Overview of Heavy-Duty Roll Forming Machines

A ağır hizmet tipi rulo şekillendirme makinesi is an advanced industrial machine designed to process thick and high-strength metal sheetsgibi galvanized steel, paslanmaz çelik, aluminum, and structural steel. These machines are used to manufacture heavy-gauge structural components, industrial beams, highway guardrails, solar mounting systems, and storage racks.

Standart rulo şekillendirme makinelerinin aksine, heavy-duty roll forming machines are built with reinforced rollers, powerful hydraulic systems, and precision CNC controls işlemek için high-tensile materials with ease.

Key Features of Heavy-Duty Roll Forming Machines

✅ Capable of processing thick materials – Up to 8mm thickness için ultra-strong structural components.

✅ Yüksek hızlı üretim - Üretir 10-40 meters per minute, depending on material strength.

✅ Heavy-duty rollers & hydraulic systems - İçin tasarlandı continuous, high-load operations.

✅ Tam otomatik operasyon – CNC-controlled for precision and efficiency.

✅ Enerji tasarruflu servo motorlar – Improves power consumption and operational efficiency.

Bu kılavuzda şunları ele alacağız:

✅ Types of heavy-duty roll forming machines

✅ Rulo şekillendirme prosesi nasıl çalışır?

✅ Best materials for heavy-duty roll forming

✅ Maliyet analizi ve fiyatlandırma kılavuzu

✅ En iyi üreticiler ve Sunway Machine'in neden güvenilir bir seçim olduğu

Hadi başlayalım!

Types of Heavy-Duty Roll Forming Machines

Different heavy-duty roll forming machines are designed for specific industrial applications and material thicknesses.

1. Heavy-Duty Structural Beam Roll Forming Machine

- Üretir I-beams, C-channels, and heavy-gauge profiles kullanılan i̇nşaat ve endüstri̇yel uygulamalar.

- Şunlar için ideal bridges, steel structures, and load-bearing elements.

2. Heavy-Duty Storage Rack Roll Forming Machine

- İmalat high-strength racking and shelving components için warehouses and logistics centers.

- Sağlar hassasiyet, güç ve dayanıklılık.

3. Heavy-Duty Guardrail Roll Forming Machine

- Used to produce highway safety barriers and crash guardrails.

- Capable of handling high-tensile steel for impact resistance.

4. Fully Automatic Heavy-Duty Roll Forming Machine

- Özellikler CNC otomasyonu için quick profile adjustments and high-precision outputs.

- İçin en iyisi large-scale, high-efficiency production.

Sunway Makine sağlar customized heavy-duty roll forming machines ile geli̇şmi̇ş otomasyon özelli̇kleri̇.

How Heavy-Duty Roll Forming Works

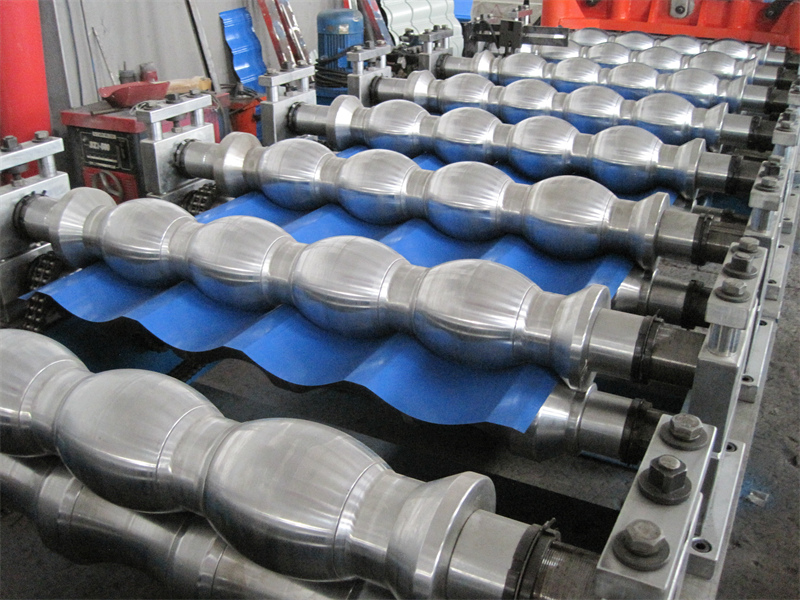

Bu rulo şekillendirme işlemi for heavy-duty applications involves gradually shaping thick and high-strength metal sheets içine heavy-gauge profiles using reinforced rollers and high-pressure hydraulic systems.

Step-by-Step Heavy-Duty Roll Forming Process

| Adım | Açıklama |

|---|---|

| 1. Çözme | The high-strength metal coil is placed on a heavy-duty decoiler, feeding material into the machine. |

| 2. Tesviye ve Besleme | Bu sayfa düzeltilmiş ve yönlendirilmiş şekillendirme istasyonlarına. |

| 3. Pre-Punching (If Required) | Hydraulic or servo-driven punching units create holes or slots in the material. |

| 4. Rulo Şekillendirme | Levha aşağıdakilerden geçer multiple reinforced roller stations, forming the desired profile. |

| 5. Cutting & Stacking | Oluşturulan profil şöyledir cut using hydraulic or servo-driven systems and stacked for shipment. |

Profesyonel ipucu: A fully automated heavy-duty roll forming machine sağlar high precision, minimal waste, and faster production speeds.

Best Materials for Heavy-Duty Roll Forming

Seçmek right metal grade sağlar optimal strength, durability, and corrosion resistance.

Comparison of Materials for Heavy-Duty Roll Forming

| Malzeme | Özellikler | İçin En İyisi |

|---|---|---|

| High-Tensile Galvanized Steel | Excellent strength, corrosion resistance | Guardrails, structural beams, heavy-duty storage racks |

| Stainless Steel 304/316 | High corrosion resistance, long lifespan | Marine structures, industrial frames |

| Alüminyum 6061/7075 | Lightweight, strong, and corrosion-resistant | Aerospace, automotive, solar mounting systems |

| Structural Steel S355/S460 | Exceptional load-bearing capacity, impact resistance | Bridges, heavy construction, industrial support beams |

Sunway Makine ile uyumlu rulo şekillendirme makineleri üretmektedir. all major heavy-duty metal grades.

Heavy-Duty Roll Forming Machine Price Guide

Maliyeti ağır hizmet tipi rulo şekillendirme makinesi gibi faktörlere bağlıdır automation level, material thickness capacity, and profile range.

Estimated Price Ranges for Heavy-Duty Roll Forming Machines

| Makine Tipi | Fiyat Aralığı (USD) | Özellikler |

|---|---|---|

| Manuel Makine | 50,000-50,000 - 50,000-100,000 | Manuel ayarlamalar, düşük hızlı üretim |

| Yarı Otomatik Makine | 100,000-100,000 - 100,000-200,000 | PLC kontrollü, manuel profil ayarlamaları gerektirir |

| Tam Otomatik Makine | 200,000–200,000 – 200,000–500,000 | CNC kontrollü, hızlı profil değiştirme |

| High-Speed Precision Machine | 500,000–500,000 – 500,000–1,000,000 | Advanced automation, high-speed production |

Özel bir teklif mi arıyorsunuz? Sunway Machine ile bugün iletişime geçin!

Top Heavy-Duty Roll Forming Machine Manufacturers

Bir seçim güveni̇li̇r üreti̇ci̇ sağlar yüksek kaliteli makineler, uzun vadeli destek ve küresel servis.

Comparison of Leading Heavy-Duty Roll Forming Machine Manufacturers

| Üretici firma | Ülke | Uzmanlık | Temel Özellikler |

|---|---|---|---|

| WUXI SUNWAY MAKİNA A.Ş., LTD | Çin | Heavy-duty roll forming machines | Custom designs, high-speed automation, IoT-enabled machines |

| Dreistern GmbH | Almanya | Precision metal forming | CNC kontrollü makineler, güçlü Ar-Ge |

| Samco Makine | Kanada | İnşaat için rulo şekillendirme | Özel mühendislik, otomasyon |

| Bradbury Grup | ABD | Ağır hizmet tipi rulo şekillendirme sistemleri | Sağlam makineler, otomasyon odaklı |

Karar: Eğer bir cost-effective, high-speed heavy-duty roll forming machine, Sunway Makine bir küresel alicilar i̇çi̇n en i̇yi̇ terci̇h.

Common Problems & Solutions in Heavy-Duty Roll Forming Machines

Hatta high-quality heavy-duty roll forming machines, certain operasyonel zorluklar can arise, such as roller misalignment, machine vibration, and inaccurate cutting. Bu sorunların tanımlanması ve giderilmesi erken sağlar smooth production and high-quality heavy-gauge profiles.

Sorun Giderme Kılavuzu

| Sorun | Olası Neden | Çözüm |

|---|---|---|

| Bent or Twisted Profiles | Roller misalignment, improper pressure settings | Adjust roller alignment and optimize pressure settings |

| Şekillendirme Sırasında Malzeme Kayması | Gevşek besleyici silindirleri, yanlış gerginlik ayarları | Besleyici silindirlerini sıkın ve malzeme gerginliğini ayarlayın |

| Aşırı Makine Titreşimi | Loose bolts, unstable installation | Secure machine components and ensure a stable foundation |

| Tutarsız Kesim Uzunlukları | Hatalı kesme sistemi, yanlış hizalanmış bıçaklar | Kesme mekanizmasını inceleyin ve yeniden kalibre edin |

| Roller Wear and Tear | High friction, improper material handling | Sertleştirilmiş silindirler kullanın ve aşınma önleyici kaplamalar uygulayın |

Profesyonel ipucu: Routine roller realignment and lubrication olabilir 40% ile makine ömrünü uzatın ve improve profile accuracy.

Future Trends in Heavy-Duty Roll Forming Machines

Bu heavy-duty metal manufacturing industry is evolving, and rulo şekillendirme makineleri are integrating Yapay zeka, IoT ve otomasyon iyileştirmek için efficiency, precision, and sustainability.

Key Innovations

1. AI-Based Quality Control

- Yapay zeka destekli sensors detect defects in real timemalzeme israfını azaltır.

- Geliştirir accuracy and consistency of heavy-duty profiles.

2. IoT & Akıllı Fabrika Entegrasyonu

- Makineler artık şu özelliklere sahip bulut tabanlı izleme, etkinleştirme gerçek zamanlı teşhis ve kestirimci bakım.

- Geliştirir üretim takibi ve operasyonel verimlilik.

3. Servo Tahrikli Rulo Şekillendirme Teknolojisi

- Geliştirir hız kontrolü, hassasiyet ve enerji verimliliği.

- Azaltır mekanik bileşenlerde aşınma ve yıpranmamakine ömrünü uzatır.

4. Tam Otomatik Profil Ayarlamaları

- Ortadan kaldırır manuel ayarlamalar farklı profiller arasında geçiş yaparken.

- CNC kontrollü otomatik profil değişiklikleri arıza süresini azaltır ve verimliliği artırır.

Upgrading to AI-powered heavy-duty roll forming machines can increase production efficiency by up to 50%!

Automation in Heavy-Duty Roll Forming Machines

Otomasyon devrim yaratan heavy-gauge profile manufacturing, making roll forming machines daha akıllı, daha hızlı ve daha uygun maliyetli.

Temel Avantajlar

| Özellik | Fayda |

|---|---|

| PLC & CNC Kontrol Sistemleri | Hassas ölçümler sağlar ve insan hatasını en aza indirir |

| Yapay Zeka Tabanlı Hata Tespiti | Identifies issues in real time, reducing material waste |

| IoT & Uzaktan İzleme | Operatörlerin makine performansını her yerden takip etmesini sağlar |

| Otomatik Profil Değiştirme | Profiller arasında geçiş yaparken kesinti süresini azaltır |

| Enerji Tasarruflu Servo Motorlar | İşletme maliyetlerini düşürür ve sürdürülebilirliği artırır |

Fully automated heavy-duty roll forming machines from Sunway Makine kadar üretim verimliliğini artırmak 40%!

Essential Maintenance Tips for Heavy-Duty Roll Forming Machines

Uygun Bakım sağlar longer machine lifespan ve tutarlı üretim kalitesi.

Maintenance Checklist

| Görev | Frekans | Amaç |

|---|---|---|

| Makaraları ve Yatakları Yağlayın | Haftalık | Aşınma ve yıpranmayı önler |

| Makara Hizalamasını Kontrol Edin | Aylık | Doğru profil üretimini sağlar |

| Kesme Mekanizmasını Kontrol Edin | Üç Aylık | Hatalı kesimleri ve yanlış hizalamayı önler |

| Temiz Makine Bileşenleri | Günlük | Performansı etkileyebilecek toz ve kalıntıları temizler |

| Yazılım Güncelleme ve Kalibrasyon | Altı ayda bir | Otomasyon fonksiyonlarının optimize edilmesini sağlar |

Profesyonel ipucu: Planlı bakım şunları yapabilir 50% ile makine ömrünü uzatın ve 70% ile arızaları azaltın.

SSS

1. How fast can a heavy-duty roll forming machine produce profiles?

Yüksek hızlı modeller aşağıdakilere kadar üretebilir Dakikada 40 metremalzeme kalınlığına bağlı olarak.

2. What materials can be processed?

Heavy-duty roll forming machines can handle high-tensile steel, stainless steel, aluminum, and structural steel.

3. How much does a heavy-duty roll forming machine cost?

Fiyat aralıkları 50,000forbasicmodels∗∗to∗∗50,000 for basic models** to **50,000forbasicmodels∗∗to∗∗1,000,000 for fully automated systems.

4. What industries use heavy-duty roll forming machines?

Common applications include construction, infrastructure, automotive, aerospace, and industrial storage systems.

5. Where can I buy a high-quality heavy-duty roll forming machine?

İçin custom-built, high-speed heavy-duty roll forming machines, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Son Düşünceler

Yatırım yapmak ağır hizmet tipi rulo şekillendirme makinesi için gereklidir. efficient, high-quality structural component production. İster bir standart veya tam otomatik sistemseçerek güveni̇li̇r üreti̇ci̇ sağlar uzun vadeli güvenilirlik ve karlılık.

WUXI SUNWAY MAKİNA A.Ş., LTD bir lider küresel üretici . custom-built heavy-duty roll forming machines, teklif ileri teknoloji, uzman desteği ve rekabetçi fiyatlandırma.

İstiyorum custom heavy-duty roll forming machine? Bugün bize ulaşın!