Kutu profil kaplama levhaları dayanıklılığı, çok yönlülüğü ve maliyet etkinliği nedeniyle modern inşaatlarda giderek daha popüler hale gelmiştir. Bu kılavuz, kutu profil kaplama levhaları hakkında bilmeniz gereken her şeyi; türleri, uygulamaları ve kurulum süreçlerinden diğer kaplama seçenekleriyle karşılaştırmalara kadar derinlemesine incelemektedir. Sonunda, bilinçli bir seçim yapmak için tüm ayrıntılara sahip olacaksınız.

Kutu Profil Kaplama Levhaları Nedir?

Kutu profil kaplama levhaları, binalar için koruyucu ve estetik katmanlar olarak kullanılan dayanıklı, oluklu metal levhalardır. Tipik olarak çelik veya alüminyumdan yapılan bu levhalar, gelişmiş yapısal bütünlük ve modern görünüm sunan "kutu gibi" nervürlü bir profile sahiptir. Endüstriyel, ticari ve tarımsal binalarda çatı ve duvar kaplaması için yaygın olarak kullanılırlar.

Neden Kutu Profil Kaplama Levhalarını Seçmelisiniz?

Kutu profil kaplama levhaları, yüksek mukavemet/ağırlık oranları, uzun ömürlü yüzeyleri ve düşük bakım gereksinimleri nedeniyle tercih edilir. Çeşitli metal tipleri ve yüzeylerde mevcut olup, farklı mimari stillere uyum sağlayabilir ve zorlu çevre koşullarına dayanabilirler.

Kutu Profil Kaplama Levha Çeşitleri

Doğru kutu profil kaplama levhasını seçmek, mevcut türleri ve bunların nasıl farklılık gösterdiğini anlamayı gerektirir. Şimdi bazı popüler modelleri, malzemeleri ve bunların özel kullanımlarını inceleyelim.

| Kutu Profil Kaplama Levhası Tipi | Malzeme | Kaburga Yüksekliği (mm) | Kalınlık (mm) | En İyi Kullanım Örneği |

|---|---|---|---|---|

| BPC 32/1000 | Galvanizli Çelik | 32 | 0.5-1.2 | Tarımsal binalar |

| BPC 40/1000 | Ön Kaplamalı Çelik | 40 | 0.5-1.2 | Endüstriyel duvar kaplamaları |

| BPC 45/1000 | Alüminyum | 45 | 0.5-1.0 | Kıyı uygulamaları |

| BPC 50/1000 | Paslanmaz Çelik | 50 | 0.6-1.5 | Yüksek nemli ortamlar |

| BPC 55/1000 | Renkli Kaplamalı Çinko | 55 | 0.7-1.2 | Büyük ölçekli ticari çatı kaplaması |

| BPC 60/1000 | Zincalume | 60 | 0.8-1.3 | Depolar ve depolama tesisleri |

| BPC 65/1000 | Galvalume | 65 | 0.7-1.4 | Konut projeleri |

| BPC 70/1000 | Bakır | 70 | 0.8-1.0 | Üst düzey mimari projeler |

| BPC 75/1000 | Toz Boya Çelik | 75 | 0.9-1.2 | Ağır hizmet tipi endüstriyel uygulamalar |

| BPC 80/1000 | Boyalı Çelik | 80 | 0.6-1.2 | Çok kullanımlı ticari kaplama |

Oluklu Demir Levhalar vs. Kutu Profil Kaplama Levhaları

Hem oluklu demir saclar hem de kutu profil kaplama sacları benzer amaçlara hizmet ederken, tasarım ve uygulama açısından farklılık gösterirler. Oluklu levhalar, esneklik sunabilen ancak kutu profillerin yapısal sertliğinden yoksun olan dalgalı bir profile sahiptir. Buna karşılık, kutu profil levhalar daha sağlamdır ve daha iyi yük taşıma kapasitesi sağlarBu da onları sağlam endüstriyel ve tarımsal kullanımlar için uygun hale getirir.

Temel Özelliklerin Karşılaştırılması

| Özellik | Oluklu Levhalar | Kutu Profil Kaplama Levhaları |

|---|---|---|

| Yapısal Sertlik | Orta düzeyde | Yüksek |

| Yük Taşıma Kapasitesi | Daha düşük | Daha yüksek |

| Görünüş | Geleneksel | Modern |

| Kurulum Karmaşıklığı | Daha kolay | Orta düzeyde |

| İçin En İyisi | Hafif uygulamalar | Ağır hizmet tipi ve uzun ömürlü ihtiyaçlar |

Kutu Profil Kaplama Levhalarının Çalışma Süreci

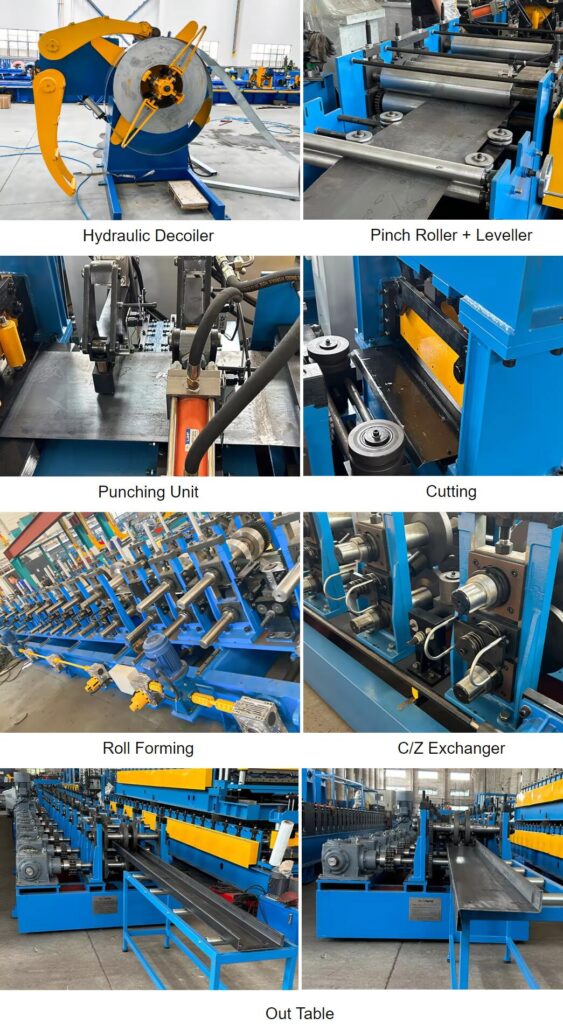

Kutu profil kaplama levhalarının üretim süreci, uzun ömürlülük ve hava koşullarına karşı direnç sağlamak için metalin kesilmesini, oluklu hale getirilmesini ve kaplanmasını içerir. Bu adım adım süreç, yüksek kaliteli bir ürün sağlar:

- Metal Seçimi: Süreç, son kullanıma göre uygun metalin (örn. galvanizli çelik, alüminyum) seçilmesiyle başlar.

- Oluklama Süreci: Metal levhalar, karakteristik kutu benzeri çıkıntıları elde etmek için silindirlerden geçirilir.

- Kaplama ve Son İşlem: Son olarak saclar, gereksinimlere bağlı olarak toz kaplama, renk bağlama veya galvanizleme içerebilen koruyucu yüzeylerle kaplanır.

Temel Bileşenler ve İşlevleri

| Bileşen | Fonksiyon |

|---|---|

| Ana Metal | Levhanın çekirdek mukavemetini sağlar |

| Koruyucu Kaplama | Korozyon direncini artırır |

| Kutu Profil Tasarımı | Yapısal bütünlük ve görsel çekicilik katar |

| Kaburga Yüksekliği | Yük taşıma kapasitesini ve su drenajını etkiler |

| Sabitleme Noktaları | Çarşafları yerinde sabitler, hareketi önler |

-

Taşıma Panosu Rulo Şekillendirme Makinesi

Taşıma Panosu Rulo Şekillendirme Makinesi -

Otoyol Otokorkuluk Uç Terminali Şekillendirme Makinesi

Otoyol Otokorkuluk Uç Terminali Şekillendirme Makinesi -

Otoyol U/C Post Rulo Şekillendirme Makinesi

Otoyol U/C Post Rulo Şekillendirme Makinesi -

2 Dalga Otoyol Otokorkuluk Rulo Şekillendirme Makinesi

2 Dalga Otoyol Otokorkuluk Rulo Şekillendirme Makinesi -

3 Dalga Otoyol Otokorkuluk Rulo Şekillendirme Makinesi

3 Dalga Otoyol Otokorkuluk Rulo Şekillendirme Makinesi -

Bağ Direği Rulo Şekillendirme Makinesi

Bağ Direği Rulo Şekillendirme Makinesi -

Otomatik Boyut Değiştirilebilir Sigma Aşık Rulo Şekillendirme Makinesi

Otomatik Boyut Değiştirilebilir Sigma Aşık Rulo Şekillendirme Makinesi -

Otomatik Boyut Değiştirilebilir CZ Aşık Rulo Şekillendirme Makinesi

Otomatik Boyut Değiştirilebilir CZ Aşık Rulo Şekillendirme Makinesi -

Otomatik Boyut Değiştirilebilir Z Aşık Rulo Şekillendirme Makinesi

Otomatik Boyut Değiştirilebilir Z Aşık Rulo Şekillendirme Makinesi

Makine Hızı ve Verimliliği

Kutu profil kaplama levhaları üretirken verimlilik çok önemlidir. Modern makineler, kaliteden ödün vermeden yüksek hızlı üretime olanak tanır.

| Makine Tipi | Üretim Hızı (m/dak) | Verimlilik |

|---|---|---|

| Standart Roll-Former | 15-25 | Orta düzeyde |

| Yüksek Hızlı Roll-Former | 30-40 | Yüksek |

| Lazer ile Otomatik Roll-Former | 40-50 | Çok Yüksek |

Uygulamaları ve Kullanım Alanları Kutu Profil Kaplama Levhaları

Kutu profil kaplama levhaları, sağlamlıkları ve çok yönlülükleri nedeniyle çeşitli sektörlerde yaygın olarak kullanılmaktadır.

| Uygulama | Kullanım Örneği |

|---|---|

| Endüstriyel Çatı Kaplama | Fabrikalar, depolar |

| Tarımsal Kaplama | Ahırlar, hayvan barınakları |

| Konut Projeleri | Modern evler, garajlar |

| Ticari Binalar | Perakende merkezleri, ofis blokları |

| Yüksek Nemli Ortamlar | Yüzme havuzları, spa binaları |

Kutu Profil Kaplama Levhalarının Kurulumu, Çalıştırılması ve Bakımı

Kutu profil kaplama levhalarının uzun ömürlü olması için doğru montaj ve bakım şarttır.

| Süreç | Detaylar |

|---|---|

| Kurulum | Özel bağlantı elemanları ve hassas hizalama gerektirir |

| Operasyon | Makineleri güvenlik için önerilen hızlarda çalıştırın |

| Bakım | Özellikle kıyı veya kirli bölgelerde düzenli temizlik |

Kutu Profil Kaplama Levhaları için Doğru Tedarikçiyi Seçme

Tedarikçi seçiminde ürün kalitesi, teslimat hızı ve müşteri hizmetleri gibi çeşitli hususlar göz önünde bulundurulur. İşte seçim yapmanıza yardımcı olacak bir kılavuz:

| Tedarikçi Kriterleri | Önem | Neden Önemli? |

|---|---|---|

| Malzeme Kalitesi | Çok Yüksek | Dayanıklılık ve güvenilirlik sağlar |

| Teslimat Zaman Çizelgeleri | Yüksek | Proje gecikmelerini azaltır |

| Müşteri Desteği | Orta düzeyde | Sorun durumunda gerekli yardımı sağlar |

| Fiyat Aralığı | Yüksek | Bütçe dahilinde kalmanıza yardımcı olur |

Artıları ve Eksilerinin Karşılaştırılması Kutu Profil Kaplama Levhaları

| Aspect | Avantajlar | Dezavantajlar |

|---|---|---|

| Dayanıklılık | Son derece dayanıklıdır, sert iklimlere dayanır | Bazı malzemelere kıyasla daha ağır |

| Maliyet | Alternatiflerine kıyasla uygun maliyetli | İlk kurulum uzmanlık gerektirebilir |

| Estetik Seçenekler | Modern görünüm, çeşitli yüzeylerde mevcuttur | Tasarımda sınırlı esneklik |

SSS

| Soru | Cevap |

|---|---|

| Bir kutu profil kaplama levhasının ortalama ömrü ne kadardır? | Bakım ve çevre koşullarına bağlı olarak tipik olarak 20-30 yıl |

| Bu levhalar kıyı bölgeleri için uygun mu? | Evet, özellikle alüminyum ve kaplamalı çelik çeşitleri |

| Kutu profil levhaları özelleştirilebilir mi? | Evet, özel boyutlarda, renklerde ve kaplamalarda sipariş edilebilirler |

| Herhangi bir özel bakım gerektiriyorlar mı? | Özellikle tuzlu ortamlarda düzenli temizlik ve inceleme yapılması önerilir |