Giriş

Hiç merak ettiniz mi nasıl uzun, düzgün metal profiller çatı kaplama levhaları, C & Z aşıkları ve otoyol korkulukları gibi? Bu sorunun cevabı rulo şekillendirme işlemi-Birçok sektörde kullanılan verimli, yüksek hızlı bir metal şekillendirme yöntemidir.

A rulo şekillendirme makinesi için tasarlanmıştır metal levhaları aşamalı olarak şekillendirme bir dizi işlemden geçirerek hassas mühendislik ürünü silindirler. Geleneksel metal bükme yöntemlerinin aksine, rulo şekillendirme malzeme israfını en aza indirir, işçilik maliyetlerini azaltır ve üretim verimliliğini artırır.

Bu kılavuzda şunları ele alacağız:

✅ Bir rulo şekillendirme makinesi nasıl çalışır?

✅ Bir rulo şekillendirme sisteminin temel bileşenleri

✅ Adım adım rulo şekillendirme süreci

✅ Rulo şekillendirme makinesi çeşitleri

✅ Rulo şekillendirmenin diğer metal şekillendirme yöntemlerine göre avantajları

Arkasındaki mekaniğe dalalım modern üretimdeki en verimli metal şekillendirme süreçlerinden biri!

Rulo Şekillendirme Makinesi Nasıl Çalışır?

A rulo şekillendirme makinesi tarafından işletilmektedir bir metal şeridin kademeli olarak bükülmesi aracılığıyla belirli bir şekle çoklu sıralı silindir istasyonları. Metali bir kerede bükmek yerine (pres frenleme gibi), rulo şekillendirme artan bükümler uygular Birkaç silindir aşaması boyunca pürüzsüz, hassas şekillendirme sağlar.

Temel Çalışma Prensibi

1️⃣ Malzeme Besleme - Bir metal bobin açılır ve makineye beslenir.

2️⃣ Kademeli Şekillendirme - Metal bir dizi işlemden geçer silindir istasyonlarıHer biri küçük kademeli kıvrımlar yapıyor.

3️⃣ Satır İçi İşleme (İsteğe Bağlı) - Zımbalama, çentik açma, kabartma veya kaynaklama sürece entegre edilebilir.

4️⃣ Boy Kesme - Oluşturulan profil gerekli boyutta kesilir.

5️⃣ Nihai Ürün Çıktısı - Bitmiş parça inceleme ve paketleme için gönderilir.

Profesyonel ipucu: Artımlı bükme işlemi şunları sağlar minimum malzeme gerilimiile sonuçlanır. yüksek mukavemetli, hassas şekillendirilmiş profiller.

Temel Bileşenler

A yüksek kaliteli rulo şekillendirme makinesi oluşturmak için birlikte çalışan çok sayıda temel bileşenden oluşur Hassasiyet ve verimlilikle karmaşık metal profiller.

Başlıca Bileşenler ve İşlevleri

| Bileşen | Fonksiyon |

|---|---|

| Decoiler | Makineye beslemek için metal bobini tutar ve çözer. |

| Besleme Kılavuz Sistemi | Sayfayı silindirlere hizalar ve yönlendirir. |

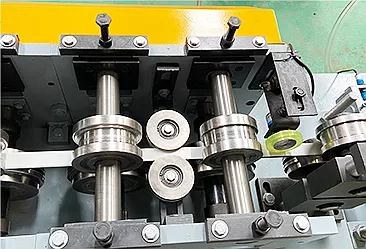

| Silindir İstasyonları | Çoklu silindirler metal levhayı aşamalı olarak şekillendirir. |

| Delme/Çentik Açma Ünitesi (Opsiyonel) | Son şekillendirmeden önce metale delikler, yuvalar veya girintiler ekler. |

| Kesim Sistemi | Şekillendirilmiş profili gerekli uzunlukta keser. |

| Hidrolik veya Servo Motor Tahriki | Silindirlere güç vererek malzemenin düzgün hareket etmesini sağlar. |

| Kontrol Sistemi (PLC/CNC) | Tüm rulo şekillendirme sürecini otomatikleştirir ve izler. |

| Ürün Çıktı Tablosu | Muayene ve paketleme için bitmiş parçaları toplar. |

Sunway Makine sağlar özel yapim rulo şeki̇llendi̇rme maki̇neleri̇ ile geli̇şmi̇ş otomasyon ve hassas kontroller.

Adım Adım Rulo Şekillendirme Süreci

Bu rulo şekillendirme işlemi için tasarlanmıştır sürekli, yüksek hızlı metal şekillendirmeiçin ideal hale getirir. tek tip profillerin seri üretimi.

Detaylı Rulo Şekillendirme Süreç Akışı

| Adım | Açıklama |

|---|---|

| 1. Malzeme Yükleme | Üzerine metal bir bobin yerleştirilir. decoilerve tabaka makineye beslenir. |

| 2. İlk Besleme ve Hizalama | Levha aşağıdakilerden geçer hi̇zalama kilavuzlari düz giriş sağlamak için. |

| 3. Aşamalı Rulo Şekillendirme | Metal tabaka şu şekilde hareket eder çoklu silindir istasyonlarıher biri kademeli kıvrımlar uygular. |

| 4. Satır İçi Delme ve Çentik Açma (Gerekirse) | Servo tahrikli delme üniteleri delikler, yuvalar veya kabartmalar gerektiği gibi. |

| 5. Boy Kesme | A hidrolik veya uçan makaslı kesme sistemi Oluşturulan profili gerekli uzunlukta dilimleyin. |

| 6. Nihai Ürün Çıktısı | Bitmiş parça, bir sonraki çıktı tablosu kalite denetimi için. |

Profesyonel ipucu: Servo kontrollü kesim sistemleri sağlamak Minimum fire ile hassas, çapaksız kesimler.

Türleri

Farklı uygulamalar şunları gerektirir farklı tipte rulo şekillendirme makineleriher bir teklif benzersiz avantajlar dayalı profil karmaşıklığı, üretim hızı ve otomasyon seviyesi.

Karşılaştırma

| Makine Tipi | İçin En İyisi | Temel Özellikler |

|---|---|---|

| Tek Profil Rulo Şekillendirme Makinesi | Sabit profilli üretim (örn. çatı kaplama levhaları) | Uygun maliyetli, kompakt tasarım |

| Çok Profilli Rulo Şekillendirme Makinesi | Hızlı değiştirilebilen takımlarla çoklu profil üretimi | Arıza süresini azaltır, esnekliği artırır |

| Ayarlanabilir Rulo Şekillendirme Makinesi | Özelleştirilebilir genişlik ve şekil ayarları | C & Z aşık üretimi için ideal |

| Yüksek Hızlı Rulo Şekillendirme Makinesi | Tek tip profillerin seri üretimi | Kadar Dakikada 50 metre |

| Tam Otomatik Rulo Şekillendirme Makinesi | Yüksek hassasiyetli, CNC kontrollü işlemler | Yapay zeka destekli hata tespiti, IoT entegrasyonu |

Özel bir rulo şekillendirme çözümü mü arıyorsunuz? Sunway Makine teklifler yüksek hızlı, hassas rulo şekillendirme makineleri için küresel üreti̇ci̇ler.

Rulo Şekillendirmenin Diğer Metal Şekillendirme Yöntemlerine Göre Avantajları

Rulo şekillendirme aşağıdakilere göre yaygın olarak tercih edilir pres frenleme, damgalama ve ekstrüzyon nedeniyle verimlilik, hassasiyet ve maliyet etkinliği.

Neden Rulo Şekillendirmeyi Seçmelisiniz?

| Avantaj | Rulo Şekillendirme | Pres Frenleme / Damgalama |

|---|---|---|

| Üretim Hızı | Sürekli süreç (en fazla 50m/dak) | Daha yavaş, parti bazlı üretim |

| Malzeme Atıkları | Artımlı bükme sayesinde minimum atık | Deneme-yanılma ayarlamaları nedeniyle daha fazla atık |

| İşçilik Maliyeti | Düşük - tam otomatik süreç | Yüksek - manuel ayarlamalar gerektirir |

| Parça Tutarlılığı | Uzun, tekrarlanan profiller için yüksek homojenlik | Seri üretimde olası varyasyonlar |

| Kalıp Maliyeti | Daha yüksek başlangıç maliyeti, ancak daha düşük birim başına maliyet | Daha düşük başlangıç maliyeti, ancak daha yüksek birim başına maliyet |

Karar: Rulo şekillendirme, yüksek hacimli, uygun maliyetli, hassas üretim için en iyi seçimdir.

Yaygın Sorunlar ve Çözümleri

Hatta son teknoloji̇ rulo şeki̇llendi̇rme maki̇neleri̇operatörler karşılaşabilir Malzeme bozulması, yanlış hizalama ve silindir aşınması gibi zorluklar. Bu sorunların tanımlanması ve giderilmesi erken sağlar sorunsuz üretim ve yüksek kaliteli çıktı.

Sorun Giderme Kılavuzu

| Sorun | Olası Neden | Çözüm |

|---|---|---|

| Profil Yanlış Hizalaması | Yanlış silindir konumlandırma, gevşek malzeme besleme | Silindirleri yeniden kalibre edin ve malzeme kılavuzlarını ayarlayın |

| Silindirlerde Malzeme Kayması | Gevşek besleyici silindirleri, yanlış gerginlik ayarları | Besleyici silindirlerini sıkın ve malzeme gerginliğini ayarlayın |

| Yüzey Çizikleri veya Deformasyon | Kirli silindirler, aşırı şekillendirme basıncı | Silindirleri düzenli olarak temizleyin ve şekillendirme basıncını ayarlayın |

| Tutarsız Kesim Uzunlukları | Hatalı kesme sistemi, yanlış hizalanmış bıçaklar | Kesme mekanizmasını inceleyin ve yeniden kalibre edin |

| Yüksek Sürtünme Nedeniyle Silindir Aşınması | Yağlama eksikliği, aşırı basınç | Uygun yağlama uygulayın ve sertleştirilmiş makaralar kullanın |

Profesyonel ipucu: Düzenli silindir kalibrasyonu ve yağlama olabilir 40% ile makine ömrünü uzatın ve profil kusurlarını önemli ölçüde azaltın.

Rulo Şekillendirme Teknolojisinde Gelecek Trendleri

Bu rulo şekillendirme endüstrisi ile hızla gelişiyor Yapay zeka, IoT ve otomasyon, iyileştirme verimlilik, doğruluk ve sürdürülebilirlik.

2025'te Rulo Şekillendirme Makinelerinde Önemli Yenilikler

1. Yapay Zeka Tabanlı Hata Tespiti ve Kendi Kendini Düzeltme

- Yapay zeka destekli kameralar ve sensörler kusurları gerçek zamanlı olarak tespit edermalzeme israfını azaltır.

- Sağlar operatör müdahalesi olmadan tutarlı profil doğruluğu.

2. IoT Destekli Uzaktan İzleme

- Makineler artık şu özelliklere sahip bulut tabanlı izleme, izin vermek operatörlerin performansı uzaktan izleyebilmesi.

- Etkinleştirir gerçek zamanlı teşhis ve kestirimci bakım.

3. Servo Tahrikli Rulo Şekillendirme Teknolojisi

- Geliştirir hız kontrolü, hassasiyet ve enerji verimliliği.

- Azaltır mekanik bileşenlerde aşınma ve yıpranmamakine ömrünü uzatır.

4. Tam Otomatik Profil Ayarlamaları

- Ortadan kaldırır manuel ayarlamalar farklı profiller arasında geçiş yaparken.

- CNC kontrollü otomatik profil değişiklikleri arıza süresini azaltır ve verimliliği artırır.

Yapay zeka destekli rulo şekillendirme makinelerine geçiş, üretim verimliliğini 50%'ye kadar artırabilir!

Rulo Şekillendirme Makinelerinde Otomasyon

Otomasyon dönüştürme hassas metal şekillendirme, rulo şekillendirme makineleri yapımı daha akıllı, daha hızlı ve daha uygun maliyetli.

Otomatik Rulo Şekillendirme Makinelerinin Temel Faydaları

| Özellik | Fayda |

|---|---|

| PLC & CNC Kontrol Sistemleri | Hassas ölçümler sağlar ve insan hatasını en aza indirir |

| Yapay Zeka Tabanlı Gerçek Zamanlı Hata Tespiti | Sorunları anında tespit ederek malzeme israfını azaltır |

| IoT & Uzaktan İzleme | Operatörlerin makine performansını her yerden takip etmesini sağlar |

| Otomatik Profil Değiştirme | Profiller arasında geçiş yaparken kesinti süresini azaltır |

| Enerji Tasarruflu Servo Motorlar | İşletme maliyetlerini düşürür ve sürdürülebilirliği artırır |

Tam otomatik rulo şekillendirme makineleri Sunway Makine kadar üretim verimliliğini artırmak 40%!

Rulo Şekillendirme Makineleri için Temel Bakım İpuçları

Uygun Bakım sağlar uzatılmış makine ömrü ve tutarlı üretim kalitesi.

Rulo Şekillendirme Makineleri için Bakım Kontrol Listesi

| Görev | Frekans | Amaç |

|---|---|---|

| Makaraları ve Yatakları Yağlayın | Haftalık | Aşınma ve yıpranmayı önler |

| Makara Hizalamasını Kontrol Edin | Aylık | Doğru profil üretimini sağlar |

| Kesme Mekanizmasını Kontrol Edin | Üç Aylık | Hatalı kesimleri ve yanlış hizalamayı önler |

| Temiz Makine Bileşenleri | Günlük | Performansı etkileyebilecek toz ve kalıntıları temizler |

| Yazılım Güncelleme ve Kalibrasyon | Altı ayda bir | Otomasyon fonksiyonlarının optimize edilmesini sağlar |

Profesyonel ipucu: Planlı bakım şunları yapabilir 50% ile makine ömrünü uzatın ve 70% ile arızaları azaltın.

SSS: Rulo Şekillendirme Makinesi Çalışma Prensibi

1. Bir rulo şekillendirme makinesi nasıl çalışır?

Bir rulo şekillendirme makinesi kademeli olarak metal levhaları şekillendirir içinden geçirerek çoklu silindir istasyonlarıher biri artan bükümler Nihai profil oluşana kadar.

2. Hangi endüstriler rulo şekillendirme makineleri kullanır?

Gibi sektörler:

✅ İnşaat (çatı panelleri, C & Z aşıkları)

✅ Otomotiv (yapısal bileşenler, çarpmaya dayanıklı kirişler)

✅ Güneş Enerjisi (güneş montaj yapıları)

✅ Raf ve Raflar (depo rafları, depolama sistemleri)

3. Rulo şekillendirmede hangi malzemeler kullanılabilir?

Yaygın malzemeler şunlardır:

✅ Galvanizli Çelik (G30-G90)

✅ Paslanmaz Çelik (304/316)

✅ Alüminyum (6061/7075)

✅ Yüksek Çekme Çelik

4. Bir rulo şekillendirme makinesi ne kadara mal olur?

Fiyat aralıkları 80,000forbasicmodels∗∗to∗∗80,000 for basic models** to **80,000forbasicmodels∗∗to∗∗1,200,000 for fully automated, AI-driven machines.

5. Yüksek kaliteli bir rulo şekillendirme makinesini nereden satın alabilirim?

İçin özel yapım, yüksek hızlı rulo şekillendirme makineleri, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Son Düşünceler

Yatırım yapmak rulo şekillendirme makinesi için gereklidir. esneklik, verimlilik ve yüksek hızlı üretim gerektiren endüstriler. Bir seçim yapmak güveni̇li̇r üreti̇ci̇ sağlar uzun vadeli güvenilirlik ve karlılık.

WUXI SUNWAY MAKİNA A.Ş., LTD bir lider küresel üretici . özel yapim rulo şeki̇llendi̇rme maki̇neleri̇, teklif ileri teknoloji, uzman desteği ve rekabetçi fiyatlandırma.

İstiyorum rulo şekillendirme makinesi? Bugün bize ulaşın!