The defense industry operates under the most demanding conditions, requiring equipment that combines strength, durability, and reliability. From armored vehicle components to structural profiles for military bases, the production of high-performance parts is critical to national security. Enter Askeri Ekipman Rulo Şekillendirme Makineleri, the cutting-edge technology behind many of the durable and precise components used in military applications. These machines meet the strict standards of defense manufacturing, enabling the production of profiles that can withstand extreme environments and rigorous conditions.

Bu kılavuzda şunları keşfedeceğiz uygulamalar, özellikler, fiyatlandırma, pazar eğilimlerive nasıl Wuxi Sunway Makine is advancing roll-forming solutions for the defense industry. Whether you’re a defense contractor, a military engineer, or simply curious about the technology powering modern military infrastructure, this article has you covered.

What is a Military Equipment Roll Forming Machine?

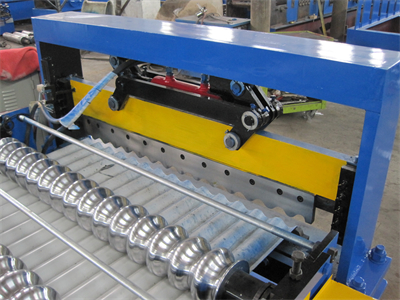

A Military Equipment Roll Forming Machine is a specialized piece of equipment designed to produce durable, high-performance profiles used in the construction of military vehicles, infrastructure, and equipment. These machines process flat metal sheets or coils—typically made from high-strength steel, ballistic-grade alloys, or corrosion-resistant materials—into precise shapes that meet the rigorous demands of military operations.

Üretilen Temel Bileşenler

- Armored Vehicle Panels: Profiles used in tanks, armored personnel carriers (APCs), and other military vehicles.

- Weapon Mounts: Components for mounting weapons on land, air, or naval platforms.

- Portable Shelter Frames: Lightweight yet durable profiles for military tents and field shelters.

- Base Infrastructure Profiles: Beams, channels, and supports for constructing military bases and outposts.

- Ammunition Storage Systems: Profiles for racks and containers used in secure storage of weapons and ammunition.

- Özel Profiller: Unique designs for specialized military applications, such as radar systems, UAV platforms, and communication towers.

These machines excel in automating the production of military components, ensuring precision, consistency, and compliance with stringent defense standards.

Applications of Military Equipment Roll Forming Machines

Çok yönlülüğü Askeri Ekipman Rulo Şekillendirme Makineleri makes them indispensable for a wide range of defense-related applications. Below are some key use cases:

1. Armored Vehicle Manufacturing

- Kullanım Örneği: Producing panels and structural profiles for tanks, APCs, and mine-resistant ambush-protected (MRAP) vehicles.

- Neden gerekli? Ensures the survivability of personnel and equipment in combat zones.

2. Weapon System Components

- Kullanım Örneği: Manufacturing mounts, brackets, and frames for weapon systems on vehicles, aircraft, and ships.

- Neden önemli? Provides the structural integrity needed for accurate and reliable weapon operation.

3. Portable Field Shelters

- Kullanım Örneği: Crafting lightweight frames for tents, shelters, and mobile command centers.

- Neden değerli? Enables rapid deployment and assembly in remote or hostile environments.

4. Military Base Construction

- Kullanım Örneği: Producing beams, columns, and supports for barracks, hangars, and other base infrastructure.

- Neden önemli? Enhances the durability and safety of military installations.

5. Ammunition and Weapon Storage

- Kullanım Örneği: Creating secure profiles for racks, lockers, and containers used to store weapons and ammunition.

- Neden Kritik? Prevents damage and ensures safe handling and transport of sensitive materials.

6. Specialized Equipment Platforms

- Kullanım Örneği: Manufacturing profiles for radar systems, UAV launch platforms, and communication towers.

- Neden Yararlı? Supports advanced military technologies and enhances operational capabilities.

Key Features of Wuxi Sunway Military Equipment Roll Forming Machines

Wuxi Sunway Makine, a global leader in roll-forming technology, offers machines tailored to the unique demands of the defense sector. Here are the standout features that make their machines ideal for military manufacturing:

1. Yüksek Mukavemetli Malzeme İşleme

- Desteklenen Materyaller:

- Balistik Sınıf Çelik

- Alüminyum Alaşımları

- Corrosion-Resistant Metals

- Titanyum

- Neden önemli? Ensures the production of durable components capable of withstanding extreme conditions.

2. Hassasiyet ve Tutarlılık

- Performans: Dimensional tolerances as low as ±0.05mm, ensuring uniformity in critical applications.

- Neden Kritik? Reduces assembly errors and ensures compatibility with other equipment.

3. Customizable Tooling for Specialized Designs

- Ne Sağlar: Modular tooling systems for creating unique profiles tailored to military specifications.

- Neden gerekli? Supports the production of bespoke components for specialized defense applications.

4. Entegre Kesme ve Delme Sistemleri

- Ne İçerir? Systems for precision cutting, hole punching, and perforation during production.

- Neden değerli? Montajı basitleştirir ve son üretim süreçlerini azaltır.

5. Yüksek Hızlı Üretim

- Performans: Şu kadar üretim kapasitesine sahiptir 20–100 meters of profiles per minuteMalzeme ve karmaşıklığa bağlı olarak.

- Neden Yararlı? Meets the high-volume demands of large-scale defense projects.

6. IoT ve Otomasyon Entegrasyonu

- Ne Sağlar: IoT sistemlerini kullanarak gerçek zamanlı izleme, otomatik ayarlamalar ve kestirimci bakım.

- Neden Oyunu Değiştiriyor?

- Üretim verimliliğini artırır.

- Arıza süresini ve bakım maliyetlerini azaltır.

- Sürekli iyileştirme için eyleme geçirilebilir içgörüler sağlar.

7. Enhanced Surface Treatments

- Özellik: Machines designed to handle coatings like anti-corrosion, anti-rust, and reflective finishes.

- Neden önemli? Extends the lifespan of components exposed to harsh environments.

Production Workflow of a Military Equipment Roll Forming Machine

The manufacturing process for military components is optimized for durability, precision, and efficiency. Below is an overview of the typical workflow:

1. Malzeme Yükleme

- Sheets or coils of ballistic-grade materials are loaded onto a decoilerBöylece sürekli bir tedarik sağlanır.

2. Düzeltme ve Tesviye

- A leveling unit ensures the material is flat and free of defects before roll forming begins.

3. Rulo Şekillendirme

- Malzeme, istenen profile dönüştürmek için kademeli olarak şekillendiren bir dizi makaradan geçer ve sıkı toleransları korur.

4. Delme ve Kesme

- Integrated systems add precision holes for fasteners or connectors and cut the profiles to custom lengths.

5. Kaplama Uygulaması

- Optional systems apply protective coatings, such as anti-corrosion or ballistic finishes, during or after production.

6. Kalite Denetimi

- Finished profiles are inspected for dimensional accuracy, strength, and compliance with military standards.

7. Paketleme ve Teslimat

- Completed components are bundled, labeled, and prepared for secure transportation to defense contractors or military facilities.

Pricing of Military Equipment Roll Forming Machines

Maliyeti Military Equipment Roll Forming Machine depends on its features, material compatibility, and customization options. Below is a general pricing guide for 2025:

| Makine Tipi | Yetenekler | Fiyat Aralığı (USD) |

|---|---|---|

| Standart Makineler | Basic profile production for defense applications | 500,000–500,000–500,000–1,200,000 |

| Gelişmiş Makineler | Yüksek hızlı, entegre kesme ve delme sistemleri | 1,200,000–1,200,000–1,200,000–2,800,000 |

| Tamamen Özelleştirilebilir Makineler | IoT, modüler takım ve gelişmiş malzeme taşıma | 2,800,000–2,800,000–2,800,000–5,000,000 |

Detaylı fiyatlandırma ve finansman seçenekleri için iletişime geçin Wuxi Sunway Makine.

Market Trends for Military Equipment Roll Forming Machines in 2025

The defense industry is rapidly evolving, driven by technological advancements and geopolitical factors. Here are the trends shaping the market:

1. Advanced Materials

- Trend: Increasing use of ballistic-grade metals and lightweight alloys in military equipment.

- Makine Rolü:

- Enable precise forming of advanced materials.

- Hassas mühendislik sayesinde malzeme israfını azaltır.

2. Autonomous Military Systems

- 4. Overlanding ve Araç Kampçılığı Rising demand for UAVs, drones, and autonomous vehicles in defense operations.

- Makine Katkısı:

- Produce lightweight and durable profiles for autonomous platforms.

- Support innovative designs for advanced military technologies.

3. Rapid Deployment Solutions

- Odak noktası: Development of portable and modular military infrastructure for rapid deployment.

- Makine Etkisi:

- Enable mass production of portable shelter frames and support structures.

- Support on-site assembly with pre-fabricated profiles.

4. Defense Spending Growth

- 4. Overlanding ve Araç Kampçılığı Increased global defense budgets driving demand for advanced military equipment.

- Makine Etkisi:

- Support large-scale production of military components.

- Enhance production efficiency to meet tight deadlines.

FAQs About Military Equipment Roll Forming Machines

| Soru | Cevap |

|---|---|

| Bu makineler hangi malzemeleri işleyebilir? | Ballistic-grade steel, aluminum alloys, titanium, and corrosion-resistant metals. |

| Bu makinelerin üretim hızı nedir? | Makineler aşağıdakilere kadar üretebilir 20–100 meters of profiles per minuteMalzeme ve karmaşıklığa bağlı olarak. |

| Bu makineler özel tasarımları işleyebilir mi? | Yes, modular tooling allows for the creation of bespoke military profiles. |

| Bu makineler enerji tasarruflu mu? | Yes, they include energy-saving motors and optimized workflows to reduce costs. |

| Bu makinelerden hangi sektörler yararlanıyor? | Defense, homeland security, and heavy infrastructure sectors. |

| Bu makineler güvenlik standartlarına uygun mu? | Yes, they meet ISO, CE, and military-specific quality standards. |

| Bu makinelerin kullanım ömrü ne kadardır? | Doğru bakım ile bu makineler uzun ömürlü olabilir 20-30 yıl ya da daha fazla. |

| Satın alma ile birlikte eğitim veriliyor mu? | Evet, Wuxi Sunway tüm müşteriler için kapsamlı eğitim ve satış sonrası destek sunmaktadır. |

| Bu makineler için fiyat aralığı nedir? | Fiyatlar arasında değişir 500,000to500,000 to 500,000to5,000,000özelliklerine ve özelleştirme seçeneklerine bağlı olarak değişir. |

| Bu makineler sürdürülebilir üretimi destekleyebilir mi? | Evet, atıkları en aza indirmek ve geri dönüştürülebilir malzemeleri desteklemek için optimize edilmişlerdir. |

Real-World Success Stories: Military Equipment Roll Forming Machines in Action

Kullanımı Askeri Ekipman Rulo Şekillendirme Makineleri is pivotal in addressing some of the most complex challenges faced by defense manufacturers. Below are real-world examples showcasing how these machines have transformed military production.

1. Case Study: Armored Personnel Carrier (APC) Panels

- Müşteri: A global defense contractor specializing in tactical ground vehicles.

- Meydan okuma: Needed high-strength steel panels for APCs capable of withstanding ballistic threats and explosive impacts.

- Çözüm: Wuxi Sunway Machinery provided a roll-forming machine designed to process ballistic-grade steel with integrated cutting and punching systems for fastener holes.

- Sonuçlar:

- Reduced production time by 40%, allowing for faster delivery of vehicles.

- Improved panel durability, meeting NATO ballistic standards.

- Lowered material waste by 15%, optimizing input costs.

2. Case Study: Rapid Deployment Infrastructure

- Müşteri: A supplier of portable military shelters and field hospitals.

- Meydan okuma: Required lightweight, modular frames for shelters that could be quickly deployed in conflict zones or disaster relief efforts.

- Çözüm: Wuxi Sunway delivered a roll-forming machine capable of producing high-strength aluminum profiles with modular tooling for various designs.

- Sonuçlar:

- Enabled the production of shelters that could be assembled in under 30 minutes.

- Reduced weight by 25% compared to traditional steel frames, easing transportation logistics.

- Increased shelter durability, ensuring reliability in harsh environments.

3. Case Study: Ammunition Storage Racks

- Müşteri: A logistics company managing ammunition and weapon storage for military bases.

- Meydan okuma: Needed corrosion-resistant profiles for ammunition racks that could withstand extreme temperatures and humidity.

- Çözüm: Wuxi Sunway provided a machine designed to process galvanized steel with anti-corrosion coatings applied during production.

- Sonuçlar:

- Produced racks that met military safety and longevity requirements.

- Reduced maintenance costs by 30% due to improved corrosion resistance.

- Allowed for efficient mass production to meet expanding storage needs.

4. Case Study: UAV (Unmanned Aerial Vehicle) Frames

- Müşteri: A drone manufacturer supplying the military with tactical UAVs for reconnaissance and logistics.

- Meydan okuma: Needed ultra-lightweight and durable frames to improve UAV flight times and payload capacity.

- Çözüm: Wuxi Sunway developed a roll-forming machine capable of processing advanced composite materials into custom UAV profiles.

- Sonuçlar:

- Increased UAV flight duration by 20%, enhancing operational capabilities.

- Reduced production lead times by 35%, enabling faster delivery to military clients.

- Supported modular designs for UAVs, allowing for rapid field customization.

Customization: The Key Advantage of Military Equipment Roll Forming Machines

In the defense industry, one size does not fit all. Military applications often require özelleştirilmiş profiller to meet unique operational requirements. Roll-forming machines from Wuxi Sunway Makine offer unparalleled flexibility in creating these bespoke solutions.

1. Modular Tooling

- Ne Sunuyor? Easily interchangeable tooling systems that allow manufacturers to switch between different profile designs quickly.

- Neden değerli?

- Supports diverse production needs, from armored panels to shelter frames.

- Takım değişiklikleriyle ilişkili arıza süresini azaltır.

- Enables small-batch production for prototypes or specialized components.

2. Malzeme Çok Yönlülüğü

- Desteklenen Materyaller:

- Balistik Sınıf Çelik

- Alüminyum Alaşımları

- Titanyum

- Composite Materials (e.g., carbon fiber)

- Neden Kritik?

- Provides the flexibility to produce components optimized for strength, weight, or corrosion resistance.

- Supports innovation in defense equipment design.

3. Profile Diversity

- Yetenekler: Machines can produce a wide range of profiles, including:

- U Kanalları

- Z-Profiles

- Box Beams

- Custom Geometries

- Neden önemli?

- Enables manufacturers to meet the specific needs of various military applications.

- Supports integration with other components for seamless assembly.

4. Advanced Coating Integration

- Ne İçerir? Systems for applying coatings like anti-corrosion, reflective, or camouflage finishes during production.

- Neden Yararlı?

- Bileşenlerin dayanıklılığını ve işlevselliğini artırır.

- Son üretim adımlarını azaltarak zaman ve maliyet tasarrufu sağlar.

Compliance Standards for Military Equipment Roll Forming Machines

Military components must adhere to strict international standards to ensure safety, durability, and performance. Wuxi Sunway Makine designs its machines to produce profiles that meet or exceed these requirements:

| Standart | Bölge | Gereksinim |

|---|---|---|

| MIL-STD Specifications | ABD | Defines military-grade requirements for materials and components. |

| ISO 9001 | Küresel | Üretim süreçlerinde tutarlı kalite yönetimini garanti eder. |

| NATO STANAG Standards | NATO Member Countries | Specifies standards for interoperability and performance of military equipment. |

| CE İşareti | Avrupa | Avrupa güvenlik ve kalite standartlarına uygunluğu onaylar. |

| RoHS Uyumluluğu | Avrupa | Üretim malzemelerinde tehlikeli maddeleri kısıtlar. |

| ITAR Compliance | ABD | Ensures compliance with International Traffic in Arms Regulations for export. |

Bu standartlara bağlı kalarak, Wuxi Sunway Makine ensures its roll-forming machines deliver components that are safe, durable, and globally compliant.

FAQs About Military Equipment Roll Forming Machines

| Soru | Cevap |

|---|---|

| Bu makineler hangi malzemeleri işleyebilir? | Ballistic-grade steel, aluminum alloys, titanium, and composite materials. |

| Bu makinelerin üretim hızı nedir? | Makineler aşağıdakilere kadar üretebilir 20–100 meters of profiles per minuteMalzeme ve karmaşıklığa bağlı olarak. |

| Bu makineler özel tasarımları işleyebilir mi? | Yes, modular tooling allows for the creation of bespoke military profiles. |

| Bu makineler enerji tasarruflu mu? | Yes, they feature energy-saving motors and optimized workflows to reduce operational costs. |

| Bu makinelerden hangi sektörler yararlanıyor? | Defense, homeland security, and emergency response sectors. |

| Bu makineler güvenlik standartlarına uygun mu? | Yes, they meet MIL-STD, NATO STANAG, and other international military standards. |

| Bu makinelerin kullanım ömrü ne kadardır? | Doğru bakım ile bu makineler uzun ömürlü olabilir 20-30 yıl ya da daha fazla. |

| Satın alma ile birlikte eğitim veriliyor mu? | Evet, Wuxi Sunway tüm müşteriler için kapsamlı eğitim ve satış sonrası destek sunmaktadır. |

| Bu makineler için fiyat aralığı nedir? | Fiyatlar arasında değişir 500,000to500,000 to 500,000to5,000,000özelliklerine ve özelleştirme seçeneklerine bağlı olarak değişir. |

| Bu makineler sürdürülebilir üretimi destekleyebilir mi? | Evet, atıkları en aza indirmek ve geri dönüştürülebilir malzemeleri desteklemek için optimize edilmişlerdir. |

Why Choose Wuxi Sunway Machinery for Military Equipment Roll Forming Machines?

Wuxi Sunway Makine has established itself as a trusted partner in defense manufacturing, offering innovative roll-forming solutions tailored to the military sector. Here’s why defense contractors choose Sunway:

- Onlarca Yıllık Uzmanlık: Proven track record in delivering high-quality machines for military applications.

- Küresel Erişim: Trusted by defense manufacturers across Asia, Europe, North America, and beyond.

- En Son Teknoloji: Features like IoT integration, modular tooling, and advanced coating systems set their machines apart.

- Sürdürülebilirlik Taahhüdü: Machines designed to minimize environmental impact through energy efficiency and recyclable material handling.

- Kapsamlı Destek: Danışmanlıktan kurulum ve devam eden servise kadar Wuxi Sunway müşterilerinin sorunsuz operasyonlarını sağlar.

Conclusion: Building Stronger Defenses with Roll Forming Machines

Askeri Ekipman Rulo Şekillendirme Makineleri are revolutionizing the defense industry by enabling the production of high-performance, durable, and reliable components that meet the demands of modern warfare and security. These machines play a critical role in strengthening national defense capabilities and supporting rapid deployment scenarios.

Ready to elevate your military equipment production? Partner with Wuxi Sunway Makine today and explore their cutting-edge roll-forming solutions. Let’s build the future of defense—one profile at a time.