Ekskavatörler, inşaat, madencilik ve altyapı geliştirme, gerektiren dayanıklı, yüksek mukavemetli bileşenler aşırı çalışma koşullarına dayanabilen. Bu talepleri karşılamak için üreticiler Ekskavatör Rulo Şekillendirme Makinelerietkinleştiren ağır ekipmanlar için yapısal bileşenlerin yüksek hızlı, hassas üretimi.

Bu gelişmiş rulo şekillendirme makineleri, aşağıdakiler için tasarlanmıştır: yüksek mukavemetli çelik, güçlendirilmiş şasi panelleri, hidrolik kol destekleri ve alt takım bileşenleri işlemesağlamak üstün dayanıklılık, hafiflik ve verimlilik, ve uygun maliyetli üretim.

Bu kılavuzda şunları keşfedeceğiz uygulamalar, fiyatlandırma, temel özellikler, sektör trendleri ve Wuxi Sunway Machinery'nin ekskavatör rulo şekillendirme çözümlerinde sektör lideri olmasının nedenleri.

Ekskavatör Rulo Şekillendirme Makineleri Nedir?

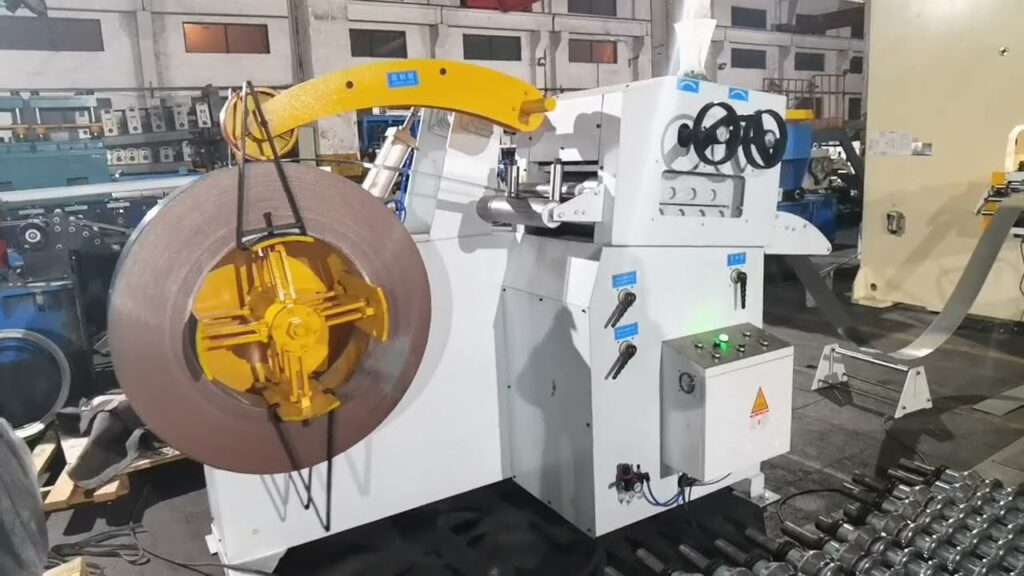

Bir Ekskavatör Rulo Şekillendirme Makinesi bir endüstri̇yel sinif si̇stem için tasarlanmıştır ağır hizmet tipi metal bileşenler üretmek kullanılan ekskavatörler, buldozerler ve diğer hafriyat ekipmanları. Bu makineler şunları sağlar hassas kesimler, bükümler ve takviye işlemleri ile otomatik, yüksek hızlı üretim, optimize etmek ekskavatör gücü ve performansı.

Ekskavatör Rulo Şekillendirme Makinelerinin Temel Özellikleri

- Yüksek Mukavemetli Çelik ve Aşınmaya Dayanıklı Malzeme İşleme - Sağlar aşırı yükler altında uzun ömürlü dayanıklılık.

- Ağır Ekipmanlar için Özelleştirilebilir Yapısal Profiller - Destekler şasi destekleri, hidrolik kol braketleri ve alt takım panelleri dahil olmak üzere çeşitli ekskavatör parçaları.

- Otomatik Delik Delme ve Hassas Kesme - Kolaylaştırır hızlı montaj ve modüler entegrasyon.

- Korozyona Dayanıklı ve Darbeye Dayanıklı Kaplamalar - Sağlar zorlu ortamlarda uzun ömür.

- Akıllı İzleme ve IoT Entegrasyonu - Şunlar için izin verir gerçek zamanlı arıza tespiti ve kestirimci bakım.

- Yüksek Hızlı Üretim - Etkinleştirir minimum malzeme israfı ile seri üretim.

- Geliştirilmiş Yük Taşıma Kapasitesi - Buluşmalar küresel inşaat ve madencilik endüstrisi standartları.

Ekskavatör Rulo Şekillendirme Makinelerinin Uygulamaları

İnşaat ve madencilik sektörlerinin ihtiyaç duyduğu sağlam, yüksek performanslı ekskavatörler, üreticilerin ihtiyacı verimli, otomatik sistemler üretmek için büyük ölçekli çelik bileşenler. Ekskavatör Rulo Şekillendirme Makineleri üreticilerin çeşitli uygulamalar için özel bileşenler üretmesini sağlar:

1. Ekskavatör Şasisi ve Şasi Yapıları

- Kullanım Örneği: Üretim ekskavatörler ve ağır makineler için güçlendirilmiş şasi çerçeveleri.

- Neden gerekli? Sağlar zorlu ortamlarda yapısal bütünlük ve darbe direnci.

2. Hidrolik Kol ve Bom Destek Panelleri

- Kullanım Örneği: Üretim ekskavatör bomları ve hidrolik sistemler için yüksek mukavemetli kol destekleri.

- Neden Yararlı? Sağlar ağır yükler altında sorunsuz çalışma ve kararlılık.

3. Alt Takım Paletleri ve Takviye Panelleri

- Kullanım Örneği: İmalat ekskavatör paletleri ve alt takımları için aşınmaya dayanıklı çelik paneller.

- Neden önemli? Geliştirir zorlu arazilerde dayanıklılık ve çekiş gücü.

4. Ekskavatör Kabini Koruma ve Güvenlik Çerçeveleri

- Kullanım Örneği: Gelişmekte olan güçlendirilmiş çelik güvenlik çerçeveleri ve operatör kabini muhafazaları.

- Neden gerekli? Korur enkaz, devrilme ve zorlu saha koşullarından operatörleri korumak.

5. Karşı Ağırlık ve Yük Dengeleme Bileşenleri

- Kullanım Örneği: Üretim ekskavatörün stabilitesini artırmak için yapısal karşı ağırlık panelleri.

- Neden Yenilikçi? Geliştirir Hassas kazı için denge ve yük dağılımı.

6. Gömülü Sensörlere Sahip Akıllı Ekskavatör Bileşenleri

- Kullanım Örneği: Üretim gerçek zamanlı izleme için akıllı sensörler ile donatılmış ekskavatör panelleri.

- Neden Kritik? Etkinleştirir öngörücü bakım ve uzaktan teşhis.

Wuxi Sunway Ekskavatör Rulo Şekillendirme Makinelerinin Temel Özellikleri

Wuxi Sunway Machinery dünya çapında bir liderdir ekskavatör rulo şekillendirme teknolojisi, teklif yüksek performanslı, hassas mühendislik çözümleri inşaat ve ağır ekipman üreticileri için. Makineleri, üretkenliği artırır, maliyetleri düşürür ve yapısal dayanıklılığı geliştirir.

1. Özelleştirilebilir Ağır Ekipman Yapısal Profilleri

- Ne Sunuyor? Şunlarla donatılmış makineler ekskavatör şasileri, destek kirişleri ve takviye panelleri üretmek için ayarlanabilir takımlar.

- Neden Kritik? Destekler kompakt modellerden büyük ölçekli madencilik ekskavatörlerine kadar çeşitli ekskavatör konfigürasyonları.

2. Çoklu Malzeme İşleme Yetenekleri

- Ne İşler:

- Yüksek Çekme Çelik - Sağlar ekskavatör yapıları için maksimum mukavemet.

- Aşınmaya Dayanıklı Çelik Alaşımları - Geliştirir aşırı çalışma ortamlarında dayanıklılık.

- Korozyon-Kanıtlanmış Kaplamalı Çelik - Sağlar ıslak ve aşındırıcı koşullarda daha uzun ömür.

- Neden gerekli? Uyum sağlar çeşitli ekskavatör üretim gereksinimleri.

3. Yüksek Hızlı, Otomatik Üretim

- Elde Ettiği Şey: Aşağıdakilere kadar işlemler Dakikada 80 metre metal ile minimum manuel müdahale.

- Neden Verimli: Buluşmalar tutarlı kaliteyi korurken yüksek hacimli üretim talepleri.

4. Entegre Delik Delme, Yuva Kesme ve Bükme

- Ne Sağlar: Önceden delinmiş montaj noktaları ve hızlı montaj için hassas büküm.

- Neden Yararlı? Azaltır manuel işçiliği azaltır ve modüler bileşen tasarımını geliştirir.

5. Korozyona Dayanıklı ve Darbeye Dayanıklı Kaplamalar

- Ne Sağlıyor? Şunları yapabilen makineler üretim sırasında koruyucu kaplamaların uygulanması.

- Neden Yararlı? Sağlar daha uzun ürün ömrü ve inşaat güvenlik standartlarına uygunluk.

6. Akıllı İzleme ve IoT Destekli Kalite Kontrol

- Ne Entegre Ediyor? Gerçek zamanlı arıza tespiti, kestirimci bakım ve uzaktan makine izleme.

- Neden Yenilikçi? Azaltır atıkları azaltır, arıza süresini en aza indirir ve operasyonel verimliliği artırır.

Ekskavatör Rulo Şekillendirme Makinelerinin Fiyatlandırılması

Maliyeti Ekskavatör Rulo Şekillendirme Makinesi bağlıdır özellikler, üretim kapasitesi ve özelleştirme seçenekleri. Aşağıda 2025 yılı için genel bir fiyatlandırma kılavuzu yer almaktadır:

| Makine Tipi | Yetenekler | Fiyat Aralığı (USD) |

|---|---|---|

| Standart Makineler | Temel ekskavatör şasi üretimi | 400,000–400,000–400,000–1,000,000 |

| Gelişmiş Makineler | Otomatik delik delme ile yüksek hızlı üretim | 1.000.000–1.000.000–1.000.000–3.000.000 |

| Özelleştirilebilir Akıllı Makineler | Tam otomatik, IoT bağlantılı Endüstri 4.0 çözümleri | 3.000.000–3.000.000–3.000.000–7.000.000 |

Kişiselleştirilmiş fiyatlandırma ve finansman seçenekleri için Wuxi Sunway Makine.

Gerçek Hayattan Başarı Öyküleri: Ekskavatör Rulo Şekillendirme Makineleri Ağır Ekipman Üretimini Nasıl Dönüştürüyor?

Kimden kentsel inşaat sahalarından derin madencilik faaliyetlerine, Ekskavatör Rulo Şekillendirme Makineleri üreticilere yardım ölçekli üretim, maliyetleri düşürme ve dayanıklılığı artırma. Aşağıdakiler gerçek dünya uygulamalari bu makinelerin etkisini sergileyen ekskavatör imalatı.

1. Amerika Birleşik Devletleri'nde Büyük Ölçekli Ekskavatör Üretimi

Müşteri: A ABD merkezli önde gelen inşaat ekipmanı üreticisi.

Meydan okuma: Gerekli ekskavatör şaseleri ve alt takım takviyeleri için yüksek mukavemetli çelik paneller.

Çözüm: Wuxi Sunway Machinery bir Aşınmaya dayanıklı çeliği işleyebilen özel rulo şekillendirme makinesi.

Sonuç:

✅ Geliştirilmiş dayanıklılıksağlamak zorlu koşullarda daha uzun çalışma ömrü.

✅ 30% ile üretim maliyetlerinde azalma, artan karlılık.

✅ Daha hızlı üretim süreci, etkinleştirme daha yüksek üretim hacimleri.

2. Güney Amerika Projeleri için Madencilik Ekskavatör Üretimi

Müşteri: A Şili ve Peru'da büyük ölçekli madencilik faaliyetlerine hizmet veren madencilik ekipmanı tedarikçisi.

Meydan okuma: Gerekli Aşırı madencilik koşullarında çalışan ekskavatörler için ağır hizmet tipi şasi ve bom takviyeleri.

Çözüm: Wuxi Sunway, bir yüksek mukavemetli çelik işleme için optimize edilmiş rulo şekillendirme makinesi.

Sonuç:

✅ Mekanik strese karşı artan direnç, önlenmesi madencilik sahalarında ekipman arızası.

✅ Ekskavatör bileşenlerinin ömrünün uzatılması, azaltılması bakım kesintisi.

✅ Geliştirilmiş yük taşıma kapasitesisağlamak derin madencilik operasyonlarında daha iyi performans.

3. Avrupa'da Kompakt Ekskavatör Şasi Üretimi

Müşteri: A Kompakt ve kentsel ekskavatörlerde uzmanlaşmış Avrupalı üretici.

Meydan okuma: Gerekli verimli kentsel kazı çalışmaları için hafif ancak sağlam çerçeve malzemeleri.

Çözüm: Wuxi Sunway, bir alüminyum alaşımlarını işleyebilen rulo şekillendirme makinesi.

Sonuç:

✅ Toplam makine ağırlığının azaltılması, artan yakıt verimliliği.

✅ Geliştirilmiş manevra kabiliyeti, iyileştirme kapalı alanlarda ekskavatör performansı.

✅ Optimize edilmiş malzeme kullanımı, minimize etmek atık ve üretim maliyetleri.

4. Orta Doğu'da İnşaat için Akıllı Ekskavatör Bileşenleri

Müşteri: A akıllı ekskavatör çözümlerine odaklanan inşaat teknolojisi şirketi.

Meydan okuma: Gerekli otomatik kazı sistemleri için sensör entegreli yapısal paneller.

Çözüm: Wuxi Sunway, bir Üretim sürecine sensörler yerleştirebilen yüksek teknolojili rulo şekillendirme makinesi.

Sonuç:

✅ Ekskavatör performansının gerçek zamanlı izlenmesini sağladı.

✅ Öngörücü bakım ile arıza riskinin azaltılması.

✅ Büyük ölçekli inşaat projelerinde akıllı ekskavatörlerin daha hızlı kullanıma sunulması.

5. Avustralya'daki Kıyı İnşaatları için Korozyona Dayanıklı Ekskavatör Parçaları

Müşteri: A kıyı altyapısı ve tarama ekipmanları konusunda uzmanlaşmış şirket.

Meydan okuma: Gerekli tuzlu ortamlarda çalışan ekskavatörler için korozyona dayanıklı çelik paneller.

Çözüm: Wuxi Sunway, bir Entegre korozyon önleyici kaplama uygulamalı rulo şekillendirme makinesi.

Sonuç:

✅ Uzatılmış bileşen ömrü, azaltılması yenileme maliyetleri.

✅ Pas ve tuzlu su hasarına karşı geliştirilmiş direnç.

✅ Kıyı kazı projelerinde ekipman güvenilirliğinin artırılması.

2025 Yılına İlişkin Ekskavatör Üretiminde Gelecek Trendler

As ağır ekipman imalatı gelişiyoriçin talep daha güçlü, daha hafif ve daha verimli ekskavatörler artıyor. Üreticiler benimsiyor yeni malzemeler, otomasyon ve yapay zeka odaklı teknolojiler ekskavatör performansını artırmak için. Aşağıda, geleceği şekillendiren temel eğilimler yer almaktadır. Ekskavatör Rulo Şekillendirme Makineleri.

1. Hassas Mühendislik için Yapay Zeka Destekli Üretim

- Trend: Yapay zeka destekli sistemler, optimize edilmiş ekskavatör bileşenleri için malzeme işlemede gerçek zamanlı ayarlamalar.

- Makineler Üzerindeki Etkisi: Roll-forming sistemleri entegre olacak Yapısal verimlilik ve dayanıklılık için yapay zeka destekli kalite kontrolü.

2. Ultra Hafif ve Yüksek Mukavemetli Malzemeler

- Trend: Artan kullanım gelişmiş çelik alaşımları, kompozit malzemeler ve güçlendirilmiş alüminyum.

- Makineler Üzerindeki Etkisi: Makineler aşağıdakiler için optimize edilecektir güç/ağırlık oranlarını iyileştirmek için çoklu malzeme işleme.

3. Özelleştirme için Modüler Ekskavatör Şasileri

- Trend: Büyüme kolay özelleştirme ve hızlı montaj için modüler ekskavatör tasarımları.

- Makineler Üzerindeki Etkisi: Roll-forming sistemleri aşağıdakilere öncelik verecektir değiştirilebilir çerçeve bileşenleri ve hızlı montaj özellikleri.

4. Korozyona Dayanıklı ve Aşınmaya Dayanıklı Kaplamalar

- Trend: Daha katı Aşırı koşullarda kullanılan ekskavatörler için dayanıklılık standartları.

- Makineler Üzerindeki Etkisi: Makineler entegre olacak bileşenlerin ömrünü uzatan kaplama uygulama sistemleri.

5. IoT ve Otonom Özelliklere Sahip Akıllı Ekskavatörler

- Trend: Yatırım otonom inşaat ekipmanları ve yapay zeka destekli kazı sistemleri.

- Makineler Üzerindeki Etkisi: Artan talep gömülü akıllı sensör teknolojisine sahip roll-form paneller.

2025 için Ekskavatör Rulo Şekillendirme Makinelerinde Yenilikler

Yeni nesil Ekskavatör Rulo Şekillendirme Makineleri devrim yaratmaya hazırlanıyor inşaat ve ağır ekipman imalatı. Aşağıda en son yeniliklerden bazıları yer almaktadır:

1. Yapay Zeka Güdümlü Hassas Üretim

- Ne Sağlar: Yapay zeka güdümlü sistemler Optimum yapısal bütünlük için şekillendirme parametrelerini otomatik olarak ayarlama.

- Neden Devrimci? Azaltır israfı önler, verimliliği artırır ve tutarlı ürün kalitesi sağlar.

2. Aşınmaya ve Korozyona Dayanıklı Kaplamalar

- Ne Ekliyor? Şunları yapabilen makineler bileşenlerin ömrünü uzatmak için koruyucu kaplamalar uygulamak.

- Neden değerli? Genişletir ekskavatörün ömrünü uzatır ve bakım maliyetlerini azaltır.

3. Taşınabilir, Yerinde Rulo Şekillendirme Üniteleri

- Ne Sunuyor? Mobil rulo şekillendirme makineleri isteğe bağlı, yerelleştirilmiş ağır ekipman üretimi.

- Neden Oyunu Değiştiriyor? Azaltır lojistik maliyetleri azaltır ve şantiyelerde hızlı bileşen üretimi sağlar.

4. Akıllı İzleme ve Kestirimci Bakım

- Ne Entegre Ediyor? IoT özellikli sistemler için gerçek zamanlı arıza tespiti ve kestirimci bakım planlaması.

- Neden gerekli? En aza indirir kesinti süresi ve sürekli üretim verimliliği sağlar.

Wuxi Sunway Machinery, Ekskavatör Üretim Sektöründe Neden Liderdir?

1. Onlarca Yıllık Uzmanlık

ile yılların deneyimiWuxi Sunway'in kanıtlanmış bir mükemmellik geçmişi içinde ekskavatör rulo şekillendirme çözümleri.

2. Son Teknoloji

Aşağıdakiler gibi gelişmiş özellikler içerir Yapay zeka, IoT odaklı otomasyon ve yüksek hızlı roll-forming.

3. Özelleştirme Mükemmelliği

Teklifler özel çözümler için ekskavatör üreticileri ve ağır ekipman tedarikçileri.

4. Küresel Sektör Liderliği

Tarafından güvenilen dünya çapında inşaat şirketleri, madencilik şirketleri ve altyapı geliştiricileri.

5. Kapsamlı Destek

Sağlar danışmanlık, kurulum, eğitim ve satış sonrası hizmetler sorunsuz çalışma için.

Ziyaret edin resmi web sitesi tekliflerini keşfetmek veya bir özelleştirilmiş ekskavatör rulo şekillendirme çözümü ihtiyaçlarınıza göre uyarlanmıştır.

Son Düşünceler: Rulo Şekillendirme Teknolojisi ile Ekskavatör Üretiminin Geleceği

Optimize etmek mi istiyorsunuz ekskavatör bileşenleri üretim süreci? İle ortak olun Wuxi Sunway Makine ve ağır ekipman imalatınızı bir üst seviyeye taşıyın.