Introduction

Vous envisagez d'acheter un machine de profilage d'occasion pour économiser de l'argent tout en augmentant votre capacité de production ? De nombreux fabricants optent pour machines de formage de rouleaux d'occasion de réduire les coûts initiaux, mais s'agit-il vraiment d'un avantage ? investissement intelligent?

Achat d'un machine de profilage d'occasion peut être un alternative rentable si l'on sait ce qu'il faut chercher. Cependant, il existe aussi des risques encourusLes coûts d'entretien sont élevés, les défauts cachés et les technologies obsolètes.

Dans ce guide, nous aborderons les sujets suivants

✅ Avantages et inconvénients de l'achat d'une profileuse d'occasion

✅ Où acheter des profileuses d'occasion de haute qualité

✅ Comment inspecter et évaluer une profileuse d'occasion avant de l'acheter ?

✅ Comparaison des coûts : Machines de formage de rouleaux neuves ou d'occasion

✅ Les erreurs à éviter lors de l'achat de machines d'occasion

Voyons si un machine de profilage d'occasion est le bon choix pour votre entreprise !

Avantages de l'achat d'une profileuse d'occasion

Achat d'un machine de formage de rouleaux d'occasion peut offrir plusieurs avantages, notamment

1. Investissement initial moins élevé

✅ Une machine de profilage d'occasion coûte généralement 30-50% moins qu'une nouvelle.

✅ Idéal pour les start-ups et les petits fabricants qui cherche à augmenter sa production avec un budget limité.

2. Disponibilité plus rapide

✅ Contrairement aux nouvelles machines qui ont un délai de fabrication de 2 à 6 moisLes machines d'occasion sont immédiatement disponible.

✅ Aide aux entreprises augmenter rapidement la production sans attendre.

3. Performances prouvées

✅ Certaines machines d'occasion ont un des antécédents en matière de fiabilitéce qui en fait un investissement plus sûr.

Souvent bien entretenus par les propriétaires précédents, ce qui garantit une efficacité continue.

4. Respect de l'environnement

✅ Achat de matériel d'occasion réduit les déchets et favorise le développement durable dans l'industrie manufacturière.

Conseil de pro : Une profileuse d'occasion bien entretenue peut encore assurer une production de haute qualité pendant 5 à 10 ans !

Inconvénients de l'achat d'une profileuse d'occasion

Alors qu'un machine de profilage d'occasion peuvent économiser de l'argent, il y a aussi des les inconvénients potentiels à prendre en considération.

1. Coûts de maintenance plus élevés

❌ Les machines plus anciennes peuvent avoir rouleaux, lames de coupe ou moteurs usésce qui entraîne des coûts de réparation plus élevés.

❌ Les pièces de rechange peuvent être difficile à trouverce qui augmente les temps d'arrêt.

2. Technologie dépassée

❌ Les machines usagées peuvent présenter des lacunes l'automatisation moderne, les servomoteurs et les systèmes de contrôle PLCréduisant ainsi la productivité.

❌ Les nouveaux modèles sont plus efficaces sur le plan énergétiquece qui permet de réduire les coûts d'exploitation à long terme.

3. Pas de garantie ni d'assistance limitée

❌ Contrairement aux machines neuves qui sont livrées avec un garantie et assistance techniqueLes machines d'occasion ont souvent aucune garantie.

❌ Si la machine tombe en panne, il se peut que vous deviez payer soi-même toutes les réparations.

4. Défauts cachés et usure

❌ Certains vendeurs ne pas divulguer les problèmes liés aux machinesce qui entraîne des pannes inattendues.

❌ Toujours inspecter soigneusement la machine avant d'acheter.

Conseil de pro : Si le coût des réparations est supérieur à la moitié du prix d'une machine neuve, l'achat d'une machine d'occasion n'en vaut peut-être pas la peine !

Où acheter des profileuses d'occasion de haute qualité ?

Trouver un source fiable pour les profileuses d'occasion est cruciale. Voici les meilleurs endroits pour acheter des machines de profilage d'occasion:

1. Directement du fabricant

✅ Certains fabricants, comme MACHINES SUNWAY DE WUXI, offre machines de profilage remises à neuf avec contrôles de qualité et garanties limitées.

✅ Les machines sont inspecté, réparé et testé par des professionnels.

2. Marchés en ligne

✅ Alibaba, eBay et TradeIndia ont des listes de profileuses d'occasion.

✅ Être prudence à l'égard des vendeurs inconnus et toujours demander spécifications détaillées de la machine.

3. Enchères industrielles et ventes de liquidation

✅ Les entreprises ferment ou modernisent souvent leurs équipements vendre des machines d'occasion à des prix inférieurs.

✅ Vérifier ventes aux enchères et ventes de liquidation d'équipements pour le travail des métaux.

4. Concessionnaires et revendeurs de machines

✅ Certains concessionnaires acheter et rénover des profileuses d'occasion à revendre.

✅ S'assurer qu'ils fournissent l'historique détaillé de la machine et les rapports d'essai.

Conseil de pro : Acheter auprès d'un fabricant de confiance comme MACHINES SUNWAY DE WUXI pour obtenir une profileuse d'occasion fiable et inspectée !

Comment inspecter une profileuse d'occasion avant de l'acheter ?

Avant d'acheter un machine de profilage d'occasionsuivre ce qui suit liste de contrôle de l'inspection pour éviter des erreurs coûteuses.

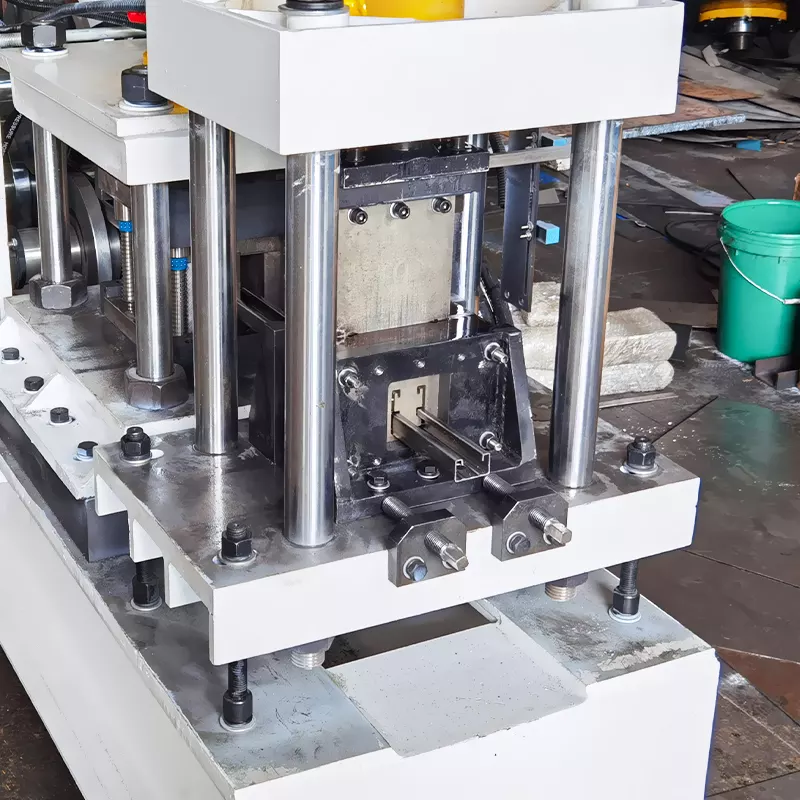

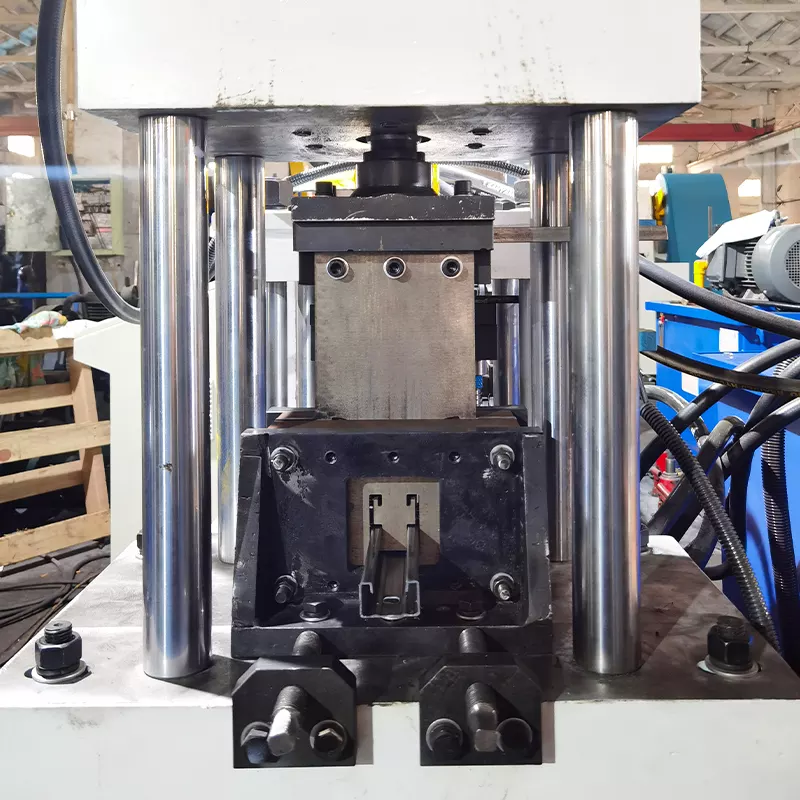

✅ 1. Vérifier les rouleaux et les stations de formage

- Rechercher des signes d'usure, de rouille ou de fissures. sur les rouleaux.

- Garantir les rouleaux sont correctement alignés pour un formage précis des feuilles.

✅ 2. Inspecter le système de coupe

- Vérifier le système de coupe hydraulique ou servo pour la netteté et la précision.

- Rechercher fuites d'huile ou lames de coupe usées.

✅ 3. Évaluer le système de contrôle (PLC et moteurs)

- Test du panneau de contrôle de l'automate pour garantir une programmation et une précision adéquates.

- Assurez-vous que le le moteur et le système d'entraînement fonctionnent sans bruit excessif.

✅ 4. Exécuter un cycle de production test

- Demander une démonstration en direct pour voir la machine en action.

- Mesurer la qualité et rapidité de la production pour s'assurer qu'il répond à vos besoins de production.

✅ 5. Demander le carnet d'entretien

- Vérifier si le l'ancien propriétaire a effectué un entretien régulier.

- Garantir des pièces de rechange sont disponibles pour le modèle de machine spécifique.

Conseil de pro : Si le vendeur refuse de fournir un essai de fonctionnement, un dossier d'entretien ou l'historique de la machine, c'est un signal d'alarme !

Machines de formage de rouleaux neuves ou d'occasion : Comparaison des coûts

| Facteur | Nouvelle machine de formage de rouleaux | Machine de formage de rouleaux d'occasion |

|---|---|---|

| Prix | 30,000-30,000 - 30,000-300,000 | 30-50% moins cher que le neuf |

| Technologie | Automatisation et servomoteurs les plus récents | Technologie plus ancienne, peut nécessiter des mises à jour |

| Durée de vie | 10-15 ans | 5 à 10 ans (selon l'état) |

| Personnalisation | Entièrement personnalisable | Options de personnalisation limitées |

| Garantie et assistance | Garantie du fabricant incluse | Pas de garantie, risques de réparation plus élevés |

Conseil de pro : Si la machine d'occasion coûte plus de 60% qu'une machine neuve, il est préférable d'investir dans un nouveau modèle !

Les erreurs à éviter lors de l'achat d'une profileuse d'occasion

🚫 Erreur #1 : Acheter sans inspecter la machine

✅ Demander un démonstration vidéo ou inspection en personne avant d'acheter.

🚫 Erreur #2 : Ignorer la disponibilité des pièces de rechange

✅ Vérifier si le remplacement des rouleaux, des moteurs et des lames de coupe sont toujours en production.

🚫 Erreur #3 : acheter des modèles dépassés

✅ Éviter les machines plus de 10 ans, car ils peuvent manquer l'automatisation et l'efficacité modernes.

🚫 Erreur #4 : Ignorer les coûts cachés

✅ Tenir compte de l'expédition, l'installation, les réparations et les mises à niveau avant de finaliser l'achat.

Conseil de pro : Une profileuse d'occasion doit être au moins 30% moins chère qu'une machine neuve pour justifier son achat !

Comment négocier le meilleur prix pour une profileuse d'occasion

Achat d'un machine de formage de rouleaux d'occasion ne signifie pas que vous devez surpayer. Une négociation intelligente peut vous aider à réduire les coûts et obtenir la meilleure offre. Voici comment négocier efficacement lors de l'achat d'une machine d'occasion.

1. Rechercher les prix du marché et comparer les offres

✅ Vérifier plusieurs listes de différents vendeurs, fabricants et concessionnaires.

✅ Comparer les caractéristiques, l'âge et l'état de la machine, ainsi que les accessoires inclus.

✅ Utiliser ces données pour négocier une meilleure affaire.

2. Demander une inspection complète de la machine avant de conclure l'accord

✅ Demander des photos détaillées, des vidéos et des relevés d'entretien.

Si possible, visiter le site du vendeur pour inspecter la machine en personne.

✅ Si la machine a usure importanteutiliser comme un point de négociation à un prix inférieur.

3. Négocier les coûts supplémentaires (expédition, installation, pièces détachées)

✅ Quelques vendeurs frais supplémentaires pour l'emballage, l'expédition et l'installation-Essayez d'obtenir ceci inclus dans le prix.

✅ Si des pièces de rechange sont nécessaires, négocier pour qu'ils soient fournis à un prix réduit.

4. Demander un essai avant l'achat

✅ Demander à voir le machine en fonctionnement pour s'assurer qu'il fonctionne correctement.

✅ Si le vendeur refuse, cela peut indiquer des défauts cachés.

5. Envisager des achats en gros pour bénéficier de remises plus importantes

✅ Si vous avez besoin de plusieurs machines, l'achat en gros peut entraîner des réductions de prix significatives.

✅ Certains fournisseurs proposent prix spéciaux pour les clients réguliers.

Conseil de pro : Si vous achetez à l'étranger, négociez la gratuité des frais de port ou une aide pour les frais de douane !

Coûts cachés de l'achat d'une profileuse d'occasion

Alors qu'une machine d'occasion peut sembler moins cher au départLes personnes qui se trouvent à l'intérieur de l'entreprise doivent être conscientes des risques qu'elles peuvent encourir. coûts cachés qui pourraient affecter votre budget.

1. Droits d'expédition et d'importation

✅ Les frais de transport international varient de 2,000-2,000 - 2,000-10,000en fonction du lieu.

Les droits d'importation et les taxes varient selon les pays. les réglementations locales avant d'acheter.

2. Installation et formation des opérateurs

✅ Nombreuses machines usagées ne sont pas accompagnées d'un support d'installationIl se peut donc que vous deviez faire appel à un technicien.

✅ La formation de l'opérateur peut être nécessaire pour comprendre le système de commande de la machine.

3. Pièces détachées et réparations

✅ Si le modèle est trop vieuxdes pièces de rechange peuvent être difficile à trouver ou sur mesure, ce qui entraîne une augmentation des coûts.

✅ Certaines machines nécessitent le réalignement des rouleaux ou l'affûtage des lames avant utilisation.

4. Consommation d'énergie et efficacité énergétique

✅ Machines plus anciennes consomment plus d'énergie, ce qui conduit à des coûts d'électricité plus élevés.

Les modèles plus récents sont plus efficace sur le plan énergétiqueréduire les dépenses à long terme.

5. Risques liés aux arrêts de production

✅ Si la machine tombe fréquemment en panneLe temps de production perdu peut coûter cher.

✅ S'assurer que la machine est en bon état de fonctionnement avant l'achat.

Conseil de pro : Prévoyez un supplément d'au moins 10-15% pour les coûts cachés lorsque vous établissez votre budget pour l'achat d'une machine d'occasion !

Machines de formage de rouleaux remises à neuf ou d'occasion : Quelle est la différence ?

Pas tous machines d'occasion sont les mêmes. Certains vendeurs proposent machines remises à neufqui peut être un un meilleur investissement.

| Facteur | Machine usagée | Machine remise à neuf |

|---|---|---|

| Condition | Vendu "en l'état" avec des traces d'usure | Entièrement inspecté et restauré |

| Réparations et améliorations | Pas de réparation, peut nécessiter un entretien | Pièces remplacées, systèmes électriques vérifiés |

| Garantie | En général, pas de garantie | Peut être assorti d'une garantie à court terme |

| Prix | Coût initial moins élevé | Légèrement plus élevé mais meilleure valeur à long terme |

| Niveau de risque | Élevé (peut avoir des problèmes cachés) | Inférieur (testé par des professionnels) |

Conseil de pro : Dans la mesure du possible, préférez une machine remise à neuf à une machine d'occasion : le coût est légèrement plus élevé, mais la fiabilité est meilleure !

Quand devriez-vous plutôt acheter une nouvelle profileuse ?

Les profileuses d'occasion permettent de réaliser des économies, dans certains cas, l'achat d'une nouvelle machine est un meilleur investissement à long terme.

Acheter une nouvelle machine si :

✅ Vous avez besoin production à grande vitesse, entièrement automatisée.

✅ Votre entreprise a besoin profils de profilage personnalisés.

✅ Vous voulez un une garantie et un service après-vente fiable.

✅ Vous êtes préoccupé par efficacité énergétique et coûts d'exploitation à long terme.

✅ Vous prévoyez d'utiliser la machine pour 10+ ans sans remplacements fréquents.

Acheter une machine d'occasion si :

✅ Vous avez un budget limité et souhaitent démarrer rapidement la production.

✅ Votre volume de production est de relativement faible.

✅ Vous êtes à l'aise avec les frais de réparation et d'entretien occasionnels.

✅ Vous trouvez un machine reconditionnée en excellent état.

Conseil de pro : Si une machine d'occasion coûte plus de 60% qu'une machine neuve, il vaut mieux investir dans un nouveau modèle !

Où acheter des profileuses d'occasion fiables ?

Pour machines de profilage d'occasion et remises à neuf de haute qualité, consultez le site WUXI SUNWAY MACHINERY CO., LTD.

Pourquoi choisir WUXI SUNWAY MACHINERY pour des machines d'occasion ?

✅ Machines remises à neuf par des professionnels - Contrôlé, testé et prêt à l'emploi.

✅ Pièces de rechange et assistance disponibles - Évitez les temps d'arrêt grâce au remplacement rapide des pièces de rechange.

✅ Prix compétitifs - Des machines abordables avec une excellente valeur à long terme.

✅ Expédition mondiale et assistance à l'installation - Livraison sans souci et assistance à l'installation.

Vous recherchez une profileuse rentable ? Contactez-nous dès aujourd'hui !

FAQ : Achat d'une profileuse d'occasion

1. Est-il intéressant d'acheter une profileuse d'occasion ?

- Oui, si la machine est en bon état et que vous économisez au moins 30-50% par rapport à une machine neuve.

- Toutefois, évitez les machines qui nécessitent des réparations coûteuses ou des modèles obsolètes sans pièces de rechange.

2. Combien coûte une profileuse d'occasion ?

- Le prix d'une profileuse d'occasion varie, mais il est généralement de 30-50% moins cher qu'un neuf.

- Les prix devraient se situer dans une fourchette de 10 000 à 10 000 à 10 000 à 150 000, en fonction de l'âge, les caractéristiques et l'état.

3. Que dois-je vérifier avant d'acheter une profileuse d'occasion ?

- Inspecter les rouleaux, système de coupe, moteurs, panneau de contrôleet l'alignement général.

- Demander les dossiers d'entretien et un essai de fonctionnement pour vérifier les performances.

4. Où puis-je trouver des profileuses d'occasion à vendre ?

- MACHINES SUNWAY DE WUXI offres machines de profilage remises à neuf et certifiées.

- Les marchés en ligne tels que Alibaba, eBay et ventes aux enchères industrielles locales répertorie également les machines d'occasion.

5. Dois-je acheter une profileuse remise à neuf ou une machine d'occasion ?

- Machines remises à neuf sont un investissement plus sûr car ils sont inspecté, réparé et testé.

- Machines d'occasion peuvent être moins chères, mais elles sont accompagnées de des risques plus élevés et des vices cachés potentiels.

Réflexions finales

Achat d'un machine de profilage d'occasion peut être un un moyen rentable d'accroître la productionmais il est essentiel de évaluer l'état de la machine, négocier judicieusement et prendre en compte les coûts cachés.

✅ Besoin d'un une profileuse abordable mais fiable?

✅ A la recherche d'un profileuse remise à neuf avec garantie de qualité?