In the world of heating, ventilation, and air conditioning (HVAC), precision and efficiency are non-negotiable. From duct systems to structural supports, the components of HVAC systems must meet stringent quality standards while ensuring cost-effective manufacturing. Enter HVAC Ekipmanları Rulo Şekillendirme Makineleri—the game-changer in modern HVAC production.

These machines are designed to manufacture HVAC components with unmatched accuracy, speed, and consistency. Whether you’re a manufacturer looking to scale production or a contractor seeking high-quality HVAC parts, roll-forming technology offers a solution that’s efficient, sustainable, and customizable.

Bu makalede, şunları keşfedeceğiz what HVAC roll-forming machines are, their applications, pricing, automation capabilities, environmental benefits, and why Wuxi Sunway Machinery is a global leader in this space. Let’s dive into how these machines are shaping the future of HVAC manufacturing.

What Are HVAC Equipment Roll Forming Machines?

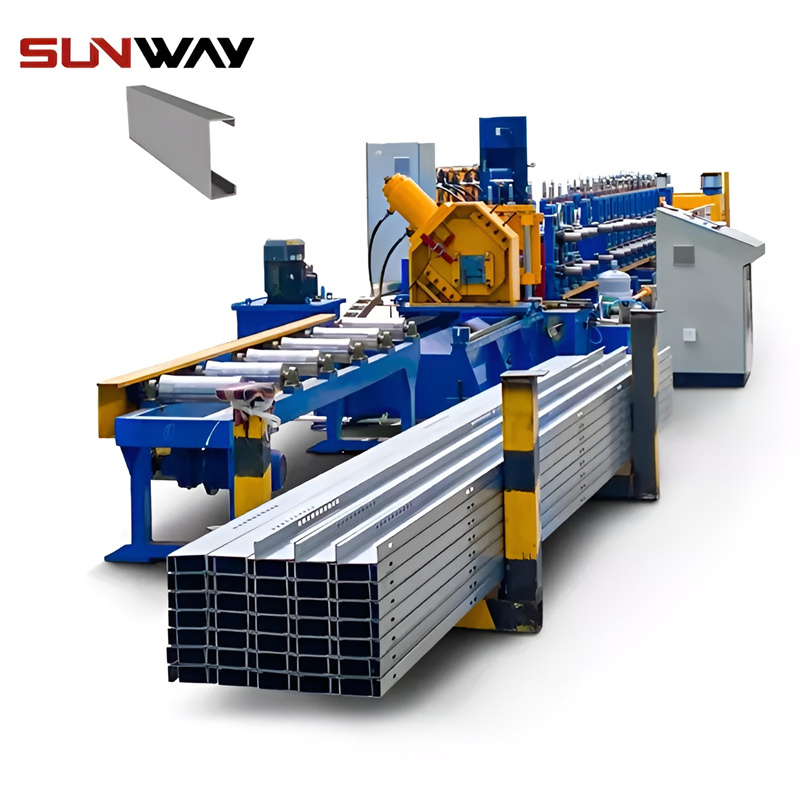

HVAC Ekipmanları Rulo Şekillendirme Makineleri are industrial systems designed to shape metal sheets or coils into specific profiles used in HVAC systems. These machines transform raw materials into components like duct panels, support channels, and frames seamlessly, ensuring precision and durability.

Temel Özellikler

- Yüksek Hassasiyet: Produces components with exact dimensions, ensuring compatibility across HVAC systems.

- Malzeme Çok Yönlülüğü: Galvanizli çelik, alüminyum ve paslanmaz çelik gibi malzemeleri işler.

- Özel Profiller: Supports diverse designs for different HVAC applications.

- Yüksek Hızlı Üretim: Ensures large-scale manufacturing for HVAC projects of all sizes.

- Çevre Dostu Faaliyetler: Malzeme israfını ve enerji tüketimini en aza indirir.

Applications of HVAC Equipment Roll Forming Machines

HVAC systems are integral to residential, commercial, and industrial buildings, and the components manufactured by roll-forming machines are essential to their functionality. Here are the primary applications:

1. Duct Panels

- Kullanım Örneği: Producing duct panels for ventilation systems in residential and commercial buildings.

- Neden gerekli? Ensures effective airflow while maintaining structural integrity and durability.

2. Structural Support Channels

- Kullanım Örneği: Manufacturing support channels for mounting HVAC equipment and duct systems.

- Neden Yararlı? Provides a stable and secure framework for HVAC installations.

3. HVAC Unit Frames

- Kullanım Örneği: Creating frames for air handling units, condensers, and heat exchangers.

- Neden gerekli? Ensures proper housing and protection of critical HVAC components.

4. Insulated Panels

- Kullanım Örneği: Producing insulated panels for climate-controlled HVAC systems.

- Neden eşsiz: Improves energy efficiency and thermal insulation in temperature-sensitive environments.

5. Custom Profiles for Specialized HVAC Systems

- Kullanım Örneği: Crafting unique profiles for custom HVAC projects, such as industrial cooling systems or smart home HVAC units.

- Neden önemli? Combines functionality with tailored designs to meet specific project requirements.

Why HVAC Equipment Roll Forming Machines Are Indispensable

The growing demand for efficient, durable, and high-quality HVAC systems has made HVAC Ekipmanları Rulo Şekillendirme Makineleri a necessity for manufacturers. Here’s why:

1. Customization for Diverse Needs

- Neden Kritik? Supports the production of components tailored to different HVAC applications, ensuring compatibility and flexibility.

2. High Production Capacity

- Neden Yararlı? Enables manufacturers to meet the increasing demand for HVAC components in residential, commercial, and industrial markets.

3. Uygun Maliyetli Üretim

- Neden pratik: Reduces material waste, labor costs, and production time, making high-quality HVAC components more affordable.

4. Dayanıklılık ve Güvenilirlik

- Neden önemli? Produces components that can withstand environmental conditions and prolonged use, ensuring long-lasting HVAC systems.

5. Çevre Dostu Uygulamalar

- Neden önemli? Makineler, enerji tüketimini en aza indirgemek ve geri dönüştürülebilir malzemelerin kullanımını desteklemek üzere tasarlanmıştır ve küresel sürdürülebilirlik hedefleriyle uyumludur.

Key Features of Wuxi Sunway HVAC Equipment Roll Forming Machines

Wuxi Sunway Makine is a trusted name in the roll-forming industry, offering machines that are specifically designed for HVAC applications. Here’s what makes their machines stand out:

1. Gelişmiş Malzeme Taşıma

- Desteklenen Materyaller:

- Galvanizli Çelik

- Alüminyum

- Paslanmaz Çelik

- Neden Yararlı? Ensures compatibility with lightweight and durable materials for HVAC systems.

2. Hassas Mühendislik

- Performans: Maintains tolerances as low as ±0.02mm, ensuring seamless fitting and performance.

- Neden önemli? Guarantees high-quality outputs that meet stringent HVAC system standards.

3. Modüler Kalıp Sistemleri

- Ne Sunuyor? Interchangeable tooling for producing multiple HVAC profiles on a single machine.

- Neden Çok Yönlü? Ek ekipmana ihtiyaç duymadan çeşitli gereksinimleri destekler.

4. Entegre Kesme, Delme ve Çentik Açma

- Ne İçerir? Rulo şekillendirme işlemi sırasında malzemeleri kesmek, delmek ve çentiklemek için yerleşik sistemler.

- Neden Verimli: Üretim süresini kısaltır ve kuruluma hazır bileşenler sağlar.

5. IoT ve Otomasyon Entegrasyonu

- Ne Sağlar: IoT sistemlerini kullanarak gerçek zamanlı izleme, otomatik ayarlamalar ve kestirimci bakım.

- Neden Devrimci?

- Üretim verimliliğini artırır.

- Arıza süresini ve işletme maliyetlerini en aza indirir.

6. Çevre Dostu Tasarım

- Ne İçerir? Enerji tasarruflu motorlar, optimize edilmiş iş akışları ve atık azaltma sistemleri.

- Neden Sürdürülebilir? Küresel sürdürülebilirlik hedefleriyle uyumludur ve üretimin çevresel etkisini azaltır.

Pricing of HVAC Equipment Roll Forming Machines

Maliyeti HVAC Equipment Roll Forming Machine özelliklerine, kapasitesine ve özelleştirme seçeneklerine bağlıdır. Aşağıda 2025 yılı için genel bir fiyatlandırma kılavuzu bulunmaktadır:

| Makine Tipi | Yetenekler | Fiyat Aralığı (USD) |

|---|---|---|

| Standart Makineler | Basic duct and channel profiles | 100.000–100.000–100.000–300.000 |

| Gelişmiş Makineler | High-speed, integrated cutting and punching | 300,000–300,000–300,000–800,000 |

| Tamamen Özelleştirilebilir Makineler | IoT-enabled, modular tooling, eco-friendly | 800,000–800,000–800,000–2,000,000 |

Detaylı fiyatlandırma ve finansman seçenekleri için iletişime geçin Wuxi Sunway Makine.

Automation in HVAC Equipment Roll Forming Machines

Automation is a driving force in the HVAC manufacturing industry, and rulo şekillendirme makineleri are no exception. By incorporating advanced automation technologies, these machines are redefining productivity and quality.

1. Gerçek Zamanlı Üretim İzleme

- Ne izler: Üretim hızı, kusur oranları ve malzeme kullanımı gibi temel ölçütler.

- Neden değerli? Helps manufacturers optimize workflows and reduce inefficiencies.

2. Kestirimci Bakım

- Ne Sağlar: IoT sensörleri makine bileşenlerini izler ve bakım ihtiyaçlarını tahmin eder.

- Neden Devrimci?

- Planlanmamış kesinti sürelerini azaltır.

- Makinenin kullanım ömrünü uzatır.

3. Otomatik Ayarlamalar

- Ne Sunuyor? Üretilen malzeme veya profile göre silindirleri, kesicileri ve zımbaları otomatik olarak ayarlar.

- Neden Verimli:

- Kurulum süresini kısaltır.

- Üretim çalışmaları boyunca tutarlı kalite sağlar.

4. Yapay Zeka Destekli Kalite Kontrol

- Ne Tespit Ediyor: Identifies defects in real-time and makes necessary adjustments.

- Neden etkili?

- Atıkları en aza indirir.

- Kusursuz ürünlerle müşteri memnuniyetini artırır.

5. Uzaktan Kumanda ve Diyagnostik

- Ne İçerir? Cloud-based systems for remote monitoring and troubleshooting.

- Neden Kullanışlı: Allows operators to oversee production from anywhere.

Environmental Benefits of HVAC Equipment Roll Forming Machines

Sustainability is a crucial consideration in modern manufacturing, and HVAC Ekipmanları Rulo Şekillendirme Makineleri çevre dostu uygulamaları desteklemek üzere tasarlanmıştır.

1. Malzeme Atıklarını En Aza İndirmek

- Bu nasıl başarıldı? Precision engineering ensures efficient use of raw materials.

- Etki: Reduces scrap and promotes sustainable resource use.

2. Enerji Verimliliği

- Nasıl Çalışır? Machines are equipped with energy-efficient motors and optimized workflows to lower power consumption.

- Etki: Significantly reduces the carbon footprint of HVAC component production.

3. Geri Dönüştürülebilir Malzeme Kullanımı

- Neyi Destekler: Alüminyum ve galvanizli çelik gibi geri dönüştürülebilir malzemeleri işler.

- Etki: Encourages a circular economy and reduces environmental impact.

4. Uzun Ömürlü Çıkışlar

- Neden önemli? Produces durable components that minimize the need for frequent replacements.

- Etki: Supports sustainable HVAC systems by extending product lifespans.

FAQs About HVAC Equipment Roll Forming Machines

| Soru | Cevap |

|---|---|

| Bu makineler hangi malzemeleri işleyebilir? | Galvanizli çelik, alüminyum ve paslanmaz çelik. |

| Üretim hızı nedir? | Kadar Dakikada 50–120 metreMalzeme ve profil karmaşıklığına bağlı olarak. |

| Bu makineler çevre dostu mu? | Evet, enerji tasarruflu motorlar içerirler ve malzeme israfını en aza indirirler. |

| Bu makineler özel tasarımları işleyebilir mi? | Absolutely! Modular tooling supports bespoke profiles for diverse HVAC applications. |

| Bu makineler için fiyat aralığı nedir? | Fiyatlar arasında değişir 100.000 ila 100.000 ila 100.000 ila 2.000.000özelliklerine ve özelleştirmeye dayalı olarak. |

| Bu makineler IoT sistemleri ile entegre oluyor mu? | Evet, IoT özellikli özellikler gerçek zamanlı izleme ve kestirimci bakım sağlar. |

Real-World Success Stories: HVAC Equipment Roll Forming Machines in Action

Çok yönlülüğü ve verimliliği HVAC Ekipmanları Rulo Şekillendirme Makineleri have allowed manufacturers across the globe to revolutionize their production processes. Here are some inspiring success stories that highlight the capabilities of these machines.

1. Large-Scale Commercial HVAC Systems in North America

Müşteri: A leading HVAC contractor specializing in large commercial projects.

Meydan okuma: The contractor needed to produce a high volume of duct panels and support channels for a high-rise office complex.

Çözüm: Wuxi Sunway Machinery provided a high-speed roll-forming machine capable of manufacturing duct panels and channels with integrated punching and notching features.

Sonuç:

- Increased production capacity by 35%, meeting project deadlines with ease.

- Reduced material waste by 18% through precision engineering.

- Enhanced the client’s reputation for delivering high-quality HVAC systems ahead of schedule.

2. Energy-Efficient HVAC Systems for Green Buildings in Europe

Müşteri: A manufacturer focused on sustainable HVAC solutions for eco-friendly buildings.

Meydan okuma: The company needed insulated panels for climate-controlled systems used in green-certified buildings.

Çözüm: Wuxi Sunway delivered a machine designed to produce insulated frames and panels with seamless joints for optimal thermal performance.

Sonuç:

- Enabled the production of energy-efficient components that met stringent EU energy standards.

- Contributed to a 20% improvement in the overall energy efficiency of the HVAC systems.

- Helped the client expand their market share in the green building sector.

3. Customized HVAC Components for Industrial Cooling in Asia

Müşteri: An industrial cooling solutions provider serving factories and data centers.

Meydan okuma: The company required custom-shaped duct panels and frames to fit non-standard HVAC layouts.

Çözüm: Wuxi Sunway supplied a roll-forming machine with modular tooling for creating bespoke profiles.

Sonuç:

- Produced custom HVAC components with 100% accuracy.

- Reduced the cost of production by 25% compared to traditional methods.

- Strengthened the company’s ability to deliver tailored solutions for unique industrial needs.

4. Lightweight HVAC Units for Residential Projects in South America

Müşteri: A developer building affordable housing units with compact HVAC systems.

Meydan okuma: The developer needed lightweight yet durable HVAC frames to fit small residential spaces.

Çözüm: Wuxi Sunway’s roll-forming machine processed aluminum and galvanized steel to create compact, lightweight components.

Sonuç:

- Reduced the weight of HVAC units by 15%, making them easier to install.

- Enhanced affordability by cutting production costs without compromising on quality.

- Enabled the developer to deliver housing projects on time and within budget.

Troubleshooting Common Issues in HVAC Equipment Roll Forming Machines

Bir yandan HVAC Ekipmanları Rulo Şekillendirme Makineleri are highly efficient, occasional issues may arise during production. Here’s a detailed guide to identifying and resolving potential problems.

1. Düzensiz Profiller

- Semptomlar: Duct panels or frames have inconsistent dimensions or warped edges.

- Olası Sebepler:

- Rollers are misaligned due to wear or improper setup.

- Material thickness varies beyond acceptable limits.

- Çözüm:

- Regularly inspect and recalibrate rollers to ensure proper alignment.

- Tutarsızlıkları önlemek için yüksek kaliteli, tek tip hammaddeler kullanın.

2. Malzeme Kayması

- Semptomlar: Material slips during the forming process, leading to incomplete or defective profiles.

- Olası Sebepler:

- Insufficient tension in the material feeder.

- Worn-out rollers or guides.

- Çözüm:

- Adjust feeder tension to match the material specifications.

- Replace worn rollers and guides to maintain proper grip.

3. Excessive Wear on Tools

- Semptomlar: Increased frequency of tool replacements or reduced product quality.

- Olası Sebepler:

- Low-quality materials causing excessive wear on cutting and punching tools.

- Hareketli parçaların yanlış yağlanması.

- Çözüm:

- Use high-grade materials to reduce tool wear.

- Implement a regular maintenance schedule to lubricate and clean components.

4. Makine Aşırı Isınması

- Semptomlar: The machine shuts down unexpectedly or operates less efficiently.

- Olası Sebepler:

- Aşırı yüklenmiş motorlar veya yüksek hızlarda uzun süreli çalışma.

- Yetersiz soğutma mekanizmaları.

- Çözüm:

- Makineyi önerilen kapasitesi dahilinde çalıştırın.

- Ensure that the cooling system is functioning correctly and clean any blocked vents.

5. Yazılım Hataları

- Semptomlar: The control system becomes unresponsive, or automated features fail to operate.

- Olası Sebepler:

- Eski veya bozuk yazılım.

- Kontrol panelindeki hatalı bağlantılar.

- Çözüm:

- Makinenin yazılımını en son sürüme güncelleyin.

- Tüm elektrik bağlantılarını kontrol edin ve sabitleyin.

Global Market Trends for HVAC Equipment Roll Forming Machines in 2025

The HVAC manufacturing industry is experiencing significant growth, and rulo şekillendirme makineleri are at the center of this expansion. Here are the key global trends shaping the market:

1. Surge in Urbanization

- Trend: Rapid urbanization is increasing the demand for HVAC systems in residential and commercial buildings.

- Etki: High-capacity roll-forming machines are essential to meet the growing production needs in urban areas.

2. Emphasis on Energy Efficiency

- Trend: Governments worldwide are enforcing stricter energy efficiency standards for buildings.

- Etki: Machines capable of producing insulated and energy-efficient HVAC components are in high demand.

3. Growth in Smart HVAC Systems

- Trend: The rise of smart buildings is driving demand for HVAC components compatible with IoT technology.

- Etki: Roll-forming machines with modular tooling for custom designs are gaining traction.

4. Expansion of Industrial Cooling

- Trend: Data centers and industrial facilities require advanced cooling systems to support high-performance operations.

- Etki: Machines designed for heavy-duty and custom-shaped HVAC components are crucial for this market.

5. Sürdürülebilirliğe Odaklanın

- Trend: Manufacturers are adopting eco-friendly practices to align with global sustainability goals.

- Etki: Energy-efficient and waste-reducing roll-forming machines are becoming the industry standard.

Additional Automation Capabilities in HVAC Equipment Roll Forming Machines

Automation continues to redefine the capabilities of HVAC Ekipmanları Rulo Şekillendirme Makineleri, making them smarter and more efficient than ever before. Here are some advanced automation features:

1. Uyarlanabilir Silindir Ayarı

- Ne işe yarıyor? Malzeme kalınlığına ve profil gereksinimlerine göre silindir konumlarını otomatik olarak ayarlar.

- Neden Yararlı? Manuel ayarlamaları ortadan kaldırarak, arıza süresini azaltır ve hassasiyeti artırır.

2. Advanced Defect Detection

- Ne İçerir? High-resolution cameras and AI algorithms to identify defects in real time.

- Neden etkili? Ensures only flawless components proceed to the assembly line, reducing waste.

3. Çoklu Malzeme İşleme

- Ne Sağlar: Seamlessly switches between different materials (e.g., steel, aluminum) within a single production run.

- Neden Devrimci? Enhances flexibility and reduces setup time for diverse production needs.

4. Bulut Tabanlı Analitik

- Ne izler: Üretim ölçümleri, makine performansı ve bakım programları.

- Neden Kullanışlı: Provides actionable insights to optimize operations and troubleshoot issues remotely.

Why Wuxi Sunway Machinery Remains the Industry Leader

Wuxi Sunway Makine sets the gold standard for roll-forming machines, particularly for HVAC applications. Here’s what makes them stand out:

- Küresel İtibar: Trusted by top manufacturers worldwide for delivering reliable and innovative machines.

- Özel Çözümler: Customizable machines designed to meet specific production needs and challenges.

- Sürdürülebilirlik Taahhüdü: Focuses on reducing energy consumption and material waste, aligning with global eco-friendly practices.

- Kapsamlı Destek: Offers exceptional pre- and post-sales support, including training, maintenance, and customization services.

- Kanıtlanmış Uzmanlık: Decades of experience in designing high-performance roll-forming machinery.

Interested in enhancing your HVAC manufacturing capabilities? Contact Wuxi Sunway Makine for a consultation.

FAQs About HVAC Equipment Roll Forming Machines

| Soru | Cevap |

|---|---|

| Bu makineler özel tasarımları işleyebilir mi? | Yes, Wuxi Sunway machines support modular tooling for bespoke HVAC profiles. |

| What types of materials are compatible? | Galvanizli çelik, alüminyum ve paslanmaz çelik. |

| Ortalama üretim hızı nedir? | Kadar Dakikada 50–120 metreMalzeme ve tasarım karmaşıklığına bağlı olarak. |

| Bu makineler çevre dostu mu? | Absolutely. They include energy-efficient motors and waste-minimizing features. |

| What’s the price range for these machines? | Fiyatlar arasında değişir 100.000 ila 100.000 ila 100.000 ila 2.000.000, özelliklere ve özelleştirmelere bağlı olarak. |

| Do these machines integrate with IoT? | Evet, IoT özellikli sistemler gerçek zamanlı izleme ve kestirimci bakım sağlar. |

Conclusion: A Smarter, More Efficient HVAC Industry

HVAC Ekipmanları Rulo Şekillendirme Makineleri are transforming the way manufacturers produce components for modern heating, ventilation, and air conditioning systems. With their precision, efficiency, and automation capabilities, these machines are paving the way for a smarter and more sustainable HVAC industry.

Ready to lead your industry with cutting-edge manufacturing technology? Partner with Wuxi Sunway Makine today and take your production line to the next level. Together, let’s build a better, more efficient future—one HVAC component at a time.