विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन का उपयोग विद्युत कैबिनेट के लिए विभिन्न रैक बनाने के लिए किया जाता है जैसे कि 17 साइड प्रोफाइल, साइड प्रोफाइल, नौ फोल्डिंग प्रोफाइल, 9 13 16-फोल्ड मेटल प्रोफाइल रिट्टल बेइंग एनक्लोजर आदि। यह एक कॉलम है और कम से कम प्रदान किया गया है। एक सीलिंग नाली। कोणीय कनेक्टर को त्रि-आयामी समन्वय आकार में डिज़ाइन किया गया है। खांचे को कॉलम और बीम पर सीलिंग खांचे से मिलाया जाता है। लाभ संरचनात्मक ताकत में वृद्धि और कैबिनेट सुरक्षा में सुधार है, जो विद्युत उत्पादों के प्रतिस्थापन और ऑपरेटरों की सुरक्षा में सुधार करता है।

इलेक्ट्रिक कैबिनेट रैक, इलेक्ट्रॉनिक बॉक्स पोल, मेटल केस फ्रेम के लिए वेल्डिंग के साथ कैबिनेट फ्रेम रोल बनाने की मशीन का उपयोग करके स्वचालित इलेक्ट्रिक फैक्ट्री जो स्विचगियर सिस्टम, लो वोल्टेज पैनल बिल्डिंग, कंट्रोल कैबिनेट इलेक्ट्रिकल इंस्ट्रूमेंट्स आदि में उपयोग करती है।

विद्युत और ऊर्जा उद्योग में, हम सौर स्ट्रट चैनल रोल बनाने की मशीन, डीआईएन रेल रोल बनाने की मशीन और विद्युत संलग्नक बॉक्स रोल बनाने की मशीन आदि जैसी अधिक संबंधित मशीनों का निर्माण करने में सक्षम हैं।

हम ग्राहकों की ड्राइंग, सहिष्णुता और बजट के अनुसार अलग-अलग समाधान करते हैं, पेशेवर एक-से-एक सेवा प्रदान करते हैं, जो आपकी सभी आवश्यकताओं के अनुकूल है। आप जो भी लाइन चुनते हैं, सनवे मशीनरी की गुणवत्ता सुनिश्चित करेगी कि आप पूरी तरह कार्यात्मक प्रोफाइल प्राप्त करें।

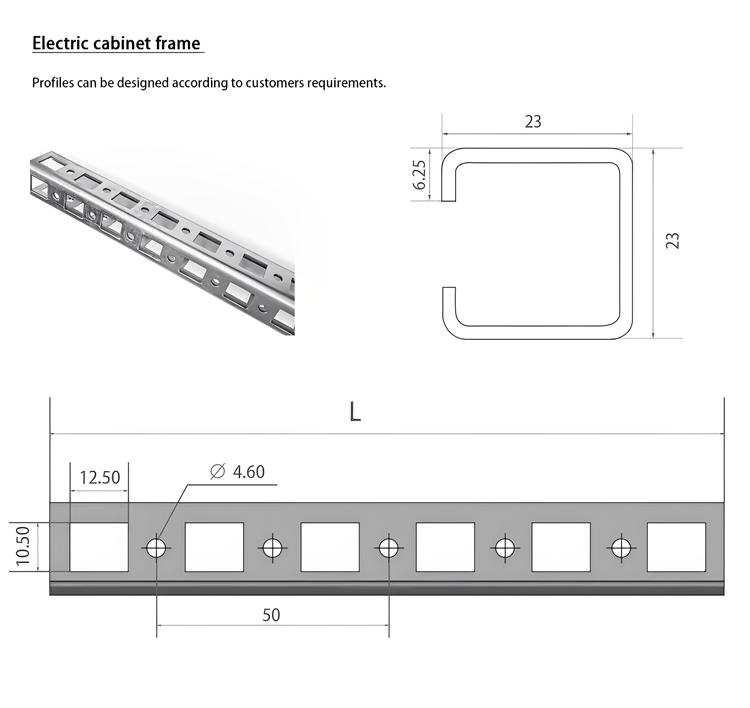

प्रोफ़ाइल चित्र

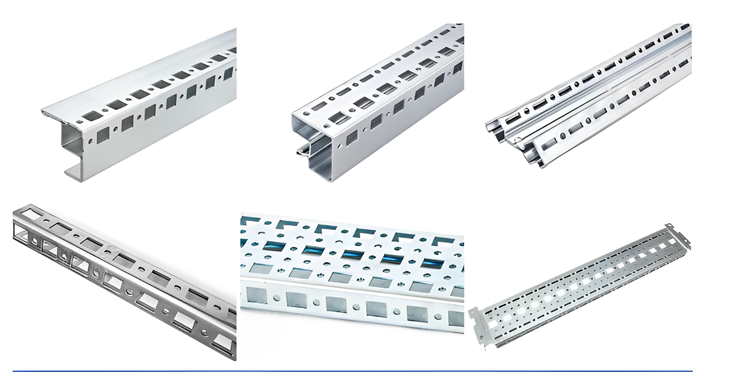

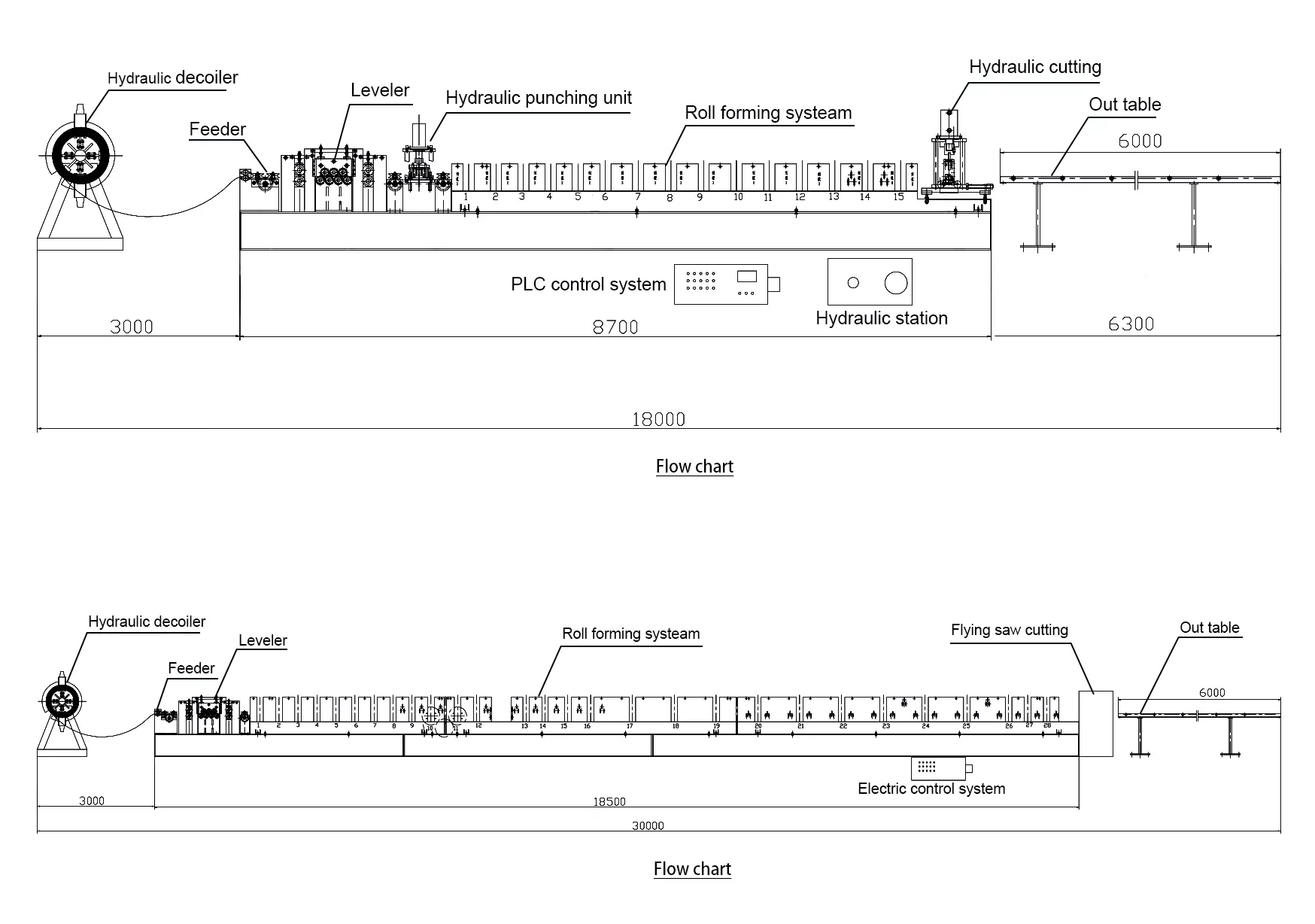

उत्पादन लाइन

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन विवरण

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन पैरामीटर

| विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन | ||

|

मशीन योग्य सामग्री

|

ए) जस्ती इस्पात |

मोटाई (एमएम): 1.0-2.0 या ग्राहक के अनुसार

|

| बी) स्टेनलेस स्टील | ||

| नम्य होने की क्षमता | 250 - 550 एमपीए | |

| तन्य तनाव | G250 एमपीए-G550 एमपीए | |

| डेकोइलर | मैनुअल डेकोइलर | * हाइड्रोलिक डेकोइलर (वैकल्पिक) |

| पंचिंग सिस्टम | हाइड्रोलिक पंचिंग स्टेशन | * पंचिंग प्रेस (वैकल्पिक) |

| फॉर्मिंग स्टेशन | 30 से अधिक स्टैंड | * आपके प्रोफाइल ड्रॉइंग के अनुसार |

| ड्राइविंग सिस्टम | चेन ड्राइव | * गियरबॉक्स ड्राइव (वैकल्पिक) |

| मशीन संरचना | दीवार पैनल स्टेशन | * कच्चा लोहा (वैकल्पिक) |

| बनाने की गति | 5-15 (एम/मिन) | * या आपके प्रोफाइल ड्रॉइंग के अनुसार |

| रोलर्स की सामग्री | जीसीआर 15 | * Cr12 (वैकल्पिक) |

| कटिंग सिस्टम | हाइड्रोलिक कटिंग | * सॉ कटिंग (वैकल्पिक) |

| आवृत्ति परिवर्तक ब्रांड | यास्कावा | * सीमेंस (वैकल्पिक) |

| पीएलसी ब्रांड | पैनासोनिक | * सीमेंस (वैकल्पिक) |

| बिजली की आपूर्ति | 380V 50Hz 3ph | * या आपकी आवश्यकता के अनुसार |

| मशीन का रंग | औद्योगिक नीला | * या आपकी आवश्यकता के अनुसार |

आवेदन

What is door frame roll forming machine?

A door frame roll forming machine is a type of industrial machinery used for manufacturing door frames through a process called roll forming. Roll forming is a continuous bending operation in which a long strip of metal, typically steel or aluminum, is passed through a series of rollers to gradually shape it into a desired cross-sectional profile.

The door frame roll forming machine consists of several components, including:

- Uncoiler: This component holds the metal coil and feeds it into the machine.

- Leveler: It straightens the metal strip to ensure consistent feeding into the roll forming process.

- Rollers: These are the main components of the machine. They are designed with specific contours and patterns to gradually bend and shape the metal strip into the desired door frame profile. The rollers are usually arranged in a series, each performing a specific bending operation.

- Cutting system: After the metal strip is formed into the door frame shape, the cutting system is used to cut the profile into the desired lengths.

- Control system: This component includes electronic controls, sensors, and software to regulate the speed, length, and other parameters of the roll forming process.

Door frame roll forming machines can produce door frames of various sizes, profiles, and designs, depending on the specific requirements. They are widely used in the manufacturing industry for producing door frames for residential, commercial, and industrial applications. The roll forming process offers high efficiency, precision, and cost-effectiveness in producing consistent and high-quality door frames.

application metal door frame roll forming machine?

A metal door frame roll forming machine is used for the production of metal door frames, which are essential components of buildings and structures. Here are some common applications of metal door frames and how the roll forming machine contributes to their production:

- Residential Buildings: Metal door frames are widely used in residential buildings such as houses, apartments, and condominiums. The roll forming machine enables the efficient and precise manufacturing of door frames in various sizes and designs to suit different architectural styles and preferences.

- Commercial Buildings: Metal door frames are commonly found in commercial buildings such as offices, retail stores, hotels, and hospitals. These frames provide durability, security, and aesthetic appeal. The roll forming machine allows for the mass production of door frames with consistent quality and dimensional accuracy, meeting the demands of commercial construction projects.

- Industrial Facilities: Industrial buildings, warehouses, factories, and other industrial facilities often require robust and heavy-duty metal door frames. The roll forming machine can handle thicker and stronger metals, enabling the production of door frames that can withstand harsh environments and heavy usage.

- Institutional Buildings: Metal door frames are also utilized in institutional buildings like schools, universities, government offices, and healthcare facilities. These frames provide stability, fire resistance, and security. The roll forming machine ensures the efficient manufacturing of door frames that meet the specific requirements and regulations of these institutions.

- Renovation and Retrofit Projects: Metal door frames are often used in renovation and retrofit projects to replace old or damaged door frames. The roll forming machine allows for the production of custom door frames that match existing architectural designs, ensuring a seamless integration with the overall aesthetics of the building.

Overall, the metal door frame roll forming machine plays a crucial role in the construction industry by enabling the mass production of high-quality, precise, and durable door frames for a wide range of applications.

How does steel door frame roll forming machine work?

A steel door frame roll forming machine works through a series of steps to transform a coil of steel into a finished steel door frame. Here is a general overview of how the machine operates:

- Coil Loading: The machine starts by loading a steel coil onto the uncoiler, which holds the coil in place. The coil is typically made of galvanized or cold-rolled steel and serves as the raw material for the door frame.

- Material Straightening: The steel strip from the coil passes through a leveling and straightening process. This ensures that the strip is flat and free from any deformations or bends, allowing for consistent feeding into the roll forming section.

- Roll Forming: The straightened steel strip is then fed into the roll forming section, which consists of a series of rollers. Each roller is carefully designed with specific contours and patterns to gradually bend and shape the strip into the desired door frame profile. The strip is guided through the rollers, with each roller performing a specific bending operation.

- Cutting and Length Measurement: Once the steel strip has been formed into the door frame shape, a cutting system is employed to cut the continuous profile into individual door frame lengths. The cutting system can be either a shear or a flying cutoff saw, depending on the design and capabilities of the machine. Simultaneously, a length measurement system ensures accurate and consistent cutting of the door frame sections.

- Output and Stacking: After the cutting process, the finished steel door frame sections are discharged from the machine. They may be collected and stacked on a conveyor or in a designated area for further processing, packaging, or transportation.

- Control System: Throughout the entire process, the steel door frame roll forming machine is controlled by an integrated control system. This system regulates the speed of the machine, controls the movements of the rollers, monitors the material feeding and cutting, and ensures the overall precision and accuracy of the manufacturing process.

It’s important to note that the specific design and configuration of a steel door frame roll forming machine may vary depending on the manufacturer and the desired door frame profile. However, the fundamental principles of material feeding, roll forming, cutting, and control remain consistent.