Strut Channel Roll Forming Machine: Introduction and Features

Strut channel roll forming machines are specialized equipment designed to produce C-shaped or U-shaped steel channels, commonly known as strut channels. These channels are widely used in construction, electrical, and mechanical industries for various support systems, including cable trays, solar panel mounting, and HVAC installations.

Key Features:

High Production Speed:

Strut channel roll forming machines can produce channels at a high speed, which increases overall productivity and reduces labor costs.

Versatility:

These machines are capable of producing strut channels with various sizes, materials, and profiles, including slotted, solid, and back-to-back configurations. This flexibility allows manufacturers to cater to a wide range of applications and customer requirements.

Precise and Consistent Profiles:

Strut channel roll forming machines utilize advanced technology to ensure precise and consistent channel profiles. This accuracy is critical for maintaining structural integrity and compatibility with other components in the support system.

Automated Control System:

Modern strut channel roll forming machines are equipped with programmable logic controllers (PLCs) that enable automated operation and minimize human intervention. This automation leads to increased efficiency, reduced errors, and consistent production quality.

Material Efficiency:

The roll forming process used by these machines results in minimal material waste, making it an environmentally friendly and cost-effective manufacturing method.

Low Maintenance:

Strut channel roll forming machines are generally built with durable components and require minimal maintenance, resulting in reduced downtime and overall lower operational costs.

In conclusion, strut channel roll forming machines offer numerous advantages, including high production speed, versatility, precise profiles, automation, material efficiency, and low maintenance. These features make them an essential piece of equipment for manufacturers in the construction, electrical, and mechanical industries.

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন প্রোফাইল অঙ্কন

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন উৎপাদন লাইন

A strut channel roll forming machine generally consists of the following components:

Decoiler: This is where the raw material (steel coil) is loaded and uncoiled before entering the roll forming process.

Leveling and Feeding Unit: This unit helps straighten the metal strip and accurately feed it into the roll forming section.

Roll Forming Stations: These stations consist of a series of rollers that progressively shape the metal strip into the desired strut channel profile. Each station contributes to gradually bending the material until the final shape is achieved.

Punching System (optional): Some machines may include a punching system for creating holes or slots in the strut channel. This can be done before, during, or after the roll forming process, depending on the machine’s design.

Cutting Unit: The cutting unit is responsible for shearing the formed strut channel to the desired length. This can be done using various methods, such as flying cut-off, stop-cut, or post-cut.

Stacking and Handling System: After the strut channels are cut to the desired length, they are collected, stacked, and removed from the machine. This can be done manually or with an automated system.

Control System: The control system, often using a programmable logic controller (PLC), manages the machine’s operation, including setting the desired length, speed, and coordinating various processes.

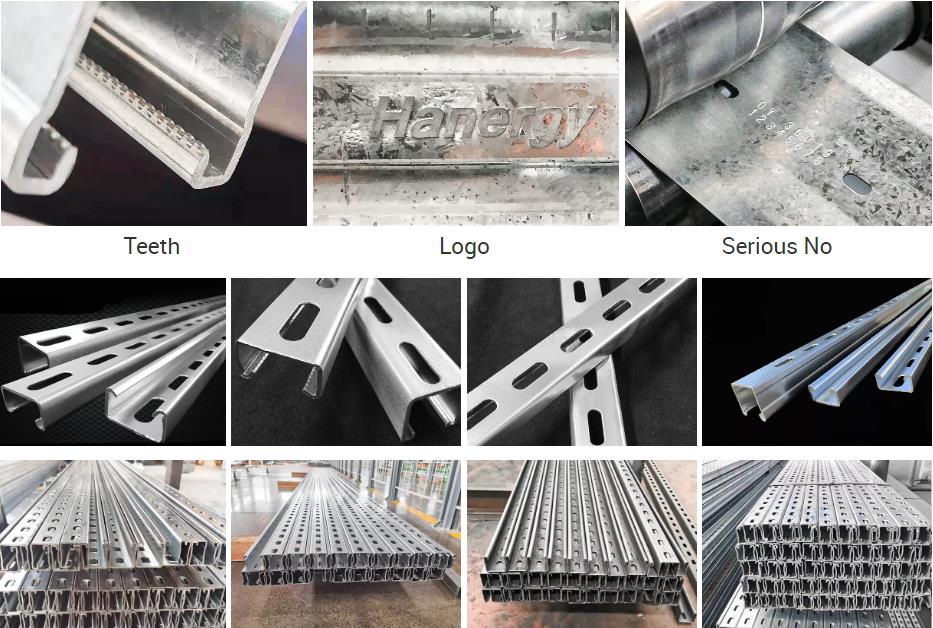

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন বিস্তারিত

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন পরামিতি

|

স্ট্রুট চ্যানেল রোল ফর্মিং মেশিন (আপডেট করা হয়েছে সংস্করণ)

|

||

|

Machinable উপাদান

|

ক) হট-রোল্ড এবং কোল্ড রোল্ড স্টিল

|

বেধ (এমএম): 1.5-2.0, 2.0-2.5, 3 মিমি পর্যন্ত |

|

খ) হট-ডিপ গ্যালভানাইজড শীট

|

||

|

গ) প্রাক-গ্যালভানাইজড স্টিল

|

||

|

ঘ) মিল (সাদা/কালো) ইস্পাত

|

||

|

উত্পাদন শক্তি

|

250 - 550 এমপিএ

|

|

|

টেনসিল স্ট্রেস

|

G250 MPa-G350 MPa

|

|

|

ডিকয়লার

|

হাইড্রোলিক ডিকয়লার

|

* লেভেলার এবং সার্ভো ফিডার সহ 2 ইন 1 ডেকোইলার (ঐচ্ছিক)

|

|

পাঞ্চিং সিস্টেম:

|

হাইড্রোলিক পাঞ্চিং স্টেশন (ব্যক্তিগত)

|

* পাঞ্চিং প্রেস (ঐচ্ছিক)

|

|

স্টেশন গঠন

|

20-22 বা 24-28 অ্যান্টি-সিসমিক স্ট্রটের জন্য

|

* আপনার প্রোফাইল অঙ্কন অনুযায়ী

|

|

ড্রাইভিং সিস্টেম

|

গিয়ারবক্স ড্রাইভ

|

|

|

মেশিন স্ট্রাকচার

|

নকল আয়রন স্টেশন

|

|

|

লাইন গঠনের গতি

|

15-20 (M/MIN)

|

* চূড়ান্ত কনফিগারেশন অনুযায়ী

|

|

রোলারের উপাদান

|

GCr15

|

* Cr12 (ঐচ্ছিক)

|

|

কাটিং সিস্টেম

|

পোস্ট-কাটিং, মেশিন স্টপ টু কাট

|

* ট্র্যাকিং কাটার (ঐচ্ছিক)

|

|

ফ্রিকোয়েন্সি চেঞ্জার ব্র্যান্ড

|

ইয়াসকাওয়া

|

|

|

পিএলসি ব্র্যান্ড

|

প্যানাসনিক

|

|

|

পাওয়ার সাপ্লাই

|

380V 50Hz 3ph

|

* অথবা আপনার প্রয়োজন অনুযায়ী

|

|

মেশিনের রঙ

|

শিল্প নীল

|

* অথবা আপনার প্রয়োজন অনুযায়ী

|

Strut channel roll forming machine applications:

Strut channel roll forming machines are used to produce C-shaped or U-shaped steel channels, commonly known as strut channels. These channels have various applications across multiple industries due to their versatile nature and ability to support various systems. Some of the primary applications of strut channels produced by roll forming machines include:

Construction and Infrastructure:

Strut channels are widely used in the construction industry as support systems for structural elements, such as beams, columns, and floors. They provide stability and reinforcement, helping to distribute loads evenly and ensuring the structural integrity of buildings and other structures.

Electrical Industry:

In the electrical industry, strut channels are used as support systems for cable trays, conduit, and wiring. They help organize and secure electrical components, protecting them from damage and ensuring that they remain accessible for maintenance and inspection.

HVAC Systems:

Strut channels are commonly used in heating, ventilation, and air conditioning (HVAC) systems as support structures for ductwork, piping, and equipment. They provide a stable and adjustable framework, allowing for the efficient installation, maintenance, and modification of HVAC components.

Solar Panel Mounting:

In the renewable energy sector, strut channels are used as support structures for solar panel installations. They provide a durable and adjustable framework that can withstand harsh environmental conditions and ensure the efficient performance of solar panels.

Mechanical and Industrial Applications:

Strut channels are utilized in various mechanical and industrial applications as support systems for equipment, machinery, and piping. They offer a customizable and modular solution for mounting and securing components, allowing for easy modifications and adjustments as needed.

Warehouse and Storage Systems:

Strut channels are used in the design and installation of warehouse storage systems, such as pallet racking and shelving units. They provide a strong and adjustable framework that can be easily reconfigured to accommodate changing storage requirements.

Transportation Industry:

In the transportation industry, strut channels are used to support various systems and components within vehicles, such as wiring, piping, and equipment mounts. They offer a lightweight and durable solution that can withstand the vibrations and stresses associated with transportation applications.

In summary, strut channel roll forming machines produce versatile steel channels that find applications across numerous industries, including construction, electrical, HVAC, renewable energy, mechanical, warehouse storage, and transportation. Their ability to provide customizable and modular support systems makes them a popular choice for a wide range of projects and applications.

Cost Analysis: Investing in a Strut Channel Roll Forming Machine

Investing in a strut channel roll forming machine can bring significant benefits to your manufacturing operations. However, it is essential to consider the costs associated with the purchase and operation of the machine to make an informed decision. This article provides a cost analysis to help you evaluate the investment in a strut channel roll forming machine.

Initial Purchase Price:

The initial cost of a strut channel roll forming machine varies depending on the type, features, and capabilities of the equipment. Factors that influence the price include production capacity, automation, customization options, and the manufacturer’s reputation. Determine your budget and choose a machine that balances affordability with the required features and capabilities.

Installation and Setup Costs:

Consider the costs associated with installing and setting up the machine, including any necessary modifications to your facility, such as electrical wiring, space requirements, and foundation work. You may also need to account for transportation and shipping fees.

Training and Labor:

Factor in the costs of training your staff to operate the machine properly and safely. Additionally, consider the labor costs associated with running the machine, including wages, benefits, and overtime.

Maintenance and Repairs:

Account for regular maintenance expenses, such as lubrication, component replacements, and wear parts. Additionally, plan for unexpected repair costs, which may include replacement parts and technician labor fees. Choosing a machine with low maintenance requirements can help reduce these costs over time.

Energy Consumption:

Evaluate the energy consumption of the machine and its impact on your utility costs. Opt for energy-efficient features, such as variable frequency drives, to minimize energy consumption and reduce operating costs.

Raw Material Costs:

Factor in the costs of the materials used to produce the strut channels, such as steel coils. Consider the material efficiency of the roll forming process, which can help reduce waste and minimize material costs.

Financing Options:

If you plan to finance the machine, consider the interest rates and loan terms. Calculate the total cost of financing and factor it into your overall investment.

Depreciation and Resale Value:

Account for the depreciation of the machine over time, which can affect its resale value. Choosing a high-quality machine from a reputable manufacturer can help maintain its value and make it easier to sell or trade-in for an upgraded model in the future.

By conducting a thorough cost analysis, you can evaluate the investment in a strut channel roll forming machine and determine its potential return on investment (ROI). This information can help you make an informed decision and ensure that your investment aligns with your business goals and budget constraints.

what is strut channel roll forming machine?

A strut channel roll forming machine shapes metal strips into strut channels, used for mounting components. Here’s how it works:

- Material Feeding: Metal strip, typically galvanized steel or aluminum, is fed into the machine.

- Roll Forming: Rollers gradually shape the strip into the strut channel’s desired profile.

- Cutting: A cutting mechanism separates the formed strut channels from the strip.

- Hole Punching: Some machines have stations for punching holes or slots in the channels.

- Length Measurement and Stacking: Channels are measured, stacked, and prepared for packaging.

Computer-controlled systems ensure precision and consistency. The machine streamlines production, meeting construction and electrical industry demands.

what is the relationship between channel roll forming machine and c channel roll forming machine?

A channel roll forming machine is a general term used for machines that are designed to shape metal strips into various types of channels. Channels are structural components that have a “U” or “C” shape when viewed in cross-section. These channels are commonly used in construction, electrical installations, and other applications to provide structural support or serve as conduits for cables or piping.

The C channel roll forming machine, on the other hand, is a specific type of channel roll forming machine that is designed specifically for producing C-shaped channels. C channels have a profile that resembles the letter “C” and are widely used in construction, especially in framing applications and the installation of electrical systems.

So, the C channel roll forming machine is a specialized variant of a channel roll forming machine, specifically tailored for the efficient production of C-shaped channels. It focuses on the unique design and dimensions of C channels, ensuring precise shaping and consistent quality.

oem u channel roll forming machine

An OEM (Original Equipment Manufacturer) U channel roll forming machine refers to a roll forming machine that is designed, manufactured, and supplied by an OEM company specifically for the production of U-shaped channels.

U channels, also known as U-sections or U-bars, have a profile that resembles the letter “U” and are widely used in various industries, including construction, automotive, and manufacturing. They provide structural support, edge protection, and framing solutions.

When referring to an OEM U channel roll forming machine, it implies that the machine is produced by an original equipment manufacturer who specializes in designing and manufacturing roll forming machines. These machines are typically customized and tailored to meet specific requirements and dimensions of U-shaped channels.

An OEM U channel roll forming machine would offer features and specifications suited for efficient and precise production of U channels. This includes adjustable rollers, precise cutting mechanisms, and potentially additional stations for hole punching, embossing, or other customization options depending on the specific needs of the customer.

OEMs are typically known for their expertise in engineering and manufacturing, ensuring the quality, reliability, and performance of the roll forming machines they produce. These machines are often built to industry standards and may incorporate advanced control systems for automation and monitoring.

By opting for an OEM U channel roll forming machine, customers can benefit from a tailored solution that meets their specific production requirements for U-shaped channels. OEMs often provide comprehensive support, including installation, training, and ongoing technical assistance, ensuring a smooth and efficient manufacturing process.

what is furring channel roll forming machine?

A furring channel roll forming machine produces metal furring channels used in construction. Here’s how it works:

- Material Feeding: Metal strip is fed into the machine.

- Roll Forming: Rollers shape the strip into the furring channel’s profile.

- Cutting: A cutting mechanism separates the channels from the strip.

- Length Measurement and Stacking: Channels are measured, stacked, and prepared for packaging.

Computer-controlled systems ensure precision. The machine enables efficient production of high-quality furring channels for construction projects.

রিভিউ

কোন রিভিউ এখনো আছে।