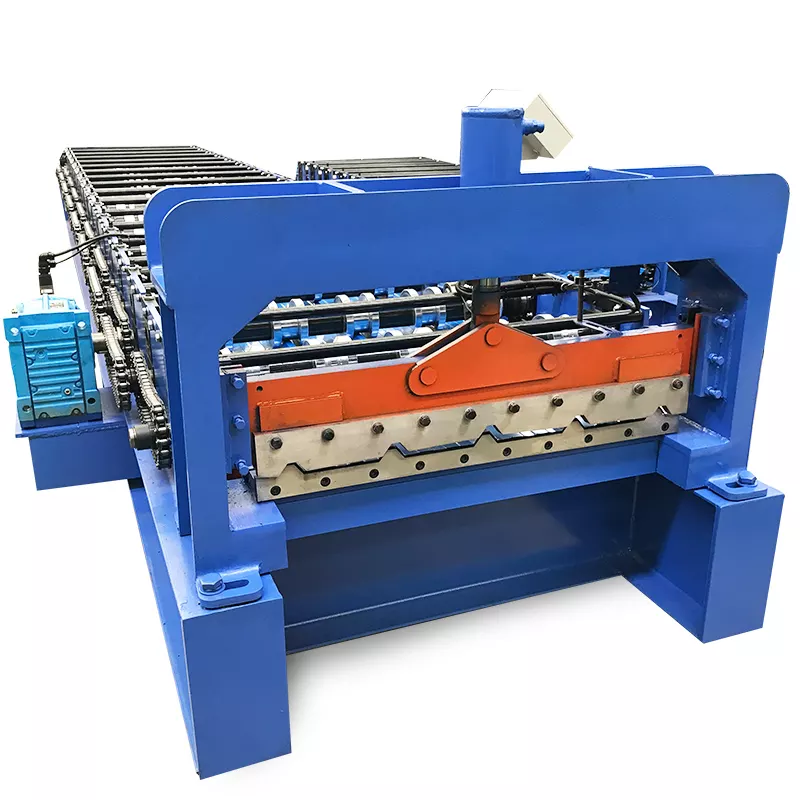

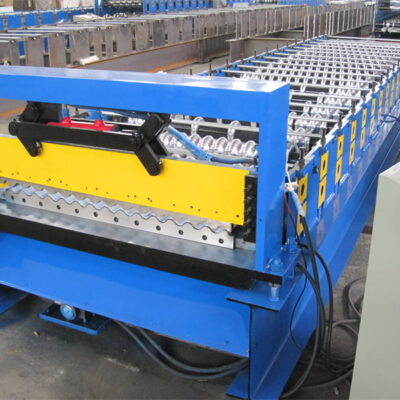

Roof Tile Forming Machine Details

স্ট্যান্ড বেস

উচ্চ শক্তি এবং ভারী শুল্ক সহ কাঁচামাল হিসাবে উচ্চ মানের ইস্পাত নির্বাচন করুন, যার বিকৃতির শক্তিশালী প্রতিরোধ রয়েছে।

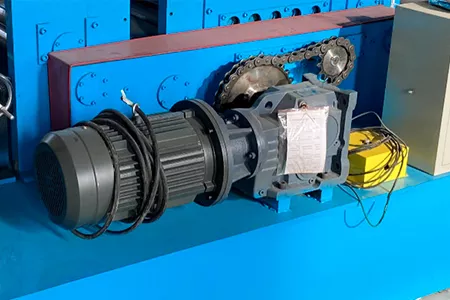

মোটর

ড্রাইভ সিস্টেমের জন্য শীর্ষ ব্র্যান্ডের মোটর গ্রহণ করুন, আরও স্থিতিশীল এবং কার্যকর।

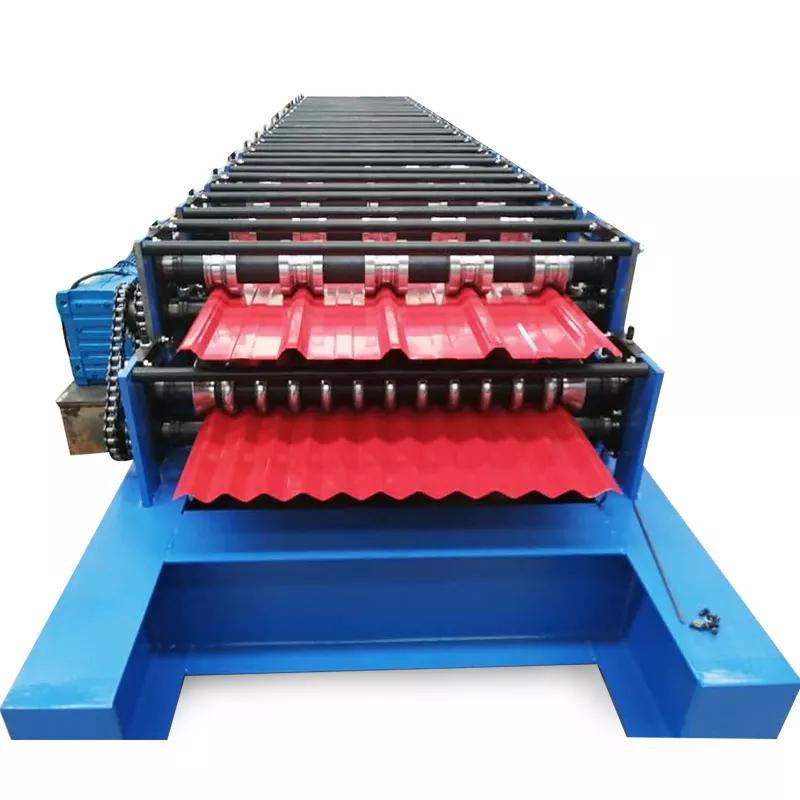

রোলার এবং শ্যাফ্ট

বহু বছরের উত্পাদন অভিজ্ঞতা, আরও পেশাদার এবং আরও নির্ভুলতার সাথে।

কাস্টমাইজেশন

সিনিয়র এবং অভিজ্ঞ প্রকৌশলী আপনার কাস্টমাইজের জন্য পুরো প্রক্রিয়া নিয়ন্ত্রণ করে।

Roof Tile Forming Machine Parameters

| পণ্য | ছাদ শীট রোল মেশিন গঠন |

| মডেল | ঢেউতোলা ট্র্যাপিজয়েডাল (কাস্টমাইজযোগ্য) |

| বেস উপাদান | GI/GL, PPGI/PPGL, অ্যালুমিনিয়াম কয়েল |

| পুরুত্ব | 0.3 মিমি-0.8 মিমি |

| কার্যকরী প্রস্থ |

600-1250 মিমি (গ্রাহকের প্রয়োজনীয়তা অনুযায়ী / কাস্টমাইজযোগ্য)

|

| রোলার স্টেশন | 14-18 স্টেশন |

| বেলন উপাদান | 45# ইস্পাত / বিয়ারিং স্টিল / Cr12Mov |

| রোলার চালিত প্রকার | চেইন/গিয়ারবক্স দ্বারা |

| রঙ |

গ্রাহকের প্রয়োজনীয়তা অনুযায়ী / কাস্টমাইজযোগ্য

|

| ব্র্যান্ড | সানওয়ে |

| নিয়ন্ত্রণ ব্যবস্থা |

বিশ্বব্যাপী বিখ্যাত ব্র্যান্ড পিএলসি (প্যানাসনিক, সিমেন্স, ডেল্টা, ইত্যাদি)

|

| শক্তি | 4KW-5.5KW-7.5KW |

| ফ্রেম | 350 এইচ ইস্পাত / 400 এইচ ইস্পাত |

| ড্রাইভ কাটা | হাইড্রোলিক ড্রাইভ |

| কাটিং এবং হাইড্রোলিক টাইপ |

প্রকার: ডাবল গাইড পিলার হাইড্রোলিক কাটিং।

হাইড্রোলিক পাম্প স্টেশন: 4kw ব্লেড: Cr12mov HRC:58-62 |

| ড্রাইভের পথ | 1.2 ইঞ্চি একক চেইন |

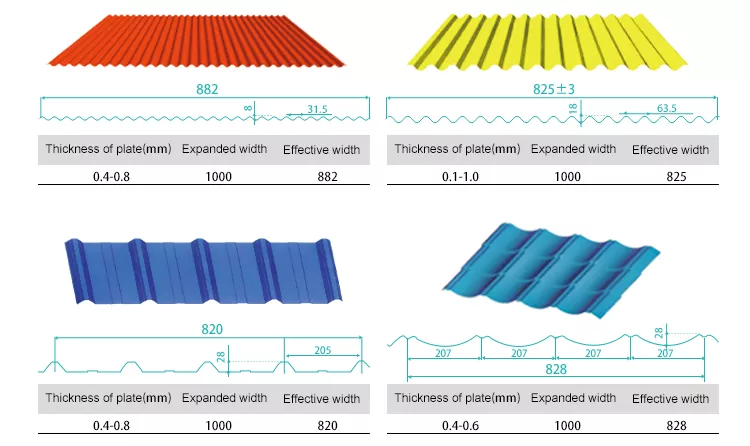

পণ্যের ধরন

what is roofing sheet roll forming machine?

The roll forming machine takes flat metal coils and shapes them into the desired roofing sheet profile. The process involves feeding the coil into the machine, where it passes through a series of rollers and tooling. These rollers progressively bend and form the metal strip into the specific shape and design of the roofing sheet. The machine is designed with various stations and roll sets that perform specific operations, including bending, profiling, embossing, and cutting.

The roofing sheet roll forming machine typically includes components such as decoilers for holding and feeding the coil, leveling units for straightening the strip, profiling rollers for shaping the sheet, embossing rollers for adding textures or patterns, and cutting units for trimming the sheet to the desired length. The machine operates automatically, driven by motors and controlled by a computerized system, ensuring high precision and efficiency in the production process.

The resulting roofing sheets can have different profiles, such as corrugated sheets, trapezoidal sheets, or standing seam sheets, depending on the design and requirements. These sheets offer durability, weather resistance, and aesthetic appeal to the buildings they are used on.

what is glazed roof tile roll forming machine?

The roll forming machine takes flat metal coils, typically steel or aluminum, and transforms them into the desired glazed roof tile profile. The process involves feeding the coil into the machine, which passes through a series of rollers and tooling. These rollers gradually bend and shape the metal strip into the specific design and dimensions of the glazed roof tile.

The glazed roof tile roll forming machine includes components such as decoilers to hold and feed the coil, leveling units to straighten the strip, profiling rollers to shape the tile, and cutting units to cut the tiles to the desired length. Depending on the specific requirements, the machine may also include additional stations for applying the glaze or coating to the surface of the tiles.

The machine operates automatically, driven by motors and controlled by a computerized system. This ensures precision and consistency in the production process, resulting in high-quality glazed roof tiles.

Glazed roof tiles offer several advantages, including enhanced aesthetics, weather resistance, and longevity. They are available in various colors, finishes, and designs, allowing for customization and versatility in architectural projects.

what is roofing tile roll forming machine?

A roofing tile roll forming machine is a type of industrial equipment used in the construction industry to manufacture roofing tiles. Roll forming is a continuous bending operation where a long strip of metal or other material is passed through a series of roller dies to gradually shape it into a desired profile.

In the case of a roofing tile roll forming machine, the machine takes a flat strip of material, typically metal such as steel or aluminum, and forms it into a specific shape resembling a roofing tile. The machine consists of a series of rollers, each with a different shape, arranged in a sequence. As the strip passes through the rollers, it undergoes a gradual transformation, acquiring the shape and dimensions of a roofing tile.

The roofing tile roll forming machine typically includes various components and features to ensure accurate and efficient production. These may include a decoiler to hold and feed the raw material, a leveling device to straighten the strip, a roll former with multiple roller stations for shaping the tile, and a cutting system to cut the tiles to the desired length. Some machines may also have additional features like embossing or stamping mechanisms to create patterns or designs on the tiles.

The finished roofing tiles produced by the machine can be used for various applications, such as residential or commercial roofing projects. The advantage of using a roll forming machine is that it allows for high-speed and precise production of roofing tiles with consistent quality.

Development of China roof tile roll forming machine

China has been a major player in the development and production of roof tile roll forming machines. Over the years, the country has made significant advancements in the design, manufacturing, and technology of these machines. Here are some key points regarding the development of China’s roof tile roll forming machines:

- Industry Growth: China has experienced rapid growth in its construction industry, including the demand for roofing materials. This growth has led to an increased focus on the development of efficient and cost-effective manufacturing equipment, such as roof tile roll forming machines.

- Technological Advancements: Chinese manufacturers have invested in research and development to improve the technology and capabilities of roof tile roll forming machines. They have integrated advanced features like computer numerical control (CNC), servo motors, hydraulic systems, and automatic control systems to enhance productivity, precision, and ease of operation.

- Wide Range of Tile Profiles: Chinese manufacturers offer a wide variety of roof tile profiles to cater to different architectural styles and customer preferences. These profiles include corrugated tiles, glazed tiles, step tiles, wave tiles, and more. The roll forming machines are designed to accommodate various tile shapes and sizes, allowing for versatility in production.

- Customization and Adaptability: Chinese manufacturers have focused on providing customized solutions to meet specific customer requirements. They offer machines that can be easily adjusted and adapted to produce different tile profiles, colors, and dimensions. This flexibility has been instrumental in meeting the diverse needs of the global market.

- Quality and Cost Competitiveness: Chinese roof tile roll forming machines have gained recognition for their quality and cost competitiveness. Manufacturers have implemented strict quality control measures and adhere to international standards. They have also been able to optimize production processes and reduce manufacturing costs, making their machines more affordable and attractive to customers worldwide.

- Export Market: Chinese manufacturers have a strong presence in the global market for roof tile roll forming machines. They export their equipment to various countries, including those with high demand for roofing materials and construction projects. This export focus has contributed to the growth and reputation of China’s roll forming machine industry.

It’s important to note that developments in the industry may continue beyond my knowledge cutoff in September 2021. Therefore, for the most up-to-date information, it would be beneficial to consult recent sources and industry reports.

রিভিউ

কোন রিভিউ এখনো আছে।