İnşaat sektörü her zaman küresel kalkınmanın temel taşlarından biri olmuştur ve 2025 yılına doğru ilerlerken daha hızlı, daha verimli ve uygun maliyetli bina çözümlerine olan talep her zamankinden daha yüksektir. Bu talebin karşılanmasında ön planda olan Zemin Döşeme Rulo Şekillendirme Makineleriçelik zemin plakalarının konut, ticari ve endüstriyel inşaatlarda kullanılmak üzere üretilme şeklini değiştiriyor.

Bu makineler, modern çok katlı binaların temelini oluşturan yüksek kaliteli, dayanıklı ve hassas mühendislik ürünü döşeme plakaları üretmek üzere tasarlanmıştır. İster gökdelenler, ister otoparklar veya prefabrik yapılar için olsun, Zemin Döşeme Rulo Şekillendirme Makineleri güçlü, hafif ve özelleştirilebilir zemin sistemlerine yönelik artan ihtiyacı karşılamak için daha hızlı, daha güvenilir ve çevre dostu bir yol sunar.

Bu kılavuzda, aşağıdakileri keşfedeceğiz uygulamalar, özelli̇kler, fi̇yatlandirma ve faydalar zemin plakası rulo şekillendirme makineleri. Ayrıca analiz edeceğiz pazar trendleri, teknoloji̇k geli̇şmelerve bu makinelerin çevresel faydaları. Son olarak, neden Wuxi Sunway Makine bu alanda güvenilir bir isimdir.

Zemin Döşeme Rulo Şekillendirme Makinesi Nedir?

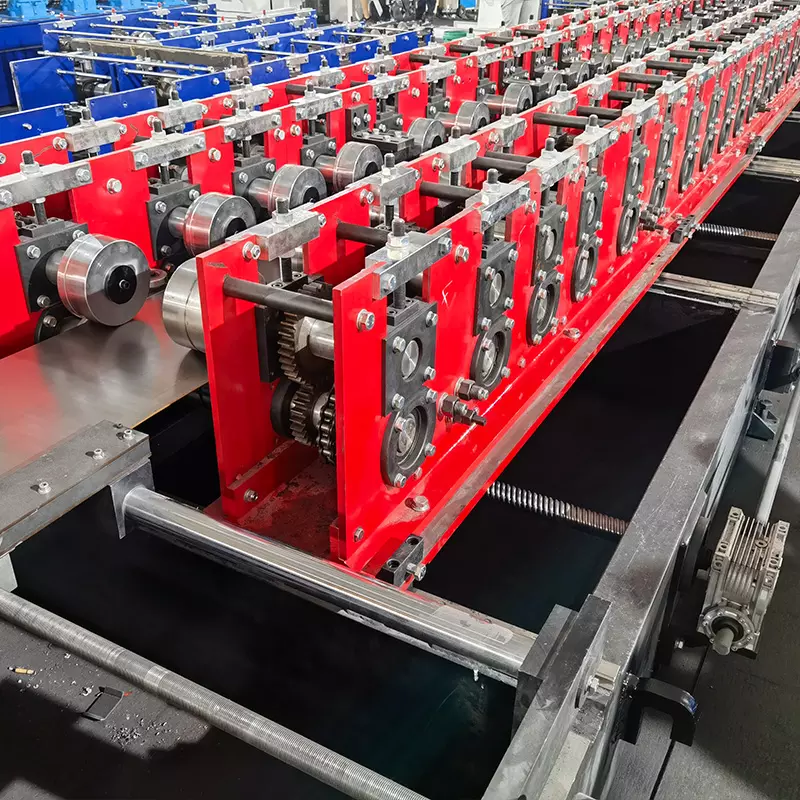

A Zemin Döşeme Rulo Şekillendirme Makinesi inşaat projelerinde kullanılan metal zemin kaplaması veya levhaları üretmek için tasarlanmış özel bir endüstriyel makinedir. Bu plakalar genellikle betonarme zemin sistemlerinde yapısal bileşenler olarak hizmet eder ve genel yapıyı güçlendirirken beton dökümü için bir taban sağlar.

Makine, ham çelik bobinleri alıp bir dizi silindirden geçirerek ve bunları hassas döşeme profillerine şekillendirerek çalışır. Bu profiller genellikle levhanın mukavemetini artıran ve betonla daha iyi bağlanmasını sağlayan oluklu veya nervürlü yüzeylere sahiptir. Sonuç mu? Modern inşaat standartlarını karşılayan sağlam, hafif ve uygun maliyetli bir döşeme çözümü.

Zemin Döşeme Rulo Şekillendirme Makineleri Uygulamaları

Roll-form makineleri tarafından üretilen zemin plakaları çeşitli inşaat projelerinde yaygın olarak kullanılmaktadır. Aşağıda başlıca uygulamalar yer almaktadır:

1. Çok Katlı Konut Binaları

- Kullanım Örneği: Apartmanlar, kat mülkiyeti ve konut kompleksleri için çelik zemin plakaları.

- Neden önemli? Hafif plakalar toplam yapısal yükü azaltarak yüksek binalar için idealdir.

2. Ticari Binalar

- Kullanım Örneği: Ofis kompleksleri, alışveriş merkezleri ve oteller için zemin kaplama sistemleri.

- Neden önemli? Rulo şekillendirilmiş plakalar, geniş ticari zeminler için mükemmel yük taşıma kapasitesi sağlar.

3. Endüstriyel Tesisler

- Kullanım Örneği: Depolar, fabrikalar ve atölyeler için zemin plakaları.

- Neden önemli? Dayanıklı ve sağlam plakalar ağır makine ve ekipman yüklerine dayanabilir.

4. Otoparklar

- Kullanım Örneği: Güçlü, hafif zeminler gerektiren çok katlı park yapıları.

- Neden önemli? Oluklu çelik levhalar son derece dayanıklıdır ve aşınma ve yıpranmaya karşı dirençlidir.

5. Prefabrik ve Modüler Yapı

- Kullanım Örneği: Prefabrik evler ve modüler binalar için zemin kaplama sistemleri.

- Neden heyecan verici: Rulo şekillendirme makineleri, plakaların seri üretimini sağlayarak inşaat sürelerini hızlandırır.

6. Köprüler ve Üst Geçitler

- Kullanım Örneği: Köprü zeminleri ve üst geçit yapıları için çelik zemin kaplaması.

- Neden önemli? Rulo şekillendirilmiş plakalar, altyapı projeleri için gerekli mukavemeti ve esnekliği sağlar.

Wuxi Sunway Zemin Döşeme Rulo Şekillendirme Makinelerinin Temel Özellikleri

Wuxi Sunway Makine inşaat sektörünün ihtiyaçlarına uygun rulo şekillendirme makineleri tasarlama ve üretme konusunda uzmanlaşmıştır. İşte öne çıkan özellikleri Zemin Döşeme Rulo Şekillendirme Makineleri:

1. Yüksek Hassasiyetli Silindirler

- Ne Sağlar: Dar toleranslara sahip döşeme profillerinin hassas şekillendirilmesi için tasarlanmış silindirler.

- Neden önemli? Her levhada homojenliği ve doğruluğu garanti ederek montaj hatalarını azaltır.

2. Çoklu Profil Uyumluluğu

- Neyi Destekler: Makineler trapez, oluklu ve özel tasarımlar da dahil olmak üzere çeşitli levha profilleri üretebilir.

- Neden önemli? Farklı inşaat ihtiyaçlarına cevap veren üreticiler için esnekliği artırır.

3. Yüksek Hızlı Üretim

- Performans: Şu kadar üretim kapasitesine sahiptir Dakikada 30 metre döşeme profilitasarıma bağlı olarak.

- Neden önemli? Büyük ölçekli inşaat projelerinin yüksek hacimli taleplerini karşılar.

4. Malzeme Çok Yönlülüğü

- Desteklenen Materyaller:

- Galvanizli çelik

- Paslanmaz çelik

- Ön kaplamalı metaller

- Alüminyum alaşımlar

- Neden önemli? Üreticilerin farklı ortamlara ve yapısal gereksinimlere uygun plakalar üretmesini sağlar.

5. Otomatik Delme Sistemleri

- Ne İçerir? Bağlantı elemanları veya kanallar için delikler ve yuvalar oluşturmak için entegre delme sistemleri.

- Neden Devrimci? Üretim sonrası işlemleri azaltır ve kurulumu hızlandırır.

6. PLC Kontrollü Operasyonlar

- Ne Sunuyor? Kullanıcı dostu bir arayüze sahip programlanabilir bir mantık denetleyicisi (PLC) tarafından kontrol edilen tam otomatik işlemler.

- Neden gerekli? Çalışmayı basitleştirir, işçilik gereksinimlerini azaltır ve tutarlı kalite sağlar.

7. Enerji Verimli Tasarım

- Ne Sağlar: Enerji tasarruflu motorlar ve optimize edilmiş güç tüketim sistemleri.

- Neden önemli? Operasyonel maliyetleri azaltır ve yeşil üretim girişimlerini destekler.

8. Dayanıklı Yapı

- Neyi Garanti Ediyor? Uzun süreli güvenilirlik için tasarlanmış yüksek kaliteli bileşenler.

- Neden önemli? Bakım maliyetlerini azaltır ve kesintisiz üretim sağlar.

Bir Döşeme Levhası Rulo Şekillendirme Makinesinin Üretim İş Akışı

Zemin plakaları için üretim süreci verimli ve hassas olacak şekilde tasarlanmıştır. İşte iş akışına genel bir bakış:

1. Malzeme Besleme

- Çelik bobinler makinenin şaftına yüklenir decoilerBu da malzemeyi silindirlere besler.

2. Tesviye

- Bir tesviye sistemi, rulo şekillendirme bölümüne girmeden önce malzemenin düz ve hatasız olmasını sağlar.

3. Rulo Şekillendirme

- Malzeme, onu kademeli olarak istenen levha profiline şekillendiren bir dizi silindirden geçer.

4. Delme ve Kesme

- Entegre sistemler delikler, yuvalar veya özel kenarlar oluşturur ve levhaları gerekli uzunluklarda keser.

5. Kalite Denetimi

- Her bir plaka, tasarım şartnamelerine uygunluğu sağlamak için boyutsal doğruluk ve yüzey kalitesi açısından denetlenir.

6. İstifleme ve Paketleme

- Bitmiş plakalar, kolay nakliye ve kurulum için otomatik olarak istiflenir ve paketlenir.

Zemin Döşeme Rulo Şekillendirme Makinelerinin Fiyatlandırılması

Maliyeti Zemin Döşeme Rulo Şekillendirme Makinesi özelliklerine, üretim kapasitesine ve otomasyon düzeyine bağlıdır. Aşağıda 2025 yılı için genel bir fiyatlandırma kılavuzu yer almaktadır:

| Makine Tipi | Yetenekler | Fiyat Aralığı (USD) |

|---|---|---|

| Standart Makineler | Temel levha üretimi | $150,000–$300,000 |

| Gelişmiş Makineler | Yüksek hızlı ve çoklu profil çıkışı | $300,000–$500,000 |

| Tamamen Özelleştirilebilir Makineler | Delme ve IoT özellikli sistemler dahil | $500,000–$750,000 |

Detaylı fiyatlandırma ve finansman seçenekleri için iletişime geçin Wuxi Sunway Makine.

Zemin Döşeme Rulo Şekillendirme Makinelerinin Çevresel Faydaları

Sürdürülebilirlik, inşaat sektöründe giderek artan bir önceliktir ve Zemin Döşeme Rulo Şekillendirme Makineleri çevre dostu uygulamalara çeşitli şekillerde katkıda bulunur:

1. Malzeme Verimliliği

- Nasıl Çalışır? Rulo şekillendirme prosesi metali yüksek hassasiyetle şekillendirerek hurda ve kesikleri en aza indirir.

- Etki:

- Değerli hammaddeleri korur.

- Çöp sahalarına gönderilen atıkları azaltır.

- Üreticiler için üretim maliyetlerini düşürür.

2. Geri Dönüştürülebilir Malzeme Kullanımı

- Neyi Destekler: Makineler galvanizli çelik ve alüminyum gibi geri dönüştürülebilir malzemeleri işler.

- Neden önemli?

- Malzemelerin yeniden kullanımını sağlayarak döngüsel bir ekonomiyi teşvik eder.

- Döşemeler için kullanım ömrü sonu aşamasında çevresel etkiyi azaltır.

- Yeşil bina sertifikaları ile uyumludur.

3. Enerji Verimli Çalışma

- İnovasyon: Modern makineler, yüksek üretim hızlarını korurken daha az enerji tüketir.

- Neden önemli?

- Üreticilerin karbon ayak izlerini azaltmalarına yardımcı olur.

- Sürdürülebilir inşaat girişimlerini destekler.

- Genel operasyonel verimliliği artırır.

4. Üretimin Yerelleştirilmesi

- Ne Sağlar: Üreticiler plakaları yerel olarak üreterek uzun mesafeli nakliye ihtiyacını azaltabilir.

- Sonuç:

- Nakliye ile ilişkili emisyonları azaltır.

- Tedarik zinciri güvenilirliğini ve bölgesel sürdürülebilirliği artırır.

Zemin Döşeme Rulo Şekillendirme Makineleri Hakkında SSS

| Soru | Cevap |

|---|---|

| Makine özel plaka tasarımları üretebilir mi? | Evet, modüler takım sistemleri özel profillerin üretilmesine olanak tanır. |

| Makinenin üretim hızı nedir? | Makineler aşağıdakilere kadar üretebilir Dakikada 30 metre döşeme profilitasarıma bağlı olarak. |

| Wuxi Sunway satış sonrası destek sağlıyor mu? | Evet, eğitim ve sorun giderme dahil olmak üzere kapsamlı destek sunulmaktadır. |

| Makinenin beklenen kullanım ömrü nedir? | Doğru bakım ile bu makineler uzun ömürlü olabilir 10-15 yıl ya da daha fazla. |

| Finansman seçenekleri mevcut mu? | Evet, nitelikli alıcılara esnek finansman seçenekleri sunulmaktadır. |

| Bu makine hangi sektörlerde kullanılıyor? | Sektörler arasında konut, ticari, endüstriyel ve prefabrik inşaat sektörleri yer almaktadır. |

Zemin Döşeme Rulo Şekillendirme Makinelerindeki Teknolojik Gelişmeler

Yetenekleri Zemin Döşeme Rulo Şekillendirme Makineleri otomasyon, dijitalleşme ve malzeme bilimindeki yeniliklerle yıllar içinde önemli ölçüde genişledi. İşte bu makinelerin geleceğini şekillendiren en son teknolojilere daha yakından bir bakış:

1. Akıllı Otomatik Sistemler

- Ne işe yarıyor? Gerçek zamanlı sensörler ve programlanabilir mantık kontrolörleri (PLC'ler) ile donatılmış tam otomatik makineler.

- Avantajlar:

- Manuel müdahaleyi azaltarak tutarlı çıktı kalitesi sağlar.

- Operatörlerin aynı anda birden fazla makineyi yönetmesini sağlar.

- Üretim hızını ve doğruluğunu artırır.

2. IoT Özellikli Bağlantı

- Nasıl Çalışır? Nesnelerin İnterneti (IoT) entegrasyonu, makinelerin fabrika sistemleriyle iletişim kurmasına, veri toplamasına ve eyleme dönüştürülebilir içgörüler sağlamasına olanak tanır.

- Avantajlar:

- Kestirimci bakım, arıza süresini azaltır ve makinelerin kullanım ömrünü uzatır.

- Gerçek zamanlı izleme, verimli enerji kullanımı ve süreç optimizasyonu sağlar.

- Tanılama ve sorun giderme için uzaktan erişilebilirlik.

3. Yapay Zeka Odaklı Kalite Kontrol

- Özellik: Yapay zeka algoritmaları, kusurları ve tutarsızlıkları tespit etmek için levha üretiminin her aşamasını izler.

- Neden Devrimci?

- Kusurları sürecin erken aşamalarında tespit ederek israfı azaltır.

- Her levhanın katı kalite standartlarını karşılamasını sağlar.

- Hatasız ürünler sunarak müşteri memnuniyetini artırır.

4. Çoklu Profil Şekillendirme Yeteneği

- Ne Sağlar: Makineler trapez, nervürlü ve özel tasarımlar da dahil olmak üzere çok sayıda plaka profilini kapsamlı bir yeniden işleme gerektirmeden üretebilir.

- Neden önemli?

- Farklı müşteri ihtiyaçlarını karşılamak için esneklik sağlar.

- Takım değişiklikleriyle ilişkili zaman ve maliyeti azaltır.

- Ürün tekliflerini genişletmek isteyen üreticileri destekler.

5. Hassasiyet ile Yüksek Hızlı Üretim

- İnovasyon: Gelişmiş silindir sistemleri ve optimize edilmiş tahrik mekanizmaları, makinelerin şu hızlara kadar çalışmasını sağlar Dakikada 30 metre.

- Neden önemli?

- Büyük inşaat projelerinde zemin plakalarına yönelik yüksek talebi karşılar.

- Yüksek hızlarda bile hassasiyeti ve tutarlılığı korur.

- Teslim sürelerini kısaltarak üreticilerin sıkı proje teslim tarihlerini karşılamasını sağlar.

6. Enerji Tasarruflu Motorlar

- Ne İçerir? Makineler, performanstan ödün vermeden güç tüketimini azaltan enerji tasarruflu motorlarla donatılmıştır.

- Neden önemli?

- Küresel sürdürülebilirlik hedefleriyle uyumludur.

- Operasyonel maliyetleri düşürerek karlılığı artırır.

- Yeşil üretim sertifikalarını destekler.

7. Modüler Makine Tasarımı

- Ne Sunuyor? Makineler zımbalama sistemleri, kabartma üniteleri veya kenar düzeltme araçları gibi ek modüllerle yapılandırılabilir.

- Neden Yararlı?

- Üreticilerin makineleri kendi özel ihtiyaçlarına göre özelleştirmelerini sağlar.

- Ayrı işleme adımlarına olan ihtiyacı azaltır.

- İş büyüdükçe üretim yeteneklerini ölçeklendirir.

2025'te Pazar Benimseme Eğilimleri

Benimsenmesi Zemin Döşeme Rulo Şekillendirme Makineleri inşaat ve altyapı sektörlerindeki temel eğilimlerin etkisiyle küresel olarak hızlanıyor. Gelin bu büyümeyi neyin tetiklediğini inceleyelim:

1. Modüler İnşaatın Yükselişi

- Trend: Binaların prefabrik bileşenlerden bir araya getirildiği modüler inşaat, hızı ve maliyet verimliliği nedeniyle popülerlik kazanıyor.

- Rulo Şekillendirme Makineleri Üzerindeki Etkisi:

- Yerinde hızlı bir şekilde kurulabilen önceden tasarlanmış zemin plakalarına yönelik yüksek talep.

- Roll-forming teknolojisi, modüler bileşenlerin seri üretimini destekleyerek inşaat sürelerini kısaltır.

2. Kentleşme ve Altyapı Gelişimi

- Rakamlar: 2050 yılına kadar şu rakamlara ulaşılacağı tahmin edilmektedir Küresel nüfusun 68%'si kentsel alanlarda yaşayacak, bu da konut ve altyapı ihtiyacını artıracaktır.

- Neden önemli?

- Döşeme plakası rulo şekillendirme makineleri, çok katlı binalar, köprüler ve kamusal alanlar için döşeme sistemlerinin hızlı bir şekilde üretilmesini sağlar.

- Gelişmiş makineler, büyük ölçekli kentsel gelişim projelerinin taleplerini karşılayabilir.

3. Sürdürülebilirlik için Zorlayın

- Hedef: Hükümetler ve inşaat şirketleri, bina projelerinin çevresel etkilerini azaltmak için çevre dostu uygulamalara öncelik veriyor.

- Rulo Şekillendirme Makineleri Nasıl Yardımcı Olur?

- Makineler galvanizli çelik gibi geri dönüştürülebilir malzemeler kullanarak döngüsel ekonomiyi destekliyor.

- Enerji tasarruflu tasarımlar, üretim süreçlerinin karbon ayak izini azaltır.

4. Hafif Malzemelere Talep

- Trend: Hafif yapı malzemeleri, özellikle yüksek binalarda nakliye ve montaj kolaylıkları nedeniyle daha popüler hale gelmektedir.

- Neden önemli?

- Rulo şekillendirilmiş plakalar hafif ancak yapısal olarak sağlamdır, bu da onları modern inşaat için ideal kılar.

- Makineler, mukavemetten ödün vermeden toplam bina ağırlığını azaltan plakalar üretebilir.

5. Prefabrikasyon Tesislerinin Genişletilmesi

- Vardiya: Prefabrikasyon tesisleri, nakliye maliyetlerini ve emisyonları azaltmak için inşaat sahalarına daha yakın kuruluyor.

- Rulo Şekillendirme Makineleri Üzerindeki Etkisi:

- Üreticiler, rulo şekillendirme makineleri kullanarak yerelleştirilmiş üretim kapasitelerine yatırım yapıyor.

- Modüler tasarıma sahip makineler, prefabrikasyon tesislerinde verimli, ölçeklenebilir üretim hatları kurmak için idealdir.

Zemin Döşeme Rulo Şekillendirme Makineleri Kullanmanın Ticari Faydaları

Yüksek kaliteli bir yatırım Zemin Döşeme Rulo Şekillendirme Makinesi üreticiler ve inşaat şirketleri için bir dizi avantaj sunar:

1. Geliştirilmiş Üretkenlik

- Nasıl yardımcı olur:

- Yüksek hızlı üretim, üretim zaman çizelgelerini kısaltır.

- Otomasyon, hataları ve iş gücü gereksinimlerini en aza indirir.

- Modüler sistemler, yeni özelliklerin sorunsuz bir şekilde eklenmesine olanak tanır.

2. Maliyet Verimliliği

- Ne kazandırır?

- Hassas şekillendirme sayesinde malzeme israfını azaltır.

- Verimli motorlar ve sistemler ile enerji maliyetlerini düşürür.

- El işçiliğine olan bağımlılığı azaltır, işgücü giderlerini düşürür.

3. Ölçeklenebilirlik

- Neden önemli?

- Makineler küçük ölçekli projelerin yanı sıra büyük ölçekli üretim taleplerini de karşılayabilir.

- Modüler tasarımlar, gelecekteki iş ihtiyaçlarını karşılamak için yükseltmelere izin verir.

- Özelleştirilebilir profiller daha geniş bir uygulama yelpazesine hitap eder.

4. Rekabet Avantajı

- Ne Sağlar:

- Yüksek kaliteli levhalar üreticilerin itibarını artırır.

- Daha hızlı üretim süreleri, zamana duyarlı projeler için sözleşmelerin güvence altına alınmasına yardımcı olur.

- IoT entegrasyonu ve yapay zeka odaklı kalite kontrolü gibi gelişmiş özellikler, şirketleri rakiplerinden ayırıyor.

5. Sürdürülebilirlik Uyumu

- Etki:

- Çevre dostu üretim süreçleri, yeşil inşaat çözümleri arayan müşterileri cezbetmektedir.

- Makineler LEED gibi yeşil bina sertifikalarına uyumu destekler.

- Azaltılmış karbon ayak izi, pazardaki marka itibarını artırır.

Zemin Döşeme Rulo Şekillendirme Makineleri Hakkında Ek SSS

| Soru | Cevap |

|---|---|

| Makine ne tür profiller üretebilir? | Makineler trapez, nervürlü, oluklu ve özel plaka profilleri üretebilir. |

| Makine galvanizli malzemeleri işleyebilir mi? | Evet, makineler galvanizli çelik, alüminyum alaşımları ve diğer malzemeleri işlemek için tasarlanmıştır. |

| Wuxi Sunway kurulum hizmetleri sunuyor mu? | Kesinlikle! Sorunsuz operasyonlar sağlamak için kurulum ve eğitim hizmetleri sağlanmaktadır. |

| Teslimat için tipik teslim süresi nedir? | Teslimat süreleri 3 ila 6 ayÖzelleştirme ve sipariş hacmine bağlı olarak. |

| Garanti seçenekleri mevcut mu? | Evet, Wuxi Sunway garantiler ve kapsamlı destek paketleri sunmaktadır. |

| Bu makine hangi sektörlerde kullanılıyor? | Sektörler arasında konut inşaatı, ticari binalar, prefabrikasyon ve altyapı bulunmaktadır. |

Wuxi Sunway Machinery Rulo Şekillendirme Çözümlerinde Neden Lider?

Söz konusu olduğunda Zemin Döşeme Rulo Şekillendirme Makineleri, Wuxi Sunway Makine küresel bir lider olarak öne çıkıyor. İşte nedeni:

- Endüstri Uzmanlığı: İnşaat sektörüne özel yenilikçi roll-form çözümleri sunma konusunda onlarca yıllık deneyim.

- Özelleştirme Mükemmelliği: Makineler, özel müşteri gereksinimlerini karşılayacak şekilde tasarlanarak maksimum fayda ve verimlilik sağlar.

- Küresel Varlık: Asya, Avrupa, Amerika ve ötesindeki üreticiler tarafından güvenilmektedir.

- Sürdürülebilirlik Taahhüdü: Malzeme verimliliğini ve enerji tasarrufunu teşvik eden çevre dostu tasarımlar.

- En Son Teknoloji: Gelişmiş performans ve güvenilirlik için IoT, AI ve modüler sistemleri bir araya getirir.

- Uçtan Uca Destek: Kurulum, eğitim, bakım ve sorun giderme dahil olmak üzere kapsamlı hizmetler.

Sonuç: Geleceği Hassasiyet ve Verimlilikle İnşa Etmek

Bu Zemin Döşeme Rulo Şekillendirme Makinesi benzersiz verimlilik, çok yönlülük ve sürdürülebilirlik sunan modern inşaatın temel taşıdır. İster yüksek konutlar, ister endüstriyel tesisler veya prefabrik yapılar inşa ediyor olun, bu makineler günümüzün rekabetçi pazarında başarılı olmak için gereken hassasiyeti ve ölçeklenebilirliği sağlar.

Üretim kapasitenizi yükseltmeye hazır mısınız? Birlikte çalışın Wuxi Sunway Makine dünya standartlarındaki roll-forming çözümlerini keşfetmek için bugün. Birlikte geleceği inşa edelim - her seferinde bir plaka!