The demand for lightweight, durable, and versatile aluminum profiles is skyrocketing across industries like construction, automotive, electronics, and renewable energy. From sleek architectural designs to robust industrial frameworks, aluminum profiles are essential components of modern infrastructure and technology. But how are these intricate profiles manufactured with such precision and scale? The answer lies in Alüminyum Profil Rulo Şekillendirme Makineleri—a groundbreaking technology that enables high-speed, cost-effective, and eco-friendly production.

Bu kapsamlı kılavuzda, aşağıdaki konulara değineceğiz features, applications, pricing, global trends, innovations, and why Wuxi Sunway Machinery is a global leader in aluminum profile roll-forming solutions. Whether you’re an industry professional or someone exploring the latest in manufacturing technology, this article will provide you with actionable insights.

What Are Aluminum Profile Roll Forming Machines?

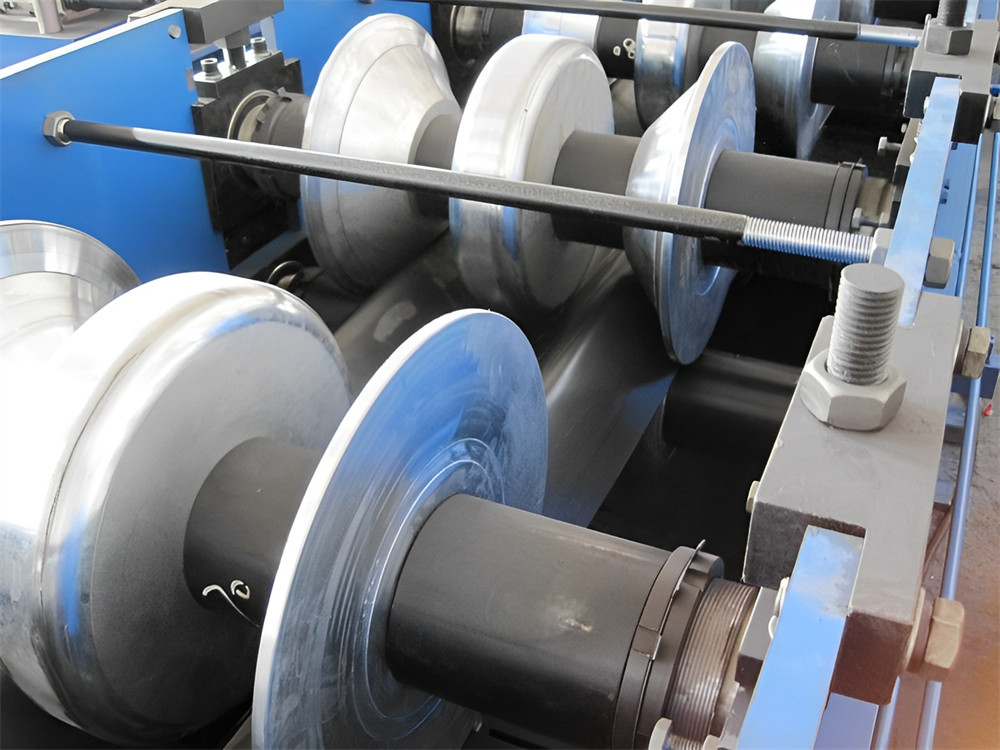

Bir Aluminum Profile Roll Forming Machine is a specialized piece of equipment designed to fabricate precise, custom aluminum profiles by feeding aluminum sheets or coils through a series of rollers. These rollers gradually shape the material into the desired cross-sectional profile, ensuring consistency, accuracy, and durability.

Temel Özellikler

- Malzeme Çok Yönlülüğü: Machines are optimized for processing various grades of aluminum, including coated, anodized, and raw aluminum.

- Yüksek Hızlı Üretim: Capable of producing complex profiles at speeds of up to 100 meters per minute.

- Hassas Mühendislik: Maintains tight tolerances to ensure every profile fits its intended application perfectly.

- Özelleştirilebilir Tasarımlar: Supports the creation of unique profiles to meet specific project requirements.

- Çevre Dostu Faaliyetler: Reduces material wastage and energy consumption, aligning with sustainability goals.

Applications of Aluminum Profile Roll Forming Machines

These machines are indispensable for manufacturing aluminum components used across a myriad of industries. Here’s a breakdown of their key applications:

1. Construction and Architecture

- Kullanım Örneği: Producing aluminum profiles for curtain walls, window frames, door frames, and structural frameworks.

- Neden gerekli? Ensures lightweight, corrosion-resistant components that are easy to install and maintain.

2. Otomotiv Endüstrisi

- Kullanım Örneği: Manufacturing components like roof rails, crash barriers, and trim profiles.

- Neden Kritik? Provides lightweight yet durable parts that improve vehicle performance and fuel efficiency.

3. Yenilenebilir Enerji

- Kullanım Örneği: Crafting mounting systems and supports for solar panels and wind turbines.

- Neden önemli? Supports the renewable energy sector with durable, weather-resistant components.

4. Electronics and Appliances

- Kullanım Örneği: Producing heat sinks, enclosures, and structural components for electrical devices.

- Neden Yararlı? Ensures precise, high-quality profiles for sensitive electronic applications.

5. Furniture and Interior Design

- Kullanım Örneği: Creating profiles for modular furniture, decorative trims, and partition systems.

- Neden eşsiz: Delivers aesthetically pleasing and functional designs for modern interiors.

6. Transportation Infrastructure

- Kullanım Örneği: Manufacturing profiles for railway tracks, airport walkways, and pedestrian bridges.

- Neden değerli? Offers lightweight solutions that reduce installation time and costs.

Why Aluminum Profile Roll Forming Machines Are Gaining Popularity

The versatility and efficiency of aluminum make it a preferred material across industries, and Alüminyum Profil Rulo Şekillendirme Makineleri are perfectly suited to meet the rising demand. Here’s why they are indispensable:

1. Lightweight and Durable

- Neden önemli? Aluminum profiles are strong yet lightweight, making them ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

2. Korozyon Direnci

- Neden Kritik? Aluminum profiles can withstand harsh environmental conditions, making them perfect for outdoor applications like construction and renewable energy systems.

3. Özelleştirme

- Neden Yararlı? Roll-forming machines can produce profiles of various shapes, sizes, and finishes, catering to diverse industry needs.

4. Eco-Friendly Manufacturing

- Neden gerekli? Aluminum is highly recyclable, and roll-forming machines minimize waste, supporting sustainable production practices.

5. High Production Efficiency

- Neden gerekli? Roll-forming machines are designed for continuous operation, enabling manufacturers to meet high-volume demands without compromising quality.

Key Features of Wuxi Sunway Aluminum Profile Roll Forming Machines

Wuxi Sunway Makine is a trusted name in the roll-forming industry, offering cutting-edge solutions for aluminum profile manufacturing. Here’s why their machines stand out:

1. Gelişmiş Malzeme Taşıma

- Desteklenen Materyaller:

- Raw Aluminum

- Anodized Aluminum

- Coated Aluminum

- Neden Yararlı? Ensures compatibility with a range of materials for versatile applications.

2. Hassas Mühendislik

- Performans: Tam boyutlar sağlayarak ±0,02 mm kadar düşük toleranslar elde eder.

- Neden önemli? Guarantees seamless assembly and compatibility with other components.

3. Modüler Kalıp Sistemleri

- Ne Sunuyor? Tek bir makinede birden fazla profil üretmek için değiştirilebilir takımlar.

- Neden değerli? Reduces downtime during tooling changes and increases production flexibility.

4. IoT ve Otomasyon Entegrasyonu

- Ne Sağlar: IoT sistemlerini kullanarak gerçek zamanlı izleme, otomatik ayarlamalar ve kestirimci bakım.

- Neden Devrimci?

- Üretim verimliliğini artırır.

- Operasyonel maliyetleri düşürür.

5. High-Speed Operation

- Performans: Produces profiles at speeds of up to Dakikada 100 metre.

- Neden gerekli? Meets the high-volume demands of industries like construction and automotive.

6. Çevre Dostu Tasarım

- Ne İçerir? Energy-efficient motors, reduced material waste, and support for recyclable aluminum.

- Neden gerekli? Aligns with global sustainability goals and reduces the carbon footprint of manufacturing.

7. Integrated Cutting and Punching

- Ne Sunuyor? Built-in systems for cutting and punching aluminum sheets during the roll-forming process.

- Neden Verimli: Speeds up production and ensures ready-to-use components.

Pricing of Aluminum Profile Roll Forming Machines

Maliyeti Aluminum Profile Roll Forming Machine özelliklerine, kapasitesine ve özelleştirme düzeyine bağlıdır. Aşağıda 2025 yılı için genel bir fiyatlandırma kılavuzu bulunmaktadır:

| Makine Tipi | Yetenekler | Fiyat Aralığı (USD) |

|---|---|---|

| Standart Makineler | Basic aluminum profile production | 150,000–150,000–150,000–400,000 |

| Gelişmiş Makineler | Yüksek hızlı, entegre kesme ve delme sistemleri | 400,000–400,000–400,000–1,000,000 |

| Tamamen Özelleştirilebilir Makineler | IoT, modüler takımlar ve çevre dostu özellikler | 1,000,000–1,000,000–1,000,000–2,500,000 |

Detaylı fiyatlandırma ve finansman seçenekleri için iletişime geçin Wuxi Sunway Makine.

Innovations in Aluminum Profile Roll Forming Technology

The roll-forming industry is evolving rapidly, with new technologies enhancing the capabilities of Alüminyum Profil Rulo Şekillendirme Makineleri. Here are the latest innovations:

1. Dijital İkiz Teknolojisi

- Neyi Taklit Ediyor: Virtual models of the roll-forming process to optimize machine settings.

- Neden Devrimci?

- Kurulum süresini ve deneme-yanılma ayarlamalarını azaltır.

- Ensures consistent quality from the first production run.

2. Yapay Zeka Destekli Kalite Kontrol

- Ne işe yarıyor? Monitors dimensions, surface quality, and material thickness in real-time.

- Neden Oyunu Değiştiriyor?

- Detects defects early, reducing waste.

- Genel ürün kalitesini artırır.

3. Çoklu Profil Özelliği

- Ne Sağlar: Produces multiple profiles in a single production cycle.

- Neden Yararlı?

- Increases production speed.

- Supports diverse manufacturing needs.

4. IoT Entegrasyonu

- Ne Sunuyor? Real-time data collection, predictive maintenance, and automated adjustments.

- Neden Kritik?

- Enhances machine uptime.

- Reduces maintenance costs.

5. Eco-Friendly Coating Systems

- Ne İçerir? Systems for applying protective or decorative coatings during the roll-forming process.

- Neden Sürdürülebilir?

- Eliminates additional coating processes.

- Reduces energy consumption.

FAQs About Aluminum Profile Roll Forming Machines

| Soru | Cevap |

|---|---|

| Bu makineler hangi malzemeleri işleyebilir? | Aluminum (raw, anodized, coated) and other lightweight metals. |

| Üretim hızı nedir? | Kadar Dakikada 100 metreprofil karmaşıklığına bağlı olarak. |

| Bu makineler çevre dostu mu? | Evet, enerji tasarruflu motorlar içerirler ve malzeme israfını en aza indirirler. |

| Bu makineler özel tasarımları işleyebilir mi? | Absolutely! Modular tooling supports bespoke profiles for diverse applications. |

| Bu makineler güvenlik standartlarına uygun mu? | Yes, they meet CE, ISO, and OSHA certifications for safety and reliability. |

| Bu makineler IoT sistemleri ile entegre olabilir mi? | Evet, IoT özellikli özellikler gerçek zamanlı izleme ve kestirimci bakım sağlar. |

Real-World Success Stories: Aluminum Profile Roll Forming Machines in Action

Çok yönlülüğü ve verimliliği Alüminyum Profil Rulo Şekillendirme Makineleri are evident in their application across diverse industries. Here are some real-world examples that illustrate their transformative impact:

1. Case Study: Solar Energy Infrastructure

- Müşteri: A solar energy company managing large-scale solar farms in North America.

- Meydan okuma: The company needed lightweight yet durable mounting systems for solar panels that could withstand extreme weather conditions.

- Çözüm: Wuxi Sunway Machinery provided a roll-forming machine capable of processing anodized aluminum and integrating custom profiles for mounting brackets.

- Sonuçlar:

- Increased production output by 35%, enabling faster installation of solar farms.

- Delivered corrosion-resistant components with precise dimensions.

- Reduced material waste by 20%, aligning with the company’s sustainability goals.

2. Case Study: Automotive Component Supplier

- Müşteri: A leading supplier of aluminum parts for elektrikli araçlar (EVs) in Europe.

- Meydan okuma: The client needed high-strength, lightweight aluminum profiles for EV battery enclosures and crash barriers.

- Çözüm: Wuxi Sunway developed a roll-forming machine with integrated cutting and punching capabilities for high-strength alloys.

- Sonuçlar:

- Reduced production lead times by 40%.

- Delivered components that improved vehicle energy efficiency and safety.

- Enabled the client to expand their product portfolio and secure new contracts.

3. Case Study: Architectural Firm

- Müşteri: A construction company specializing in modern architectural designs in the Middle East.

- Meydan okuma: The firm needed customized aluminum profiles for curtain walls and decorative trims that could withstand high temperatures and sand exposure.

- Çözüm: Wuxi Sunway supplied a roll-forming machine optimized for pre-coated aluminum with advanced surface finishes.

- Sonuçlar:

- Produced elegant, weather-resistant profiles that met the aesthetic and functional requirements of the project.

- Reduced production costs by 25% compared to traditional fabrication methods.

- Enhanced the firm’s reputation for delivering high-quality architectural projects.

4. Case Study: Modular Furniture Manufacturer

- Müşteri: A furniture manufacturer specializing in modular and customizable designs.

- Meydan okuma: The company needed lightweight, easy-to-assemble aluminum profiles for their furniture systems.

- Çözüm: Wuxi Sunway provided a roll-forming machine with modular tooling for creating diverse profile designs.

- Sonuçlar:

- Increased production flexibility, allowing the company to cater to evolving customer preferences.

- Delivered components with a flawless finish, enhancing the product’s market appeal.

- Reduced production waste, supporting the company’s eco-friendly initiatives.

Sustainability Practices in Aluminum Profile Manufacturing

Sustainability is a key focus in modern manufacturing, and Alüminyum Profil Rulo Şekillendirme Makineleri are designed to support eco-friendly practices. Here’s how they contribute to a greener future:

1. Energy-Efficient Operations

- Bu nasıl başarıldı? Gelişmiş motorlar ve optimize edilmiş iş akışları elektrik tüketimini azaltır.

- Etki: Lowers the carbon footprint of manufacturing processes, aligning with global sustainability goals.

2. Reduced Material Waste

- Bu nasıl başarıldı? Hassas kesim ve şekillendirme sistemleri üretim sırasında hurdayı en aza indirir.

- Etki: Hammadde tasarrufu sağlar ve üretim maliyetlerini düşürür.

3. Geri Dönüştürülebilir Malzemelere Destek

- Bu nasıl başarıldı? Machines are designed to process recyclable aluminum materials.

- Etki: Promotes the reuse of materials, reducing waste and supporting circular economy practices.

4. Uzun Ömürlü Bileşenler

- Neden önemli? Durable aluminum profiles require less frequent replacement, reducing overall material consumption.

- Etki: Extends the lifecycle of products, minimizing environmental impact.

5. Coating Integration

- Bu nasıl başarıldı? Machines support eco-friendly coatings that enhance the durability and aesthetics of aluminum profiles.

- Etki: Eliminates the need for additional coating processes, reducing energy usage.

Safety Standards for Aluminum Profile Roll Forming Machines

Safety is paramount in manufacturing, and Alüminyum Profil Rulo Şekillendirme Makineleri are equipped with advanced features to protect operators and ensure compliance with global standards.

1. Acil Durdurma Sistemleri

- Ne işe yarıyor? Allows operators to halt machine operations instantly in case of an emergency.

- Neden Kritik? Öngörülemeyen olaylar sırasında kazaları önler ve ekipman hasarını en aza indirir.

2. Güvenlik Koruyucuları ve Kalkanları

- Ne İçerir? Kazara teması önlemek için hareketli parçaların etrafında koruyucu bariyerler.

- Neden önemli? İnsan hatası veya mekanik arızalardan kaynaklanan yaralanma riskini azaltır.

3. Işık Perdeleri

- Ne Tespit Ediyor: Tehlikeli bölgelerdeki nesneleri veya personeli tanımlar ve makine işlemlerini otomatik olarak duraklatır.

- Neden etkili? Enhances safety without interrupting production workflows.

4. Gürültü ve Titreşim Azaltma

- Neyi Azaltır: Çalışma sırasında gürültü seviyelerini ve titreşimleri en aza indirir.

- Neden Yararlı? Operatörler için daha güvenli ve konforlu bir çalışma ortamı yaratır.

5. Küresel Standartlara Uyum

- Sertifikalar: Makineler güvenlik ve çevre koruma için CE, ISO 45001 ve OSHA standartlarını karşılamaktadır.

- Neden gerekli? Ensures reliability and safety in diverse global markets.

Global Market Trends for Aluminum Profile Roll Forming Machines in 2025

As industries adapt to changing demands and technological advancements, the market for Alüminyum Profil Rulo Şekillendirme Makineleri continues to expand. Here are the key trends driving growth:

1. Increasing Adoption in Renewable Energy

- Trend: The renewable energy sector’s growth is fueling demand for lightweight, corrosion-resistant aluminum profiles.

- Etki: Roll-forming machines capable of producing solar panel mounting systems and wind turbine components are in high demand.

2. Expansion of the Automotive Industry

- Trend: The rise of electric vehicles (EVs) is driving the need for lightweight aluminum components.

- Etki: Manufacturers require high-capacity roll-forming machines to meet production targets.

3. Growth in Urbanization and Infrastructure Development

- Trend: Rapid urbanization is increasing demand for construction materials like aluminum frames, doors, and windows.

- Etki: Roll-forming machines designed for architectural applications are becoming essential.

4. Shift Towards Sustainable Manufacturing

- Trend: Şirketler, tüketici beklentilerini ve yasal gereklilikleri karşılamak için çevre dostu uygulamaları benimsiyor.

- Etki: Machines optimized for energy efficiency and recyclable materials are gaining traction.

5. Endüstri 4.0 ile entegrasyon

- Trend: The adoption of IoT and AI in manufacturing is driving demand for smart roll-forming machines.

- Etki: Machines with real-time monitoring and predictive maintenance capabilities are becoming industry standards.

Why Choose Wuxi Sunway Machinery for Aluminum Profile Roll Forming Machines?

Wuxi Sunway Makine is a global leader in roll-forming technology, trusted by manufacturers across industries. Here’s why they are the go-to partner for aluminum profile production:

- Kanıtlanmış Uzmanlık: Yüksek performanslı roll-form makineleri tasarlama konusunda onlarca yıllık deneyim.

- Küresel Erişim: Machines are used successfully in Asia, Europe, the Americas, and beyond.

- İnovasyon Odaklı: IoT entegrasyonu, modüler takımlar ve yapay zeka destekli kalite kontrol gibi özellikler, makinelerini diğerlerinden ayırıyor.

- Sürdürülebilirlik Taahhüdü: Makineler, küresel sürdürülebilirlik hedeflerini destekleyen çevre dostu üretim için optimize edilmiştir.

- Kapsamlı Destek: Danışmanlıktan satış sonrası hizmete kadar, Wuxi Sunway kusursuz bir deneyim sunar.

Conclusion: Shaping the Future of Manufacturing with Aluminum Profiles

Alüminyum Profil Rulo Şekillendirme Makineleri are revolutionizing modern manufacturing by combining precision, efficiency, and sustainability. Their versatility makes them indispensable for industries ranging from construction and automotive to renewable energy and electronics.

Ready to transform your manufacturing processes? Partner with Wuxi Sunway Makine and explore their innovative roll-forming solutions tailored to your needs. Together, let’s shape a smarter, more sustainable future—one aluminum profile at a time.