Overview of Heavy-Duty Roll Forming Machines

UN machine de formage de rouleaux à usage intensif is an advanced industrial machine designed to process thick and high-strength metal sheets, tels que galvanized steel, acier inoxydable, aluminum, and structural steel. These machines are used to manufacture heavy-gauge structural components, industrial beams, highway guardrails, solar mounting systems, and storage racks.

Contrairement aux machines de profilage standard, heavy-duty roll forming machines are built with reinforced rollers, powerful hydraulic systems, and precision CNC controls pour gérer high-tensile materials with ease.

Key Features of Heavy-Duty Roll Forming Machines

✅ Capable of processing thick materials – Up to 8mm thickness pour ultra-strong structural components.

✅ Production à grande vitesse - Produit 10-40 meters per minute, depending on material strength.

✅ Heavy-duty rollers & hydraulic systems - Conçu pour continuous, high-load operations.

✅ Fonctionnement entièrement automatisé – CNC-controlled for précision et efficacité.

✅ Servomoteurs à haut rendement énergétique - Améliore power consumption and operational efficiency.

Dans ce guide, nous aborderons les sujets suivants

✅ Types of heavy-duty roll forming machines

✅ Comment fonctionne le processus de profilage

✅ Best materials for heavy-duty roll forming

✅ Analyse des coûts et guide des prix

✅ Principaux fabricants et raisons pour lesquelles Sunway Machine est un choix de confiance

C'est parti !

Types of Heavy-Duty Roll Forming Machines

Différents heavy-duty roll forming machines are designed for specific industrial applications and material thicknesses.

1. Heavy-Duty Structural Beam Roll Forming Machine

- Produit I-beams, C-channels, and heavy-gauge profiles utilisé dans construction and industrial applications.

- Idéal pour bridges, steel structures, and load-bearing elements.

2. Heavy-Duty Storage Rack Roll Forming Machine

- Fabrications high-strength racking and shelving components pour warehouses and logistics centers.

- Veille précision, solidité et durabilité.

3. Heavy-Duty Guardrail Roll Forming Machine

- Used to produce highway safety barriers and crash guardrails.

- Capable of handling high-tensile steel for impact resistance.

4. Fully Automatic Heavy-Duty Roll Forming Machine

- Caractéristiques Automatisation CNC pour quick profile adjustments and high-precision outputs.

- Meilleur pour production à grande échelle et à haut rendement.

Machine Sunway fournit customized heavy-duty roll forming machines avec fonctions d'automatisation avancées.

How Heavy-Duty Roll Forming Works

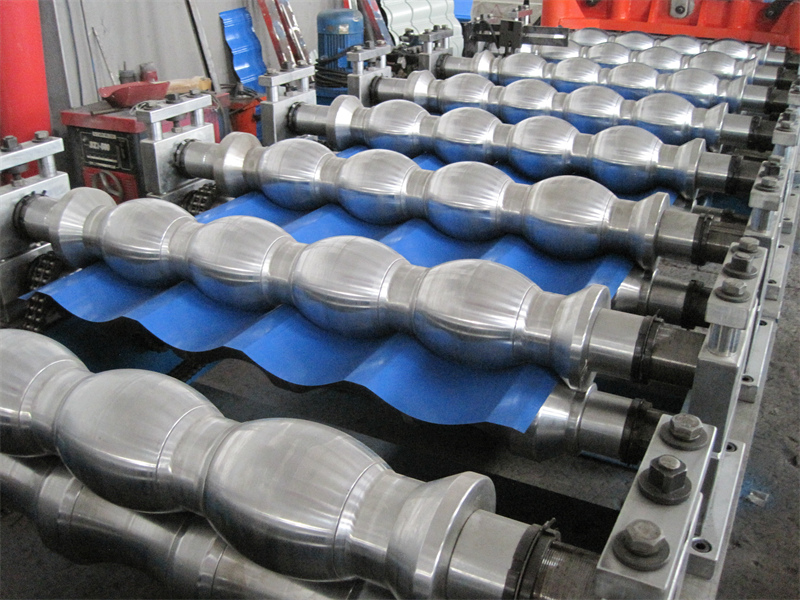

La processus de formage par laminage for heavy-duty applications involves gradually shaping thick and high-strength metal sheets into heavy-gauge profiles en utilisant reinforced rollers and high-pressure hydraulic systems.

Step-by-Step Heavy-Duty Roll Forming Process

| Étape | Description |

|---|---|

| 1. Déshuilage | The high-strength metal coil is placed on a heavy-duty decoilerL'alimentation de la machine en matériaux. |

| 2. Mise à niveau et alimentation | La feuille est redressé et guidé dans les stations de formage. |

| 3. Pre-Punching (If Required) | Hydraulic or servo-driven punching units create holes or slots in the material. |

| 4. Formage de rouleaux | La feuille passe à travers multiple reinforced roller stationspour former le profil souhaité. |

| 5. Découpage et empilage | Le profil formé est cut using hydraulic or servo-driven systems et empilés pour être expédiés. |

Conseil de pro : UN fully automated heavy-duty roll forming machine assure une grande précision, un minimum de déchets et des vitesses de production plus rapides.

Best Materials for Heavy-Duty Roll Forming

Choisir le right metal grade assure optimal strength, durability, and corrosion resistance.

Comparison of Materials for Heavy-Duty Roll Forming

| Matériau | Propriétés | Meilleur pour |

|---|---|---|

| High-Tensile Galvanized Steel | Excellent strength, corrosion resistance | Guardrails, structural beams, heavy-duty storage racks |

| Stainless Steel 304/316 | High corrosion resistance, long lifespan | Marine structures, industrial frames |

| Aluminium 6061/7075 | Lightweight, strong, and corrosion-resistant | Aerospace, automotive, solar mounting systems |

| Structural Steel S355/S460 | Exceptional load-bearing capacity, impact resistance | Bridges, heavy construction, industrial support beams |

Machine Sunway fabrique des machines de profilage compatibles avec all major heavy-duty metal grades.

Heavy-Duty Roll Forming Machine Price Guide

Le coût d'un machine de formage de rouleaux à usage intensif dépend de facteurs tels que automation level, material thickness capacity, and profile range.

Estimated Price Ranges for Heavy-Duty Roll Forming Machines

| Type de machine | Fourchette de prix (USD) | Caractéristiques |

|---|---|---|

| Machine manuelle | 50,000-50,000 - 50,000-100,000 | Réglages manuels, production à faible vitesse |

| Machine semi-automatique | 100,000-100,000 - 100,000-200,000 | Contrôlé par PLC, nécessite des ajustements manuels du profil |

| Machine entièrement automatique | 200,000–200,000 – 200,000–500,000 | Changement rapide de profil à commande CNC |

| Machine de précision à grande vitesse | 500,000–500,000 – 500,000–1,000,000 | Automatisation avancée, production à grande vitesse |

Vous souhaitez un devis personnalisé ? Contactez Sunway Machine dès aujourd'hui !

Top Heavy-Duty Roll Forming Machine Manufacturers

Choisir un fabricant fiable assure des machines de haute qualité, une assistance à long terme et un service mondial.

Comparison of Leading Heavy-Duty Roll Forming Machine Manufacturers

| Fabricant | Pays | Spécialisation | Caractéristiques principales |

|---|---|---|---|

| WUXI SUNWAY MACHINERY CO., LTD | Chine | Heavy-duty roll forming machines | Conceptions personnalisées, automatisation à grande vitesse, machines compatibles avec l'IdO. |

| Dreistern GmbH | Allemagne | Formage de précision des métaux | Machines à commande numérique, forte activité de R&D |

| Machines Samco | Canada | Profilage pour la construction | Ingénierie sur mesure, automatisation |

| Groupe Bradbury | ÉTATS-UNIS | Systèmes de profilage à usage intensif | Des machines robustes, axées sur l'automatisation |

Verdict : Si vous êtes à la recherche d'un cost-effective, high-speed heavy-duty roll forming machine, Machine Sunway est un le premier choix des acheteurs mondiaux.

Common Problems & Solutions in Heavy-Duty Roll Forming Machines

Même avec high-quality heavy-duty roll forming machines, certain défis opérationnels peuvent survenir, tels que roller misalignment, machine vibration, and inaccurate cutting. Identifier et résoudre ces problèmes précoce assure smooth production and high-quality heavy-gauge profiles.

Guide de dépannage

| Enjeu | Cause possible | Solution |

|---|---|---|

| Profils pliés ou tordus | Mauvais alignement des rouleaux, mauvais réglage de la pression | Ajuster l'alignement des rouleaux et optimiser les réglages de la pression |

| Glissement du matériau pendant le formage | Rouleaux d'alimentation desserrés, réglages de tension incorrects | Serrer les rouleaux du margeur et ajuster la tension du matériau |

| Vibrations excessives de la machine | Loose bolts, unstable installation | Secure machine components and ensure a stable foundation |

| Longueurs de coupe incohérentes | Système de coupe défectueux, lames mal alignées | Inspecter et recalibrer le mécanisme de coupe |

| Usure des rouleaux | Frottement élevé, mauvaise manipulation des matériaux | Utiliser des rouleaux trempés et appliquer des revêtements anti-usure |

Conseil de pro : Routine roller realignment and lubrication peut prolonger la durée de vie de la machine par 40% et améliorer la précision des profils.

Future Trends in Heavy-Duty Roll Forming Machines

La heavy-duty metal manufacturing industry is evolving, and machines de profilage are integrating IA, IoT et automatisation pour améliorer efficacité, précision et durabilité.

Principales innovations

1. Contrôle de qualité basé sur l'IA

- alimenté par l'IA sensors detect defects in real timeréduire les déchets de matériaux.

- Améliore accuracy and consistency of heavy-duty profiles.

2. Intégration de l'IdO et de l'usine intelligente

- Les machines sont désormais dotées des caractéristiques suivantes surveillance basée sur l'informatique dématérialisée, permettant diagnostic en temps réel et maintenance prédictive.

- Améliore le suivi de la production et l'efficacité opérationnelle.

3. Technologie de formage de rouleaux à commande assistée

- Améliore contrôle de la vitesse, précision et efficacité énergétique.

- Réduit l'usure des composants mécaniquesce qui augmente la durée de vie de la machine.

4. Ajustements de profil entièrement automatisés

- Élimine ajustements manuels lors du passage d'un profil à l'autre.

- Contrôlé par CNC changement automatique de profil réduire les temps d'arrêt et améliorer l'efficacité.

Upgrading to AI-powered heavy-duty roll forming machines can increase production efficiency by up to 50%!

Automation in Heavy-Duty Roll Forming Machines

L'automatisation est révolutionner heavy-gauge profile manufacturing, making roll forming machines plus intelligent, plus rapide et plus rentable.

Principaux avantages

| Fonctionnalité | Bénéfice |

|---|---|

| Systèmes de contrôle PLC et CNC | Assure des mesures précises et minimise l'erreur humaine |

| Détection des défauts basée sur l'IA | Identifies issues in real time, reducing material waste |

| IoT et surveillance à distance | Permet aux opérateurs de suivre les performances de la machine depuis n'importe quel endroit |

| Changement de profil automatisé | Réduit les temps d'arrêt lors du passage d'un profil à l'autre |

| Servomoteurs à haut rendement énergétique | Réduction des coûts opérationnels et amélioration de la durabilité |

Fully automated heavy-duty roll forming machines from Machine Sunway améliorer l'efficacité de la production jusqu'à 40%!

Essential Maintenance Tips for Heavy-Duty Roll Forming Machines

Correct entretien assure une durée de vie plus longue de la machine et une qualité de production constante.

Liste de contrôle pour l'entretien

| Tâche | Fréquence | Objectif |

|---|---|---|

| Lubrifier les rouleaux et les roulements | Hebdomadaire | Prévient l'usure |

| Vérifier l'alignement des rouleaux | Mensuel | Veiller à la précision de la production des profils |

| Inspecter le mécanisme de coupe | Trimestrielle | Prévient les coupes défectueuses et les défauts d'alignement |

| Nettoyer les composants de la machine | Quotidiennement | Élimine la poussière et les débris qui peuvent nuire à la performance |

| Mise à jour du logiciel et de l'étalonnage | Semestriellement | Optimisation des fonctions d'automatisation |

Conseil de pro : L'entretien programmé peut prolonger la durée de vie de la machine de 50% et réduire les échecs par 70%.

FAQ

1. How fast can a heavy-duty roll forming machine produce profiles?

Les modèles à grande vitesse peuvent produire jusqu'à 40 mètres par minuteen fonction de l'épaisseur du matériau.

2. What materials can be processed?

Heavy-duty roll forming machines can handle high-tensile steel, stainless steel, aluminum, and structural steel.

3. How much does a heavy-duty roll forming machine cost?

Le prix varie de 50,000forbasicmodels∗∗to∗∗50,000 for basic models** to **50,000forbasicmodels∗∗to∗∗1,000,000 for fully automated systems.

4. What industries use heavy-duty roll forming machines?

Common applications include construction, infrastructure, automotive, aerospace, and industrial storage systems.

5. Where can I buy a high-quality heavy-duty roll forming machine?

Pour custom-built, high-speed heavy-duty roll forming machines, visiter WUXI SUNWAY MACHINERY CO., LTD.

Réflexions finales

Investir dans un machine de formage de rouleaux à usage intensif est essentielle pour efficient, high-quality structural component production. Que vous ayez besoin d'un système standard ou entièrement automatiséen choisissant un fabricant de confiance assure fiabilité et rentabilité à long terme.

WUXI SUNWAY MACHINERY CO., LTD est un fabricant mondial de premier plan de custom-built heavy-duty roll forming machines, offrant une technologie de pointe, un soutien d'experts et des prix compétitifs.

Vous voulez un custom heavy-duty roll forming machine? Contactez-nous dès aujourd'hui !