Kablo Kanalı Rulo Şekillendirme Makinelerine Genel Bakış

A kablo kanalı rulo şekillendirme makinesi üretmek için tasarlanmış özel bir ekipmandır. metal cable trays, which are used for supporting and organizing electrical cables in buildings, industrial plants, and data centers. These machines produce perforated, ladder-type, and solid-bottom cable trays ile high efficiency and precision.

Kablo Kanalı Rulo Şekillendirme Makinelerinin Temel Özellikleri

✅ Tam otomatik çalışma – PLC-controlled for precision and high efficiency.

✅ Özelleştirilebilir profiller - Üretir perforated, ladder, and solid-bottom cable trays.

✅ Yüksek hızlı üretim - Üretim kabiliyeti 10-30 meters per minute.

✅ Dayanıklı yapı - Kullanım Alanları hardened steel rollers and hydraulic cutting systems.

✅ Integrated punching system - Etkinleştirir hole perforation for easy cable management.

Bu kılavuzda şunları ele alacağız:

✅ Types of cable tray roll forming machines

✅ Rulo şekillendirme prosesi nasıl çalışır?

✅ Best materials for cable trays

✅ Maliyet analizi ve fiyatlandırma kılavuzu

✅ En iyi üreticiler ve Sunway Machine'in neden güvenilir bir seçim olduğu

Hadi dalalım!

Kablo Kanalı Rulo Şekillendirme Makinesi Çeşitleri

Different kablo kanalı rulo şekillendirme makineleri cater to various production needs and automation levels.

1. Perforated Cable Tray Roll Forming Machine

- Üretir perforated trays ile pre-punched holes for ventilation.

- Şunlar için ideal high-heat environments where airflow is necessary.

2. Ladder Cable Tray Roll Forming Machine

- Yaratır ladder-type trays ile rung supports for heavy cables.

- İçin en iyisi industrial and power plant applications.

3. Solid-Bottom Cable Tray Roll Forming Machine

- İmalat solid-bottom trays için complete cable protection.

- Şunlar için uygundur data centers and hazardous environments.

4. Fully Automatic Cable Tray Roll Forming Machine

- Özellikler CNC otomasyonu için quick profile changes.

- Şunlar için ideal large-scale, high-efficiency production.

Sunway Makine sağlar customized cable tray roll forming machines ile geli̇şmi̇ş otomasyon özelli̇kleri̇.

How Cable Tray Roll Forming Works

Bu rulo şekillendirme işlemi for cable trays involves gradually shaping a flat metal sheet into a high-strength cable support structure.

Step-by-Step Cable Tray Roll Forming Process

| Adım | Açıklama |

|---|---|

| 1. Çözme | Metal bobin üzerine yerleştirilir decoiler, feeding material into the machine. |

| 2. Tesviye ve Besleme | Bu sayfa düzeltilmiş ve yönlendirilmiş şekillendirme istasyonlarına. |

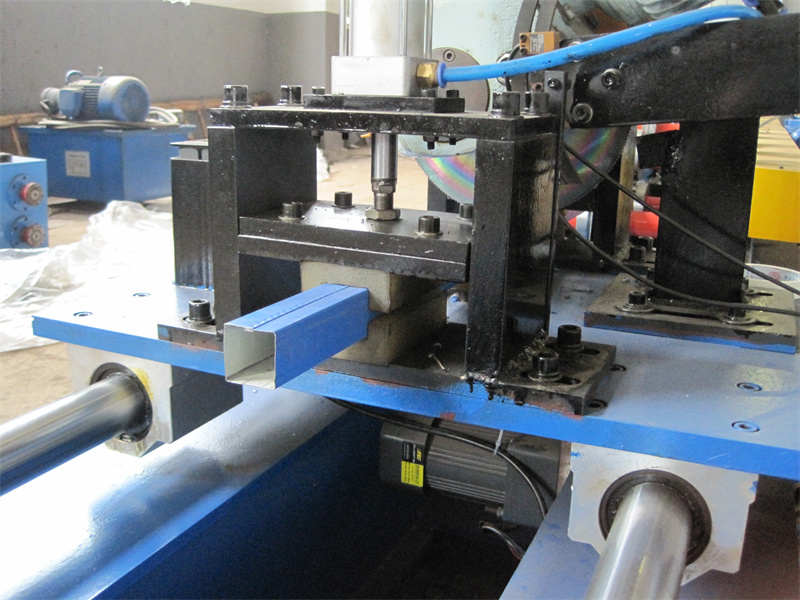

| 3. Delme ve Kesme | Hidrolik sistem şunları gerçekleştirir hole punching for cable management. |

| 4. Rulo Şekillendirme | Levha aşağıdakilerden geçer çoklu silindir istasyonları, forming the cable tray shape. |

| 5. Final Cutting & Stacking | The formed cable tray is gerekli uzunlukta kesilmiş and stacked for shipment. |

Profesyonel ipucu: A fully automated cable tray roll forming machine sağlar high precision, minimal waste, and faster production speeds.

Best Materials for Cable Trays

Seçmek doğru malzeme sağlar strength, corrosion resistance, and durability.

Comparison of Materials for Cable Trays

| Malzeme | Özellikler | İçin En İyisi |

|---|---|---|

| Galvanizli Çelik (GI) | Corrosion-resistant, cost-effective | Standard electrical installations |

| Paslanmaz Çelik (SS) | High strength, rust-proof | Industrial and outdoor applications |

| Alüminyum Alaşım | Hafif, korozyona dayanıklı | Data centers & IT infrastructure |

| Toz Boya Çelik | Aesthetic finish, durable | Ticari binalar |

Sunway Makine ile uyumlu rulo şekillendirme makineleri üretmektedir. all major cable tray materials.

Cable Tray Roll Forming Machine Price Guide

Maliyeti kablo kanalı rulo şekillendirme makinesi gibi faktörlere bağlıdır otomasyon seviyesi, üretim hızı ve profil aralığı.

Estimated Price Ranges for Cable Tray Roll Forming Machines

| Makine Tipi | Fiyat Aralığı (USD) | Özellikler |

|---|---|---|

| Manuel Makine | 20,000–20,000 – 20,000–50,000 | Manuel ayarlamalar, düşük hızlı üretim |

| Yarı Otomatik Makine | 50,000-50,000 - 50,000-100,000 | PLC kontrollü, manuel profil ayarlamaları gerektirir |

| Tam Otomatik Makine | 100,000–100,000 – 100,000–250,000 | CNC kontrollü, hızlı profil değiştirme |

| High-Speed Machine | 250,000–250,000 – 250,000–500,000 | Advanced automation, high-speed production |

Özel bir teklif mi arıyorsunuz? Sunway Machine ile bugün iletişime geçin!

Top Cable Tray Roll Forming Machine Manufacturers

Bir seçim güveni̇li̇r üreti̇ci̇ sağlar yüksek kaliteli makineler, uzun vadeli destek ve küresel servis.

Comparison of Leading Cable Tray Roll Forming Machine Manufacturers

| Üretici firma | Ülke | Uzmanlık | Temel Özellikler |

|---|---|---|---|

| WUXI SUNWAY MAKİNA A.Ş., LTD | Çin | Kablo kanalı rulo şekillendirme makineleri | Custom designs, high-speed automation, IoT-enabled machines |

| Dreistern GmbH | Almanya | Precision metal forming | CNC kontrollü makineler, güçlü Ar-Ge |

| Samco Makine | Kanada | İnşaat için rulo şekillendirme | Özel mühendislik, otomasyon |

| Bradbury Grup | ABD | Ağır hizmet tipi rulo şekillendirme sistemleri | Sağlam makineler, otomasyon odaklı |

Karar: Eğer bir cost-effective, high-speed cable tray roll forming machine, Sunway Makine bir küresel alicilar i̇çi̇n en i̇yi̇ terci̇h.

Common Problems & Solutions in Cable Tray Roll Forming Machines

Even the most advanced cable tray roll forming machines can encounter operational challenges, such as roller misalignment, material deformation, and inaccurate perforation. Bu sorunların ele alınması proaktif olarak sağlar smooth production and high-quality cable trays.

Sorun Giderme Kılavuzu

| Sorun | Olası Neden | Çözüm |

|---|---|---|

| Distorted or Uneven Cable Trays | Roller misalignment, improper pressure settings | Silindir hizalamasını ayarlayın ve eşit basınç dağılımı sağlayın |

| Şekillendirme Sırasında Malzeme Kayması | Gevşek besleyici silindirleri, yanlış gerginlik ayarları | Besleyici silindirlerini sıkın ve malzeme gerginliğini ayarlayın |

| Inaccurate Hole Punching | Faulty hydraulic system, misaligned punching dies | Inspect hydraulic pressure and realign punching dies |

| Aşırı Makine Titreşimi | Loose bolts, unstable machine foundation | Makine bileşenlerini sabitleyin ve sağlam bir kurulum sağlayın |

| Kesim Hatası | Dull cutting blades, misaligned cutters | Körelmiş bıçakları değiştirin ve kesicileri düzgün hizalayın |

Profesyonel ipucu: Düzenli roller realignment and servo-driven adjustments geliştirebilir cable tray accuracy by 30%.

Future Trends in Cable Tray Roll Forming Machines

Bu imalat sanayi is evolving, and kablo kanalı rulo şekillendirme makineleri are integrating Yapay zeka, IoT ve otomasyon to enhance efficiency, precision, and sustainability.

Key Innovations

1. AI-Based Quality Control

- Yapay zeka destekli sensörler kusurları gerçek zamanlı olarak tespit edermalzeme israfını azaltır.

- Geliştirir ürün doğruluğu ve ret oranlarını en aza indirir.

2. IoT & Akıllı Fabrika Entegrasyonu

- Makineler artık şu özelliklere sahip bulut tabanlı izleme, izin vermek gerçek zamanlı teşhis ve kestirimci bakım.

- Geliştirir üretim takibi ve operasyonel verimlilik.

3. Servo Tahrikli Rulo Şekillendirme Teknolojisi

- Geliştirir hız kontrolü, hassasiyet ve enerji verimliliği.

- Azaltır mekanik bileşenlerde aşınma ve yıpranma, increasing lifespan.

4. Tam Otomatik Profil Ayarlamaları

- Ortadan kaldırır manuel ayarlamalar when switching between different cable tray profiles.

- CNC kontrollü otomatik profil değişiklikleri arıza süresini azaltır ve verimliliği artırır.

Upgrading to AI-powered cable tray roll forming machines can increase production efficiency by up to 50%!

Roll Forming vs. Press Braking for Cable Tray Production

Manufacturers must evaluate üretim hızı, malzeme israfı ve maliyet verimliliği when choosing between rulo şekillendirme ve pres frenleme for cable tray production.

Comparison Between Roll Forming and Press Braking for Cable Trays

| Özellik | Rulo Şekillendirme | Basın Freni |

|---|---|---|

| Üretim Hızı | Uzun, sürekli profiller için daha hızlı | Özel bükümler için daha yavaş |

| Malzeme Atıkları | Minimum atık | Daha yüksek malzeme hurdası |

| Kalıp Maliyetleri | Daha yüksek ilk yatırım, daha düşük uzun vadeli maliyet | Daha düşük ön maliyet, daha yüksek işletme maliyeti |

| İçin En İyisi | Yüksek hacimli, endüstriyel üretim | Özel, düşük hacimli metal bileşenler |

Karar: Eğer ihtiyacınız varsa Minimum atıkla yüksek hızlı, sürekli üretim, cable tray roll forming is the better choice.

Automation in Cable Tray Roll Forming Machines

Otomasyon devrim yaratan üretim süreci, rulo şekillendirme makinelerinin yapımı daha akıllı, daha hızlı ve daha verimli.

Temel Avantajlar

| Özellik | Fayda |

|---|---|

| PLC & CNC Kontrol Sistemleri | Hassas ölçümler sağlar ve insan hatasını en aza indirir |

| Yapay Zeka Tabanlı Hata Tespiti | Sorunları gerçek zamanlı olarak tespit ederek malzeme israfını azaltır |

| IoT & Uzaktan İzleme | Operatörlerin makine performansını her yerden takip etmesini sağlar |

| Otomatik Profil Değiştirme | Profiller arasında geçiş yaparken kesinti süresini azaltır |

| Enerji Tasarruflu Servo Motorlar | İşletme maliyetlerini düşürür ve sürdürülebilirliği artırır |

Fully automated cable tray roll forming machines from Sunway Makine kadar üretim verimliliğini artırmak 40%!

Essential Maintenance Tips for Cable Tray Roll Forming Machines

Uygun Bakım sağlar longer machine lifespan ve tutarlı üretim kalitesi.

Maintenance Checklist

| Görev | Frekans | Amaç |

|---|---|---|

| Makaraları ve Yatakları Yağlayın | Haftalık | Aşınma ve yıpranmayı önler |

| Makara Hizalamasını Kontrol Edin | Aylık | Doğru profil üretimini sağlar |

| Kesme Mekanizmasını Kontrol Edin | Üç Aylık | Hatalı kesimleri ve yanlış hizalamayı önler |

| Temiz Makine Bileşenleri | Günlük | Performansı etkileyebilecek toz ve kalıntıları temizler |

| Yazılım Güncelleme ve Kalibrasyon | Altı ayda bir | Otomasyon fonksiyonlarının optimize edilmesini sağlar |

Profesyonel ipucu: Planlı bakım şunları yapabilir 50% ile makine ömrünü uzatın ve 70% ile arızaları azaltın.

SSS

1. How fast can a cable tray roll forming machine produce trays?

Yüksek hızlı modeller aşağıdakilere kadar üretebilir Dakikada 30 metreprofile bağlı olarak.

2. What cable tray profiles can be produced?

Çoğu makine şunları üretebilir perforated, ladder, and solid-bottom cable trays.

3. How much does a cable tray roll forming machine cost?

Fiyat aralıkları 20,000forbasicmodels∗∗to∗∗20,000 for basic models** to **20,000forbasicmodels∗∗to∗∗500,000 for fully automated systems.

4. What materials can be used in cable tray roll forming machines?

Yaygın malzemeler şunları içerir galvanized steel, stainless steel, aluminum, and powder-coated steel.

5. Where can I buy a high-quality cable tray roll forming machine?

İçin custom-built, high-speed cable tray roll forming machines, ziyaret edin WUXI SUNWAY MAKİNA A.Ş., LTD.

Son Düşünceler

Yatırım yapmak kablo kanalı rulo şekillendirme makinesi için gereklidir. efficient, high-quality cable tray production. İster bir standart veya tam otomatik sistemseçerek güveni̇li̇r üreti̇ci̇ sağlar uzun vadeli güvenilirlik ve karlılık.

WUXI SUNWAY MAKİNA A.Ş., LTD bir lider küresel üretici . custom-built cable tray roll forming machines, teklif ileri teknoloji, uzman desteği ve rekabetçi fiyatlandırma.

İstiyorum custom cable tray roll forming machine? Bugün bize ulaşın!