Introduction

UN machine de formage de rouleaux est un high-precision metal forming system conçu pour continuous production of metal profiles. However, like any industrial equipment, proper maintenance is essential to ensure maximum efficiency, extended lifespan, and minimal downtime.

Neglecting maintenance can lead to:

❌ Qualité inégale des produits

❌ Increased machine wear and tear

❌ Unexpected breakdowns and costly repairs

Dans ce guide, nous aborderons les sujets suivants

✅ Importance of roll forming machine maintenance

✅ Daily, weekly, and monthly maintenance tasks

✅ Common maintenance issues and solutions

✅ How to extend the lifespan of your roll forming machine

✅ Best practices for maintaining high efficiency

Plongeons dans la best maintenance practices to keep your roll forming machine running smoothly and efficiently!

Why Is Roll Forming Machine Maintenance Important?

Regular maintenance helps prevent breakdowns, reduces repair costs, and ensures une qualité de produit constante. The key benefits include:

✅ Increased Machine Lifespan – Proper lubrication and calibration reduce wear and tear.

✅ Qualité constante des produits – Prevents misalignment and surface defects in formed profiles.

✅ Reduced Downtime – Prevents unexpected failures that cause production delays.

✅ Lower Repair Costs – Detecting and fixing issues précoce empêche major breakdowns.

✅ Efficacité accrue – Ensures the machine operates at optimal speed and accuracy.

Conseil de pro : A well-maintained roll forming machine can last over 20 years with minimal downtime!

Daily, Weekly, and Monthly Maintenance Tasks

Proper maintenance involves routine inspections, lubrication, and calibration to keep the machine running efficiently.

Daily Maintenance Checklist

| Tâche | Objectif |

|---|---|

| Clean the machine surface and rollers | Prevents dirt buildup that can affect metal forming quality. |

| Check for unusual vibrations or noises | Detects early signs of mechanical wear or misalignment. |

| Inspect lubrication levels | Ensures proper roller and bearing function. |

| Ensure proper material feeding | Prevents jamming and misalignment. |

| Check hydraulic and pneumatic systems | Ensures smooth operation of cutting and punching units. |

Conseil de pro : A clean machine reduces defects by 30% et extends roller lifespan.

Weekly Maintenance Checklist

| Tâche | Objectif |

|---|---|

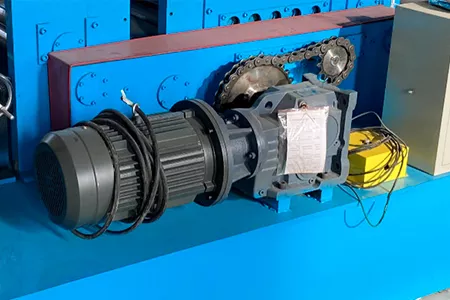

| Lubricate rollers, bearings, and chains | Reduces friction and wear. |

| Inspect roller alignment | Ensures accurate profile shaping. |

| Check electrical connections and sensors | Prevents malfunctions due to loose wiring. |

| Inspect hydraulic fluid levels | Ensures smooth operation of cutting and punching systems. |

| Tighten loose bolts and fasteners | Prevents mechanical failures from vibrations. |

Conseil de pro : Proper lubrication can extend roller lifespan by 40% et réduire la consommation d'énergie.

Monthly Maintenance Checklist

| Tâche | Objectif |

|---|---|

| Calibrate the entire roll forming system | Ensures precision forming and consistent profiles. |

| Inspect cutting blades for wear | Prevents burrs and uneven cuts. |

| Check roller wear and replace if necessary | Maintains forming accuracy and prevents defects. |

| Inspect and clean hydraulic and pneumatic systems | Ensures smooth operation and prevents leaks. |

| Test emergency stop functions | Ensures operator safety. |

Conseil de pro : Replacing worn-out rollers on time prevents misalignment and extends machine lifespan.

Common Roll Forming Machine Maintenance Issues & Solutions

Même avec un solid maintenance routine, some common issues may arise. Here’s how to identify and fix them before they affect production.

| Enjeu | Causes | Solution |

|---|---|---|

| Roller Misalignment | Loose roller settings, worn bearings | Re-calibrate rollers and tighten all settings |

| Usure excessive des rouleaux | Inconsistent lubrication, improper material feeding | Apply proper lubrication and use wear-resistant rollers |

| Material Slipping in Rollers | Incorrect tension settings, worn feed rollers | Adjust material guides and replace worn feed rollers |

| Rayures de surface sur les profilés formés | Rouleaux encrassés, pression de formage excessive | Clean rollers and reduce forming pressure |

| Hydraulic Cutting System Malfunctions | Faibles niveaux d'huile hydraulique, filtres colmatés | Refill hydraulic fluid and clean filters |

| Irregular Cutting Lengths | Calibrage défectueux du capteur, lames de coupe usées | Recalibrate sensors and replace worn blades |

Conseil de pro : 80% of machine failures are due to improper lubrication and misalignment—regular inspections prevent costly repairs!

How to Extend the Lifespan of Your Roll Forming Machine

UN well-maintained roll forming machine can last decades if proper care is taken. Follow these meilleures pratiques to maximize its lifespan.

1. Maintain a Strict Lubrication Schedule

- Utilisation lubrifiants de haute qualité suitable for metal forming machines.

- Appliquer la lubrification hebdomadaire to rollers, bearings, and chains.

2. Use High-Quality Raw Materials

- Tôles de mauvaise qualité augmentation de l'usure des rouleaux et provoquer un désalignement.

- Choisir matériaux d'épaisseur uniforme et inoxydables pour une performance optimale.

3. Regularly Train Operators

- Ensure operators understand proper machine handling and troubleshooting.

- Improper use accelerates wear and increases downtime.

4. Keep a Spare Parts Inventory

- Maintain extra rollers, bearings, cutting blades, and hydraulique seals.

- Prevents long downtimes due to waiting for parts delivery.

5. Schedule Preventive Maintenance

- Exécuter quarterly machine inspections to identify early wear and tear.

- Preventive maintenance reduces repair costs by up to 50%.

Conseil de pro : Scheduled maintenance checks help avoid 90% of unexpected machine failures!

Best Practices for Maintaining High Efficiency in Roll Forming Machines

UN well-maintained roll forming machine not only lasts longer but also operates at peak efficiency, reducing production costs.

Efficiency Tips for Roll Forming Machines

✅ Optimize Material Feeding – Ensure proper alignment to prevent material jams.

✅ Passage à des moteurs servo-commandés – Improves speed control and reduces energy consumption.

✅ Use AI-Based Monitoring Systems – Detects defects in real-time and prevents material waste.

✅ Implement IoT-Enabled Remote Monitoring - Suivi des performances de la machine et programmation de l'entretien.

✅ Investir dans un outillage de haute qualité - Réduit l'usure des rouleaux et assure un profilage précis.

Upgrading to AI-powered maintenance systems can improve efficiency by 30% and reduce downtime by 50%!

Common Problems & Solutions in Roll Forming Machine Maintenance

Même avec entretien régulier, roll forming machines can still encounter unexpected issues. Quick detection and troubleshooting can prevent costly downtime and production losses.

Guide de dépannage pour les machines de formage de rouleaux

| Enjeu | Cause possible | Solution |

|---|---|---|

| Roller Misalignment | Loose roller settings, worn bearings | Re-align rollers and tighten all settings |

| Formage inégal ou déformation du profil | Incorrect roller spacing, material thickness variation | Adjust roller spacing and use high-quality material |

| Usure excessive des rouleaux | Inconsistent lubrication, improper material feeding | Apply proper lubrication and use wear-resistant rollers |

| Blocage du matériau dans les rouleaux | Poor feeding alignment, incorrect material thickness | Adjust material feeder guides and check material specs |

| Rayures de surface sur les profilés formés | Rouleaux encrassés, pression de formage excessive | Clean rollers and reduce forming pressure |

| Hydraulic Cutting System Malfunctions | Faibles niveaux d'huile hydraulique, filtres colmatés | Refill hydraulic fluid and clean filters |

| Irregular Cutting Lengths | Calibrage défectueux du capteur, lames de coupe usées | Recalibrate sensors and replace worn blades |

| Surchauffe de la machine | Frottement excessif, mauvais système de refroidissement | Ensure proper lubrication and check cooling fans |

Conseil de pro : 80% of machine failures are due to improper lubrication and misalignment—regular inspections prevent costly repairs!

Future Trends in Roll Forming Machine Maintenance

The roll forming industry is une évolution rapide, and new technologies are making maintenance smarter, more predictive, and more efficient.

Key Maintenance Innovations for 2025

1. Maintenance prédictive alimentée par l'IA

- Real-time monitoring detects early signs of wear and tear.

- AI-driven analytics predict when maintenance is needed, reducing unplanned downtime.

2. Surveillance à distance basée sur l'IdO

- Les machines sont désormais équipées de suivi basé sur l'informatique dématérialiséepermettant aux fabricants de monitor machine performance remotely.

- Helps in real-time diagnostics and scheduling preventive maintenance.

3. Automated Lubrication Systems

- Advanced lubrication systems automatically apply oil/grease at regular intervals.

- Réduit manual maintenance effort et ensures consistent lubrication.

4. Servo-Driven Components for Longer Lifespan

- Servo motors provide precise control, réduisant wear and tear.

- Améliore energy efficiency and extends machine life.

Investing in AI-powered maintenance solutions can reduce downtime by 50% and extend machine lifespan by 30%!

Best Practices for Roll Forming Machine Maintenance

UN preventive maintenance strategy is the best way to ensure long-term efficiency and reliability.

1. Maintain a Strict Lubrication Schedule

- Utilisation lubrifiants de haute qualité suitable for metal forming machines.

- Apply lubrication weekly to rollers, bearings, and chains.

2. Use High-Quality Raw Materials

- Tôles de mauvaise qualité augmentation de l'usure des rouleaux et provoquer un désalignement.

- Choisir matériaux d'épaisseur uniforme et inoxydables pour une performance optimale.

3. Regularly Train Operators

- Ensure operators understand proper machine handling and troubleshooting.

- Improper use accelerates wear and increases downtime.

4. Keep a Spare Parts Inventory

- Maintain extra rollers, bearings, cutting blades, and hydraulic seals.

- Prevents long downtimes due to waiting for parts delivery.

5. Schedule Preventive Maintenance

- Exécuter quarterly machine inspections to identify early wear and tear.

- Preventive maintenance reduces repair costs by up to 50%.

Conseil de pro : Scheduled maintenance checks help avoid 90% of unexpected machine failures!

FAQ: Roll Forming Machine Maintenance

1. How often should I lubricate my roll forming machine?

You should lubricate rollers, bearings, and chains weekly to prevent wear and ensure smooth operation.

2. What is the most common cause of roll forming machine failure?

The most common causes are roller misalignment, poor lubrication, and worn-out cutting blades.

3. How do I know if my rollers need replacement?

If you notice profile distortion, uneven forming, or excessive roller wear, it’s time to replace the rollers.

4. Can AI and IoT improve roll forming machine maintenance?

Oui ! Détection des défauts par l'IA et IoT-based predictive maintenance help prevent failures and optimize machine performance.

5. Where can I buy high-quality roll forming machines and spare parts?

Pour machines de profilage sur mesure et pièces de rechange, visiter WUXI SUNWAY MACHINERY CO., LTD.

Réflexions finales

Correct roll forming machine maintenance assure high efficiency, long lifespan, and consistent product quality. By following a strict maintenance schedulevous pouvez prevent breakdowns, reduce repair costs, and maximize production output.

WUXI SUNWAY MACHINERY CO., LTD est un fabricant mondial de premier plan de machines de profilage sur mesure, offrant une technologie de pointe, un soutien d'experts et des prix compétitifs.

Vous voulez un une machine de profilage de haute qualité ? Contactez-nous dès aujourd'hui !