Overview of Highway Guardrail Roll Forming Machines

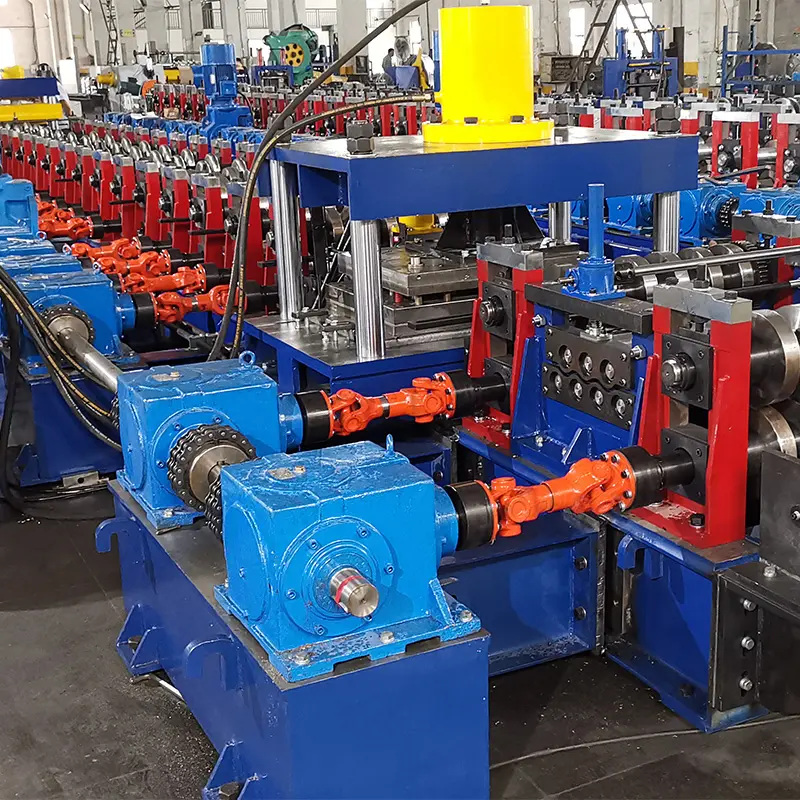

A otoyol korkuluk rulo şekillendirme makinesi is an advanced piece of equipment designed to manufacture steel guardrails için kullanılır road safety barriers. These machines are essential for producing W-beam, thrie-beam, and custom guardrailssağlamak high-strength, durable roadside protection.

Key Features of Highway Guardrail Roll Forming Machines

✅ Yüksek hızlı üretim - Üretim kabiliyeti 10-30 meters per minute.

✅ Tam otomatik çalışma – PLC-controlled for precision and efficiency.

✅ Özelleştirilebilir profiller - Üretir W-beam, thrie-beam, and special designs.

✅ Heavy-duty construction - İle inşa edilmiştir high-strength steel rollers and hydraulic cutting systems.

✅ Hot-dip galvanization compatibility - Sağlar long-lasting corrosion resistance.

Bu kılavuzda şunları ele alacağız:

✅ Types of highway guardrail roll forming machines

✅ Rulo şekillendirme prosesi nasıl çalışır?

✅ Best materials for highway guardrails

✅ Maliyet analizi ve fiyatlandırma kılavuzu

✅ En iyi üreticiler ve Sunway Machine'in neden güvenilir bir seçim olduğu

Hadi dalalım!

Otoyol Otokorkuluk Rulo Şekillendirme Makinesi Çeşitleri

Different korkuluk rulo şeki̇llendi̇rme maki̇neleri̇ cater to various production needs and automation levels.

1. W-Beam Guardrail Roll Forming Machine

- Üretir standard W-beam guardrails (most commonly used worldwide).

- Şunlar için ideal highway and road safety applications.

2. Thrie-Beam Guardrail Roll Forming Machine

- Yaratır stronger, wider thrie-beam guardrails için high-risk areas.

- Şunlar için uygundur high-speed highways and crash-prone zones.

3. Custom Guardrail Roll Forming Machine

- Designed to manufacture customized guardrail profiles.

- Şunlar için ideal specialized safety projects and non-standard road applications.

4. Fully Automatic Highway Guardrail Roll Forming Machine

- Özellikler CNC otomasyonu için hızlı profil ayarlamaları.

- İçin en iyisi large-scale, high-efficiency production.

Sunway Makine sağlar customized highway guardrail roll forming machines ile geli̇şmi̇ş otomasyon özelli̇kleri̇.

How Highway Guardrail Roll Forming Works

Bu rulo şekillendirme işlemi for guardrails involves gradually shaping a flat steel coil into a high-strength guardrail profile.

Step-by-Step Highway Guardrail Roll Forming Process

| Adım | Açıklama |

|---|---|

| 1. Çözme | The steel coil is placed on the decoiler malzemeyi beslemek için. |

| 2. Tesviye ve Besleme | Bu sayfa düzeltilmiş ve yönlendirilmiş şekillendirme istasyonlarına. |

| 3. Delme ve Kesme | Hidrolik sistem şunları gerçekleştirir hole punching for guardrail installation. |

| 4. Rulo Şekillendirme | Levha aşağıdakilerden geçer çoklu silindir istasyonları, forming the guardrail shape. |

| 5. Son Kesim ve Çıktı | The formed guardrail is gerekli uzunlukta kesilmiş ve istiflenmiş. |

👉 Profesyonel ipucu: A fully automated guardrail roll forming machine sağlar high precision, minimal waste, and faster production speeds.

Best Materials for Highway Guardrails

Seçmek doğru malzeme sağlar güç, dayanıklılık ve korozyon direnci.

Comparison of Materials for Highway Guardrails

| Malzeme | Özellikler | İçin En İyisi |

|---|---|---|

| Oluklu Galvanizli Sac Levha Hakkında Tam Rehber 108 | Corrosion-resistant, long lifespan | Standard highways & roads |

| Soğuk Haddelenmiş Çelik | High strength, smooth finish | Urban roads & bridges |

| Paslanmaz Çelik | Pas geçirmez, dayanıklı | High-end infrastructure projects |

| Alüminyum Alaşım | Hafif, korozyona dayanıklı | Low-traffic zones and decorative applications |

Sunway Makine manufactures guardrail roll forming machines compatible with all major highway guardrail materials.

Highway Guardrail Roll Forming Machine Price Guide

Maliyeti otoyol korkuluk rulo şekillendirme makinesi gibi faktörlere bağlıdır otomasyon seviyesi, üretim hızı ve profil aralığı.

Estimated Price Ranges for Highway Guardrail Roll Forming Machines

| Makine Tipi | Fiyat Aralığı (USD) | Özellikler |

|---|---|---|

| Manuel Makine | 30,000-30,000 - 30,000-60,000 | Manuel ayarlamalar, düşük hızlı üretim |

| Yarı Otomatik Makine | 60,000–60,000 – 60,000–120,000 | PLC kontrollü, manuel profil ayarlamaları gerektirir |

| Tam Otomatik Makine | 120,000–120,000 – 120,000–250,000 | CNC kontrollü, hızlı profil değiştirme |

| High-Speed Machine | 250,000–250,000 – 250,000–500,000 | Advanced automation, high-speed production |

Özel bir teklif mi arıyorsunuz? Sunway Machine ile bugün iletişime geçin!

Top Highway Guardrail Roll Forming Machine Manufacturers

Bir seçim güveni̇li̇r üreti̇ci̇ sağlar yüksek kaliteli makineler, uzun vadeli destek ve küresel servis.

Comparison of Leading Highway Guardrail Roll Forming Machine Manufacturers

| Üretici firma | Ülke | Uzmanlık | Temel Özellikler |

|---|---|---|---|

| WUXI SUNWAY MAKİNA A.Ş., LTD | Çin | Highway guardrail roll forming machines | Custom designs, high-speed automation, IoT-enabled machines |

| Dreistern GmbH | Almanya | Precision metal forming | CNC kontrollü makineler, güçlü Ar-Ge |

| Samco Makine | Kanada | İnşaat için rulo şekillendirme | Özel mühendislik, otomasyon |

| Bradbury Grup | ABD | Ağır hizmet tipi rulo şekillendirme sistemleri | Sağlam makineler, otomasyon odaklı |

Karar: Eğer bir cost-effective, high-speed highway guardrail roll forming machine, Sunway Makine bir küresel alicilar i̇çi̇n en i̇yi̇ terci̇h.

Common Problems & Solutions in Highway Guardrail Roll Forming Machines

Hatta high-quality highway guardrail roll forming machines, certain operasyonel zorluklar may arise, such as roller misalignment, material warping, and inaccurate hole punching. Identifying and resolving these problems quickly is essential for maintaining efficient production and high-quality guardrails.

Troubleshooting Guide for Highway Guardrail Roll Forming Machines

| Sorun | Olası Neden | Çözüm |

|---|---|---|

| Misaligned or Twisted Guardrails | Roller misalignment, uneven pressure distribution | Check and adjust roller alignment and pressure settings |

| Inaccurate Hole Punching | Arızalı hidrolik sistem veya yanlış hizalanmış delme kalıpları | Inspect hydraulic pressure and realign punching dies |

| Şekillendirme Sırasında Malzeme Kayması | Gevşek besleyici silindirleri veya yanlış gerginlik ayarları | Besleyici silindirlerini sıkın ve malzeme gerginliğini ayarlayın |

| Aşırı Makine Titreşimi | Loose bolts, unstable machine foundation | Makine bileşenlerini sabitleyin ve sağlam bir kurulum sağlayın |

| Kesim Hatası | Aşınmış kesme bıçakları veya yanlış hizalanmış kesiciler | Körelmiş bıçakları değiştirin ve kesicileri düzgün hizalayın |

Profesyonel ipucu: Routine roller realignment and servo-driven adjustments geliştirebilir guardrail accuracy by up to 30%.

Future Trends in Highway Guardrail Roll Forming Machines

As technology advances, highway guardrail roll forming machines are becoming daha akıllı, daha hızlı ve daha verimli. Manufacturers are integrating Yapay zeka, IoT ve otomasyon to enhance productivity and quality control.

Key Innovations in Highway Guardrail Roll Forming Machines for 2025

1. AI-Powered Quality Inspection

- Yapay zeka destekli sensörler kusurları gerçek zamanlı olarak tespit eder, minimizing waste.

- Geliştirir accuracy and consistency of guardrail production.

2. IoT & Akıllı Fabrika Entegrasyonu

- Makineler artık şu özelliklere sahip bulut bağlanabilirliği, etkinleştirme uzaktan tanılama ve kestirimci bakım.

- Geliştirir real-time monitoring and operational efficiency.

3. Servo Tahrikli Rulo Şekillendirme Teknolojisi

- Geliştirir speed control, energy efficiency, and precision.

- Azaltır mekanik bileşenlerde aşınma ve yıpranma, extending machine lifespan.

4. Tam Otomatik Profil Ayarlamaları

- Ortadan kaldırır manuel ayarlamalar when switching between different guardrail profiles.

- CNC kontrollü otomatik profil değişiklikleri arıza süresini azaltır ve verimliliği artırır.

Upgrading to AI-powered guardrail roll forming machines can increase production efficiency by up to 50%!

Roll Forming vs. Press Braking for Highway Guardrails

When choosing between rulo şekillendirme ve press brakingüreticiler şunları dikkate almalıdır speed, material waste, and cost efficiency.

Comparison Between Roll Forming and Press Braking for Guardrails

| Özellik | Rulo Şekillendirme | Basın Freni |

|---|---|---|

| Üretim Hızı | Uzun, sürekli profiller için daha hızlı | Özel bükümler için daha yavaş |

| Malzeme Atıkları | Minimum atık | Daha yüksek malzeme hurdası |

| Kalıp Maliyetleri | Daha yüksek ilk yatırım, daha düşük uzun vadeli maliyet | Daha düşük ön maliyet, daha yüksek işletme maliyeti |

| İçin En İyisi | Yüksek hacimli, endüstriyel üretim | Özel, düşük hacimli metal bileşenler |

Karar: Eğer ihtiyacınız varsa Minimum atıkla yüksek hızlı, sürekli üretim, highway guardrail roll forming is the better choice.

Automation in Highway Guardrail Roll Forming Machines

Otomasyon dönüştürme üretim süreci, rulo şekillendirme makinelerinin yapımı daha akıllı, daha hızlı ve daha uygun maliyetli.

Key Benefits of Automated Highway Guardrail Roll Forming Machines

| Özellik | Fayda |

|---|---|

| PLC & CNC Kontrol Sistemleri | Hassas ölçümler sağlar ve insan hatasını en aza indirir |

| Yapay Zeka Tabanlı Hata Tespiti | Sorunları gerçek zamanlı olarak tespit ederek malzeme israfını azaltır |

| IoT & Uzaktan İzleme | Operatörlerin makine performansını her yerden takip etmesini sağlar |

| Otomatik Profil Değiştirme | Profiller arasında geçiş yaparken kesinti süresini azaltır |

| Enerji Tasarruflu Servo Motorlar | İşletme maliyetlerini düşürür ve sürdürülebilirliği artırır |

Fully automated highway guardrail roll forming machines from Sunway Makine kadar üretim verimliliğini artırmak 40%!

Essential Maintenance Tips for Highway Guardrail Roll Forming Machines

Uygun bakım aşağıdakileri sağlar daha uzun makine ömrü ve kesintisiz üretim.

Maintenance Checklist for Highway Guardrail Roll Forming Machines

| Görev | Frekans | Amaç |

|---|---|---|

| Makaraları ve Yatakları Yağlayın | Haftalık | Aşınma ve yıpranmayı önler |

| Makara Hizalamasını Kontrol Edin | Aylık | Doğru profil üretimini sağlar |

| Kesme Mekanizmasını Kontrol Edin | Üç Aylık | Hatalı kesimleri ve yanlış hizalamayı önler |

| Temiz Makine Bileşenleri | Günlük | Performansı etkileyebilecek toz ve kalıntıları temizler |

| Yazılım Güncelleme ve Kalibrasyon | Altı ayda bir | Otomasyon fonksiyonlarının optimize edilmesini sağlar |

Profesyonel ipucu: Planlı bakım şunları yapabilir 50% ile makine ömrünü uzatın ve 70% ile arızaları azaltın.

FAQ: Highway Guardrail Roll Forming Machines

1. How fast can a highway guardrail roll forming machine produce guardrails?

Yüksek hızlı modeller aşağıdakilere kadar üretebilir Dakikada 30 metreprofile bağlı olarak.

2. What guardrail profiles can be produced?

Çoğu makine şunları üretebilir W-beam, thrie-beam, and custom guardrail profiles.

3. How much does a highway guardrail roll forming machine cost?

Fiyat aralıkları 30,000forbasicmodels∗∗to∗∗30,000 for basic models** to **30,000forbasicmodels∗∗to∗∗500,000 for fully automated systems.

4. What materials can be used in highway guardrail roll forming machines?

Yaygın malzemeler şunları içerir hot-dip galvanized steel, cold-rolled steel, stainless steel, and aluminum alloys.

5. Where can I buy a high-quality highway guardrail roll forming machine?

İçin custom-built, high-speed highway guardrail roll forming machines, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Son Düşünceler

Yatırım yapmak otoyol korkuluk rulo şekillendirme makinesi için gereklidir. efficient, high-quality guardrail production. İster bir standart veya tam otomatik sistemseçerek güveni̇li̇r üreti̇ci̇ sağlar uzun vadeli güvenilirlik ve karlılık.

WUXI SUNWAY MAKİNA A.Ş., LTD bir lider küresel üretici . custom-built highway guardrail roll forming machines, teklif ileri teknoloji, uzman desteği ve rekabetçi fiyatlandırma.

İstiyorum custom highway guardrail roll forming machine? Bugün bize ulaşın!