The solar energy industry is booming, with solar water heaters gaining significant traction as an eco-friendly, cost-effective solution for residential, commercial, and industrial heating needs. Behind the seamless functionality of these systems are the precision-engineered components that ensure durability, efficiency, and ease of installation. At the heart of manufacturing these components lies the Solar Water Heater Roll Forming Machines—a game-changing technology designed to produce high-quality profiles for solar water heating systems.

From supporting brackets and frames to solar panel enclosures and structural profiles, Solar Water Heater Roll Forming Machines are pivotal in enabling manufacturers to meet the growing demand for renewable energy solutions. These machines streamline production, enhance precision, and reduce material waste, ensuring that manufacturers can deliver products that align with the sustainability goals of the global market.

In this detailed guide, we’ll explore the applications, features, production process, pricing, technological advancements, and market trends of Solar Water Heater Roll Forming Machines. We’ll also spotlight why Wuxi Sunway Machinery is the trusted partner for manufacturers aiming to lead in the renewable energy sector.

What is a Solar Water Heater Roll Forming Machine?

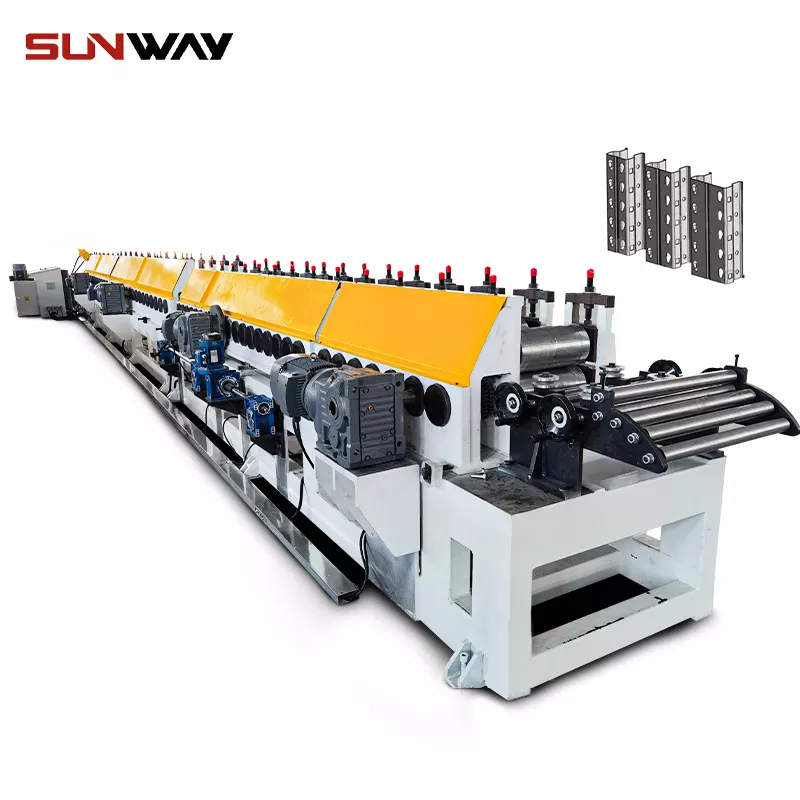

ক Solar Water Heater Roll Forming Machine is a specialized industrial system designed to produce profiles and structural components used in the assembly of solar water heaters. These machines shape raw materials such as galvanized steel, stainless steel, or aluminum into precise profiles through a series of rollers.

The resulting components include mounting brackets, frames, and support structures that hold solar panels and water tanks securely. With integrated punching, embossing, and cutting systems, these machines enable manufacturers to produce durable, lightweight, and corrosion-resistant components that are essential for solar water heating systems.

Applications of Solar Water Heater Roll Forming Machines

Solar water heating systems have diverse applications, and the components produced by Solar Water Heater Roll Forming Machines are integral to their functionality. Here’s a closer look at their key applications:

1. Mounting Structures

- Use Case: Profiles for mounting solar panels and water tanks on rooftops or ground installations.

- Why It Matters: Provides stability and ensures optimal positioning for maximum solar energy absorption.

2. Solar Panel Frames

- Use Case: Frames for solar thermal panels that collect and transfer solar energy.

- Why It’s Crucial: Protects the panels and enhances their efficiency by maintaining structural integrity.

3. Support Brackets

- Use Case: Brackets that secure solar water tanks and panels in place.

- Why It’s Important: Ensures safety and durability, even in harsh weather conditions.

4. Reflective Surfaces

- Use Case: Metal profiles with reflective coatings for concentrated solar power applications.

- Why It’s Relevant: Improves the efficiency of solar water heaters by directing more sunlight onto thermal collectors.

5. Enclosures for Control Systems

- Use Case: Profiles for housing electronic components like temperature controllers and sensors.

- Why It’s Useful: Protects sensitive equipment from environmental damage, ensuring reliable operation.

6. Modular Solar Water Heating Systems

- Use Case: Lightweight profiles for portable or modular solar water heaters used in remote locations.

- Why It’s Exciting: Enables quick deployment and flexibility in areas with limited infrastructure.

Key Features of Wuxi Sunway Solar Water Heater Roll Forming Machines

Wuxi Sunway Machinery is renowned for its innovative roll-forming solutions, and its Solar Water Heater Roll Forming Machines are specifically designed to meet the unique challenges of the renewable energy industry. Here are the standout features:

1. High Material Compatibility

- Supported Materials:

- Galvanized steel

- Stainless steel

- Aluminum alloys

- Why It Matters: Ensures the production of corrosion-resistant components that can withstand outdoor environments.

2. Multi-Profile Capability

- What It Supports: Machines can produce a variety of profiles, including U-channels, C-channels, and frames.

- Why It’s Beneficial: Allows manufacturers to cater to diverse design and installation requirements.

3. Integrated Punching and Cutting

- What It Offers: Built-in systems for punching holes, creating slots, and cutting profiles to length.

- Why It’s Revolutionary:

- Reduces the need for additional machinery.

- Ensures precision for easy assembly on-site.

- Accelerates production timelines.

4. High-Speed Production

- Performance: Capable of producing up to 30 meters of profiles per minute, depending on the material and design complexity.

- Why It’s Relevant: Meets the growing demand for solar water heating systems in large-scale projects.

5. Customizable Tooling

- What It Allows: Quick-change tooling systems for creating custom profiles tailored to specific solar water heater designs.

- Why It’s Essential: Supports flexibility for manufacturers serving diverse markets.

6. IoT and Automation Integration

- What It Provides: Real-time monitoring, data collection, and automated adjustments through IoT-enabled sensors.

- Why It’s Critical:

- Enhances production efficiency.

- Minimizes errors and reduces waste.

- Enables predictive maintenance to prevent downtime.

7. Energy-Efficient Design

- What It Includes: Energy-saving motors and optimized power consumption systems.

- Why It Matters: Aligns with the sustainability goals of the renewable energy sector.

Production Workflow of a Solar Water Heater Roll Forming Machine

The production process for solar water heater components is designed to be seamless, precise, and scalable. Here’s an overview of the workflow:

1. Material Loading

- Raw metal coils are loaded onto the machine’s decoiler, which feeds the material into the rollers.

2. Leveling

- A leveling system ensures the material is flat and free of defects before entering the roll-forming section.

3. Roll Forming

- The material passes through a series of rollers that shape it into the desired profile incrementally.

4. Punching and Slot Creation

- Integrated punching systems create holes and slots for screws, bolts, and other fasteners.

5. Cutting to Length

- Profiles are cut to the required lengths with high precision.

6. Quality Inspection

- Each profile is inspected for dimensional accuracy and surface finish to ensure compliance with design specifications.

7. Packaging and Storage

- Finished profiles are stacked and prepared for transportation or assembly.

Pricing of Solar Water Heater Roll Forming Machines

The cost of a Solar Water Heater Roll Forming Machine varies depending on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic profile production | $150,000–$250,000 |

| Advanced Machines | High-speed and multi-profile output | $250,000–$400,000 |

| কাস্টমাইজযোগ্য মেশিনসমূহ | Including punching, IoT, and automation | $400,000–$600,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Technological Advancements in Solar Water Heater Roll Forming Machines

The renewable energy sector is evolving rapidly, and Solar Water Heater Roll Forming Machines are keeping pace with innovations that enhance efficiency, sustainability, and precision. Here are some technological advancements:

1. AI-Powered Quality Assurance

- How It Works: Artificial Intelligence algorithms analyze production data to ensure every profile meets exacting standards.

- Why It’s Revolutionary:

- Reduces waste by catching defects early.

- Improves overall product quality.

- Enhances customer satisfaction through consistent performance.

2. Modular Tooling Systems

- What It Allows: Quick customization for producing different profiles without extensive downtime.

- Why It’s Essential:

- Supports the production of components for various solar water heater designs.

- Increases flexibility for manufacturers catering to unique market demands.

3. IoT-Enabled Production Monitoring

- What It Delivers: Real-time insights into machine performance, material usage, and output rates.

- Why It’s Critical:

- Facilitates predictive maintenance.

- Optimizes production efficiency.

- Supports data-driven decision-making.

4. High-Precision Cutting Systems

- What It Adds: Laser or hydraulic cutting systems for clean, burr-free edges.

- Why It’s Beneficial:

- Eliminates the need for secondary finishing processes.

- Supports intricate designs for specialized applications.

Global Market Trends for Solar Water Heater Roll Forming Machines in 2025

The market for Solar Water Heater Roll Forming Machines is growing rapidly, fueled by increasing investments in renewable energy. Key trends include:

1. Expansion of Green Infrastructure

- The Trend: Governments and private sectors are investing in renewable energy projects to meet sustainability goals.

- Impact on Machines:

- Higher demand for scalable production of solar water heater components.

- Machines must deliver high-volume outputs without compromising quality.

2. Focus on Energy Efficiency

- The Opportunity: Consumers and businesses are seeking energy-efficient solutions for heating water.

- Why It Matters:

- Roll-forming machines must process lightweight and durable materials.

- Supports the production of eco-friendly solar water heaters.

3. Rise in Modular Solar Systems

- The Shift: Modular systems are becoming popular in remote and off-grid areas.

- Impact on Machines:

- Increased demand for lightweight, portable profiles.

- Machines must support customizable designs for diverse applications.

FAQs About Solar Water Heater Roll Forming Machines

| Question | Answer |

|---|---|

| Can these machines handle custom designs? | Yes, modular tooling systems allow for the production of tailored profiles. |

| What materials can the machine process? | Supported materials include galvanized steel, stainless steel, and aluminum alloys. |

| Does Wuxi Sunway provide installation support? | Absolutely! Full installation and training support are provided with every machine. |

| What is the expected lifespan of these machines? | With proper maintenance, they can last 15–25 years or more. |

| Are these machines energy-efficient? | Yes, Wuxi Sunway machines are designed with energy-saving motors and optimized workflows. |

Solar Water Heater Roll Forming Machines: Enabling Innovation in Renewable Energy Manufacturing

The global shift toward renewable energy solutions has positioned solar water heaters as a key player in reducing carbon footprints and energy costs. Behind every efficient and reliable solar water heater is a finely engineered support structure, frame, or mounting bracket, many of which are produced using Solar Water Heater Roll Forming Machines. These machines empower manufacturers to create durable, lightweight, and high-quality components at scale, enabling them to meet the growing demand for solar water heating systems in residential, commercial, and industrial settings.

In this continuation, we’ll dive deeper into real-world examples, workflow optimizations, global market drivers, and the environmental impact of these machines. We will also answer additional FAQs about Solar Water Heater Roll Forming Machines and explore why Wuxi Sunway Machinery is the first choice for manufacturers worldwide.

Real-World Applications of Solar Water Heater Roll Forming Machines

The components produced by Solar Water Heater Roll Forming Machines are indispensable for the construction and operation of solar water heating systems. Let’s take a closer look at how these machines are revolutionizing the renewable energy sector through real-world applications:

1. Large-Scale Solar Farms

- Scenario: A company develops a solar water heating farm to supply hot water to an industrial processing plant.

- Machine Contribution:

- Produces profiles for mounting systems that ensure the stability of solar thermal panels in outdoor environments.

- Creates lightweight frames for easy assembly and transportation to the installation site.

- Supports high-volume production to meet the large-scale demands of the project.

2. Residential Solar Water Heating Systems

- Scenario: A solar energy company designs compact solar water heaters for households in urban areas.

- Machine Contribution:

- Produces small yet sturdy brackets and frames that can be easily installed on residential rooftops.

- Incorporates custom designs to match aesthetic preferences and optimize space utilization.

- Ensures corrosion-resistant profiles for long-lasting durability in outdoor conditions.

3. Off-Grid Solar Water Heating Solutions

- Scenario: A nonprofit organization installs solar water heaters in remote villages to provide access to hot water.

- Machine Contribution:

- Crafts lightweight, modular profiles that can be transported to remote locations with limited infrastructure.

- Produces easy-to-assemble components for quick installation by local teams.

- Ensures the structural integrity of solar water heaters in extreme weather conditions.

4. Commercial Solar Water Heating Systems

- Scenario: A luxury hotel chain invests in solar water heaters to reduce energy costs and align with sustainability goals.

- Machine Contribution:

- Creates sleek, custom-designed profiles that complement the hotel’s architectural aesthetics.

- Ensures high-precision cuts and finishes for seamless integration with advanced heating systems.

- Produces corrosion-resistant brackets for installations near coastal areas with high humidity levels.

5. Industrial Solar Heating Applications

- Scenario: A manufacturing hub installs solar water heaters to provide hot water for cleaning and processing machinery.

- Machine Contribution:

- Produces heavy-duty profiles capable of supporting large water tanks and thermal panels.

- Crafts precise components for secure installations on factory rooftops.

- Ensures the longevity of structures in high-temperature and industrial environments.

Workflow Optimizations in Solar Water Heater Roll Forming Machines

Efficiency is key when manufacturing components for solar water heating systems, where demand is both high and diverse. Modern Solar Water Heater Roll Forming Machines incorporate advanced workflows to optimize every step of the production process. Here’s how:

1. Automated Material Feeding

- How It Works: The machine uses a decoiler to automatically feed raw metal coils into the roll-forming section.

- Benefits:

- Reduces manual intervention, minimizing errors.

- Ensures a continuous material flow for uninterrupted production.

- Supports high-speed operations, enabling manufacturers to scale production.

2. Precision Roll Forming

- What It Does: A series of rollers incrementally shape the metal into precise profiles.

- Why It’s Efficient:

- Guarantees uniformity and accuracy in every component.

- Reduces material wastage, saving costs.

- Enables the production of complex profiles for advanced solar water heater designs.

3. Integrated Punching and Slotting

- The Feature: Machines are equipped with systems for punching holes, creating slots, and embossing patterns.

- Efficiency Gains:

- Eliminates the need for secondary operations, reducing production timelines.

- Ensures perfect alignment and precision for easy assembly.

- Supports custom designs to meet unique client requirements.

4. High-Speed Cutting

- What It Achieves: Profiles are cut to exact lengths using hydraulic or laser cutting systems.

- Why It’s Critical:

- Ensures clean, burr-free edges, enhancing the quality of finished components.

- Reduces the need for additional finishing processes.

- Supports high-volume production without compromising accuracy.

5. Automated Stacking and Packaging

- What It Does: Finished profiles are automatically stacked and bundled for transportation.

- Why It’s Beneficial:

- Simplifies logistics by organizing components into ready-to-ship packages.

- Protects profiles from damage during storage or transit.

- Reduces labor costs and handling time.

Environmental Impact of Solar Water Heater Roll Forming Machines

Sustainability is at the core of the renewable energy sector, and Solar Water Heater Roll Forming Machines contribute significantly to environmental goals. Here’s how:

1. Promoting Renewable Energy Adoption

- How It Helps: Machines enable the production of components for solar water heaters, reducing reliance on fossil fuels.

- Environmental Benefit:

- Supports the transition to clean energy solutions.

- Reduces greenhouse gas emissions by promoting energy efficiency.

2. Efficient Material Use

- The Advantage: High-precision rollers and cutting systems minimize material waste during production.

- Why It’s Important:

- Conserves natural resources by optimizing raw material usage.

- Reduces the environmental footprint of manufacturing operations.

3. Energy-Efficient Manufacturing

- The Feature: Machines are designed with energy-saving motors and optimized workflows.

- Environmental Benefit:

- Lowers electricity consumption during production.

- Aligns with green manufacturing initiatives and energy efficiency standards.

4. Long-Lasting Components

- What It Ensures: Roll-formed profiles are engineered for durability and resistance to environmental factors.

- Why It Matters:

- Extends the lifecycle of solar water heaters, reducing the need for frequent replacements.

- Enhances the sustainability of renewable energy systems.

Global Market Drivers for Solar Water Heater Roll Forming Machines in 2025

The demand for Solar Water Heater Roll Forming Machines is driven by the expanding renewable energy market and global sustainability goals. Key market drivers include:

1. Increasing Government Incentives

- The Trend: Governments worldwide are offering subsidies and tax benefits for adopting renewable energy systems.

- Impact on Machines:

- Higher demand for solar water heating systems.

- Machines must deliver scalable production to meet growing market needs.

2. Rising Energy Costs

- The Opportunity: Businesses and households are turning to solar water heaters to reduce energy expenses.

- Why It Matters:

- Drives demand for cost-effective and efficient solar heating solutions.

- Machines must support the production of affordable components.

3. Sustainability Mandates

- The Push: Corporations are adopting green practices to meet environmental regulations and consumer expectations.

- Impact on Machines:

- Increased need for eco-friendly manufacturing processes.

- Machines must process recyclable and sustainable materials.

Additional FAQs About Solar Water Heater Roll Forming Machines

| Question | Answer |

|---|---|

| What is the lead time for installing these machines? | Installation typically takes 2–4 weeks, depending on the complexity of the machine. |

| Can these machines handle lightweight materials? | Yes, they are designed to process lightweight materials such as aluminum and thin galvanized steel. |

| What is the average lifespan of the finished profiles? | Profiles are engineered to last 20–30 years, depending on the material and environmental conditions. |

| Do these machines support Industry 4.0 standards? | Absolutely! Wuxi Sunway machines are IoT-enabled and fully compatible with smart factory ecosystems. |

| How does Wuxi Sunway ensure machine quality? | Every machine undergoes rigorous testing and complies with international quality standards. |

Why Choose Wuxi Sunway Machinery for Solar Water Heater Roll Forming Machines?

Here’s why Wuxi Sunway Machinery is the trusted partner for manufacturers in the renewable energy sector:

- Proven Expertise: Decades of experience in delivering roll-forming solutions tailored to the solar energy industry.

- Global Reach: Trusted by clients in Asia, Europe, the Americas, and beyond.

- Sustainability Leadership: Machines designed to support eco-friendly manufacturing practices.

- Cutting-Edge Technology: Features such as IoT integration, AI-driven quality control, and high-speed production capabilities.

- Comprehensive Support: From installation to training and troubleshooting, Wuxi Sunway provides end-to-end assistance.

Conclusion: Driving Renewable Energy Manufacturing Forward

দ্য Solar Water Heater Roll Forming Machine is more than a manufacturing tool—it’s a key enabler in the global transition to renewable energy. By producing precision-engineered, durable, and eco-friendly components, these machines empower manufacturers to meet the growing demand for solar water heating systems.

Ready to lead the charge in renewable energy manufacturing? Contact Wuxi Sunway Machinery today to explore their state-of-the-art roll-forming solutions. Together, let’s create a brighter, greener future—one profile at a time!