and South America are adopting wind energy to meet growing electricity demands.

- Impact : Cost-effective and scalable roll-forming solutions are essential for these markets.

3. Focus on Hybrid Energy Systems

- Tendance : The integration of wind energy with solar and battery storage is gaining traction.

- Impact : Machines that can produce multi-functional components are becoming increasingly valuable.

4. Advancements in Blade Design

- Tendance : New blade designs aim to improve efficiency and reduce noise.

- Impact : Roll-forming machines with advanced tooling for blade reinforcements are crucial.

5. Commitment to Sustainability

- Tendance : Les fabricants adoptent des pratiques respectueuses de l'environnement pour s'aligner sur les objectifs mondiaux de développement durable.

- Impact : Machines designed to minimize waste and use recyclable materials are setting industry benchmarks.

Advanced Automation Features in Wind Turbine Roll Forming Machines

Automation is revolutionizing the manufacturing process, enabling greater efficiency and precision in producing wind turbine components. Here are some of the most advanced automation features available in Machines de formage de rouleaux pour éoliennes:

1. AI-Powered Defect Detection

- Ce qui est inclus : Artificial intelligence systems that identify defects in real time.

- Pourquoi il est précieux : Reduces waste and ensures only high-quality components proceed to assembly.

2. Maintenance prédictive

- Ce qu'il trace : IoT sensors monitor machine components and predict maintenance needs before issues arise.

- Pourquoi c'est révolutionnaire : Minimizes downtime and extends the machine’s operational lifespan.

3. Réglage adaptatif des rouleaux

- Ce qu'il fait : Ajuste automatiquement la position des rouleaux en fonction de l'épaisseur du matériau et des exigences du profil.

- Pourquoi c'est bénéfique : Improves precision and reduces setup time.

4. Production multi-profils

- Ce qu'il permet : Permet de passer en toute transparence d'un profil de composant à l'autre au cours d'un même cycle de production.

- Pourquoi c'est pratique : Permet de répondre à des besoins de fabrication diversifiés sans modification supplémentaire de l'outillage.

5. Surveillance et contrôle à distance

- Ce qui est inclus : Cloud-based systems for monitoring and controlling the machine from any location.

- Pourquoi c'est utile : Allows operators to oversee production and troubleshoot issues remotely, ensuring maximum uptime.

Why Choose Wuxi Sunway Machinery for Wind Turbine Roll Forming Machines?

Wuxi Sunway Machinery has established itself as a global leader in roll-forming technology, offering cutting-edge solutions for the renewable energy sector. Here’s why manufacturers consistently turn to Wuxi Sunway:

- Une expertise reconnue : Decades of experience in designing high-performance roll-forming machines for energy applications.

- Une portée mondiale : Des clients d'Asie, d'Europe, des Amériques et d'ailleurs lui font confiance.

- Axé sur l'innovation : Incorporates IoT, AI, and modular tooling into their machines to enhance efficiency.

- Engagement en matière de développement durable : Designs machines that align with the renewable energy industry’s focus on reducing environmental impact.

- Soutien global : Fournit des services exceptionnels de consultation, d'installation, de formation et d'après-vente.

Explore their range of roll-forming solutions on the site officiel.

FAQs About Wind Turbine Roll Forming Machines

| Question | Réponse |

|---|---|

| Quels matériaux ces machines peuvent-elles traiter ? | High-strength steel, galvanized steel, and aluminum. |

| Quelle est la vitesse de production ? | Jusqu'à 100 mètres par minuteen fonction du matériau et de la complexité du profil. |

| Ces machines sont-elles respectueuses de l'environnement ? | Oui, ils sont équipés de moteurs à haut rendement énergétique et réduisent au minimum les déchets matériels. |

| Ces machines peuvent-elles prendre en charge des conceptions personnalisées ? | Absolutely! Modular tooling supports bespoke profiles for diverse wind turbine components. |

| Quelle est la fourchette de prix de ces machines ? | Les prix varient de 500,000to500,000 to 500,000to5,000,000Les prix sont calculés sur la base des caractéristiques et de la personnalisation. |

| Ces machines s'intègrent-elles aux systèmes IdO ? | Oui, les fonctions compatibles avec l'IdO permettent une surveillance en temps réel et une maintenance prédictive. |

Conclusion: A New Era of Renewable Energy Manufacturing

Machines de formage de rouleaux pour éoliennes are revolutionizing the renewable energy sector by enabling the efficient production of critical wind turbine components. With their precision, scalability, and eco-friendly design, these machines are paving the way for a sustainable energy future.

Ready to power up your manufacturing capabilities? Partner with Wuxi Sunway Machinery and explore their state-of-the-art roll-forming solutions for the wind energy industry. Together, let’s harness the power of the wind to build a greener, brighter future.