Genel Bakış

A hassas rulo şekillendirme makinesi is an advanced industrial system designed to create complex, high-accuracy metal profiles with minimal material waste and maximum efficiency. These machines are widely used in industries like aerospace, automotive, medical equipment manufacturing, electronics, and renewable energy nedeniyle tight tolerances, repeatability, and exceptional surface finish.

Standart rulo şekillendirme makinelerinin aksine, hassas rulo şekillendirme makineleri use high-precision rollers, CNC controls, and servo-driven technology üretmek için custom metal profiles with extreme accuracy.

Temel Özellikler

✅ Ultra-precise tolerances – Achieves ±0.1mm accuracy için high-spec components.

✅ Yüksek hızlı üretim - Üretir 10-50 meters per minute, depending on profile complexity.

✅ Gelişmiş CNC ve servo tahrikli sistemler - Sağlar tekrarlanabilir doğruluk ve minimum hata oranları.

✅ Suitable for thin & high-strength metals – Processes aluminum, paslanmaz çelik, titanium, and specialty alloys.

✅ Automated inline quality inspection – Detects defects in real time for zero-waste production.

Bu kılavuzda şunları ele alacağız:

✅ Types of precision roll forming machines

✅ How the precision roll forming process works

✅ Best materials for precision roll forming

✅ Maliyet analizi ve fiyatlandırma kılavuzu

✅ En iyi üreticiler ve Sunway Machine'in neden güvenilir bir seçim olduğu

Hadi dalalım!

Türleri

Different hassas rulo şekillendirme makineleri cater to various industrial applications and profile complexities.

1. High-Speed Precision Roll Forming Machine

- Şunlar için tasarlandı thin-gauge materials and high-speed production.

- Şunlar için ideal electronic components, medical devices, and automotive trim.

2. Multi-Station Precision Roll Forming Machine

- Özellikler çoklu şekillendirme istasyonları için complex profiles with tight tolerances.

- İçinde kullanılır aerospace, renewable energy, and high-tech industries.

3. Precision Roll Forming Machine with Inline Laser Cutting

- Kombinasyonlar roll forming with laser cutting için intricate designs and hole patterns.

- İçin en iyisi automotive and precision engineering applications.

4. Fully Automated CNC Precision Roll Forming Machine

- Özellikler AI-driven automation and real-time defect detection.

- İçin en iyisi mass production requiring minimal human intervention.

Sunway Makine sağlar customized precision roll forming machines ile cutting-edge automation and high-speed capabilities.

How Precision Roll Forming Works

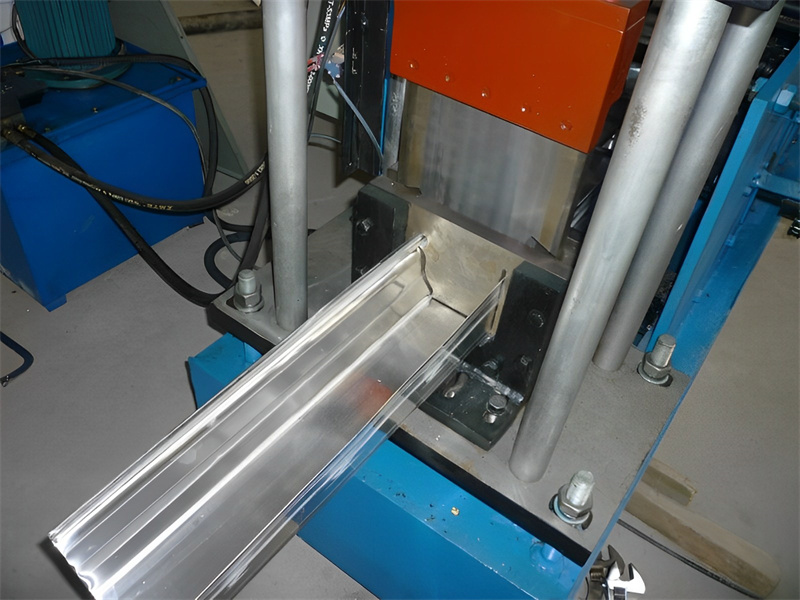

Bu precision roll forming process içerir gradually shaping a metal coil into a high-accuracy profile using computer-controlled rollers and servo-driven forming stations.

Step-by-Step Precision Roll Forming Process

| Adım | Açıklama |

|---|---|

| 1. Çözme | The metal coil is placed on a high-precision decoiler, feeding material into the machine. |

| 2. Tesviye ve Besleme | Bu sayfa düzeltilmiş ve yönlendirilmiş şekillendirme istasyonlarına. |

| 3. Pre-Punching or Laser Cutting | Satır içi hole punching or laser cutting ensures accurate profile modifications. |

| 4. Precision Roll Forming | Levha aşağıdakilerden geçer multiple CNC-controlled rollers, forming the final profile. |

| 5. Quality Inspection & Cutting | The formed profile undergoes real-time inspection and precision cutting. |

Profesyonel ipucu: A fully automated precision roll forming machine sağlar high accuracy, zero defects, and faster production speeds.

Best Materials for Precision Roll Forming

Seçme doğru malzeme sağlar optimal performance, durability, and tight tolerance compliance.

Comparison of Materials for Precision Roll Forming

| Malzeme | Özellikler | İçin En İyisi |

|---|---|---|

| Stainless Steel 304/316 | Corrosion-resistant, strong, excellent finish | Medical devices, aerospace components |

| Alüminyum 6061/7075 | Lightweight, strong, high corrosion resistance | Automotive, electronics, renewable energy |

| Titanyum Alaşımları | Yüksek mukavemet/ağırlık oranı, biyouyumluluk | Havacılık ve uzay, tıbbi implantlar |

| Yüksek Çekme Çelik | Güçlü, darbeye dayanıklı, uzun ömürlü | Automotive crash structures, precision framing |

Sunway Makine ile uyumlu rulo şekillendirme makineleri üretmektedir. all major precision metal grades.

Precision Roll Forming Machine Price Guide

Maliyeti hassas rulo şekillendirme makinesi gibi faktörlere bağlıdır otomasyon seviyesi, malzeme kapasitesi ve profil karmaşıklığı.

Estimated Price Ranges

| Makine Tipi | Fiyat Aralığı (USD) | Özellikler |

|---|---|---|

| Basic Precision Machine | 50,000–50,000 – 50,000–120,000 | Manuel ayarlamalar, yarı otomatik kontroller |

| CNC Hassas Makine | 120,000–120,000 – 120,000–300,000 | Yüksek hızlı üretim, CNC kontrollü hassasiyet |

| Tam Otomatik Makine | 300,000–300,000 – 300,000–600,000 | Yapay zeka destekli otomasyon, sıfır hatalı kalite kontrol |

| High-Speed Multi-Station Machine | 600,000–600,000 – 600,000–1,000,000 | Gelişmiş yapay zeka, lazer kesim, yüksek hızlı işleme |

Özel bir teklif mi arıyorsunuz? Sunway Machine ile bugün iletişime geçin!

Top Precision Roll Forming Machine Manufacturers

Bir seçim güveni̇li̇r üreti̇ci̇ sağlar yüksek kaliteli makineler, uzun vadeli destek ve küresel servis.

Comparison of Leading Precision Roll Forming Machine Manufacturers

| Üretici firma | Ülke | Uzmanlık | Temel Özellikler |

|---|---|---|---|

| WUXI SUNWAY MAKİNA A.Ş., LTD | Çin | Precision roll forming machines | Ultra-high accuracy, CNC-controlled, AI automation |

| Dreistern GmbH | Almanya | Precision metal forming | High-tech R&D, advanced laser integration |

| Samco Makine | Kanada | Roll forming for medical & aerospace | Custom engineering, servo-driven precision |

| Bradbury Grup | ABD | High-speed precision roll forming | Advanced automation, low waste production |

Karar: Eğer bir cost-effective, high-speed precision roll forming machine, Sunway Makine bir küresel alicilar i̇çi̇n en i̇yi̇ terci̇h.

Common Problems & Solutions in Precision Roll Forming Machines

Hatta high-end precision roll forming machines, operators may encounter issues like profile deformation, roller misalignment, surface defects, and cutting inaccuracies. Identifying and troubleshooting these problems erken sağlar consistent, high-accuracy production with minimal downtime.

Sorun Giderme Kılavuzu

| Sorun | Olası Neden | Çözüm |

|---|---|---|

| Profil Bozulması veya Çarpılması | Eşit olmayan silindir basıncı, yanlış malzeme besleme hizalaması | Silindir basıncını ayarlayın ve malzemenin doğru yönlendirilmesini sağlayın |

| Şekillendirme Sırasında Malzeme Kayması | Gevşek besleyici silindirleri, yanlış gerginlik ayarları | Besleyici silindirlerini sıkın ve malzeme gerginliğini ayarlayın |

| Yüzey Çizikleri veya İşaretleri | Kirli silindirler, yanlış yağlama | Silindirleri düzenli olarak temizleyin ve iz bırakmayan kaplamalar uygulayın |

| Tutarsız Kesim Uzunlukları | Hatalı kesme sistemi, yanlış hizalanmış bıçaklar | Kesme mekanizmasını inceleyin ve yeniden kalibre edin |

| Roller Wear and Tear | Yüksek sürtünme, yanlış malzeme seçimi | Sertleştirilmiş silindirler kullanın ve aşınma önleyici kaplamalar uygulayın |

Profesyonel ipucu: Düzenli silindir kalibrasyonu ve otomatik kalite kontrolleri olabilir 30%'ye kadar malzeme israfını azaltın ve profil doğruluğunu önemli ölçüde iyileştirir.

Future Trends in Precision Roll Forming Machines

Bu precision manufacturing industry is rapidly evolving, integrating Yapay zeka, IoT ve otomasyon to enhance verimlilik, doğruluk ve sürdürülebilirlik.

Key Innovations

1. Yapay Zeka Tabanlı Hata Tespiti

- Yapay zeka destekli kameralar ve sensörler tespit etmek mikro kusurlar gerçek zamanlı olarak.

- Azaltır malzeme israfını önler ve genel ürün kalitesini artırır.

2. IoT & Akıllı Fabrika Entegrasyonu

- Makineler artık şu özelliklere sahip bulut tabanlı izleme, etkinleştirme gerçek zamanlı teşhis ve kestirimci bakım.

- Geliştirir üretim takibi ve operasyonel verimlilik.

3. Servo Tahrikli Rulo Şekillendirme Teknolojisi

- Geliştirir hız kontrolü, hassasiyet ve enerji verimliliği.

- Azaltır mekanik bileşenlerde aşınma ve yıpranmamakine ömrünü uzatır.

4. Tam Otomatik Profil Ayarlamaları

- Ortadan kaldırır manuel ayarlamalar farklı profiller arasında geçiş yaparken.

- CNC kontrollü otomatik profil değişiklikleri arıza süresini azaltır ve verimliliği artırır.

Upgrading to AI-powered precision roll forming machines can increase production efficiency by up to 50%!

Automation in Precision Roll Forming Machines

Otomasyon dönüştürme hassas profil imalatı, rulo şekillendirme makineleri yapımı daha akıllı, daha hızlı ve daha uygun maliyetli.

Temel Avantajlar

| Özellik | Fayda |

|---|---|

| PLC & CNC Kontrol Sistemleri | Hassas ölçümler sağlar ve insan hatasını en aza indirir |

| Yapay Zeka Tabanlı Gerçek Zamanlı Hata Tespiti | Sorunları anında tespit ederek malzeme israfını azaltır |

| IoT & Uzaktan İzleme | Operatörlerin makine performansını her yerden takip etmesini sağlar |

| Otomatik Profil Değiştirme | Profiller arasında geçiş yaparken kesinti süresini azaltır |

| Enerji Tasarruflu Servo Motorlar | İşletme maliyetlerini düşürür ve sürdürülebilirliği artırır |

Fully automated precision roll forming machines from Sunway Makine kadar üretim verimliliğini artırmak 40%!

Essential Maintenance Tips for Precision Roll Forming Machines

Uygun Bakım sağlar uzatılmış makine ömrü ve tutarlı üretim kalitesi.

Maintenance Checklist

| Görev | Frekans | Amaç |

|---|---|---|

| Makaraları ve Yatakları Yağlayın | Haftalık | Aşınma ve yıpranmayı önler |

| Makara Hizalamasını Kontrol Edin | Aylık | Doğru profil üretimini sağlar |

| Kesme Mekanizmasını Kontrol Edin | Üç Aylık | Hatalı kesimleri ve yanlış hizalamayı önler |

| Temiz Makine Bileşenleri | Günlük | Performansı etkileyebilecek toz ve kalıntıları temizler |

| Yazılım Güncelleme ve Kalibrasyon | Altı ayda bir | Otomasyon fonksiyonlarının optimize edilmesini sağlar |

Profesyonel ipucu: Planlı bakım şunları yapabilir 50% ile makine ömrünü uzatın ve 70% ile arızaları azaltın.

SSS

1. How accurate is a precision roll forming machine?

Most precision roll forming machines achieve ±0,1 mm toleranslarMalzeme ve profil karmaşıklığına bağlı olarak.

2. What industries use precision roll forming machines?

Aşağıdakiler gibi sektörler aerospace, medical equipment, electronics, and high-end automotive rely on precision roll forming for customized, high-spec components.

3. How much does a precision roll forming machine cost?

Fiyat aralıkları 50,000forbasicmodels∗∗to∗∗50,000 for basic models** to **50,000forbasicmodels∗∗to∗∗1,000,000 for fully automated, AI-driven machines.

4. Can precision roll forming machines handle stainless steel?

Evet! Çoğu yüksek hassasiyetli makine şunları işleyebilir paslanmaz çelik, titanyum ve diğer yüksek mukavemetli alaşımlar.

5. Where can I buy a high-quality precision roll forming machine?

İçin custom-built, high-speed precision roll forming machines, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Son Düşünceler

Yatırım yapmak hassas rulo şekillendirme makinesi için gereklidir. Ultra yüksek hassasiyet, minimum atık ve yüksek hızlı üretim gerektiren endüstriler. İster bir standart veya tam otomatik sistemseçerek güveni̇li̇r üreti̇ci̇ sağlar uzun vadeli güvenilirlik ve karlılık.

WUXI SUNWAY MAKİNA A.Ş., LTD bir lider küresel üretici . custom-built precision roll forming machines, teklif ileri teknoloji, uzman desteği ve rekabetçi fiyatlandırma.

İstiyorum custom precision roll forming machine? Bugün bize ulaşın!