Introduction

Vous êtes-vous déjà demandé comment profilés métalliques longs et uniformes comme les tôles de toiture, les pannes C & Z et les glissières de sécurité des autoroutes ? La réponse se trouve dans le processus de formage par laminage-une méthode de façonnage des métaux efficace et à grande vitesse, utilisée dans de nombreuses industries.

UN machine de formage de rouleaux est conçu pour façonner progressivement des feuilles de métal en les faisant passer par une série de rouleaux conçus avec précision. Contrairement aux méthodes traditionnelles de pliage des métaux, le profilage minimise les déchets de matériaux, réduit les coûts de main-d'œuvre et améliore l'efficacité de la production.

Dans ce guide, nous aborderons les sujets suivants

✅ Fonctionnement d'une profileuse

✅ Composants clés d'un système de profilage

✅ Processus de profilage étape par étape

✅ Types de Machines De Formage De Rouleaux

✅ Avantages du profilage par rapport aux autres méthodes de formage des métaux

Examinons les mécanismes qui sous-tendent le projet l'un des procédés de mise en forme des métaux les plus efficaces de l'industrie moderne !

Comment fonctionne une machine de formage de rouleaux ?

UN machine de formage de rouleaux fonctionne par plier progressivement une bande de métal dans une forme spécifique grâce à plusieurs stations de rouleaux séquentielles. Au lieu de plier le métal en une seule fois (comme le freinage à la presse), le profilage applique des courbes incrémentales sur plusieurs étages de rouleaux, ce qui garantit une mise en forme douce et précise.

Principe de fonctionnement de base

1️⃣ Alimentation en matériaux - Une bobine de métal est déroulée et introduite dans la machine.

2️⃣ Formation progressive - Le métal passe par une série de postes à rouleauxchacun effectuant de petites courbes incrémentales.

3️⃣ Traitement en ligne (optionnel) - Le poinçonnage, l'encochage, le gaufrage ou le soudage peuvent être intégrés dans le processus.

4️⃣ Coupe en longueur - Le profilé formé est coupé à la taille requise.

5️⃣ Produit final - La pièce finie est envoyée pour inspection et emballage.

Conseil de pro : Le processus de pliage incrémental garantit contrainte matérielle minimale, ce qui donne profilés de précision à haute résistance.

Composants clés

UN Machine de formage de rouleaux de haute qualité se compose de plusieurs éléments essentiels qui s'associent pour créer des des profils métalliques complexes avec précision et efficacité.

Principaux composants et leurs fonctions

| Composant | Fonction |

|---|---|

| Dérouleur | Maintient et déroule la bobine de métal pour l'introduire dans la machine. |

| Système de guidage de l'alimentation | Aligne et dirige la feuille dans les rouleaux. |

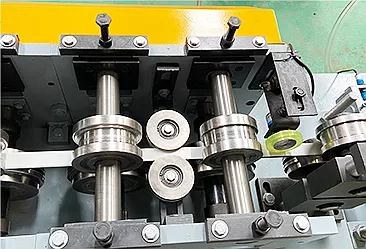

| Stations de rouleaux | Plusieurs rouleaux façonnent progressivement la tôle. |

| Unité de poinçonnage et d'encochage (en option) | Ajoute des trous, des fentes ou des indentations dans le métal avant le formage final. |

| Système de coupe | Coupe le profilé formé à la longueur requise. |

| Entraînement par moteur hydraulique ou servomoteur | Alimente les rouleaux, assurant ainsi un mouvement régulier du matériau. |

| Système de contrôle (PLC/CNC) | Automatise et surveille l'ensemble du processus de profilage. |

| Tableau de sortie des produits | Rassemble les pièces finies pour les inspecter et les emballer. |

Machine Sunway fournit machines de profilage sur mesure avec automatisation avancée et contrôles de précision.

Processus de formage de rouleaux étape par étape

La processus de formage par laminage est conçu pour façonnage continu et à grande vitesse des métauxIl s'agit donc d'une solution idéale pour production en masse de profils uniformes.

Flux détaillé du processus de formage de rouleaux

| Étape | Description |

|---|---|

| 1. Chargement du matériel | Une bobine métallique est placée sur le décolleuret la feuille est introduite dans la machine. |

| 2. Alimentation initiale et alignement | La feuille passe à travers guides d'alignement pour garantir une entrée directe. |

| 3. Formage par laminage progressif | La tôle se déplace à travers plusieurs stations de rouleaux, chacun appliquant des courbes progressives. |

| 4. Poinçonnage et grugeage en ligne (si nécessaire) | Les unités de poinçonnage servo-motorisées créent trous, fentes ou gaufrages si nécessaire. |

| 5. Coupe à longueur | UN système de coupe hydraulique ou à cisaille volante couper le profilé formé à la longueur voulue. |

| 6. Produit final | La pièce finie sort sur le table de sortie pour l'inspection de la qualité. |

Conseil de pro : Systèmes de coupe servocommandés garantir coupes précises, sans bavures, avec un minimum de déchets.

Les types

Différentes applications requièrent les différents types de machines de profilage, chacun offrant des avantages uniques sur la base de la complexité du profil, la vitesse de production et le niveau d'automatisation.

Comparaison

| Type de machine | Meilleur pour | Caractéristiques principales |

|---|---|---|

| Ligne de profilage à profil unique | Production de profilés fixes (par exemple, tôles de toiture) | Conception compacte et rentable |

| Profileuse multi-profils | Production de profils multiples avec des outils à changement rapide | Réduction des temps d'arrêt et augmentation de la flexibilité |

| Profileuse réglable | Ajustements personnalisables de la largeur et de la forme | Idéal pour la production de pannes C et Z |

| Machine de formage de rouleaux à grande vitesse | Production en masse de profils uniformes | Jusqu'à 50 mètres par minute |

| Machine de formage de rouleaux entièrement automatisée | Opérations de haute précision commandées par CNC | Détection des défauts alimentée par l'IA, intégration de l'IoT |

Vous recherchez une solution de profilage sur mesure ? Machine Sunway offres machines de profilage de précision à grande vitesse pour fabricants mondiaux.

Avantages du profilage par rapport aux autres méthodes de formage des métaux

Le profilage est largement préféré au le freinage à la presse, l'estampage et l'extrusion en raison de son efficacité, précision et rentabilité.

Pourquoi choisir le profilage ?

| Avantage | Forme rouleau | Freinage de la presse / estampage |

|---|---|---|

| Vitesse de production | Processus continu (jusqu'à 50m/min) | Production plus lente, par lots |

| Déchets matériels | Déchets minimaux grâce au pliage incrémentiel | Davantage de déchets dus à des ajustements par tâtonnement |

| Coût du travail | Faible - processus entièrement automatisé | Élevé - nécessite des ajustements manuels |

| Cohérence des pièces | Grande uniformité pour les profils longs et répétés | Variations possibles dans la production par lots |

| Coût de l'outillage | Coût initial plus élevé, mais coût unitaire plus faible | Coût initial plus faible, mais coût unitaire plus élevé |

Verdict : Le profilage est le meilleur choix pour la fabrication de précision en grande quantité et à moindre coût..

Problèmes courants et solutions

Même avec des machines de profilage à la pointe de la technologieles opérateurs peuvent rencontrer des défis tels que la déformation des matériaux, le désalignement et l'usure des rouleaux. Identifier et résoudre ces problèmes précoce assure une production fluide et de haute qualité.

Guide de dépannage

| Enjeu | Cause possible | Solution |

|---|---|---|

| Désalignement du profil | Mauvais positionnement du rouleau, alimentation en matériau non homogène | Recalibrer les rouleaux et ajuster les guides de matériau |

| Le matériau glisse dans les rouleaux | Rouleaux d'alimentation desserrés, réglages de tension incorrects | Serrer les rouleaux du margeur et ajuster la tension du matériau |

| Rayures ou déformations superficielles | Rouleaux encrassés, pression de formage excessive | Nettoyer régulièrement les rouleaux et ajuster la pression de formage |

| Longueurs de coupe incohérentes | Système de coupe défectueux, lames mal alignées | Inspecter et recalibrer le mécanisme de coupe |

| Usure des rouleaux due à un frottement élevé | Manque de lubrification, pression excessive | Appliquer une lubrification adéquate et utiliser des rouleaux trempés |

Conseil de pro : Régulière calibrage et lubrification des rouleaux peut prolonger la durée de vie de la machine par 40% et réduire considérablement les défauts de profil.

Tendances futures de la technologie du laminage

La l'industrie du profilage évolue rapidement avec la mise en place de IA, IoT et automatisation, en améliorant efficacité, précision et durabilité.

Principales innovations dans le domaine des machines de formage de rouleaux pour 2025

1. Détection des défauts et autocorrection basées sur l'IA

- alimenté par l'IA des caméras et des capteurs détectent les défauts en temps réelréduire les déchets de matériaux.

- Veille précision constante du profil sans intervention de l'opérateur.

2. Surveillance à distance basée sur l'IdO

- Les machines sont désormais dotées des caractéristiques suivantes suivi basé sur l'informatique dématérialisée, permettant la possibilité pour les opérateurs de contrôler les performances à distance.

- Active diagnostic en temps réel et maintenance prédictive.

3. Technologie de formage de rouleaux à commande assistée

- Améliore contrôle de la vitesse, précision et efficacité énergétique.

- Réduit l'usure des composants mécaniquesce qui augmente la durée de vie de la machine.

4. Ajustements de profil entièrement automatisés

- Élimine ajustements manuels lors du passage d'un profil à l'autre.

- Contrôlé par CNC changement automatique de profil réduire les temps d'arrêt et améliorer l'efficacité.

Le passage à des profileuses alimentées par l'IA peut accroître l'efficacité de la production jusqu'à 50% !

Automatisation des machines de formage de rouleaux

L'automatisation est la transformation formage de précision des métaux, fabrication de machines de formage par rouleaux plus intelligent, plus rapide et plus rentable.

Principaux avantages des profileuses automatisées

| Fonctionnalité | Bénéfice |

|---|---|

| Systèmes de contrôle PLC et CNC | Assure des mesures précises et minimise l'erreur humaine |

| Détection des défauts en temps réel grâce à l'IA | Identifie instantanément les problèmes, réduisant ainsi le gaspillage de matériaux |

| IoT et surveillance à distance | Permet aux opérateurs de suivre les performances de la machine depuis n'importe quel endroit |

| Changement de profil automatisé | Réduit les temps d'arrêt lors du passage d'un profil à l'autre |

| Servomoteurs à haut rendement énergétique | Réduction des coûts opérationnels et amélioration de la durabilité |

Machines de profilage entièrement automatisées de Machine Sunway améliorer l'efficacité de la production jusqu'à 40%!

Conseils essentiels pour l'entretien des machines de formage de rouleaux

Correct entretien assure prolongation de la durée de vie de la machine et une qualité de production constante.

Liste de contrôle de la maintenance des profileuses

| Tâche | Fréquence | Objectif |

|---|---|---|

| Lubrifier les rouleaux et les roulements | Hebdomadaire | Prévient l'usure |

| Vérifier l'alignement des rouleaux | Mensuel | Veiller à la précision de la production des profils |

| Inspecter le mécanisme de coupe | Trimestrielle | Prévient les coupes défectueuses et les défauts d'alignement |

| Nettoyer les composants de la machine | Quotidiennement | Élimine la poussière et les débris qui peuvent nuire à la performance |

| Mise à jour du logiciel et de l'étalonnage | Semestriellement | Optimisation des fonctions d'automatisation |

Conseil de pro : L'entretien programmé peut prolonger la durée de vie de la machine de 50% et réduire les échecs par 70%.

FAQ : Principe de fonctionnement de la profileuse

1. Comment fonctionne une profileuse ?

Une machine de profilage forme progressivement des tôles en les faisant passer par plusieurs stations de rouleaux, chacun appliquant coudes incrémentaux jusqu'à ce que le profil final soit formé.

2. Quelles sont les industries qui utilisent des profileuses ?

Des industries telles que :

✅ La construction (panneaux de toiture, pannes C et Z)

✅ Automobile (composants structurels, poutres résistantes aux chocs)

✅ Énergie solaire (structures de montage solaire)

✅ Rayonnage et rayonnage (rayonnages d'entrepôt, systèmes de stockage)

3. Quels matériaux peuvent être utilisés pour le profilage ?

Les matériaux les plus courants sont les suivants

✅ Acier galvanisé (G30-G90)

✅ Acier inoxydable (304/316)

✅ Aluminium (6061/7075)

✅ Acier à haute résistance

4. Quel est le coût d'une profileuse ?

Le prix varie de 80 000 pour les modèles de base∗to∗80 000 pour les modèles de base** à **80 000 pour les modèles de base∗to∗∗1 200 000 pour les machines entièrement automatisées et pilotées par l'IA..

5. Où puis-je acheter une profileuse de haute qualité ?

Pour des machines de profilage à grande vitesse fabriquées sur mesure, visiter WUXI SUNWAY MACHINERY CO., LTD.

Réflexions finales

Investir dans un machine de formage de rouleaux est essentielle pour les industries qui exigent de la flexibilité, de l'efficacité et une production à grande vitesse. Choisir un fabricant de confiance assure fiabilité et rentabilité à long terme.

WUXI SUNWAY MACHINERY CO., LTD est un fabricant mondial de premier plan de machines de profilage sur mesure, offrant une technologie de pointe, un soutien d'experts et des prix compétitifs.

Vous voulez un machine à former des rouleaux ? Contactez-nous dès aujourd'hui !