Otomotiv endüstrisi, daha hafif, daha güçlü ve daha verimli araçlara yönelik talepleri karşılamak için sürekli gelişen bir inovasyon yuvasıdır. Bu evrimin merkezinde hassas üretimin rolü yer almaktadır ve Otomobil Parçaları Rulo Şekillendirme Makineleri öncülük ediyor. Bu makineler, modern otomobiller için kritik önem taşıyan yüksek kaliteli, dayanıklı ve özel tasarımlı bileşenlerin üretilmesini sağlıyor.

Bu makalede, aşağıdaki konulara değineceğiz Otomobil parçaları rulo şekillendirme makinelerinin ne olduğu, uygulamaları, avantajları, fiyatları, otomasyon yetenekleri, çevresel faydaları ve Wuxi Sunway Machinery'nin neden sektörde güvenilir bir isim olduğu. Üretim süreçlerinizi kolaylaştırmak isteyen bir üretici veya otomotiv teknolojisinde bir sonraki büyük sıçramayı hedefleyen bir tedarikçiyseniz, bu kılavuz ihtiyacınız olan bilgileri sağlayacaktır.

Otomobil Parçaları Rulo Şekillendirme Makineleri Nedir?

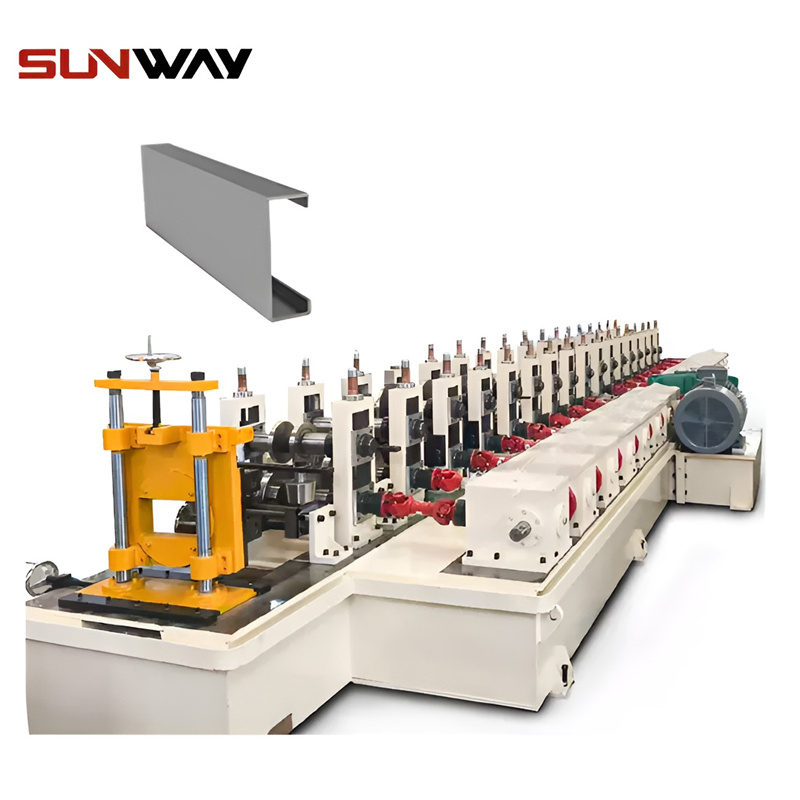

Otomobil Parçaları Rulo Şekillendirme Makineleri metal levhaları veya bobinleri otomotiv üretiminde kullanılan belirli profillere göre şekillendirmek için tasarlanmış özel endüstriyel sistemlerdir. Bu makineler, hassasiyet ve verimlilikle bileşenler oluşturmak için sürekli bir bükme işleminden yararlanarak kaliteden ödün vermeden seri üretime olanak tanır.

Temel Özellikler

- Yüksek Hassasiyet: Araç tasarımları ile uyumluluğu sağlayarak tam spesifikasyonlara sahip bileşenler üretir.

- Malzeme Esnekliği: Alüminyum, yüksek mukavemetli çelik ve galvanizli çelik gibi hafif ancak güçlü malzemeleri işler.

- Özel Profiller: Farklı araç modelleri ve uygulamaları için uyarlanmış çeşitli tasarımları destekler.

- Yüksek Hızlı Üretim: Büyük ölçekli otomotiv üretiminin taleplerini karşılar.

- Çevre Dostu Uygulamalar: Sürdürülebilirlik hedefleriyle uyumlu olarak atık ve enerji kullanımını en aza indirir.

Otomobil Parçaları Rulo Şekillendirme Makineleri Uygulamaları

Otomobil parçaları rulo şekillendirme makineleri, modern otomobiller, kamyonlar ve diğer araçların yapımında kullanılan çok çeşitli bileşenlerin üretilmesi için gereklidir. İşte ana uygulamalar:

1. Otomotiv Yapısal Bileşenleri

- Kullanım Örneği: Yan darbe kirişleri, tavan rayları ve B sütunları gibi yapısal takviyelerin üretimi.

- Neden gerekli? Darbeyi emen ve yapısal bütünlüğü iyileştiren bileşenler oluşturarak araç güvenliğini artırır.

2. Şasi ve Çerçeve Parçaları

- Kullanım Örneği: Traversler, marşpiye panelleri ve zemin takviyeleri dahil olmak üzere şasi bileşenlerinin üretilmesi.

- Neden Yararlı? Araçlar için hafif ancak güçlü bir temel sağlayarak performansı ve yakıt verimliliğini artırır.

3. Kapı ve Pencere Çerçeveleri

- Kullanım Örneği: Hassas kapı kasaları, pencere kanalları ve sızdırmazlık profilleri oluşturma.

- Neden gerekli? Mükemmel uyum ve dayanıklılık sağlayarak aracın genel estetiğine ve işlevselliğine katkıda bulunur.

4. Elektrikli Araçlar için Akü Tepsileri

- Kullanım Örneği: Elektrikli araç batarya sistemleri için tepsi ve muhafaza üretimi.

- Neden eşsiz: Hafif, korozyona dayanıklı bileşenler sağlayarak büyüyen elektrikli araç pazarını destekler.

5. Özel Trim ve Dekoratif Parçalar

- Kullanım Örneği: Pervazlar, ısı yalıtım şeritleri ve vurgu profilleri gibi özel trim elemanlarının üretilmesi.

- Neden önemli? Dayanıklılık ve hassasiyeti korurken aracın görsel çekiciliğini artırır.

6. Süspansiyon ve Destek Parçaları

- Kullanım Örneği: Süspansiyon takviyeleri, braketler ve desteklerin hazırlanması.

- Neden Kritik? Sağlam ve güvenilir süspansiyon bileşenleri sağlayarak sürüş kalitesini ve araç dengesini artırır.

Otomobil Parçaları Rulo Şekillendirme Makineleri Neden Vazgeçilmezdir?

Otomotiv sektörü yenilik yapma, maliyetleri düşürme ve sürdürülebilirlik hedeflerini karşılama konusunda sürekli baskı altında. İşte nedeni Otomobil Parçaları Rulo Şekillendirme Makineleri bu hedeflere ulaşmak için kritik öneme sahiptir:

1. Hassas Mühendislik

- Neden hayati: Her bileşenin, araç güvenliği ve performansı için çok önemli olan sıkı tasarım toleranslarını karşılamasını sağlar.

2. Farklı Modeller için Özelleştirme

- Neden Yararlı? Üreticilerin hem standart modellere hem de lüks otomobillere uygun, belirli araç tasarımlarına göre uyarlanmış parçalar üretmesine olanak tanır.

3. Ölçeklenebilirlik

- Neden pratik: Küresel pazarlarda otomotiv bileşenlerine yönelik artan talebi karşılamak için yüksek hızlı üretim sağlar.

4. Malzeme Verimliliği

- Neden Ekonomik? Hassas kesim ve şekillendirme sayesinde malzeme israfını azaltarak genel üretim maliyetlerini düşürür.

5. Hafif Tasarım

- Neden önemli? Yakıt verimliliğini artıran ve emisyonları azaltan hafif bileşenlerin üretimini kolaylaştırarak sektör trendlerine uyum sağlar.

6. Sürdürülebilirlik

- Neden önemli? Enerji tüketimini en aza indirerek ve geri dönüştürülebilir malzemelerin kullanılmasını sağlayarak çevre dostu üretimi destekler.

Wuxi Sunway Otomobil Parçaları Rulo Şekillendirme Makinelerinin Temel Özellikleri

Roll-forming teknolojisi söz konusu olduğunda, Wuxi Sunway Makine küresel bir liderdir. Onların Otomobil Parçaları Rulo Şekillendirme Makineleri en yüksek hassasiyet, verimlilik ve yenilik standartlarını karşılamak üzere tasarlanmıştır. İşte onları diğerlerinden ayıran özellikler:

1. Gelişmiş Malzeme Taşıma

- Desteklenen Materyaller:

- Yüksek mukavemetli çelik

- Galvanizli çelik

- Alüminyum

- Paslanmaz çelik

- Neden Yararlı? Modern araç üretimi için gerekli olan hafif ve dayanıklı malzemelerle uyumluluk sağlar.

2. Modüler Kalıp Sistemleri

- Ne Sunuyor? Tek bir makinede birden fazla bileşen tasarımı üretmek için değiştirilebilir takımlar.

- Neden Çok Yönlü? Ek ekipman gerektirmeden çeşitli üretim ihtiyaçlarını destekler.

3. Entegre Kesme ve Delme

- Ne İçerir? Roll-forming işlemi sırasında hassas kesme, delme ve çentik açma için yerleşik sistemler.

- Neden Verimli: Üretim süresini azaltır ve montaja hazır bileşenler sağlar.

4. IoT ve Otomasyon Entegrasyonu

- Ne Sağlar: IoT sistemlerini kullanarak gerçek zamanlı izleme, otomatik ayarlamalar ve kestirimci bakım.

- Neden Devrimci?

- Operasyonel verimliliği artırır.

- Arıza süresini ve bakım maliyetlerini en aza indirir.

5. Yüksek Hızlı Üretim

- Ne Sağlıyor? Dakikada 120 metreye kadar bileşen üretebilen makineler.

- Neden gerekli? Otomotiv üretiminin yüksek hacimli taleplerine ayak uydurur.

6. Çevre Dostu Tasarım

- Ne İçerir? Enerji tasarruflu motorlar, optimize edilmiş iş akışları ve atık azaltma sistemleri.

- Neden Sürdürülebilir? Otomobil parçaları üretiminin çevresel etkisini azaltır.

Otomobil Parçaları Rulo Şekillendirme Makinelerinin Fiyatlandırılması

Maliyeti Otomobil Parçaları Rulo Şekillendirme Makinesi özelleştirme, gelişmiş özellikler ve üretim kapasitesi gibi faktörlere bağlıdır. Aşağıda 2025 yılı için genel bir fiyatlandırma kılavuzu yer almaktadır:

| Makine Tipi | Yetenekler | Fiyat Aralığı (USD) |

|---|---|---|

| Standart Makineler | Temel otomotiv profilleri | 150,000–150,000–150,000–400,000 |

| Gelişmiş Makineler | Yüksek hızlı, entegre kesme ve delme sistemleri | 400,000–400,000–400,000–900,000 |

| Tamamen Özelleştirilebilir Makineler | IoT özellikli, modüler takımlar, çevre dostu özellikler | 900,000–900,000–900,000–2,500,000 |

Özel fiyatlandırma ve finansman seçenekleri için Wuxi Sunway Makine.

Otomobil Parçaları Rulo Şekillendirme Makinelerinde Otomasyon

Otomasyon otomotiv üretim endüstrisinde devrim yaratıyor ve otomobil parçaları rulo şekillendirme makineleri bu dönüşümün ön saflarında yer almaktadır. Bu makineler, en son teknolojiden yararlanarak üstün verimlilik ve kalite sunmaktadır.

1. Gerçek Zamanlı Üretim İzleme

- Ne izler: Üretim hızı, malzeme kullanımı ve hata oranları gibi temel metrikler.

- Neden değerli? Üreticilerin iş akışlarını optimize etmelerine ve verimsizlikleri belirlemelerine yardımcı olur.

2. Kestirimci Bakım

- Ne Sağlar: IoT sensörleri bileşenlerdeki aşınma ve yıpranmayı izler ve bakım ihtiyaçlarını tahmin eder.

- Neden Devrimci?

- Beklenmedik arızaları önler.

- Makinenin kullanım ömrünü uzatır.

3. Otomatik Ayarlamalar

- Ne Sunuyor? Farklı malzemeler veya tasarımlar için silindirleri, kesicileri ve zımbaları otomatik olarak ayarlar.

- Neden Verimli: Kurulum süresini azaltır ve tutarlı kalite sağlar.

4. Yapay Zeka Destekli Kalite Kontrol

- Ne Tespit Ediyor: Kusurları gerçek zamanlı olarak belirler ve kaliteyi korumak için gerekli ayarlamaları yapar.

- Neden etkili? İsrafı azaltır ve müşteri memnuniyetini artırır.

5. Uzaktan Kumanda ve Diyagnostik

- Ne İçerir? Uzaktan izleme, sorun giderme ve kontrol için bulut tabanlı sistemler.

- Neden Kullanışlı: Operatörlerin her yerden üretimi denetlemesine ve sorunları çözmesine olanak tanır.

Otomobil Parçaları Rulo Şekillendirme Makinelerinin Çevresel Faydaları

Sürdürülebilirlik, otomotiv endüstrisi için temel bir odak noktasıdır ve Otomobil Parçaları Rulo Şekillendirme Makineleri çevre dostu uygulamaları desteklemek üzere tasarlanmıştır.

1. Azaltılmış Malzeme Atığı

- Bu nasıl başarıldı? Hassas mühendislik, üretim sürecinde hurda malzemeyi en aza indirir.

- Etki: Kaynakları korur ve çöp sahası atıklarını azaltır.

2. Enerji Verimliliği

- Nasıl Çalışır? Güç tüketimini azaltmak için enerji tasarruflu motorlar ve optimize edilmiş iş akışları ile donatılmıştır.

- Etki: Otomotiv üretiminin karbon ayak izini azaltır.

3. Geri Dönüştürülebilir Malzeme Kullanımı

- Neyi Destekler: Alüminyum ve galvanizli çelik gibi geri dönüştürülebilir metalleri işler.

- Etki: Döngüsel bir ekonomiyi teşvik eder ve kaynak çıkarımını azaltır.

4. Dayanıklı Bileşenler

- Neden önemli? Uzun süre dayanacak şekilde üretilmiş yüksek kaliteli bileşenler üreterek sık sık değiştirme ihtiyacını azaltır.

- Etki: Parça ömürlerini uzatarak sürdürülebilir araç üretimini destekler.

Otomobil Parçaları Rulo Şekillendirme Makineleri Hakkında SSS

| Soru | Cevap |

|---|---|

| Bu makineler hangi malzemeleri işleyebilir? | Yüksek mukavemetli çelik, alüminyum, galvanizli çelik ve paslanmaz çelik. |

| Üretim hızı nedir? | Kadar Dakikada 120 metreMalzeme ve profil karmaşıklığına bağlı olarak. |

| Bu makineler çevre dostu mu? | Evet, enerji tasarruflu motorlar içerirler ve malzeme israfını en aza indirirler. |

| Bu makineler özel tasarımları işleyebilir mi? | Kesinlikle! Modüler takımlar, çeşitli otomotiv uygulamaları için ısmarlama profilleri destekler. |

| Bu makineler için fiyat aralığı nedir? | Fiyatlar arasında değişir 150,000 ila 150,000 ila 150,000 ila 2,500,000özelliklerine ve özelleştirmeye dayalı olarak. |

| Bu makineler IoT sistemleri ile entegre oluyor mu? | Evet, IoT özellikli özellikler gerçek zamanlı izleme ve kestirimci bakım sağlar. |

Gerçek Dünyadan Başarı Hikayeleri: Otomobil Parçaları Rulo Şekillendirme Makineleri İş Başında

dönüştürücü yetenekleri Otomobil Parçaları Rulo Şekillendirme Makineleri dünyanın dört bir yanındaki üreticilerin otomotiv üretim hatlarını yenilemelerini ve ölçeklendirmelerini sağladı. Aşağıda, bu makinelerin operasyonlarda nasıl devrim yarattığına dair bazı gerçek dünya örnekleri yer almaktadır.

1. Önde Gelen Bir Elektrikli Araç Üreticisi için EV Akü Tepsileri

Müşteri: Küresel bir elektrikli araç (EV) markası.

Meydan okuma: Üretici, yeni nesil elektrikli araç serisi için hafif, korozyona dayanıklı akü tepsilerine ihtiyaç duyuyordu.

Çözüm: Wuxi Sunway, alüminyum ve galvanizli çeliği işlemek üzere tasarlanmış, yuvalar ve delikler için entegre delme özelliğine sahip bir rulo şekillendirme makinesi teslim etti.

Sonuç:

- Akü tepsilerinin ağırlığı 20% azaltılarak araç menzili artırıldı.

- Üretim hızını 30% artırarak elektrikli araç lansmanı için kısıtlı teslim tarihlerini karşıladı.

- Sürdürülebilir otomotiv çözümlerinde öncü olarak şirketin itibarını artırdı.

2. Kuzey Amerika'da Bir Ticari Kamyon Üreticisi için Yapısal Bileşenler

Müşteri: Önde gelen bir kamyon üreticisi.

Meydan okuma: Şirket, yüksek yüklere ve zorlu koşullara dayanabilecek ağır hizmet tipi şasi bileşenlerine ihtiyaç duyuyordu.

Çözüm: Wuxi Sunway, güçlendirilmiş profiller için gelişmiş takımlara sahip yüksek mukavemetli bir çelik rulo şekillendirme makinesi tedarik etti.

Sonuç:

- Üstün güç ve dayanıklılığa sahip şasi bileşenleri teslim edildi.

- Malzeme israfını 18% azaltarak üretim maliyetlerini düşürdü.

- Kamyonun performansı ve güvenilirliği iyileştirilerek müşteri memnuniyeti artırıldı.

3. Avrupa'da Lüks Bir Otomobil Markası için Özel Trim Profilleri

Müşteri: Ismarlama araçlar konusunda uzmanlaşmış lüks bir otomobil üreticisi.

Meydan okuma: Otomobil üreticisi, premium araçlarının estetiğini geliştirmek için özel tasarım trim elemanlarına ihtiyaç duyuyordu.

Çözüm: Wuxi Sunway, karmaşık tasarımlar ve dekoratif yüzeyler için modüler takımlara sahip bir rulo şekillendirme makinesi sağladı.

Sonuç:

- Benzersiz, yüksek kaliteli trim profillerinin oluşturulmasını sağladı.

- Otomobil üreticisinin müşterilerine kişiselleştirilmiş tasarım seçenekleri sunma kabiliyetini artırdı.

- Markanın lüks otomotiv segmentindeki pazar konumunu yükseltti.

4. Asyalı Bir Otomotiv Tedarikçisi için Hafif Süspansiyon Bileşenleri

Müşteri: Birçok küresel otomobil üreticisinin Tier-1 tedarikçisi.

Meydan okuma: Tedarikçi, aracın yakıt verimliliğini artırmak için hafif ancak dayanıklı süspansiyon bileşenlerine ihtiyaç duyuyordu.

Çözüm: Wuxi Sunway, entegre kesme ve delme özelliklerine sahip yüksek mukavemetli çeliği işlemek için özel olarak tasarlanmış bir makine teslim etti.

Sonuç:

- Bileşen ağırlığı 15% azaltılarak daha iyi yakıt verimliliğine katkıda bulunuldu.

- 40% ile üretim kapasitesi artırılarak tedarikçinin artan talebi karşılaması sağlandı.

- Tedarikçinin önde gelen otomobil üreticileriyle olan ortaklığı güçlendirildi.

Otomobil Parçaları Rulo Şekillendirme Makinelerinde Sık Karşılaşılan Sorunların Giderilmesi

Hatta en gelişmiş Otomobil Parçaları Rulo Şekillendirme Makineleri operasyonel zorluklarla karşılaşabilir. İşte üretim hattınızın sorunsuz çalışmasını sağlamak için bazı yaygın sorunlar ve çözümleri.

1. Tutarsız Profiller

- Semptomlar: Üretilen bileşenler eşit olmayan boyutlara sahiptir veya tasarım özelliklerini karşılamamaktadır.

- Olası Sebepler:

- Yanlış hizalanmış makaralar veya aşınmış takımlar.

- Yanlış malzeme besleme.

- Çözüm:

- Silindirleri düzenli olarak inceleyin ve yeniden hizalayın.

- Kılavuzları ve besleyicileri kalibre ederek doğru malzeme beslemesini sağlayın.

2. Malzeme Sıkışması

- Semptomlar: Malzeme silindirlere sıkışarak üretimi durdurur.

- Olası Sebepler:

- Malzeme kalınlığı makinenin kapasitesini aşıyor.

- Şekillendirme alanında enkaz veya yabancı cisimler.

- Çözüm:

- Malzemelerin makinenin teknik özelliklerine uygun olduğunu doğrulayın.

- Her üretim çalışmasından önce silindirleri ve kılavuzları temizleyin.

3. Aşırı Takım Aşınması

- Semptomlar: Kesme ve delme takımları çabuk aşınarak üretim kalitesini etkiler.

- Olası Sebepler:

- Düşük kaliteli hammaddeler.

- Hareketli parçaların yanlış yağlanması.

- Çözüm:

- Takım aşınmasını en aza indirmek için yüksek kaliteli malzemeler kullanın.

- Bileşenleri temizlemek ve yağlamak için düzenli bir bakım programı uygulayın.

4. Makine Titreşimleri

- Semptomlar: Çalışma sırasında aşırı gürültü ve titreşim.

- Olası Sebepler:

- Gevşek bileşenler veya dengesiz silindirler.

- Makinenin önerilen kapasitesinin üzerinde çalıştırılması.

- Çözüm:

- Tüm bileşenleri ve balans silindirlerini sıkın.

- Makineyi belirtilen sınırlar dahilinde çalıştırın.

5. Yazılım Arızaları

- Semptomlar: Kontrol sistemi donuyor veya komutları yürütemiyor.

- Olası Sebepler:

- Eski yazılım veya ürün yazılımı.

- Kontrol panelindeki elektrik arızaları.

- Çözüm:

- Yazılımı en son sürüme güncelleyin.

- Kontrol panelindeki hatalı kabloları veya bileşenleri inceleyin ve onarın.

2025'te Otomobil Parçaları Rulo Şekillendirme Makineleri için Küresel Sektör Eğilimleri

Otomotiv endüstrisi, teknoloji, sürdürülebilirlik ve tüketici tercihlerindeki gelişmelerin etkisiyle bir paradigma değişiminden geçiyor. İşte pazarı şekillendiren temel trendler Otomobil Parçaları Rulo Şekillendirme Makineleri:

1. Elektrikli Araçlara (EV) Geçiş

- Trend: Elektrikli araçlara yönelik küresel değişim, hafif ve korozyona dayanıklı bileşenlere yönelik talebi artırıyor.

- Etki: Alüminyum ve diğer hafif malzemeler için tasarlanmış rulo şekillendirme makineleri yüksek talep görmektedir.

2. Sürdürülebilirlik Vurgusu

- Trend: Otomobil üreticileri, katı küresel emisyon standartlarını karşılamak için çevre dostu uygulamaları benimsiyor.

- Etki: Atıkları en aza indiren ve geri dönüştürülebilir malzemelerin kullanılmasını sağlayan makineler endüstri standartları haline geliyor.

3. Özelleştirmenin Yükselişi

- Trend: Tüketicilerin kişiselleştirilmiş araç tasarımları arayışında olması, özelleştirilmiş bileşenlere olan talebi artırıyor.

- Etki: Ismarlama profiller üretebilen modüler rulo şekillendirme makineleri ilgi görüyor.

4. Akıllı Fabrika Entegrasyonu

- Trend: Endüstri 4.0 teknolojilerinin benimsenmesi otomotiv üretimini yeniden şekillendiriyor.

- Etki: Gerçek zamanlı izleme ve kestirimci bakım özelliklerine sahip IoT özellikli roll-form makineleri bu konuda başı çekiyor.

5. Hafif Malzemelerde Büyüme

- Trend: Yakıt verimliliğini artırmak için yüksek mukavemetli çelik, alüminyum ve kompozitlerin kullanımı giderek yaygınlaşmaktadır.

- Etki: Bu malzemeler için optimize edilmiş makineler, gelecekteki otomotiv ihtiyaçlarını karşılamak için kritik öneme sahiptir.

Otomobil Parçaları Rulo Şekillendirme Makinelerinde Gelişmiş Otomasyon Yetenekleri

Otomasyon modern üretimin bel kemiğidir ve Otomobil Parçaları Rulo Şekillendirme Makineleri istisna değildir. İşte bazı son teknoloji otomasyon özelliklerine bir göz atın:

1. Uyarlanabilir Malzeme Taşıma

- Ne işe yarıyor? İşlenmekte olan malzemeye göre ayarları otomatik olarak yapar.

- Neden Devrimci? Kurulum süresini azaltır ve farklı malzemeler arasında tutarlı kalite sağlar.

2. Akıllı Kusur Tespiti

- Ne İçerir? Yüzey kusurlarını, yanlış hizalamaları veya boyutsal hataları gerçek zamanlı olarak tespit eden yapay zeka destekli sistemler.

- Neden etkili? İsrafı en aza indirir ve manuel denetim ihtiyacını azaltır.

3. Çoklu Profil Üretimi

- Ne Sağlar: Tek bir üretim çalışmasında farklı bileşen profilleri arasında sorunsuz geçiş.

- Neden Kullanışlı: Esnekliği artırır ve çeşitli üretim gereksinimlerini destekler.

4. Bulut Tabanlı Analitik

- Ne izler: Üretim ölçümleri, makine performansı ve bakım programları.

- Neden değerli? Operasyonları optimize etmek ve arıza sürelerini önlemek için eyleme geçirilebilir içgörüler sağlar.

Otomobil Parçaları Rulo Şekillendirme Makinelerinin Çevresel Etkisi

Sürdürülebilirlik, otomotiv endüstrisi için giderek artan bir odak noktasıdır ve Otomobil Parçaları Rulo Şekillendirme Makineleri bu hedeflerle uyumlu olacak şekilde tasarlanmıştır. İşte çevre dostu üretime nasıl katkıda bulundukları:

1. Verimli Malzeme Kullanımı

- Bu nasıl başarıldı? Hassas mühendislik hurdayı azaltır ve hammaddelerin en iyi şekilde kullanılmasını sağlar.

- Etki: Kaynakları korur ve üretim maliyetlerini düşürür.

2. Enerji Verimliliği

- Nasıl Çalışır? Makineler enerji tasarruflu motorlar ve güç tasarrufu özellikleriyle donatılmıştır.

- Etki: Enerji tüketimini ve üretimin karbon ayak izini azaltır.

3. Geri Dönüştürülebilir Malzemelere Destek

- Ne Sağlar: Alüminyum ve galvanizli çelik gibi kolayca geri dönüştürülebilen malzemeleri işler.

- Etki: Sürdürülebilir uygulamaları teşvik eder ve döngüsel bir ekonomiyi destekler.

4. Uzun Ömürlü Çıkışlar

- Neden önemli? Sık değiştirme ihtiyacını azaltan dayanıklı otomotiv bileşenleri üretir.

- Etki: Parça ömürlerini uzatarak sürdürülebilir araç üretimini destekler.

Wuxi Sunway Machinery Neden Rulo Şekillendirme Sektörüne Liderlik Ediyor?

Onlarca yıllık uzmanlık ve yeniliğe olan bağlılığımızla, Wuxi Sunway Makine roll-forming teknolojisinde küresel bir lider olarak kendini kanıtlamıştır. İşte bu yüzden ölçütleri belirlemeye devam ediyorlar:

- Küresel Uzmanlık: Asya, Avrupa, Amerika ve ötesindeki üreticiler tarafından güvenilmektedir.

- Özelleştirilebilir Çözümler: Özel üretim ihtiyaçlarını karşılamak için özel makineler sunar.

- Sürdürülebilirlik Odağı: Küresel çevre hedefleriyle uyumlu çevre dostu makineler tasarlar.

- Kapsamlı Destek: Danışmanlıktan satış sonrası desteğe kadar uçtan uca hizmetler sunar.

- Kanıtlanmış Yenilik: IoT, yapay zeka ve modüler takımlar gibi en son teknolojileri makinelerine dahil ediyor.

Ürünleri hakkında daha fazla bilgi için resmi web sitesi.

Otomobil Parçaları Rulo Şekillendirme Makineleri Hakkında SSS

| Soru | Cevap |

|---|---|

| Bu makineler hangi malzemeleri işleyebilir? | Yüksek mukavemetli çelik, alüminyum, galvanizli çelik ve paslanmaz çelik. |

| Üretim hızı nedir? | Kadar Dakikada 120 metreMalzeme ve profil karmaşıklığına bağlı olarak. |

| Bu makineler çevre dostu mu? | Evet, enerji tasarruflu motorlar içerirler ve malzeme israfını en aza indirirler. |

| Bu makineler özel tasarımları işleyebilir mi? | Kesinlikle! Modüler takımlar, çeşitli otomotiv uygulamaları için ısmarlama profilleri destekler. |

| Bu makineler için fiyat aralığı nedir? | Fiyatlar arasında değişir 150,000 ila 150,000 ila 150,000 ila 2,500,000özelliklerine ve özelleştirmeye dayalı olarak. |

| Bu makineler IoT sistemleri ile entegre oluyor mu? | Evet, IoT özellikli özellikler gerçek zamanlı izleme ve kestirimci bakım sağlar. |

Sonuç: Rulo Şekillendirme Teknolojisi ile Otomotiv Endüstrisine İvme Kazandırmak

Otomobil Parçaları Rulo Şekillendirme Makineleri hassasiyet, verimlilik ve sürdürülebilirlik sağlayarak otomotiv üretiminin geleceğini şekillendiriyor. Hafif elektrikli araç bileşenlerinden özel lüks kaplamalara kadar, bu makineler hızla gelişen bir sektörün taleplerini karşılamak için gereklidir.

Üretim hattınızda inovasyonu teşvik etmeye hazır mısınız? Birlikte çalışın Wuxi Sunway Makine ve otomotiv sektörüne yönelik son teknoloji roll-forming çözümlerini keşfedin. Birlikte, ulaşımın geleceğini hızlandıralım - her seferinde bir bileşen.