Giriş

Bu rulo şekillendirme endüstrisi tarafından yönlendirilen hızla gelişmektedir. teknolojik gelişmeler, otomasyon ve hafif, yüksek mukavemetli malzemelere olan talep. İçine girerken 2025üreticilerin bir adım önde olması gerekir. yükselen trendler rekabetçi kalabilmek için.

Ama ne merdaneli̇ şeki̇llendi̇rme endüstri̇si̇nde deği̇şi̇m? Ne gibi metal şekillendirmenin geleceğini şekillendiren en önemli trendler?

Bu kılavuzda şunları keşfedeceğiz:

✅ Rulo şekillendirme teknolojisindeki en son gelişmeler

✅ Otomasyon ve yapay zeka destekli rulo şekillendirme

✅ Sürdürülebilirlik ve çevre dostu üretim

✅ Metal şekillendirmede yeni malzeme trendleri

✅ Rulo şekillendirme için pazar büyümesi ve gelecekteki görünüm

Haydi biraz da 2025 ve ötesi için rulo şekillendirme sektörü trendleri!

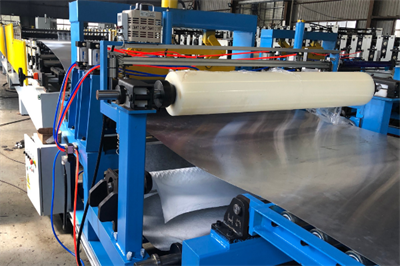

1. Otomasyon ve Akıllı Rulo Şekillendirme Makineleri

Otomasyon rulo şeki̇llendi̇rme endüstri̇si̇nde devri̇m yaratiyorüreticilerin şunları yapmasına olanak tanır işgücü maliyetlerini düşürürken üretkenliği artırın.

Otomatik Rulo Şekillendirmede Önemli Gelişmeler

✅ CNC ve PLC kontrollü makineler - Hassasiyeti ve tekrarlanabilirliği artırın.

✅ Yapay zeka destekli kalite kontrol - Kusurları gerçek zamanlı olarak tespit ederek israfı azaltır.

✅ IoT özellikli makineler - Uzaktan izleme ve kestirimci bakım.

✅ Tam otomatik rulo şekillendirme hatları - İnsan müdahalesini en aza indirerek verimliliği artırır.

Rulo Şekillendirmede Otomasyonun Faydaları

✅ Daha yüksek üretim hızları - Otomatik hatlar çalışır Minimum gözetim ile 7/24.

✅ Daha düşük işgücü maliyetleri - Kalifiye operatörlere olan bağımlılığı azaltır.

✅ Geliştirilmiş ürün tutarlılığı - Şekillendirme ve kesme işlemlerinde insan hatasını ortadan kaldırır.

Profesyonel ipucu: 2025 yılına kadar, 60%'den fazla hadde şekillendirme üreticisinin yapay zeka destekli otomasyonu benimsemesi bekleniyor!

2. Sürdürülebilirlik ve Çevre Dostu Üretim

Sürdürülebilirlik bir metal şekillendirmede ana odak noktasıyatırım yapan üreticiler ile enerji tasarruflu rulo şekillendirme makineleri ve geri dönüştürülebilir malzemeler.

Rulo Şekillendirmede Yeşil Yenilikler

✅ Enerji tasarruflu servo motorlar - Güç tüketimini azaltın.

✅ Güneş enerjisiyle çalışan rulo şekillendirme hatları - Daha düşük karbon ayak izi.

✅ Geri dönüştürülebilir çelik ve alüminyum - Döngüsel ekonomi girişimlerini destekleyin.

✅ Su bazlı yağlayıcılar - Zararlı kimyasal bazlı yağlayıcıları değiştirin.

Sürdürülebilirlik Neden Önemlidir?

✅ Hükümetler şunları uygulamaya koyuyor daha sıkı çevre düzenlemeleri.

Tüketicilerin talebi çevre dostu yapı malzemeleri ve metal ürünler.

Benimseyen şirketler yeşi̇l üreti̇m rekabet üstünlüğü kazaniyor.

Profesyonel ipucu: Sürdürülebilir rulo şekillendirme, marka itibarını artırırken üretim maliyetlerini 20% azaltabilir!

3. Rulo Şekillendirmede Yüksek Mukavemetli ve Hafif Malzemeler

için talep daha güçlü, daha hafif malzemeler gibi sektörlerde büyümektedir. otomotiv, havacılık ve inşaat.

Rulo Şekillendirmede Trend Malzemeler

✅ Gelişmiş Yüksek Mukavemetli Çelik (AHSS) - İçinde kullanılır otomoti̇v şasi̇ ve yapisal bi̇leşenleri̇.

✅ Alüminyum Alaşımları - Hafif, korozyona dayanıklı, aşağıdakiler için ideal güneş paneli̇ çerçeveleri̇ & havacilik.

✅ Galvanizli ve Kaplamalı Metaller - Geliştirmek dayanıklılık ve hava koşullarına direnç.

✅ Kompozit Metal Paneller - Metallerin polimerlerle birleştirilmesi geliştirilmiş güç/ağırlık oranı.

Daha Hafif ve Daha Güçlü Malzemeler Neden Önemlidir?

✅ Otomotiv üreticileri için araç ağırlığını azaltmayı amaçlamaktadır. daha iyi yakıt verimliliği.

✅ Güneş enerjisi ve inşaat sektörleri talep hafif ancak dayanıklı bileşenler.

✅ Azaltılmış nakliye maliyetleri nedeniyle daha hafif malzemeler.

Profesyonel ipucu: 2025 yılına kadar, otomotiv endüstrisindeki haddelenmiş parçaların 70%'sinden fazlasında Gelişmiş Yüksek Mukavemetli Çelik (AHSS) kullanılacaktır.

4. Özel Rulo Şekillendirme ve İsteğe Bağlı Üretimin Büyümesi

Özelleştirme bir rulo şekillendirme endüstrisinde kilit faktörsunan üreticilerle birlikte farklı sektörler için özel çözümler.

Özel Rulo Şekillendirme Neden Büyüyor?

için talep uzman profi̇ller içinde güneş enerjisi, raf ve raflar ve HVAC.

✅ 3D modelleme ve CAD entegrasyonu hızlı prototip oluşturmaya olanak sağlar.

✅ Talep üzerine üretim envanter maliyetlerini azaltır ve esnekliği artırır.

Özel Rulo Şekillendirmenin Büyümesine Yön Veren Sektörler

✅ Güneş Enerjisi - Şunlar için özel profiller güneş paneli montaj yapıları.

✅ Otomotiv - Hassas şekillendirilmiş gövde panelleri̇ ve takvi̇yeleri̇.

✅ İnşaat - Eşsiz mi̇mari̇ metal paneller ve çati kaplama bi̇leşenleri̇.

Profesyonel ipucu: Özel rulo şekillendirme, işletmelerin malzeme israfını azaltırken yüksek fiyatlar talep etmelerini sağlar!

5. Rulo Şekillendirme için Pazar Büyümesi ve Geleceğe Bakış

Bu küresel rulo şeki̇llendi̇rme pazari talebin etkisiyle önemli ölçüde büyümesi beklenmektedir. inşaat, altyapı ve otomotiv sektörleri.

Rulo Şekillendirme Pazarı Büyüme Projeksiyonları (2025-2030)

| Bölge | Pazar Büyüme Oranı | Büyümeye Yön Veren Başlıca Sektörler |

|---|---|---|

| Kuzey Amerika | 6% CAGR | İnşaat, çelik çerçeve, güneş enerjisi |

| Avrupa | 5,5% CAGR | Otomotiv, havacılık, yenilenebilir enerji |

| Asya-Pasifik | 7.2% CAGR | Altyapı, endüstriyel raflar, demiryolu |

| Orta Doğu ve Afrika | 4,8% CAGR | Çatı kaplama, boru hatları, petrol ve gaz |

Pazarın Büyümesini Sağlayan Faktörler

✅ Hızlı kentleşme ve altyapı gelişimi.

✅ Yenilenebilir enerji projelerinde rulo şekillendirmenin giderek daha fazla benimsenmesi.

✅ Yüksek hızlı, otomatik rulo şekillendirme makinelerindeki teknolojik gelişmeler.

Profesyonel ipucu: Asya-Pasifik, inşaat ve ulaşım projelerine yönelik artan taleple birlikte, rulo şekillendirme için en hızlı büyüyen pazar konumunda!

6. Rulo Şekillendirmede Dijital Entegrasyon ve Endüstri 4.0

Bu merdaneli̇ şeki̇llendi̇rmeni̇n geleceği̇ içinde yatıyor akıllı üretim ve dijital entegrasyon.

Rulo Şekillendirmede Endüstri 4.0 Teknolojileri

✅ IoT Sensörleri - Gerçek zamanlı makine performansı takibi.

✅ Bulut Tabanlı Üretim Yönetimi - Uzaktan izleme ve kestirimci bakım.

✅ Yapay Zeka Odaklı Süreç Optimizasyonu - Malzeme israfını azaltır ve verimliliği artırır.

✅ 3D Baskı ve Hibrit Üretim - Daha hızlı prototipleme ve kalıplama.

Dijital Rulo Şekillendirmenin Faydaları

✅ Daha hızlı üretim süreleri ile veri odaklı otomasyon.

✅ Daha düşük bakım maliyetleri ile tahmine dayalı analitik.

✅ Daha yüksek doğruluk ve daha az atık yapay zeka destekli süreç optimizasyonu.

Profesyonel ipucu: 2030 yılına kadar, 80%'den fazla rulo şekillendirme üreticisi Endüstri 4.0 teknolojilerini benimseyecek!

2025'in En Yeni Rulo Şekillendirme Makineleri Nereden Alınır?

İçin son teknoloji̇ rulo şeki̇llendi̇rme maki̇neleri̇ buluşan gelecekteki sektör talepleri, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Neden WUXI SUNWAY MACHINERY'yi Seçmelisiniz?

✅ 15+ Yıllık Sektör Deneyimi - Güvenilir bir küresel tedarikçi.

✅ Gelişmiş Otomasyon ve Özel Rulo Şekillendirme Çözümleri.

✅ Enerji Tasarruflu ve Yüksek Hızlı Makineler maksimum üretkenlik için.

✅ Güvenilir Satış Sonrası Destek ve Yedek Parça Bulunabilirliği.

Rulo şekillendirme teknolojinizi yükseltmek mi istiyorsunuz? Bugün bize ulaşın!

7. Rulo Şekillendirmenin Geleceğinde Yapay Zeka ve Robotiklerin Rolü

Yapay Zeka (YZ) ve robotik sektörü dönüştürüyor rulo şekillendirme endüstrisi geliştirerek verimlilik, hassasiyet ve kestirimci bakım.

Yapay Zeka ve Robotik Rulo Şekillendirmeyi Nasıl Değiştiriyor?

✅ Yapay Zeka Destekli Kalite Kontrol - Kusurları gerçek zamanlı olarak tespit ederek israfı azaltır.

✅ Robotik Malzeme Taşıma - Otomatikleştirir bobin besleme, istifleme ve paketleme.

✅ Kestirimci Bakım - Yapay zeka tahminleri makine arızaları meydana gelmeden öncekesinti süresini en aza indirir.

✅ Otomatik Takım Değiştirme Sistemleri - Aşağıdakiler için kurulum süresini azaltın çok profilli rulo şekillendirme makineleri.

Rulo Şekillendirmede Yapay Zeka ve Robotiğin Faydaları

✅ İnsan hatasını en aza indirirBu da daha yüksek hassasiyet.

✅ İşçilik maliyetlerini azaltır tekrarlayan görevleri otomatikleştirerek.

✅ Üretim hızını artırır kaliteyi korurken.

✅ Makine ömrünü uzatır erken arızaları önleyerek.

Profesyonel ipucu: 2030 yılına kadar, neredeyse tüm üst düzey rulo şekillendirme makineleri yapay zeka destekli otomasyonu entegre edecek!

8. Rulo Şeklinde Güneş Enerjisi Montaj Yapılarına Yönelik Artan Talep

Bu güneş enerjisi endüstrisi patlama yaşıyor ve rulo şekillendirme kritik rol üretimde güneş paneli montaj yapıları.

Rulo Şekillendirme Güneş Enerjisi Endüstrisi için Neden İdealdir?

✅ Yüksek Hassasiyet ve Mukavemet - Sağlar dayanıklı ve sağlam güneş paneli çerçeveleri.

✅ Hafif ama Güçlü - Alüminyum ve galvanizli çelik profiller ağırlığı azaltır.

✅ Korozyon Direnci - İçin gerekli dış mekan güneş enerjisi kurulumları.

✅ Yüksek Üretim Hızı - Artan talebi karşılar güneş enerjisi altyapısı.

Küresel Güneş Enerjisi Pazarının Büyümesi ve Rulo Şekillendirme Üzerindeki Etkisi

| Yıl | Küresel Güneş Enerjisi Pazar Değeri | Rulo Şekillendirme Üzerindeki Etkisi |

|---|---|---|

| 2023 | $180 Milyar | Artan talep özelleştirilmiş güneş paneli çerçeveleri |

| 2025 | $250 Milyar | Artan üretim çeli̇k ve alümi̇nyum güneş yapilari |

| 2030 | $400 Milyar | Tam otomatik rulo şekillendirme hatları için güneş enerji̇si̇ uygulamalari |

Profesyonel ipucu: Güneş enerjisi montaj rulo şekillendirme makinelerine yatırım yapan şirketler önümüzdeki yıllarda güçlü bir talep artışı görecek!

9. Modüler ve Esnek Rulo Şekillendirme Makinelerine Geçiş

Üreticiler şu yöne doğru ilerliyor modüler rulo şekillendirme makineleriiçin izin verir hızlı profil değişiklikleri ve esnek üretim.

Neden Modüler Rulo Şekillendirme Gelecektir?

✅ Hızlı Takım Değiştirme Sistemleri - Azaltma profil değiştirme sırasında kesinti süresi.

✅ Çoklu Profil Özelliği - Üretmek aynı makinede farklı şekiller.

✅ Ölçeklenebilir Tasarım - Üretimi kolayca genişletin yeni şekillendirme istasyonları ekleme.

✅ Daha İyi Yatırım Getirisi - Yatırım yapın birden fazla uygulama için tek makine.

Modüler Rulo Şekillendirmeden Yararlanan Sektörler

✅ Otomotiv - Üretim tek bir hat üzerinde birden fazla gövde bileşeni.

✅ İnşaat - Esnek makineler için çatı kaplaması, duvar panelleri ve çerçeveleme.

✅ Endüstriyel Depolama - Aşağıdakiler için uyarlanabilir tasarımlar raf ve raflar.

Profesyonel ipucu: Modüler rulo şekillendirme makineleri, birden fazla özel hat ihtiyacını ortadan kaldırarak maliyetleri düşürür!

10. Rulo Şekillendirme Takımlarında 3D Baskının Yükselişi

3D baskı devrim yaratıyor rulo şekillendirme takımlarıdaha hızlı ve daha fazla daha uygun maliyetli çözümler.

3D Baskı Rulo Şekillendirmeyi Nasıl Değiştiriyor?

✅ Hızlı Prototipleme - Tasarım ve test yeni rulo şekillendirme profilleri hızla.

✅ Daha Düşük Kalıp Maliyetleri - Geleneksel kalıplar pahalıdır-3D baskılı kalıplar daha ucuzdur.

✅ Küçük Partiler için Özel Kalıplar - Şunlar için ideal düşük hacimli, yüksek hassasiyetli uygulamalar.

✅ Karmaşık Geometriler - Oluştur karmaşık rulo profiller Daha önce imkansız olan şeyler.

3D Baskılı Rulo Şekillendirme Aletlerini Kullanan Sektörler

✅ Havacılık ve Uzay - Hafif, yüksek mukavemetli rulo şekillendirilmiş bileşenler.

✅ Tıbbi Ekipman - Tıbbi cihazlar için hassas şekillendirilmiş metal parçalar.

✅ Otomotiv - Aşağıdakiler için özel rulo şekillendirilmiş parçalar elektrikli araç (EV) üretimi.

Profesyonel ipucu: 3D baskı, kalıp maliyetlerini 50%'ye kadar düşürerek rulo şekillendirmede oyunun kurallarını değiştiriyor!

11. Küresel Rekabet ve Rulo Şekillendirme Üretiminin Geleceği

As küresel rekabet artiyorüreticiler şunlara odaklanmalıdır verimlilik, otomasyon ve sürdürülebilirlik önde olmak için.

Rulo Şekillendirme Sektöründeki Temel Rekabet Faktörleri

✅ Uygun Maliyetli Üretim - Daha düşük malzeme atığı, enerji tüketimi ve işçilik maliyetleri.

✅ Yüksek Hızlı Otomasyon - Minimum duruş süresiyle daha hızlı üretim döngüleri.

✅ Özelleştirme ve Esneklik - Üretme yeteneği benzersiz, yüksek marjlı ürünler.

✅ Sürdürülebilirlik Girişimleri - ile Uyumluluk yeşi̇l üreti̇m standartlari.

Rulo Şekillendirme Sektörüne Hangi Ülkeler Liderlik Ediyor?

| Ülke | Sektörün Gücü | Rekabet Avantajı |

|---|---|---|

| Çin | En büyük üretici | Uygun maliyetli seri üretim |

| Almanya | Hassas mühendislik | Yüksek teknolojili otomasyon ve yapay zeka entegrasyonu |

| ABD | İnovasyon lideri | Gelişmiş malzeme şekillendirme ve sürdürülebilirlik odağı |

| Hindistan | Hızla büyüyen pazar | Uygun işgücü ve artan altyapı talebi |

Profesyonel ipucu: Otomasyon ve sürdürülebilirliğe yatırım yapan üreticiler küresel rulo şekillendirme pazarına öncülük edecek!

12. 2025'te En Gelişmiş Rulo Şekillendirme Makineleri Nereden Alınır?

İçin yeni̇ nesi̇l rulo şeki̇llendi̇rme maki̇neleri̇ için tasarlanmıştır otomasyon, veri̇mli̇li̇k ve sürdürülebi̇li̇rli̇k, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Neden WUXI SUNWAY MACHINERY'yi Seçmelisiniz?

✅ 15+ Yıllık Uzmanlık - Rulo şekillendirme makinesi üretiminde küresel bir lider.

✅ Yapay Zeka Destekli ve Yüksek Hızlı Makineler - Aşağıdakiler için son teknoloji otomasyon maksimum yatırım getirisi.

✅ Özel Rulo Şekillendirme Çözümleri - Şunlar için özel olarak tasarlanmış makineler çatı kaplama, raf, otomotiv ve güneş enerjisi uygulamaları.

✅ Rekabetçi Fiyatlandırma ve Küresel Nakliye - Uygun fiyatlı ve dünya çapında teslim.

✅ Güvenilir Satış Sonrası Destek - Yedek parça, teknik yardım ve kurulum hizmetleri.

Rulo şekillendirme teknolojinizi yükseltmek mi istiyorsunuz? Bugün bize ulaşın!

SIKÇA SORULAN SORULAR: Rulo Şekillendirme Sektörü Trendleri 2025

1. Rulo şekillendirmedeki en büyük teknolojik gelişmeler nelerdir?

- Yapay zeka, robotik, IoT ve kestirimci bakım sektörü dönüştürüyor.

2. Sürdürülebilirlik rulo şekillendirmeyi nasıl etkiliyor?

- Üreticiler benimsiyor enerji tasarruflu makineler, geri dönüştürülebilir malzemeler ve güneş enerjisiyle çalışan üretim hatları.

3. Hangi sektörler rulo şekillendirmede büyümeyi yönlendirecek?

- İnşaat, güneş enerjisi, otomotiv, havacılık ve endüstriyel depolama en yüksek talebi görecektir.

4. Modüler rulo şekillendirme makineleri geleneksel makinelerden daha mı iyidir?

- Evet! İzin veriyorlar hızlı profil değişiklikleri, çoklu ürün kapasitesi ve daha iyi ölçeklenebilirlik.

5. En gelişmiş rulo şekillendirme makinelerini nerede bulabilirim?

- WUXI SUNWAY MAKİNE sağlar son teknoloji̇ rulo şeki̇llendi̇rme çözümleri̇ ile otomasyon, yapay zeka ve enerji tasarruflu tasarımlar.

Son Düşünceler

Rulo şekillendirme endüstrisi büyük dönüşümler ile otomasyon, sürdürülebilirlik ve yapay zeka odaklı üretim öncülük ediyor. Rekabetçi kalabilmek için üreticiler şunları yapmalıdır en yeni rulo şekillendirme teknolojisine yatırım yapın ve uyum sağlamak pazar trendleri.

✅ İhtiyaç akıllı, yüksek hızlı rulo şekillendirme makineleri?

Aradığım özelleştirilmiş rulo şekillendirme çözümleri?